-

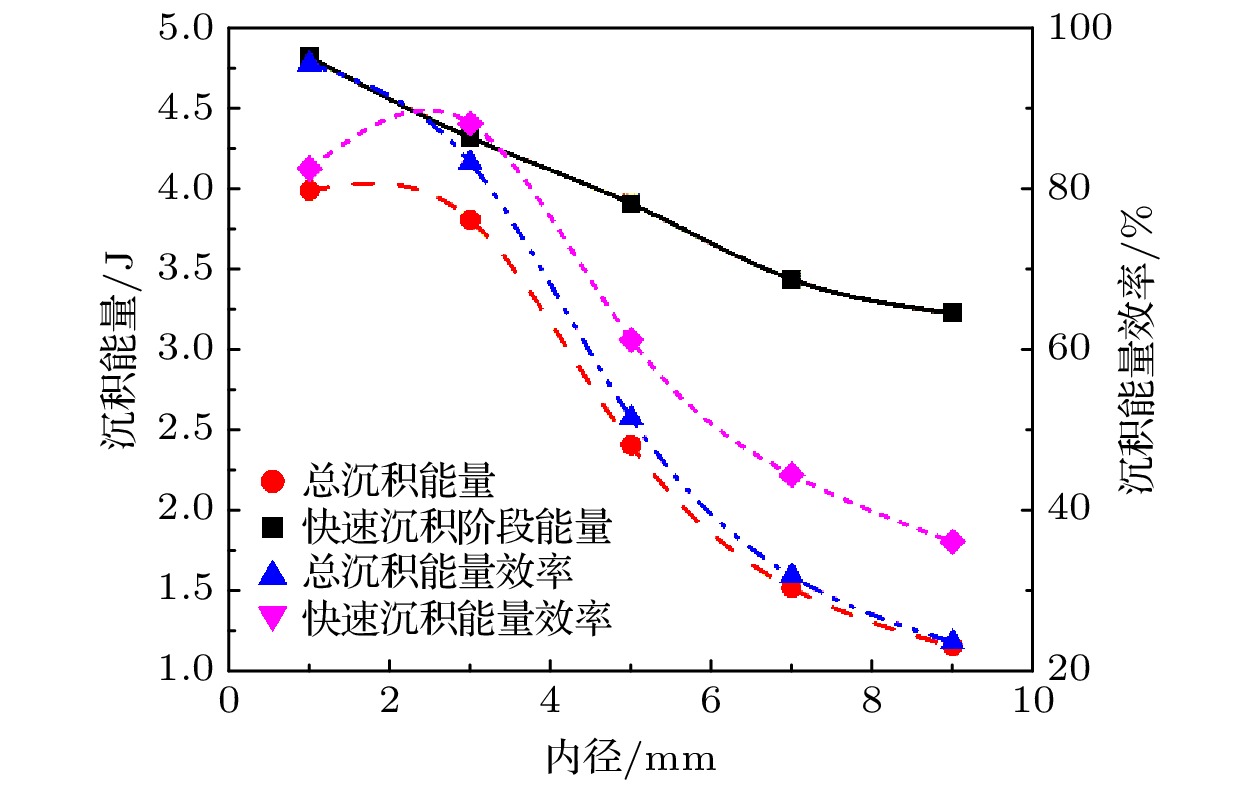

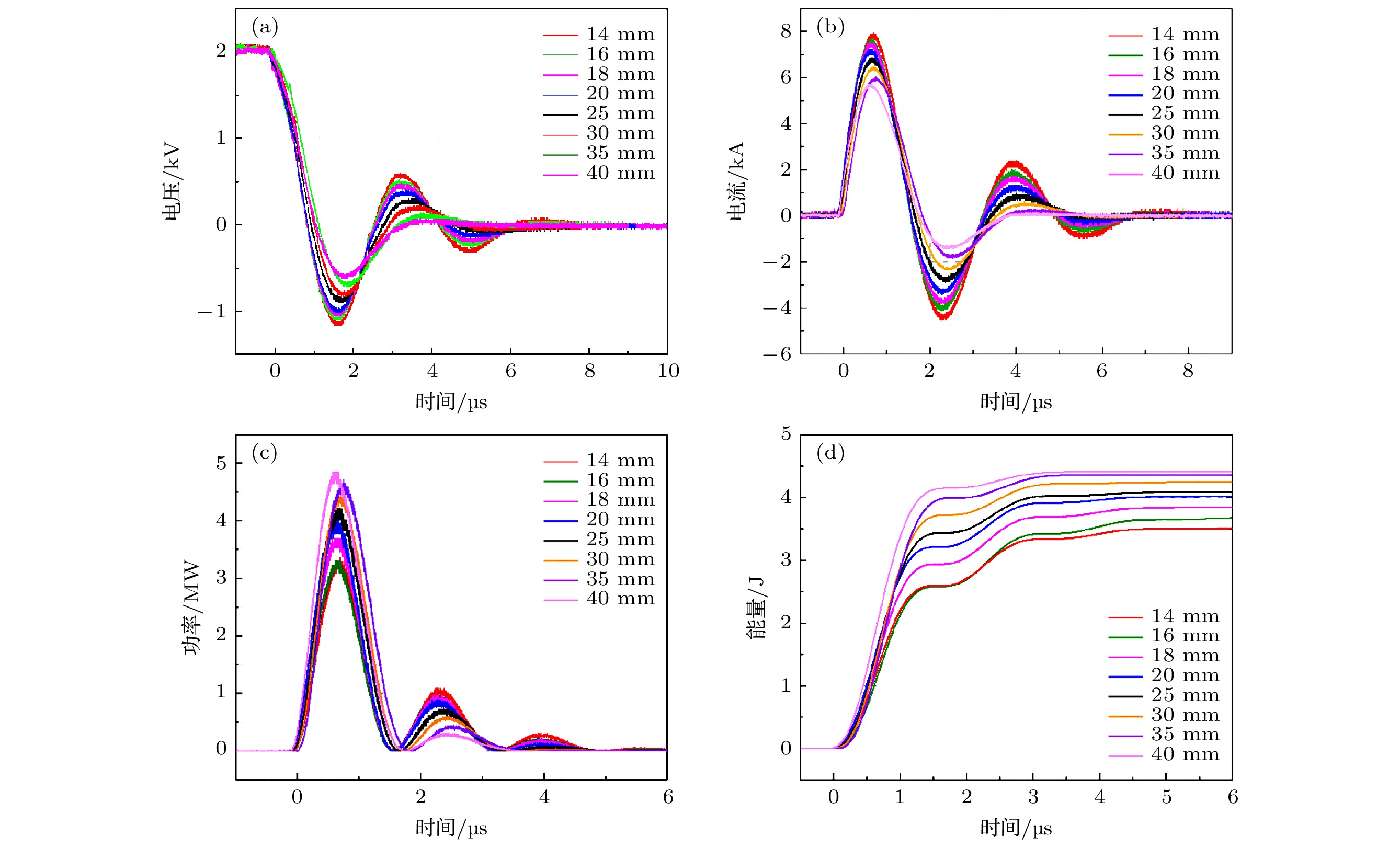

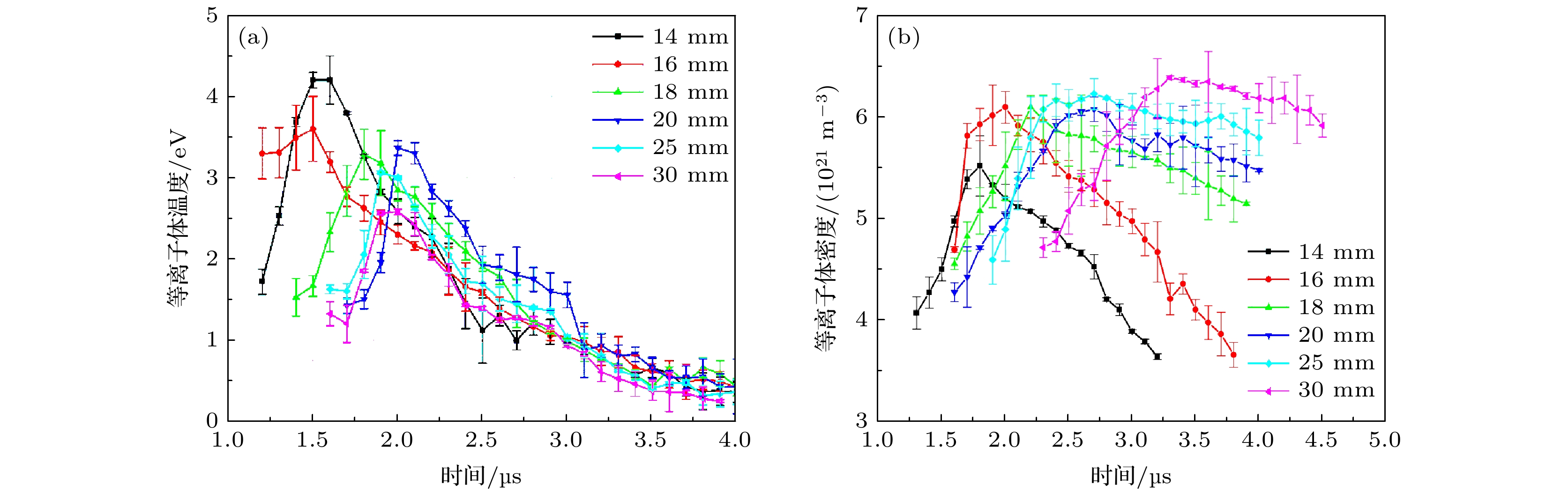

毛细管放电型脉冲等离子体推力器在微纳卫星在轨机动应用中具备良好的发展前景. 本文系统研究了单次放电能量5 J条件下, 不同毛细管腔体尺寸参数对推力器能量沉积特性、烧蚀特性、输出推力参数和等离子体羽流参数的影响规律. 实验结果表明, 增大毛细管腔体内径会显著降低放电电流密度, 减小沉积能量和等效功率; 增大腔体长度有助于提升能量传递效率. 腔体结构尺寸变化影响单位面积沉积能量和管壁温度, 进而改变烧蚀特性. 当毛细管内径从1 mm增加至3 mm时烧蚀质量显著下降, 随着腔体内径的进一步增大, 等效烧蚀质量近似不变; 烧蚀质量随毛细管长度的增加持续增大, 但单位面积烧蚀质量不断下降. 推力器元冲量取决于烧蚀质量与其等效速度, 烧蚀特性的差异进一步影响腔体内等离子体密度和等效压强, 影响等离子体电热加速过程. 毛细管腔体内径和长度的不断增加, 使得加速过程滞后于放电和烧蚀过程, 作用于加速过程的电弧沉积能量比例降低, 降低推力器等离子体喷射速度, 元冲量减小, 比冲降低, 总体效率下降. 结合总体效率传递模型分析, 毛细管内径对推力器效率的影响主要体现在能量传递效率方面, 毛细管长度变化主要影响等离子体电热加速效率, 优化推力器总体效率需要从能量沉积效率和加速效率两方面入手.Capillary discharge based pulsed plasma thrusters have great prospects of applications in in-orbit maneuvering of

micro-nano satellites. In this paper, the influence of different capillary cavity structure parameters on the thruster's energy deposition process, ablation characteristics, output thrust parameters and plasma plume parameters under an energy level of 5 J were studied. The experimental results indicate that the increase of the inner diameter of the capillary cavity will significantly reduce the discharge current density, which leads the deposition energy and equivalent power to decrease; the increase of the cavity length helps to improve the energy transfer efficiency. The influence of cavity structure on the ablation characteristics is reflected in the influence of deposition energy per unit area on the tube wall temperature. When the inner diameter of the capillary increases from 1 mm to 3 mm, the ablation mass decreases significantly, and then the equivalent ablation mass remains approximately unchanged as the inner diameter of the cavity increases further; the ablation mass continues to increase as the capillary length increases, while the ablation mass per unit area continues to decrease. The impulse bit depends on the ablation mass and plasma plume velocity, and the difference in ablation characteristic further affects the plasma in the cavity. The density and equivalent pressure determine the plasma electrothermal acceleration process. The continuous increase in the diameter and length of the capillary cavity will induce the acceleration process to lag behind the discharge and ablation process. And the decrease of the deposited energy impedes the electrothermal acceleration process, which results in the decrease of the impulse bit, specific impulse, and the overall efficiency. Furthermore, the overall efficiency transfer model analysis indicates the influence of the capillary inner diameter on thruster efficiency is mainly reflected in the energy transfer efficiency, and the capillary length change mainly affects the electrothermal acceleration efficiency. The overall efficiency optimization of the thruster needs to start from increasing both energy deposition efficiency and acceleration efficiency. -

Keywords:

- pulsed plasma thruster /

- capillary discharge /

- cavity structure /

- plasma acceleration

[1] Levchenko I, Keidar M, Cantrell J, Wu Y L, Kuninaka H, Bazaka K, Xu S Y 2018 Nature 562 185

Google Scholar

Google Scholar

[2] 马定坤, 匡银, 杨新权 2017 空间电子技术 14 42

Google Scholar

Google Scholar

Ma D K, Kuang Y, Yang X Q 2017 Space Electron. Technol. 14 42

Google Scholar

Google Scholar

[3] Esper J, Neeck S, Slavin J A, Wiscombe W, Bauer F H 2003 Acta Astronaut 52 785

Google Scholar

Google Scholar

[4] 于达仁, 乔磊, 蒋文嘉, 刘辉 2020 推进技术 41 1

Yu D R, Qiao L, Jiang W J, Liu H 2020 J. Propul. Technol. 41 1

[5] Levchenko I, Bazaka K, Ding Y J, Ratses Y, Mazouffe S, Henning T J, Klar P, Shinahara S, Schein J, Garrigues L, Kim M, Lev D, Taccogna F, Boswell R W, Charles C, Koizumi H, Shen Y, Scharlemann C, Keidar M, Xu S Y 2018 Appl. Phys. Rev. 5 11104

Google Scholar

Google Scholar

[6] Wright W P, Ferrer P 2015 Prog. Aerosp. Sci. 74 48

Google Scholar

Google Scholar

[7] Molina-Cabrera P, Herdrich G, Lau M, Fausolas S, Schoenherr T, Komurasaki K 2011 Proceedings of 32nd International Electric Propulsion Conference (IEPC), Wiesbaden, Germany, September 11−15, 2011 pp1−18

[8] 王亚楠, 丁卫东, 程乐, 李悦, 孙安邦 2018 电工技术学报 33 218

Wang Y N, Ding W D, Cheng L, Li Y, Sun A B 2018 Trans. Chin. Electrotech. Soc. 33 218

[9] Ozaki J, Ikeda T, Fujiwara T, Nishizawa M, Araki S, Tahara H, Watanabe Y 2011 The 32nd International Electric Propulsion Conference, Wiesbaden, Germany, September 11−15, 2011 IEPC-2011-035

[10] Keidar M, Boyd I D, Beilis I I 2001 J. Phys D: Appl. Phys. 34 1675

Google Scholar

Google Scholar

[11] Zaghloul M R 2004 J. Appl. Phys. 95 3339

Google Scholar

Google Scholar

[12] Schonherr T, Nees F, Arakawa Y, Komurasaki K, Herdrich G 2013 Phys. Plasma 20 033503

Google Scholar

Google Scholar

[13] Wang W Z, Kong L H, Geng J Y, Wei F, Xia G Q 2017 J. Phys. D: Appl. Phys. 50 074005

Google Scholar

Google Scholar

[14] Edamitsu T, Tahara H 2005 The 29th International Electric Propulsion Conference, Princeton, USA, October 31–November 4, 2005 IEPC 2005−105

[15] Aoyagi J, Mukai M, Kamishima Y, Sasaki T, Shintani K, Takegahara H, Wakizono T, Sugiki M 2008 Vacuum 83 72

Google Scholar

Google Scholar

[16] Hiroki T, Hirokazu T 2009 The 31st International Electric Propulsion Conference, Michigan, USA, September 20−24, 2009 IEPC-2009-154

[17] Matthias L, Georg H, Stefanos F, Roser H P 2011 The 32nd International Electric Propulsion Conference, Wiesbaden, Germany, September 11−15, 2011 IEPC-2011-140

[18] Wang Y N, Ding W D, Cheng L, Yan J Q, Wang J C, and Wang Y S 2017 IEEE Trans. Plasma Sci. 45 2715

Google Scholar

Google Scholar

[19] 孔策 2013 等离子体光谱学导论 (北京: 北京大学出版社)

Kunze H J 2013 Introduction to Plasma Spectroscopy (Beijing: Peking University Press) (in Chinese)

[20] Spores 1997 The 33rd Joint Propulsion Conference and Exhibit: Seattle, W. A., USA, July 6−9, 1997 2922

[21] Griem H R 1964 Plasma Spectroscopy (Cambriadge: Cambriadge University Press)

[22] Tie W, Zhang Y, Meng C, Zhang Q G, Yan Z, He P 2018 Plasma Sources Sci. Technol. 27 015005

[23] Wang Y, Ding W, Cheng L, Li Y, Ge C J, Han R Y, Yan J Q, Zhao Z, Sun A B 2018 Rev. Sci. Instrum. 89 075104

Google Scholar

Google Scholar

[24] Wang Y N, Ge C J, Cheng L, Ding W D, Geng J Y 2019 Rev. Sci. Instrum. 90 076111

Google Scholar

Google Scholar

[25] 李瑞 2012 博士学位论文(西安: 西安交通大学)

Li R 2012 Ph. D. Dissertation (Xi'an: Xi'an Jiaotong University) (in Chinese)

[26] Bushman S S, Burton R L 2011 J. Propul. Power 17 959

[27] Pekker L 2009 J. Propul. Power 25 958

Google Scholar

Google Scholar

[28] Liao H T, Wu M L, Wang N H 1999 J. Propul. Technol. 20 107

[29] Branch M C, Sawyer R F 1969 The 5th Propulsion Joint Specialist, Colorado Springs, CO, USA, June13−17, 1969 p469

-

表 1 毛细管推力器工作参数与结构参数

Table 1. Operation parameters and structural parameters of CDPPT.

参数 取值 主电容容值 C0/μF 2.5 充电电压 U0/kV 2 毛细管长度 l0/mm 14, 16, 18, 20, 25, 30, 35, 40 毛细管内径 R0/mm 1, 3, 5, 7, 9 表 2 不同容值下等效放电回路参数

Table 2. Equivalent circuit parameters of CDPPT with different capacitance.

主电容值/μF 0.5 1.0 1.5 2.0 2.5 Lc + L0/nH 97.13 89.02 86.32 84.97 84.16 表 3 不同内径下等效放电回路参数

Table 3. Equivalent circuit parameters of CDPPT with different cavity diameter.

毛细管内径/mm 初始储能/J 主电流幅值/A 弧道电阻/mΩ 弧道电感/nH 1 5.06 2379 ± 38.20 703.10 ± 15.43 49.98 ± 2.38 3 5.00 6116 ± 8.94 143.70 ± 0.53 35.50 ± 3.08 5 5.18 ± 0.01 7568 ± 17.89 58.72 ± 0.13 28.19 ± 1.92 7 5.05 ± 0.01 8148 ± 26.83 49.74 ± 0.70 27.75 ± 2.05 9 5.08 ± 0.01 8400 39.38 ± 0.18 21.53 ± 2.94 表 4 不同长度下等效放电回路参数

Table 4. Equivalent circuit parameters of CDPPT with different cavity length.

毛细管长度/mm 初始储能/J 主电流幅值/A 弧道电阻/mΩ 弧道电感/nH 14 5.16 ± 0.01 7944 ± 35.78 53.00 ± 0.07 14.14 ± 0.46 16 5.11 ± 0.03 7640 56.47 ± 0.36 19.36 ± 1.69 18 5.07 ± 0.01 7544 ± 35.78 66.20 ± 0.45 22.25 ± 2.12 20 5.16 ± 0.06 7256 ± 35.78 77.56 ± 0.40 22.32 ± 0.22 25 5.05 6872 ± 43.82 90.66 ± 0.81 22.74 ± 3.12 30 5.09 6436 ± 21.91 107.34 ± 0.19 25.67 ± 2.12 35 5.17 ± 0.01 6004 ± 21.91 129.86 ± 0.34 34.27 ± 2.84 40 5.10 ± 0.08 5684 ± 21.91 148.86 ± 0.73 36.24 ± 1.89 -

[1] Levchenko I, Keidar M, Cantrell J, Wu Y L, Kuninaka H, Bazaka K, Xu S Y 2018 Nature 562 185

Google Scholar

Google Scholar

[2] 马定坤, 匡银, 杨新权 2017 空间电子技术 14 42

Google Scholar

Google Scholar

Ma D K, Kuang Y, Yang X Q 2017 Space Electron. Technol. 14 42

Google Scholar

Google Scholar

[3] Esper J, Neeck S, Slavin J A, Wiscombe W, Bauer F H 2003 Acta Astronaut 52 785

Google Scholar

Google Scholar

[4] 于达仁, 乔磊, 蒋文嘉, 刘辉 2020 推进技术 41 1

Yu D R, Qiao L, Jiang W J, Liu H 2020 J. Propul. Technol. 41 1

[5] Levchenko I, Bazaka K, Ding Y J, Ratses Y, Mazouffe S, Henning T J, Klar P, Shinahara S, Schein J, Garrigues L, Kim M, Lev D, Taccogna F, Boswell R W, Charles C, Koizumi H, Shen Y, Scharlemann C, Keidar M, Xu S Y 2018 Appl. Phys. Rev. 5 11104

Google Scholar

Google Scholar

[6] Wright W P, Ferrer P 2015 Prog. Aerosp. Sci. 74 48

Google Scholar

Google Scholar

[7] Molina-Cabrera P, Herdrich G, Lau M, Fausolas S, Schoenherr T, Komurasaki K 2011 Proceedings of 32nd International Electric Propulsion Conference (IEPC), Wiesbaden, Germany, September 11−15, 2011 pp1−18

[8] 王亚楠, 丁卫东, 程乐, 李悦, 孙安邦 2018 电工技术学报 33 218

Wang Y N, Ding W D, Cheng L, Li Y, Sun A B 2018 Trans. Chin. Electrotech. Soc. 33 218

[9] Ozaki J, Ikeda T, Fujiwara T, Nishizawa M, Araki S, Tahara H, Watanabe Y 2011 The 32nd International Electric Propulsion Conference, Wiesbaden, Germany, September 11−15, 2011 IEPC-2011-035

[10] Keidar M, Boyd I D, Beilis I I 2001 J. Phys D: Appl. Phys. 34 1675

Google Scholar

Google Scholar

[11] Zaghloul M R 2004 J. Appl. Phys. 95 3339

Google Scholar

Google Scholar

[12] Schonherr T, Nees F, Arakawa Y, Komurasaki K, Herdrich G 2013 Phys. Plasma 20 033503

Google Scholar

Google Scholar

[13] Wang W Z, Kong L H, Geng J Y, Wei F, Xia G Q 2017 J. Phys. D: Appl. Phys. 50 074005

Google Scholar

Google Scholar

[14] Edamitsu T, Tahara H 2005 The 29th International Electric Propulsion Conference, Princeton, USA, October 31–November 4, 2005 IEPC 2005−105

[15] Aoyagi J, Mukai M, Kamishima Y, Sasaki T, Shintani K, Takegahara H, Wakizono T, Sugiki M 2008 Vacuum 83 72

Google Scholar

Google Scholar

[16] Hiroki T, Hirokazu T 2009 The 31st International Electric Propulsion Conference, Michigan, USA, September 20−24, 2009 IEPC-2009-154

[17] Matthias L, Georg H, Stefanos F, Roser H P 2011 The 32nd International Electric Propulsion Conference, Wiesbaden, Germany, September 11−15, 2011 IEPC-2011-140

[18] Wang Y N, Ding W D, Cheng L, Yan J Q, Wang J C, and Wang Y S 2017 IEEE Trans. Plasma Sci. 45 2715

Google Scholar

Google Scholar

[19] 孔策 2013 等离子体光谱学导论 (北京: 北京大学出版社)

Kunze H J 2013 Introduction to Plasma Spectroscopy (Beijing: Peking University Press) (in Chinese)

[20] Spores 1997 The 33rd Joint Propulsion Conference and Exhibit: Seattle, W. A., USA, July 6−9, 1997 2922

[21] Griem H R 1964 Plasma Spectroscopy (Cambriadge: Cambriadge University Press)

[22] Tie W, Zhang Y, Meng C, Zhang Q G, Yan Z, He P 2018 Plasma Sources Sci. Technol. 27 015005

[23] Wang Y, Ding W, Cheng L, Li Y, Ge C J, Han R Y, Yan J Q, Zhao Z, Sun A B 2018 Rev. Sci. Instrum. 89 075104

Google Scholar

Google Scholar

[24] Wang Y N, Ge C J, Cheng L, Ding W D, Geng J Y 2019 Rev. Sci. Instrum. 90 076111

Google Scholar

Google Scholar

[25] 李瑞 2012 博士学位论文(西安: 西安交通大学)

Li R 2012 Ph. D. Dissertation (Xi'an: Xi'an Jiaotong University) (in Chinese)

[26] Bushman S S, Burton R L 2011 J. Propul. Power 17 959

[27] Pekker L 2009 J. Propul. Power 25 958

Google Scholar

Google Scholar

[28] Liao H T, Wu M L, Wang N H 1999 J. Propul. Technol. 20 107

[29] Branch M C, Sawyer R F 1969 The 5th Propulsion Joint Specialist, Colorado Springs, CO, USA, June13−17, 1969 p469

计量

- 文章访问数: 8461

- PDF下载量: 112

- 被引次数: 0

下载:

下载: