-

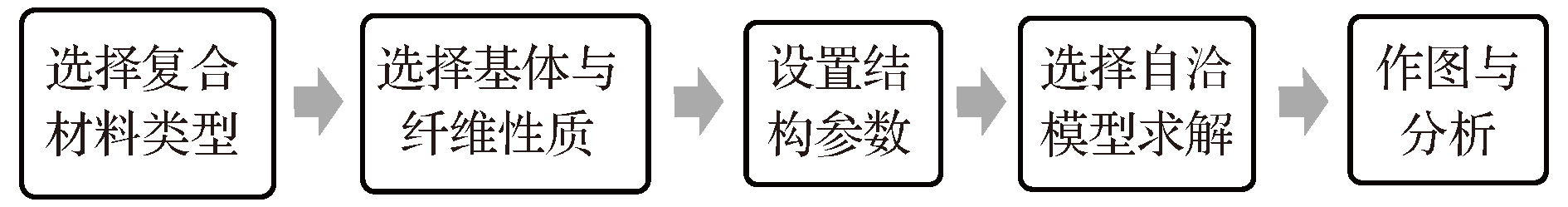

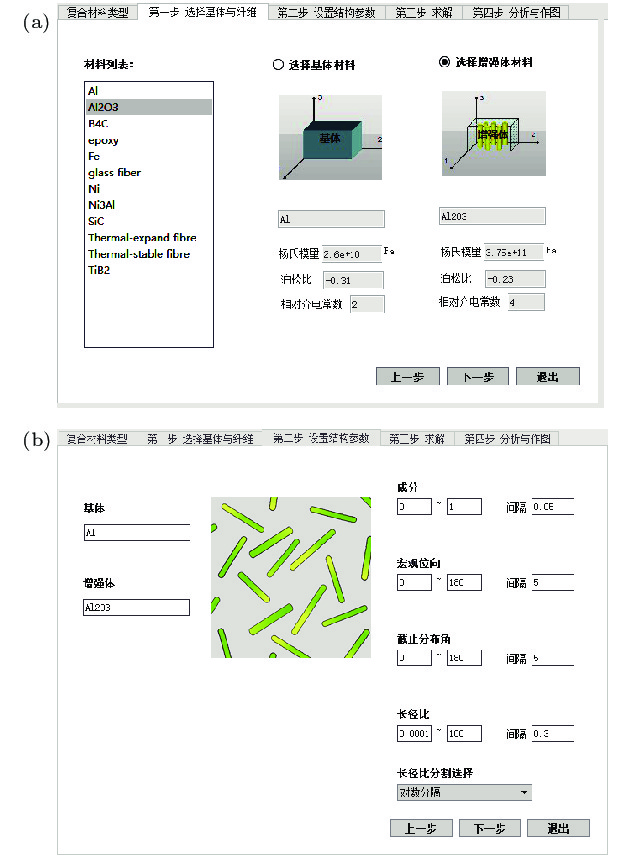

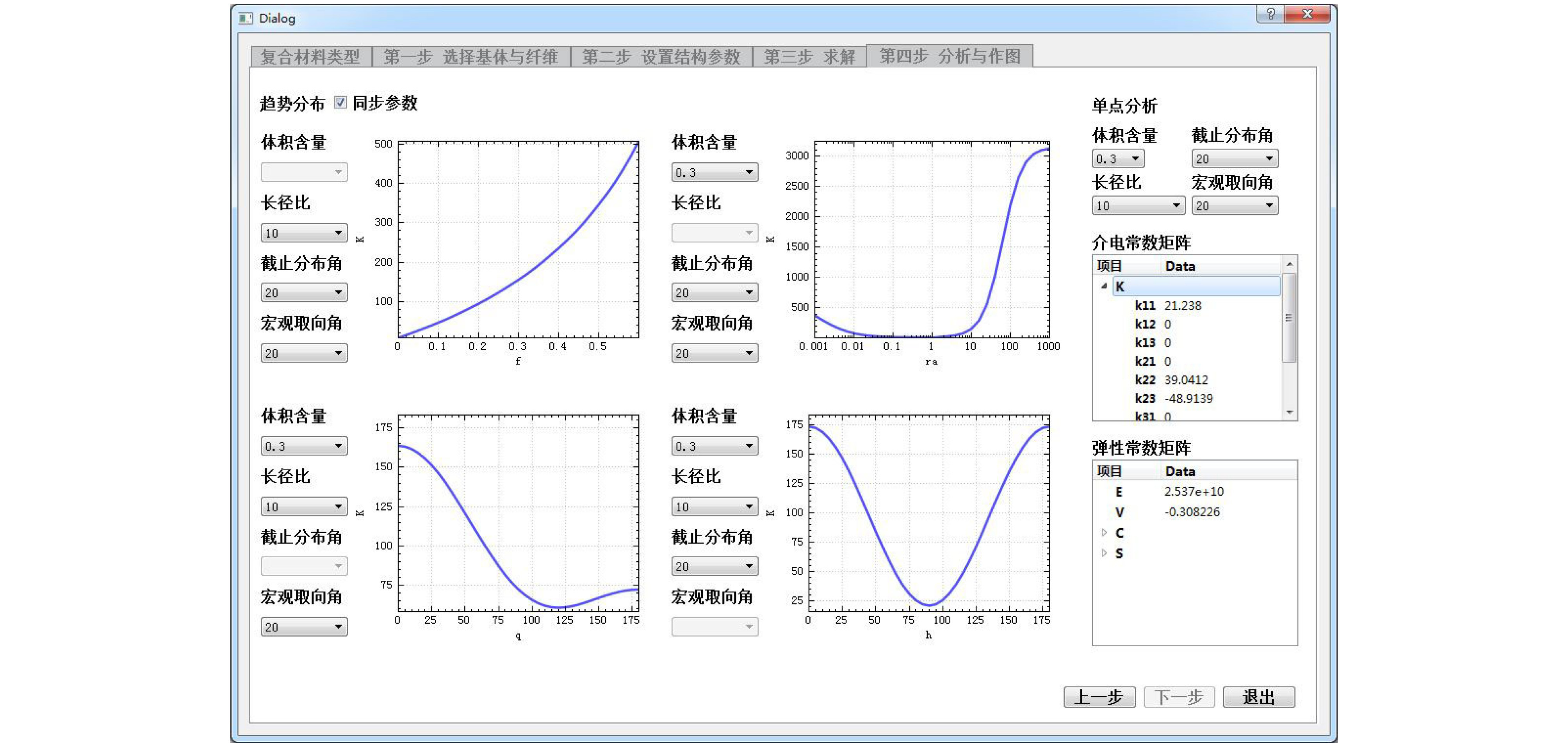

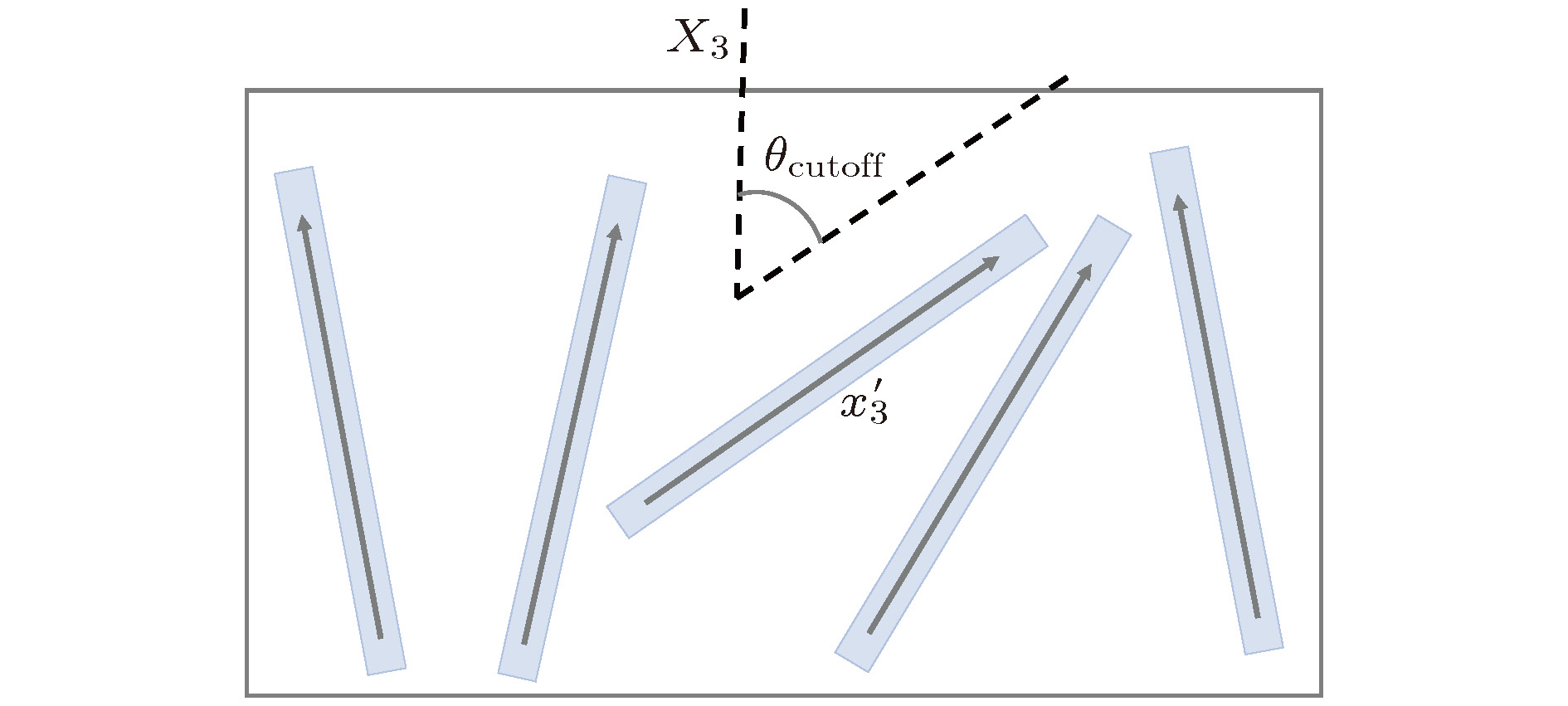

In this paper, a composite physical property calculation software—Composite Studio is developed based on the modified effective medium theory. The computing kernel of the software is written in C++ language and its GUI is designed by Qt. With the development of the computation technique, the material genome project is proposed, which tries to shorten the period of the material design by high-throughput computation, data mining and property database establishment. On a mesoscopic scale, there are several kinds of the models to calculate the physical properties of the composite materials. However, these models usually have the formula in quite a lot of kinds of forms. A general commercial software for physical property calculation on a mesoscopic scale is still leaking. The software uses Green’s function to solve the constitutive equations. It calculates the effects of microstructural factors on physical properties. These factors include volume fraction, aspect ratio of reinforce particles, orientation distribution, and macroscopic orientation. It can obtain more than 10000 composites by freely combining four microstructure factors. The operation process of software includes 5 steps. The first step is to choose the materials of matrix and reinforcement. The second step is to select the shape type of reinforcement. The third step is to set the range of values for the microstructure factors of the composite materials. The fourth step is to choose the calculation model and start calculations. The last step is to plot and analyze the results. In addition, researchers can directly have the calculation results through the single point analysis module of the software. We use several two-dimensional line plots to display multi-dimensional calculation results. This is convenient and efficient for researchers to observe and analyze the results. Until now, two calculation modules were developed in Composite Studio, i.e. the elastic modulus calculation module and the dielectric constant calculation module. The software can be applied to different computer systems. In the future, the Composite Studio can be used as a general-purpose calculation tool embedded into an server platform for popular composite design.

-

Keywords:

- effective medium theory /

- physical properties /

- microstructure /

- software design

[1] Nan C W 1993 Prog. Mater. Sci. 37 1

Google Scholar

Google Scholar

[2] 南策文 2005 非均质材料物理: 显微结构-性能关联 (北京: 科学出版社) 第1−72页

Nan C W 2005 Heterogeneous Material Physics: Microstructure-performance Correlation (Beijing: Science Press) pp1−72 (in Chinese)

[3] O'Callaghan C, da Rocha C G D, Manning H G, Boland J J, Ferreira M S 2016 Phys. Chem. Chem. Phys. 18 27564

Google Scholar

Google Scholar

[4] Rabari R, Mahmud S, Dutta A 2015 Int. J. Heat Mass Transfer 91 190

Google Scholar

Google Scholar

[5] Monsalve-Bravo G M, Bhatia S K 2017 J. Membr. Sci. 531 148

Google Scholar

Google Scholar

[6] 刘晓辉, 陈默涵, 李鹏飞, 沈瑜, 任新国, 郭光灿, 何力新 2015 64 187104

Google Scholar

Google Scholar

Liu X H, Chen M H, Li P F, Shen Y, Ren X G, Guo G C, He L X 2015 Acta Phys. Sin. 64 187104

Google Scholar

Google Scholar

[7] 李刚, 邓力, 张宝印, 李瑞, 史敦福, 上官丹骅, 胡泽华, 付元光, 马彦 2016 65 052801

Google Scholar

Google Scholar

Li G, Deng L, Zhang B Y, Li R, Shi D F, Shangguan D H, Hu Z H, Fu Y G, Ma Y 2016 Acta Phys. Sin. 65 052801

Google Scholar

Google Scholar

[8] 施展, 南策文 2004 53 2766

Google Scholar

Google Scholar

Shi Z, Nan C W 2004 Acta Phys. Sin. 53 2766

Google Scholar

Google Scholar

[9] 忻隽, 郑燕青, 施尔畏 2007 无机材料学报 22 193

Google Scholar

Google Scholar

Xin J, Zheng Y Q, Shi E W 2007 J. Inorg. Mater. 22 193

Google Scholar

Google Scholar

[10] 王彦成, 邱吴劼, 杨宏亮, 席丽丽, 杨炯, 张文清 2018 67 016301

Google Scholar

Google Scholar

Wang Y C, Qiu W J, Yang H L, Xi L L, Yang J, Zhang W Q 2018 Acta Phys. Sin. 67 016301

Google Scholar

Google Scholar

[11] Bensoussan A, Lions J L, Papanicolaou G 1978 Asymptotic Analysis for Periodic Structures (Amsterdam: North-Holland) p392

[12] Nemat-Nasser S, Lori M, Datta S K 1996 J. Appl. Mech. 63 561

Google Scholar

Google Scholar

[13] 张研, 张子明 2008 材料细观力学(北京: 科学出版社) 第20−81页

Zhang Y, Zhang Z M 2008 Mesomechanics of Materials (Beijing: Science Press) pp20−81 (in Chinese)

[14] Eshelby J D 1957 Proc. R. Soc. London, Ser. A 241 376

Google Scholar

Google Scholar

[15] Choy T C 2015 Effective Medium Theory: Principles and Applications (Oxford: Oxford University Press) pp1−26

[16] Bergman D J, Stroud D 1992 Solid State Phys. 46 147

Google Scholar

Google Scholar

[17] Gubernatis J E, Krumhansl J A 1975 J. Appl. Phys. 46 1875

Google Scholar

Google Scholar

[18] Nan C W, Jin F S 1993 Phys. Rev. B: Condens. Matter 48 8578

Google Scholar

Google Scholar

[19] Liu Z Y, Chan C T, Sheng P 2005 Phys. Rev. B 71 014103

Google Scholar

Google Scholar

[20] Mei J, Liu Z Y, Wen W,Sheng P 2006 Phys. Rev. Lett. 96 024301

Google Scholar

Google Scholar

[21] Mei J, Liu Z Y, Wen W, Sheng P 2007 Phys. Rev. B 76 134205

Google Scholar

Google Scholar

[22] Mei J, Wu Y, Liu Z Y 2012 Europhys. Lett. 98 54001

Google Scholar

Google Scholar

[23] Fang X Q, Tian J Y 2018 Int. J. Eng. Sci. 130 1

Google Scholar

Google Scholar

[24] Marur P R 2004 Mater. Lett. 58 3971

Google Scholar

Google Scholar

[25] Petrovsky V, Jasinski P, Dogan F 2012 J. Electroceram. 28 185

Google Scholar

Google Scholar

[26] Chýlek, Petr, Srivastava V 1984 Phys. Rev. B: Condens. Matter. 30 1008

Google Scholar

Google Scholar

[27] Lakhtakia A, Weiglhofer W S 1993 Acta Crystallogr. Sect. A: Found. Crystallogr. A49 266

[28] Merrill W M, Diaz R E, Lore M M, Squires M C, Alexopoulos N G 1999 IEEE T. Antenn. Propag. 47 142

Google Scholar

Google Scholar

-

-

[1] Nan C W 1993 Prog. Mater. Sci. 37 1

Google Scholar

Google Scholar

[2] 南策文 2005 非均质材料物理: 显微结构-性能关联 (北京: 科学出版社) 第1−72页

Nan C W 2005 Heterogeneous Material Physics: Microstructure-performance Correlation (Beijing: Science Press) pp1−72 (in Chinese)

[3] O'Callaghan C, da Rocha C G D, Manning H G, Boland J J, Ferreira M S 2016 Phys. Chem. Chem. Phys. 18 27564

Google Scholar

Google Scholar

[4] Rabari R, Mahmud S, Dutta A 2015 Int. J. Heat Mass Transfer 91 190

Google Scholar

Google Scholar

[5] Monsalve-Bravo G M, Bhatia S K 2017 J. Membr. Sci. 531 148

Google Scholar

Google Scholar

[6] 刘晓辉, 陈默涵, 李鹏飞, 沈瑜, 任新国, 郭光灿, 何力新 2015 64 187104

Google Scholar

Google Scholar

Liu X H, Chen M H, Li P F, Shen Y, Ren X G, Guo G C, He L X 2015 Acta Phys. Sin. 64 187104

Google Scholar

Google Scholar

[7] 李刚, 邓力, 张宝印, 李瑞, 史敦福, 上官丹骅, 胡泽华, 付元光, 马彦 2016 65 052801

Google Scholar

Google Scholar

Li G, Deng L, Zhang B Y, Li R, Shi D F, Shangguan D H, Hu Z H, Fu Y G, Ma Y 2016 Acta Phys. Sin. 65 052801

Google Scholar

Google Scholar

[8] 施展, 南策文 2004 53 2766

Google Scholar

Google Scholar

Shi Z, Nan C W 2004 Acta Phys. Sin. 53 2766

Google Scholar

Google Scholar

[9] 忻隽, 郑燕青, 施尔畏 2007 无机材料学报 22 193

Google Scholar

Google Scholar

Xin J, Zheng Y Q, Shi E W 2007 J. Inorg. Mater. 22 193

Google Scholar

Google Scholar

[10] 王彦成, 邱吴劼, 杨宏亮, 席丽丽, 杨炯, 张文清 2018 67 016301

Google Scholar

Google Scholar

Wang Y C, Qiu W J, Yang H L, Xi L L, Yang J, Zhang W Q 2018 Acta Phys. Sin. 67 016301

Google Scholar

Google Scholar

[11] Bensoussan A, Lions J L, Papanicolaou G 1978 Asymptotic Analysis for Periodic Structures (Amsterdam: North-Holland) p392

[12] Nemat-Nasser S, Lori M, Datta S K 1996 J. Appl. Mech. 63 561

Google Scholar

Google Scholar

[13] 张研, 张子明 2008 材料细观力学(北京: 科学出版社) 第20−81页

Zhang Y, Zhang Z M 2008 Mesomechanics of Materials (Beijing: Science Press) pp20−81 (in Chinese)

[14] Eshelby J D 1957 Proc. R. Soc. London, Ser. A 241 376

Google Scholar

Google Scholar

[15] Choy T C 2015 Effective Medium Theory: Principles and Applications (Oxford: Oxford University Press) pp1−26

[16] Bergman D J, Stroud D 1992 Solid State Phys. 46 147

Google Scholar

Google Scholar

[17] Gubernatis J E, Krumhansl J A 1975 J. Appl. Phys. 46 1875

Google Scholar

Google Scholar

[18] Nan C W, Jin F S 1993 Phys. Rev. B: Condens. Matter 48 8578

Google Scholar

Google Scholar

[19] Liu Z Y, Chan C T, Sheng P 2005 Phys. Rev. B 71 014103

Google Scholar

Google Scholar

[20] Mei J, Liu Z Y, Wen W,Sheng P 2006 Phys. Rev. Lett. 96 024301

Google Scholar

Google Scholar

[21] Mei J, Liu Z Y, Wen W, Sheng P 2007 Phys. Rev. B 76 134205

Google Scholar

Google Scholar

[22] Mei J, Wu Y, Liu Z Y 2012 Europhys. Lett. 98 54001

Google Scholar

Google Scholar

[23] Fang X Q, Tian J Y 2018 Int. J. Eng. Sci. 130 1

Google Scholar

Google Scholar

[24] Marur P R 2004 Mater. Lett. 58 3971

Google Scholar

Google Scholar

[25] Petrovsky V, Jasinski P, Dogan F 2012 J. Electroceram. 28 185

Google Scholar

Google Scholar

[26] Chýlek, Petr, Srivastava V 1984 Phys. Rev. B: Condens. Matter. 30 1008

Google Scholar

Google Scholar

[27] Lakhtakia A, Weiglhofer W S 1993 Acta Crystallogr. Sect. A: Found. Crystallogr. A49 266

[28] Merrill W M, Diaz R E, Lore M M, Squires M C, Alexopoulos N G 1999 IEEE T. Antenn. Propag. 47 142

Google Scholar

Google Scholar

计量

- 文章访问数: 14736

- PDF下载量: 215

- 被引次数: 0

下载:

下载: