-

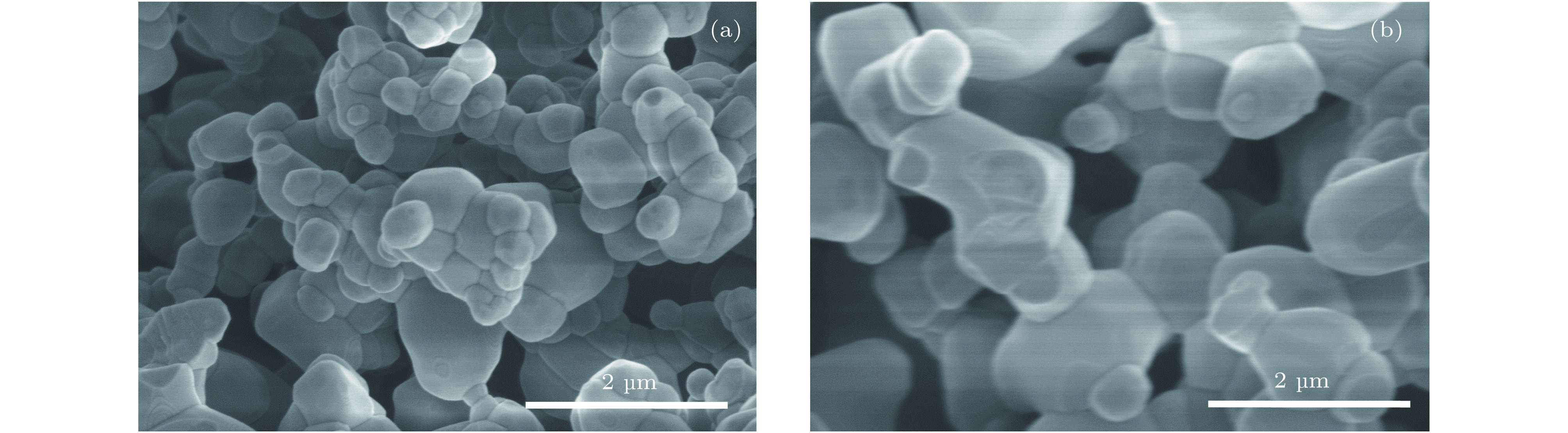

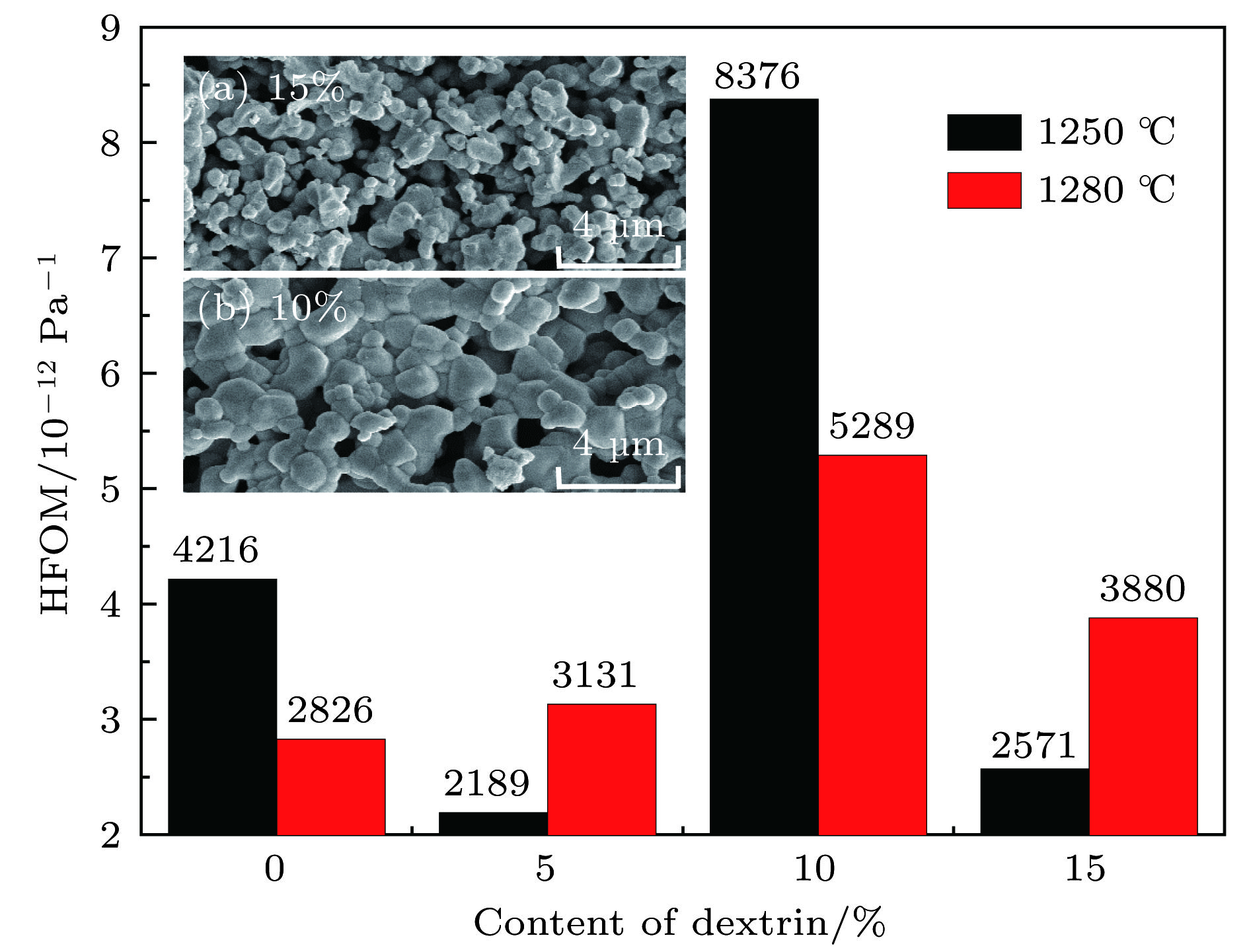

在压电陶瓷中增加孔洞数量, 可以有效改善陶瓷的静水压优值, 提高其压电灵敏性. 考虑到铅基压电陶瓷对环境和人体的危害, 本文以糊精为造孔剂, 采用传统固相烧结法制备无铅钛酸钡(BaTiO3)多孔压电陶瓷. 研究烧结温度(1250, 1280, 1300 ℃)和糊精含量(5%, 10%, 15%)对BaTiO3陶瓷晶体结构、孔隙率以及孔形貌特征的影响, 探索孔隙率与BaTiO3陶瓷介电、压电、声阻抗以及静水压优值等性能之间的相关性. 结果表明: 所有多孔陶瓷表现出三维贯通的开气孔, 尺寸约为1—7

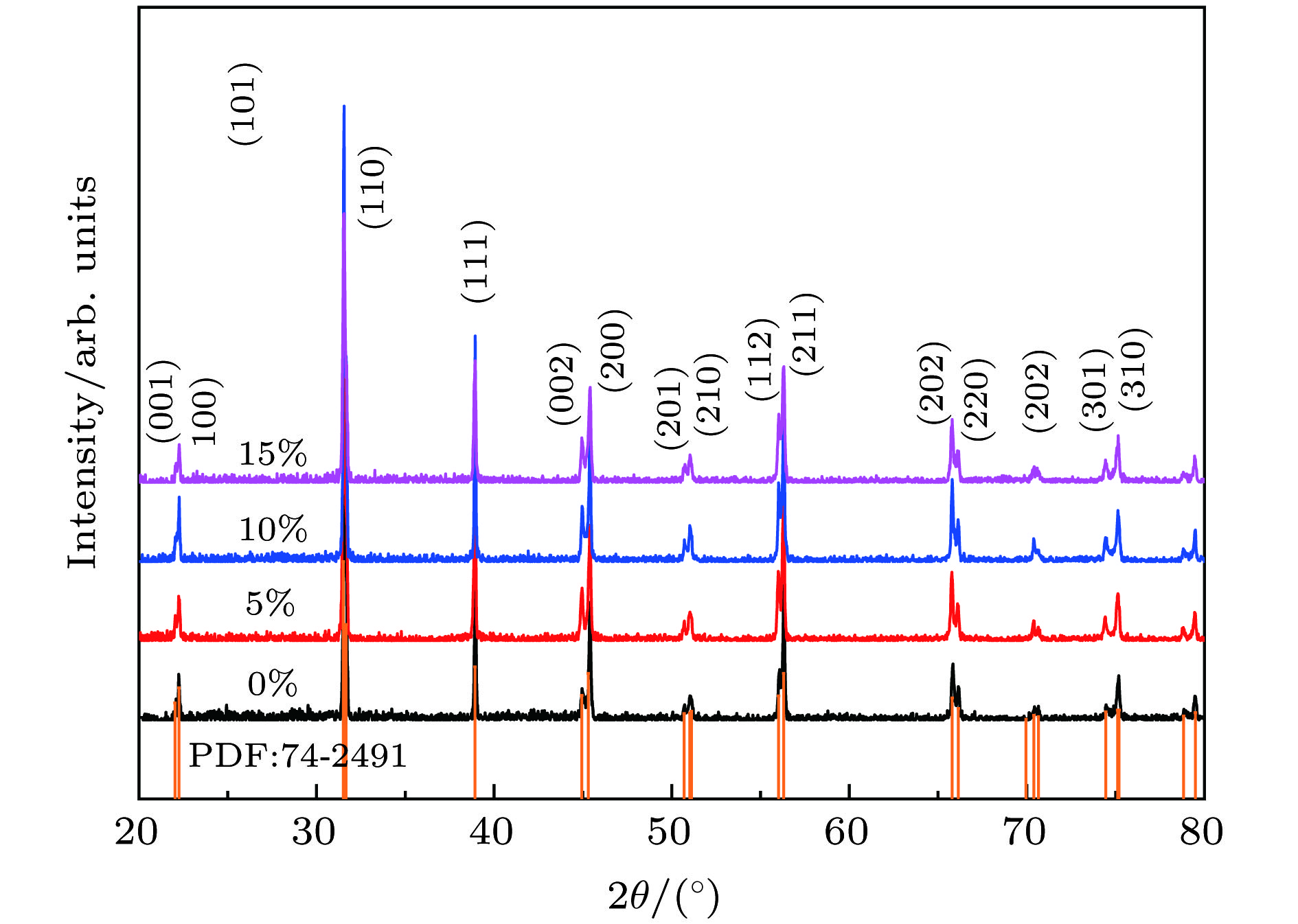

${\text{μ}}{\rm m}$ . 烧结温度强烈影响BaTiO3陶瓷的孔隙率, 加入10%低沸点的糊精时, 1250 ℃和1280 ℃烧结均获得孔隙率高达58%的多孔BaTiO3陶瓷; 然而1300 ℃烧结, 陶瓷孔隙率急速下降到13%. 1250 ℃烧结10%糊精含量的陶瓷表现出高的静水压优值(约8376 × 10–15 Pa–1)和低的声阻抗(约2.84 MRrayls (1 Rayl = 10 Pa·s/m)). 与1250 ℃相比, 1280 ℃烧结的陶瓷晶粒之间的结合力明显增强, 有利于提高陶瓷的力学强度. 这些优异的性能预示着多孔钛酸钡陶瓷在传感器和水听器领域有着潜在的应用前景.Porous piezoelectric ceramic shows some advantages, such as high hydrostatic figure of merit, low acoustic impedance, and excellent piezoelectric sensitivity, compared with its compact counterpart. These merits make it used widely in various electronic devices, such as underwater acoustic transducer, ultrasonic transducer, and sensor. Currently, the researches of porous piezoelectric ceramics mainly focus on the Pb(Zr, Ti)O3 ceramic, which is harmful to environment and human health. In this paper, the lead-free porous barium titanate (BaTiO3) ceramic doped with dextrin is prepared by using the conventional solid-state method. The effects of sintered temperature and dextrin content on the structure, porosity, and morphology of the pores are studied experimentally and theoretically. Also, the relationship between porosity and dielectric, piezoelectricity, electro-mechanical coupling factor, acoustic impedance, and hydrostatic figure of merit are explored. The X-ray diffraction pattern shows that the lattice constants of ceramic are not affected by dextrin. The BaTiO3 ceramic demonstrates single perovskite structure with P4mm space group. The SEM micrograph reveals that the porous ceramic has three-dimensional open pores with the size of 1−7${\text{μ}}{\rm m}$ . Sintering temperature plays a key role in porosity in the BaTiO3 ceramic. The porosity of ceramic gradually declines with sintered temperature increasing from 1250 to 1300 °C. The max porosity of up to 58% is obtained in 10% dextrin-doped BaTiO3 ceramic sintered at 1250 °C. The porosity of 5% dextrin-doped ceramic is smaller than that of the undoped one when the sintering temperature is 1250 °C or 1280 °C, indicating that a small amount of dextrin is beneficial to the densification of BaTiO3 ceramic. Both the dielectric and piezoelectric property gradually decrease with dextrin content increasing. For the BaTiO3 ceramic, high sintering temperature contributes to better dielectric and piezoelectric property than low temperature. Here, the ceramic with 10% of dextrin sintered at 1250 °C exhibits the highest hydrostatic figure of merit (8376 × 10–15 Pa–1) and the lowest acoustic impedance (~ 2.84 Mrayls). The binding force between grains is also obviously enhanced in the ceramic sintered at 1280 °C, which is very helpful for their mechanical strength improvement. The excellent properties of the BaTiO3 ceramic doped with dextrin indicate its potential applications in sensor and hydrophone.-

Keywords:

- lead-free piezoelectric ceramics /

- barium titanate /

- porous structure /

- hydrostatic figure of merit

[1] Deville S 2008 Adv. Eng. Mater. 10 155

Google Scholar

Google Scholar

[2] 朱小龙, 苏雪筠 2000 中国陶瓷 36 36

Google Scholar

Google Scholar

Zhu X L, Su X Y 2000 Chin. Ceram. 36 36

Google Scholar

Google Scholar

[3] Guo R, Wang C A, Yang A K 2011 J. Eur. Ceram. Soc. 31 605

Google Scholar

Google Scholar

[4] Ryosuke B, Tomoaki K, Tadashi F 2016 J. Chin. Ceram. Soc. 3 9

Google Scholar

Google Scholar

[5] Zhu S, Cao L, Xiong Z, Lu C, Gao Z 2018 J. Eur. Ceram. Soc. 38 2251

Google Scholar

Google Scholar

[6] 全宸良, 娄盛涵, 刘勃, 陈宇翔, 张里程, 唐佩福 2017 解放军医学院学报 38 430

Google Scholar

Google Scholar

Quan C L, Lou S H, Liu B, Chen Y X, Zhang L C, Tang P F 2017 J. PLA Med. Coll. 38 430

Google Scholar

Google Scholar

[7] Zhang Y, Roscow J, Xie M, Bowen C 2018 J. Eur. Ceram. Soc. 38 4203

Google Scholar

Google Scholar

[8] 蒋招绣, 辛铭之, 申海艇, 刘雨生 2015 64 134601

Google Scholar

Google Scholar

Jiang Z X, Xin M Z, Shen H T, Liu Y S 2015 Acta Phys. Sin. 64 134601

Google Scholar

Google Scholar

[9] 刘炜 2014 博士学位论文(山西: 中北大学)

Liu W 2014 Ph. D. Dissertation (Shanxi: North University) (in Chinese)

[10] Eichhorn F, Stenzel A, Weisenseel B, Travitzky N, Kakimoto K I 2017 Mater. Lett. 206 158

Google Scholar

Google Scholar

[11] Xu T, Wang C A 2016 Mater. Des. 91 242

Google Scholar

Google Scholar

[12] Roscow J I, Lewis R W C, Taylor J, Bowen C R 2017 Acta Mater. 128 207

Google Scholar

Google Scholar

[13] Liu B L, Chen L J, Shao C S, Zhang F Q, Zhou K C, Cao J, Zhang D 2016 Mater. Sci. Eng., C 61 8

Google Scholar

Google Scholar

[14] Li P, Pu Y, Dong Z, Gao P 2014 J. Electron. Mater. 43 459

Google Scholar

Google Scholar

[15] Kim J G, Ha J G, Lim T W, Park K 2006 Mater. Lett. 60 1505

Google Scholar

Google Scholar

[16] Tan J, Li Z R 2016 J. Mater. Sci. 51 5092

Google Scholar

Google Scholar

[17] 汤婷 2009 硕士学位论文(湖北: 华中科技大学)

Tang T 2009 M.S. Thesis (Hubei: Huazhong University of Science and Technology) (in Chinese)

[18] 曾涛, 董显林, 毛朝梁, 梁瑞虹, 杨洪 2006 55 3073

Google Scholar

Google Scholar

Zeng T, Dong X L, Mao C L, Liang R H, Yang H 2006 Acta Phys. Sin. 55 3073

Google Scholar

Google Scholar

[19] 聂恒昌, 王永龄, 贺红亮, 王根水, 董显林 2018 无机材料学报 33 153

Nie H C, Wang Y L, He H L, Wang G S, Dong X L 2018 J. Inorg. Mater. 33 153

[20] Xu T, Wang C A 2016 J. Eur. Ceram. Soc. 36 2647

Google Scholar

Google Scholar

[21] Okazaki K, Nagata K 1973 J. Am. Ceram. Soc. 56 82

Google Scholar

Google Scholar

-

-

[1] Deville S 2008 Adv. Eng. Mater. 10 155

Google Scholar

Google Scholar

[2] 朱小龙, 苏雪筠 2000 中国陶瓷 36 36

Google Scholar

Google Scholar

Zhu X L, Su X Y 2000 Chin. Ceram. 36 36

Google Scholar

Google Scholar

[3] Guo R, Wang C A, Yang A K 2011 J. Eur. Ceram. Soc. 31 605

Google Scholar

Google Scholar

[4] Ryosuke B, Tomoaki K, Tadashi F 2016 J. Chin. Ceram. Soc. 3 9

Google Scholar

Google Scholar

[5] Zhu S, Cao L, Xiong Z, Lu C, Gao Z 2018 J. Eur. Ceram. Soc. 38 2251

Google Scholar

Google Scholar

[6] 全宸良, 娄盛涵, 刘勃, 陈宇翔, 张里程, 唐佩福 2017 解放军医学院学报 38 430

Google Scholar

Google Scholar

Quan C L, Lou S H, Liu B, Chen Y X, Zhang L C, Tang P F 2017 J. PLA Med. Coll. 38 430

Google Scholar

Google Scholar

[7] Zhang Y, Roscow J, Xie M, Bowen C 2018 J. Eur. Ceram. Soc. 38 4203

Google Scholar

Google Scholar

[8] 蒋招绣, 辛铭之, 申海艇, 刘雨生 2015 64 134601

Google Scholar

Google Scholar

Jiang Z X, Xin M Z, Shen H T, Liu Y S 2015 Acta Phys. Sin. 64 134601

Google Scholar

Google Scholar

[9] 刘炜 2014 博士学位论文(山西: 中北大学)

Liu W 2014 Ph. D. Dissertation (Shanxi: North University) (in Chinese)

[10] Eichhorn F, Stenzel A, Weisenseel B, Travitzky N, Kakimoto K I 2017 Mater. Lett. 206 158

Google Scholar

Google Scholar

[11] Xu T, Wang C A 2016 Mater. Des. 91 242

Google Scholar

Google Scholar

[12] Roscow J I, Lewis R W C, Taylor J, Bowen C R 2017 Acta Mater. 128 207

Google Scholar

Google Scholar

[13] Liu B L, Chen L J, Shao C S, Zhang F Q, Zhou K C, Cao J, Zhang D 2016 Mater. Sci. Eng., C 61 8

Google Scholar

Google Scholar

[14] Li P, Pu Y, Dong Z, Gao P 2014 J. Electron. Mater. 43 459

Google Scholar

Google Scholar

[15] Kim J G, Ha J G, Lim T W, Park K 2006 Mater. Lett. 60 1505

Google Scholar

Google Scholar

[16] Tan J, Li Z R 2016 J. Mater. Sci. 51 5092

Google Scholar

Google Scholar

[17] 汤婷 2009 硕士学位论文(湖北: 华中科技大学)

Tang T 2009 M.S. Thesis (Hubei: Huazhong University of Science and Technology) (in Chinese)

[18] 曾涛, 董显林, 毛朝梁, 梁瑞虹, 杨洪 2006 55 3073

Google Scholar

Google Scholar

Zeng T, Dong X L, Mao C L, Liang R H, Yang H 2006 Acta Phys. Sin. 55 3073

Google Scholar

Google Scholar

[19] 聂恒昌, 王永龄, 贺红亮, 王根水, 董显林 2018 无机材料学报 33 153

Nie H C, Wang Y L, He H L, Wang G S, Dong X L 2018 J. Inorg. Mater. 33 153

[20] Xu T, Wang C A 2016 J. Eur. Ceram. Soc. 36 2647

Google Scholar

Google Scholar

[21] Okazaki K, Nagata K 1973 J. Am. Ceram. Soc. 56 82

Google Scholar

Google Scholar

计量

- 文章访问数: 13964

- PDF下载量: 215

- 被引次数: 0

下载:

下载: