-

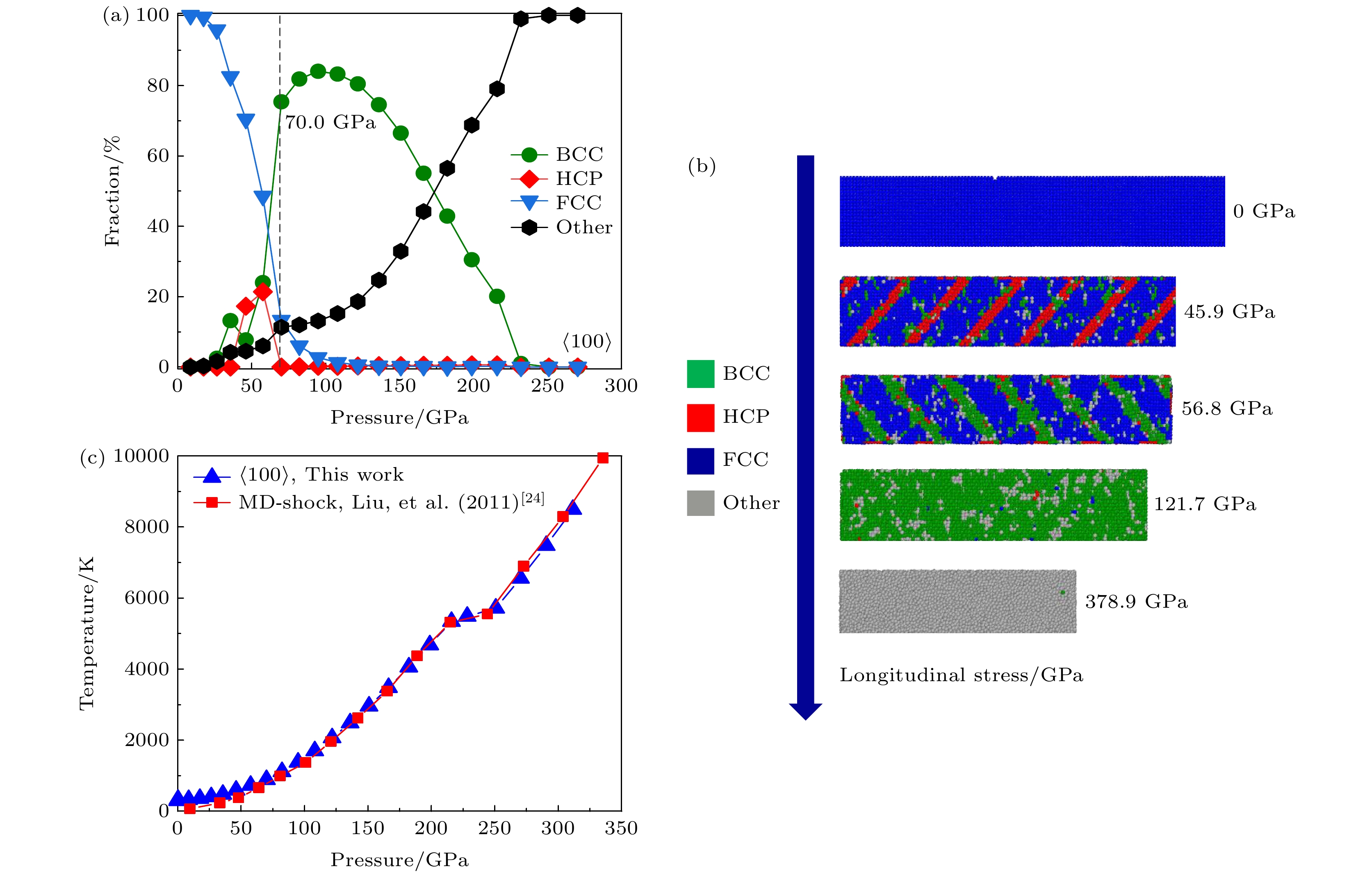

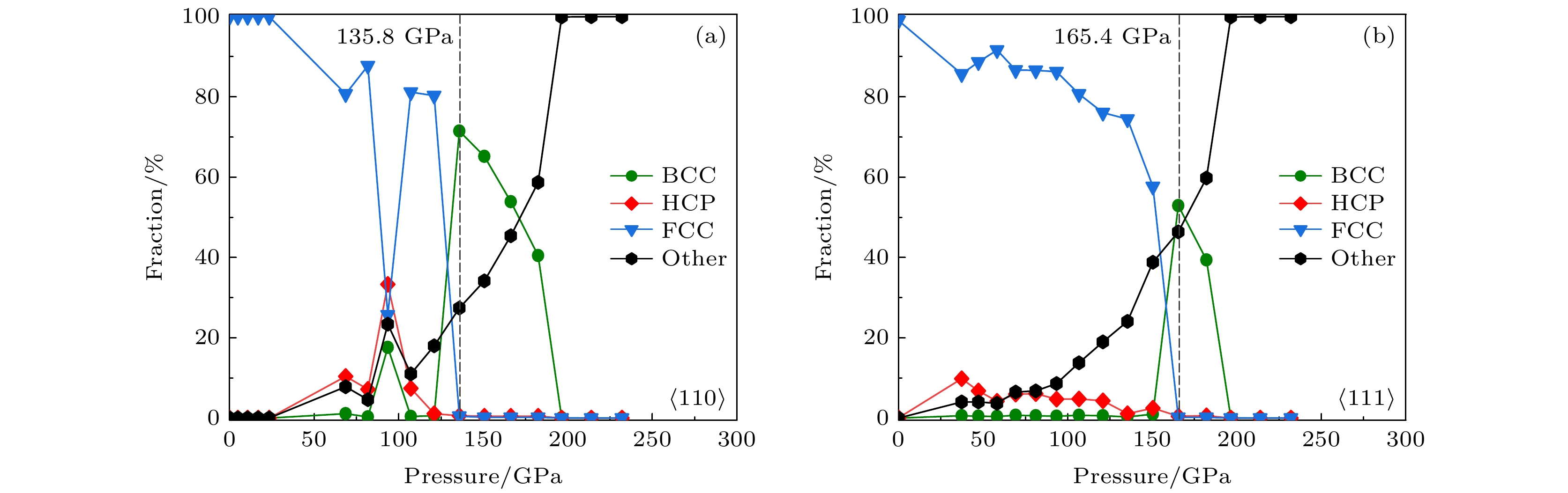

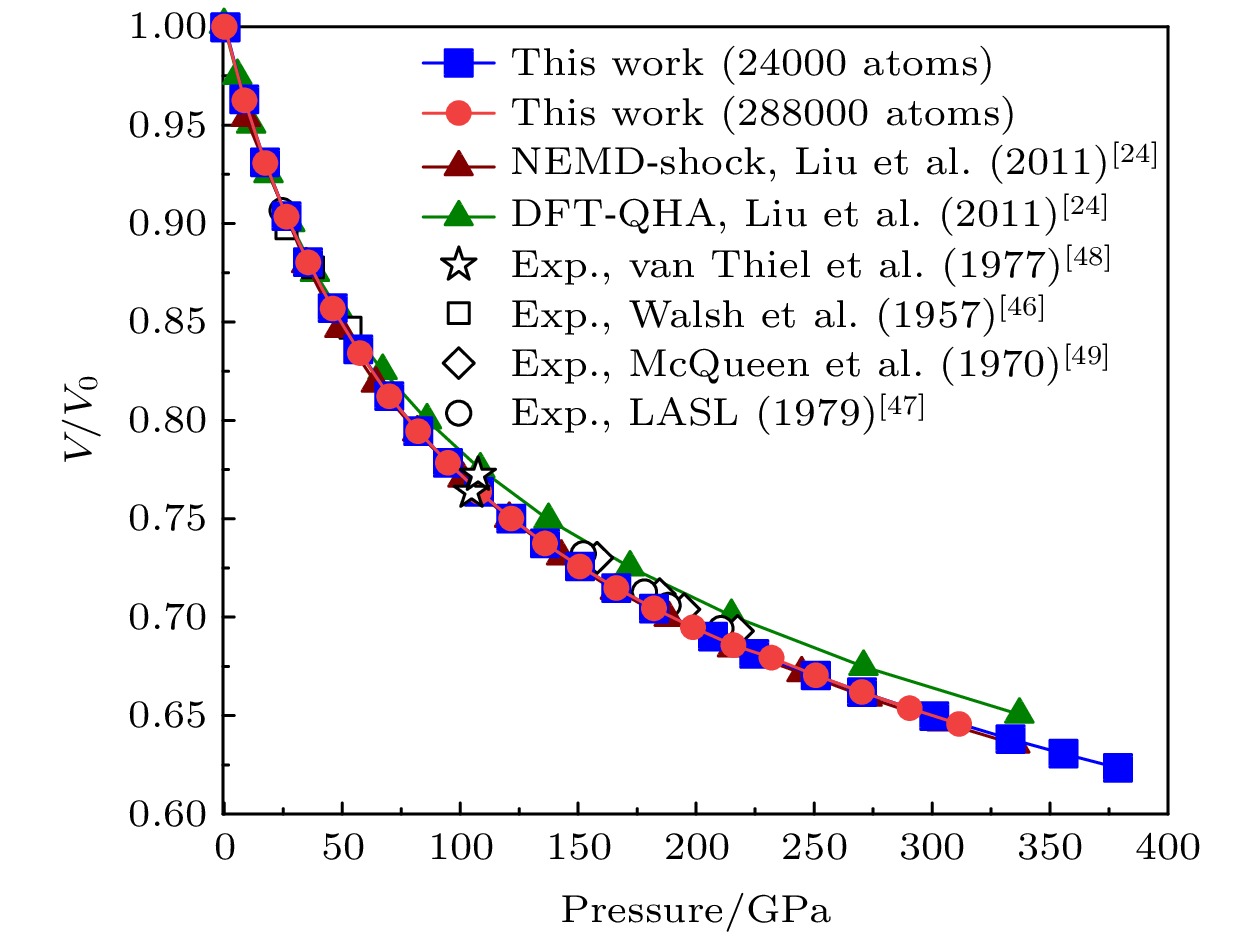

钯作为典型高压标定材料, 研究其在极端条件下的结构变化以及热力学性质具有广泛需求并充满了挑战, 特别是冲击加载下钯的固-固相变过程研究仍然匮乏. 本文基于嵌入原子势, 使用经典分子动力学方法从原子角度揭示了冲击载荷加载下钯的结构相变路径, 在0—375 GPa的压力区间观察到一系列复杂的结构转变特征, 从初始的面心立方(FCC)结构, 至带密排六方(HCP)结构的层错体心立方(BCC)结构, 直至完全熔化. 在沿

$ \langle100\rangle $ 晶向冲击下, 在70.0 GPa发现了FCC-BCC相变过程, 远低于之前研究中静高压的结果. 此外, 还发现了冲击方向依赖的相变点, 在沿着$ \langle110\rangle $ 及$ \langle111 \rangle $ 晶向冲击时FCC-BCC相变压力分别增加至135.8和165.4 GPa, 同时相比完美晶体, 引入缺陷会使FCC-BCC相变压强值有20—30 GPa的增幅, 并通过势能分布的分析予以验证. 本文发现冲击加载下钯的FCC-BCC相变压力大大降低的特殊现象, 为钯在高压实验等极端条件下的应用提供了新的理论认识.For palladium (Pd) as a typical high-pressure standard material, studying its structural changes and thermodynamic properties under extreme conditions is widely demanded and challenging. Particularly, the solid-solid phase transition process of Pd under shock loading is understood still scarcely. In this paper, using the classical molecular dynamics simulations with embedded atom method (EAM) based on the interatomic potential, we investigate the phase transition of single crystal Pd from atomic scale under shock loading. A series of structural features is observed in a pressure range of 0–375 GPa, revealing that the structure feature transforms from the initial face-centered cubic (FCC) structure to the stacking faults body-centered cubic (BCC) structure with hexagonal close-packed (HCP) structure, and finally complete melting. Under shock loading of$ \left\langle {100} \right\rangle $ oriented bulk Pd, we find the transformation to BCC structure can take place almost at 70.0 GPa, which is much lower than the previous static calculation result. In addition, we find that the phase transition depends on the direction initially impacting crystal. Under impacting along the$ \left\langle {110} \right\rangle $ direction and the$ \left\langle {111} \right\rangle $ direction, the FCC-BCC phase transition pressures increase to 135.8 GPa and 165.4 GPa, respectively. Also, the introduction of defects will increase the phase transition pressure of FCC-BCC by 20–30 GPa in comparison with perfect crystals, which is verified by the distribution of the potential energy. An interesting phenomenon that FCC-BCC transition pressure of Pd decreases under shock loading is found in this work, which provides a new theoretical insight into the application of high pressure experiments in the future.-

Keywords:

- palladium /

- shock compression /

- molecular dynamics /

- structural phase change

[1] Graziani F, Desjarlais M P, Redmer R, Trickey S B 2014 Frontiers and Challenges in Warm Dense Matter (Vol. 1) (Switzerland: Springer) pp1–3

[2] Moses E I, Boyd R N, Remington B A, Keane C J, Al-Ayat R 2009 Phys. Plasmas 16 041006

Google Scholar

Google Scholar

[3] Mitchell A C, Nellis W J, Moriarty J A, Heinle R A, Holmes N C, Tipton R E, Repp G W 1991 J. Appl. Phys. 69 2981

Google Scholar

Google Scholar

[4] Nagao H, Nakamura K J, Kondo K, Ozaki N, Takamatsu K, Ono T, Shiota T, Ichinose D, Tanaka K A, Wakabayashi K 2006 Phys. Plasmas 13 052705

Google Scholar

Google Scholar

[5] Yokoo M, Kawai N, Nakamura K G, Kondo K I 2008 Appl. Phys. Lett. 92 051901

Google Scholar

Google Scholar

[6] Nellis W J, Weir S T, Mitchell A C 1996 Science 273 936

Google Scholar

Google Scholar

[7] Weir S T, Mitchell A C, Nellis W J 1996 Phys. Rev. Lett. 76 1860

Google Scholar

Google Scholar

[8] Hartley N J, Brown S, Cowan T E, Cunningham E, Döppner T, Falcone R W, Fletcher L B, Frydrych S, Galtier E, Gamboa E J 2019 Sci. Rep. 9 1

[9] Briggs R, Coppari F, Gorman M G, Smith R F, Tracy S J, Coleman A L, Fernandez-Panella A, Millot M, Eggert J H, Fratanduono D E 2019 Phys. Rev. Lett. 123 045701

Google Scholar

Google Scholar

[10] Sharma S M, Turneaure S J, Winey J M, Li Y, Rigg P, Schuman A, Sinclair N, Toyoda Y, Wang X, Weir N, Zhang J, Gupta Y M 2019 Phys. Rev. Lett. 123 045702

Google Scholar

Google Scholar

[11] Li Q J, Liu B B 2016 Chin. Phys. B 25 076107

Google Scholar

Google Scholar

[12] Guo Y L, Wei J H, Liu X, Ke X Z, Jiao Z Y 2021 Chin. Phys. B 30 016101

Google Scholar

Google Scholar

[13] Lu M Y, Huang Y P, Tian F B, Li D, Duan D F, Zhou Q, Cui T 2020 Chin. Phys. B 29 053104

Google Scholar

Google Scholar

[14] Hesse R W 2007 Jewelry-Making Through History: an Encyclopedia (Westport: Greenwood Publishing Group) p146

[15] Colon P, Pradelle-Plasse N, Galland J 2003 Dent. Mater. 19 232

Google Scholar

Google Scholar

[16] Harper C A 1997 Passive Electronic Component Handbook. McGraw-Hill Professional (New York: McGraw-Hill) pp580

[17] Fleischmann M, Pons S, Hawkins M 1989 J. Electroanal. Chem. 261 301

Google Scholar

Google Scholar

[18] Mutschele T, Kirchheim R 1987 Scr. Mater. 21 1351101

[19] Pundt A, Sachs C, Winter M, Reetz M T, Fritsch D, Kirchheim R 1999 J. Alloys Compd. 293-295 480

[20] Bonivardi A L, Baltanas M A 1994 React. Kinet. Catal. Lett. 52 95

[21] Eastman J A, Thompson L J, Kestel B J 1993 Phys. Rev. 48 84

Google Scholar

Google Scholar

[22] Foiles S M, Adams J B 1989 Phys. Rev. B 40 9

[23] Foiles S M, Baskes M I, Daw M S 1986 Phys. Rev. B 33 7983

Google Scholar

Google Scholar

[24] Liu Z L, Yang J H, Cai L C, Jing F Q, Alfѐ D 2011 Phys. Rev. B 83 144113

Google Scholar

Google Scholar

[25] Errandonea D 2013 Phys. Rev. B 87 054108

Google Scholar

Google Scholar

[26] Jeong J W, Chang K 1999 J. Phys. Condens. Matter 11 3799

Google Scholar

Google Scholar

[27] Liu Z L, Zhang X L, Cai L C 2015 J. Chem. Phys. 11 637

[28] Zheng Z Y, Zhao J J 2016 Chin. Phys. B 25 076202

Google Scholar

Google Scholar

[29] 孙小伟, 褚衍东, 刘子江, 刘玉孝, 王成伟, 刘维民 2005 54 5830

Google Scholar

Google Scholar

Sun X W, Zhe Y D, Liu Z J, Liu Y X, Wang C W, Liu W M 2005 Acta Phys. Sin. 54 5830

Google Scholar

Google Scholar

[30] 段芳莉, 王家序, 雒建斌, 温诗铸 2007 56 6552

Google Scholar

Google Scholar

Duan F L, Wang J X, Luo J B, Weng S Z 2007 Acta Phys. Sin. 56 6552

Google Scholar

Google Scholar

[31] 邵建立, 王裴, 秦承森, 周洪强 2007 56 5389

Google Scholar

Google Scholar

Shao J L, Wang F, Qing C S, Zhou H Q 2007 Acta Phys. Sin. 56 5389

Google Scholar

Google Scholar

[32] 周化光, 林鑫, 王猛, 黄卫东 2013 62 056803

Google Scholar

Google Scholar

Zhou H G, Lin X, Wang M, Huang W D 2013 Acta Phys. Sin. 62 056803

Google Scholar

Google Scholar

[33] Plimpton S J 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[34] Reed E J, Fried L E, Joannopoulos J D 2003 Phys. Rev. Lett. 90 235503

Google Scholar

Google Scholar

[35] Stukowski A 2009 Modell. Simul. Mater. Sci. Eng. 18 015012

[36] 韦昭召, 马骁, 柯常波, 张新平 2020 69 136102

Google Scholar

Google Scholar

Wei Z Z, Ma X, Ke C B, Zhang X P 2020 Acta Phys. Sin. 69 136102

Google Scholar

Google Scholar

[37] Kien P H 2014 Int. Scholarly Res. Not. 2014 253627

[38] Sun H Y, Kang D D, Hou Y, Dai J Y 2017 Matter Radiat. at Extremes 2 287

Google Scholar

Google Scholar

[39] Neogi A, Mitra N 2017 Sci. Rep. 7 1

Google Scholar

Google Scholar

[40] Honeycutt J D, Andersen H C 1987 J. Phys. Chem. 91 4950

Google Scholar

Google Scholar

[41] Schiøtz J, Tolla F D D, Jacobsen K W 1998 Nature 391 561

Google Scholar

Google Scholar

[42] Stukowski A 2012 Model. Simul. Mater. Sci. Eng. 20 045021

Google Scholar

Google Scholar

[43] Faken D, Jónsson H 1994 Comput. Mater. Sci. 2 279

Google Scholar

Google Scholar

[44] Tsuzuki H, Branicio P, Rino J 2007 Comput. Phys. Commun. 177 518

Google Scholar

Google Scholar

[45] Zeng Q Y, Dai J Y 2020 Sci. China Phys. Mech. Astron. 63 263011

Google Scholar

Google Scholar

[46] Walsh J M, Rice M H, Mcqueen R G, Yarger F L 1957 Phys. Rev. 108 196

Google Scholar

Google Scholar

[47] Marsh S P 1979 Los Alamos Shock Hugoniot Data (Berkeley: University of California Press)

[48] Thiel M V 1997 Compendium of Shock Wave Data (Livermore: Lawrence Livermore National Laboratory) Report UCRL 50108

[49] Mcqueen R G, Marsh, S P, Taylor J W, Fritz J N, Carter W J 1970 The Equation of State of Solids from Shock Wave Studies (New York: Academic) pp348–350

-

图 2 (a)沿

$\left\langle {100} \right\rangle $ 晶向冲击后不同结构特征的钯的原子分数与纵向应力的关系; (b)不同结构特征随纵向应力变化的可视化表示; (c)温度与纵向应力的关系, 其中红色点线图为刘中利等[24]冲击熔化的分子动力学模拟数据Fig. 2. (a) Fraction of atoms with different structural features versus longitudinal stress along the crystallographic direction

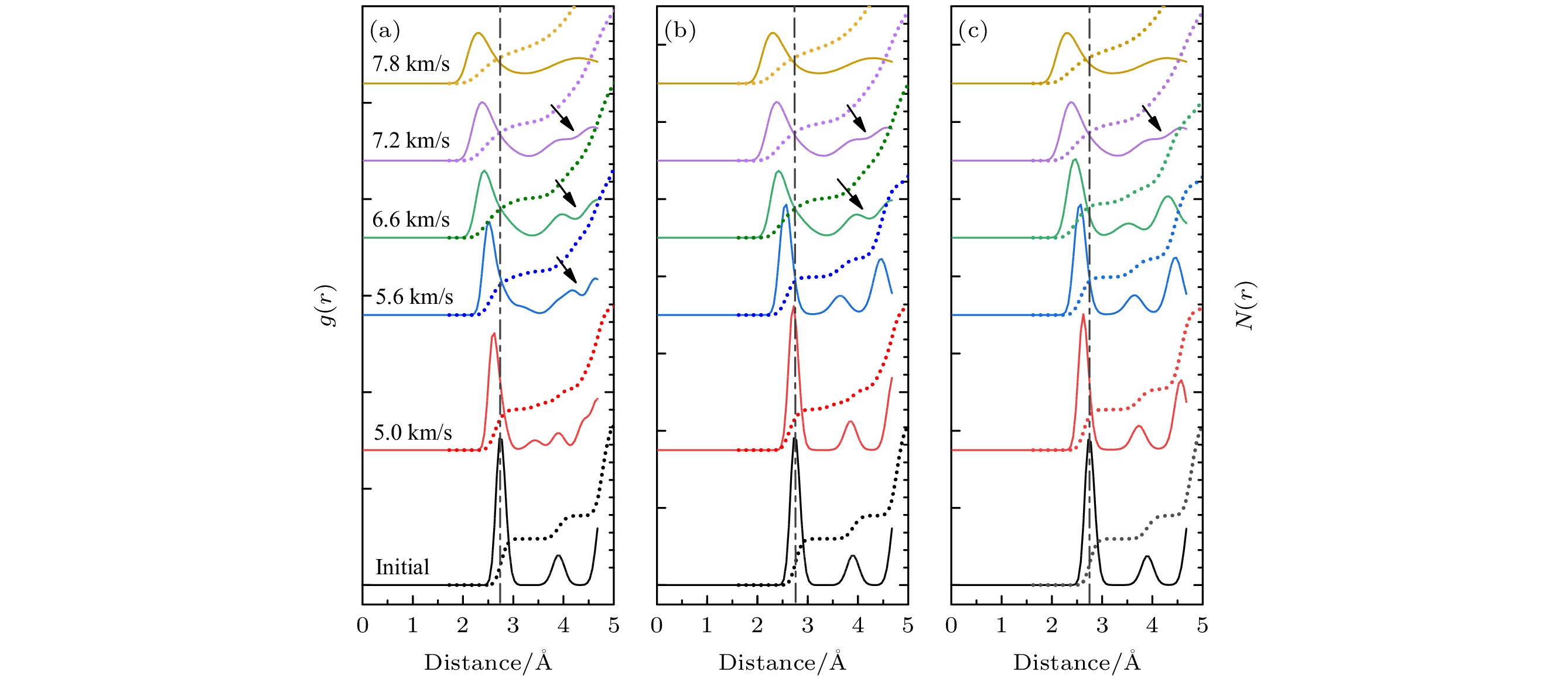

$\left\langle {100} \right\rangle $ ; (b) visual representation of the variation of different structural features with longitudinal stress; (c) temperature versus longitudinal stress, the red dotted line plot shows the MD simulation data of Liu et al.[24] shock melting.图 3 沿不同晶向冲击后的结果 (a)

$\left\langle {100} \right\rangle $ 晶向; (b)$\left\langle {110} \right\rangle $ 晶向; (c)$\left\langle {100} \right\rangle $ 晶向. 其中实线表示冲击速度在5.0—7.8 km/s范围内结构的RDF图像, 点划线表示与之对应的配位数曲线, 黑色虚线位置指向初始状态下的第一峰的位置Fig. 3. Results along different crystallographic directions: (a)

$\left\langle {100} \right\rangle $ ; (b)$\left\langle {110} \right\rangle $ ; (c)$\left\langle {111} \right\rangle $ . The solid lines indicate radial distribution functions of deformed micro-structure shocked at a range of shock velocity of 5.0–7.8 km/s. The dotted lines indicate the coordination number curves that correspond to the RDF, and the dashed lines points to the position of the first peak in the initial state.图 4 利用a-CNA方法得到的沿不同晶向冲击的不同结构比例随压强的变化 (a)

$\left\langle {110} \right\rangle $ 晶向; (b)$\left\langle {111} \right\rangle $ 晶向Fig. 4. Fraction of atoms with different structural versus compressing stress along different crystallographic directions obtained by a-CNA: (a)

$\left\langle {110} \right\rangle $ ; (b)$\left\langle {111} \right\rangle $ .图 5 (a)不同缺陷率的晶体结构在冲击压缩后温度与压力的关系; (b), (c), (d)分别表示冲击压缩下含不同缺陷率体系的原子类别占比随冲击压强的变化

Fig. 5. (a) Comparison of Hugoniot P-T curve among crystal structures with different porosities defects; (b), (c), (d) comparison of phase transition processes of atoms of system with variation porosities defects under shock compression.

图 6 (a)完美晶体与含缺陷晶体在冲击前后的势能差值分布图; (b)不同体系中势能差值的概率分布曲线

Fig. 6. (a) Distribution diagram of potential energy difference between perfect crystal and defective crystal before and after compression; (b) probability distribution curves of potential energy differences in perfect crystal and defective crystal.

-

[1] Graziani F, Desjarlais M P, Redmer R, Trickey S B 2014 Frontiers and Challenges in Warm Dense Matter (Vol. 1) (Switzerland: Springer) pp1–3

[2] Moses E I, Boyd R N, Remington B A, Keane C J, Al-Ayat R 2009 Phys. Plasmas 16 041006

Google Scholar

Google Scholar

[3] Mitchell A C, Nellis W J, Moriarty J A, Heinle R A, Holmes N C, Tipton R E, Repp G W 1991 J. Appl. Phys. 69 2981

Google Scholar

Google Scholar

[4] Nagao H, Nakamura K J, Kondo K, Ozaki N, Takamatsu K, Ono T, Shiota T, Ichinose D, Tanaka K A, Wakabayashi K 2006 Phys. Plasmas 13 052705

Google Scholar

Google Scholar

[5] Yokoo M, Kawai N, Nakamura K G, Kondo K I 2008 Appl. Phys. Lett. 92 051901

Google Scholar

Google Scholar

[6] Nellis W J, Weir S T, Mitchell A C 1996 Science 273 936

Google Scholar

Google Scholar

[7] Weir S T, Mitchell A C, Nellis W J 1996 Phys. Rev. Lett. 76 1860

Google Scholar

Google Scholar

[8] Hartley N J, Brown S, Cowan T E, Cunningham E, Döppner T, Falcone R W, Fletcher L B, Frydrych S, Galtier E, Gamboa E J 2019 Sci. Rep. 9 1

[9] Briggs R, Coppari F, Gorman M G, Smith R F, Tracy S J, Coleman A L, Fernandez-Panella A, Millot M, Eggert J H, Fratanduono D E 2019 Phys. Rev. Lett. 123 045701

Google Scholar

Google Scholar

[10] Sharma S M, Turneaure S J, Winey J M, Li Y, Rigg P, Schuman A, Sinclair N, Toyoda Y, Wang X, Weir N, Zhang J, Gupta Y M 2019 Phys. Rev. Lett. 123 045702

Google Scholar

Google Scholar

[11] Li Q J, Liu B B 2016 Chin. Phys. B 25 076107

Google Scholar

Google Scholar

[12] Guo Y L, Wei J H, Liu X, Ke X Z, Jiao Z Y 2021 Chin. Phys. B 30 016101

Google Scholar

Google Scholar

[13] Lu M Y, Huang Y P, Tian F B, Li D, Duan D F, Zhou Q, Cui T 2020 Chin. Phys. B 29 053104

Google Scholar

Google Scholar

[14] Hesse R W 2007 Jewelry-Making Through History: an Encyclopedia (Westport: Greenwood Publishing Group) p146

[15] Colon P, Pradelle-Plasse N, Galland J 2003 Dent. Mater. 19 232

Google Scholar

Google Scholar

[16] Harper C A 1997 Passive Electronic Component Handbook. McGraw-Hill Professional (New York: McGraw-Hill) pp580

[17] Fleischmann M, Pons S, Hawkins M 1989 J. Electroanal. Chem. 261 301

Google Scholar

Google Scholar

[18] Mutschele T, Kirchheim R 1987 Scr. Mater. 21 1351101

[19] Pundt A, Sachs C, Winter M, Reetz M T, Fritsch D, Kirchheim R 1999 J. Alloys Compd. 293-295 480

[20] Bonivardi A L, Baltanas M A 1994 React. Kinet. Catal. Lett. 52 95

[21] Eastman J A, Thompson L J, Kestel B J 1993 Phys. Rev. 48 84

Google Scholar

Google Scholar

[22] Foiles S M, Adams J B 1989 Phys. Rev. B 40 9

[23] Foiles S M, Baskes M I, Daw M S 1986 Phys. Rev. B 33 7983

Google Scholar

Google Scholar

[24] Liu Z L, Yang J H, Cai L C, Jing F Q, Alfѐ D 2011 Phys. Rev. B 83 144113

Google Scholar

Google Scholar

[25] Errandonea D 2013 Phys. Rev. B 87 054108

Google Scholar

Google Scholar

[26] Jeong J W, Chang K 1999 J. Phys. Condens. Matter 11 3799

Google Scholar

Google Scholar

[27] Liu Z L, Zhang X L, Cai L C 2015 J. Chem. Phys. 11 637

[28] Zheng Z Y, Zhao J J 2016 Chin. Phys. B 25 076202

Google Scholar

Google Scholar

[29] 孙小伟, 褚衍东, 刘子江, 刘玉孝, 王成伟, 刘维民 2005 54 5830

Google Scholar

Google Scholar

Sun X W, Zhe Y D, Liu Z J, Liu Y X, Wang C W, Liu W M 2005 Acta Phys. Sin. 54 5830

Google Scholar

Google Scholar

[30] 段芳莉, 王家序, 雒建斌, 温诗铸 2007 56 6552

Google Scholar

Google Scholar

Duan F L, Wang J X, Luo J B, Weng S Z 2007 Acta Phys. Sin. 56 6552

Google Scholar

Google Scholar

[31] 邵建立, 王裴, 秦承森, 周洪强 2007 56 5389

Google Scholar

Google Scholar

Shao J L, Wang F, Qing C S, Zhou H Q 2007 Acta Phys. Sin. 56 5389

Google Scholar

Google Scholar

[32] 周化光, 林鑫, 王猛, 黄卫东 2013 62 056803

Google Scholar

Google Scholar

Zhou H G, Lin X, Wang M, Huang W D 2013 Acta Phys. Sin. 62 056803

Google Scholar

Google Scholar

[33] Plimpton S J 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[34] Reed E J, Fried L E, Joannopoulos J D 2003 Phys. Rev. Lett. 90 235503

Google Scholar

Google Scholar

[35] Stukowski A 2009 Modell. Simul. Mater. Sci. Eng. 18 015012

[36] 韦昭召, 马骁, 柯常波, 张新平 2020 69 136102

Google Scholar

Google Scholar

Wei Z Z, Ma X, Ke C B, Zhang X P 2020 Acta Phys. Sin. 69 136102

Google Scholar

Google Scholar

[37] Kien P H 2014 Int. Scholarly Res. Not. 2014 253627

[38] Sun H Y, Kang D D, Hou Y, Dai J Y 2017 Matter Radiat. at Extremes 2 287

Google Scholar

Google Scholar

[39] Neogi A, Mitra N 2017 Sci. Rep. 7 1

Google Scholar

Google Scholar

[40] Honeycutt J D, Andersen H C 1987 J. Phys. Chem. 91 4950

Google Scholar

Google Scholar

[41] Schiøtz J, Tolla F D D, Jacobsen K W 1998 Nature 391 561

Google Scholar

Google Scholar

[42] Stukowski A 2012 Model. Simul. Mater. Sci. Eng. 20 045021

Google Scholar

Google Scholar

[43] Faken D, Jónsson H 1994 Comput. Mater. Sci. 2 279

Google Scholar

Google Scholar

[44] Tsuzuki H, Branicio P, Rino J 2007 Comput. Phys. Commun. 177 518

Google Scholar

Google Scholar

[45] Zeng Q Y, Dai J Y 2020 Sci. China Phys. Mech. Astron. 63 263011

Google Scholar

Google Scholar

[46] Walsh J M, Rice M H, Mcqueen R G, Yarger F L 1957 Phys. Rev. 108 196

Google Scholar

Google Scholar

[47] Marsh S P 1979 Los Alamos Shock Hugoniot Data (Berkeley: University of California Press)

[48] Thiel M V 1997 Compendium of Shock Wave Data (Livermore: Lawrence Livermore National Laboratory) Report UCRL 50108

[49] Mcqueen R G, Marsh, S P, Taylor J W, Fritz J N, Carter W J 1970 The Equation of State of Solids from Shock Wave Studies (New York: Academic) pp348–350

计量

- 文章访问数: 6269

- PDF下载量: 133

- 被引次数: 0

下载:

下载: