-

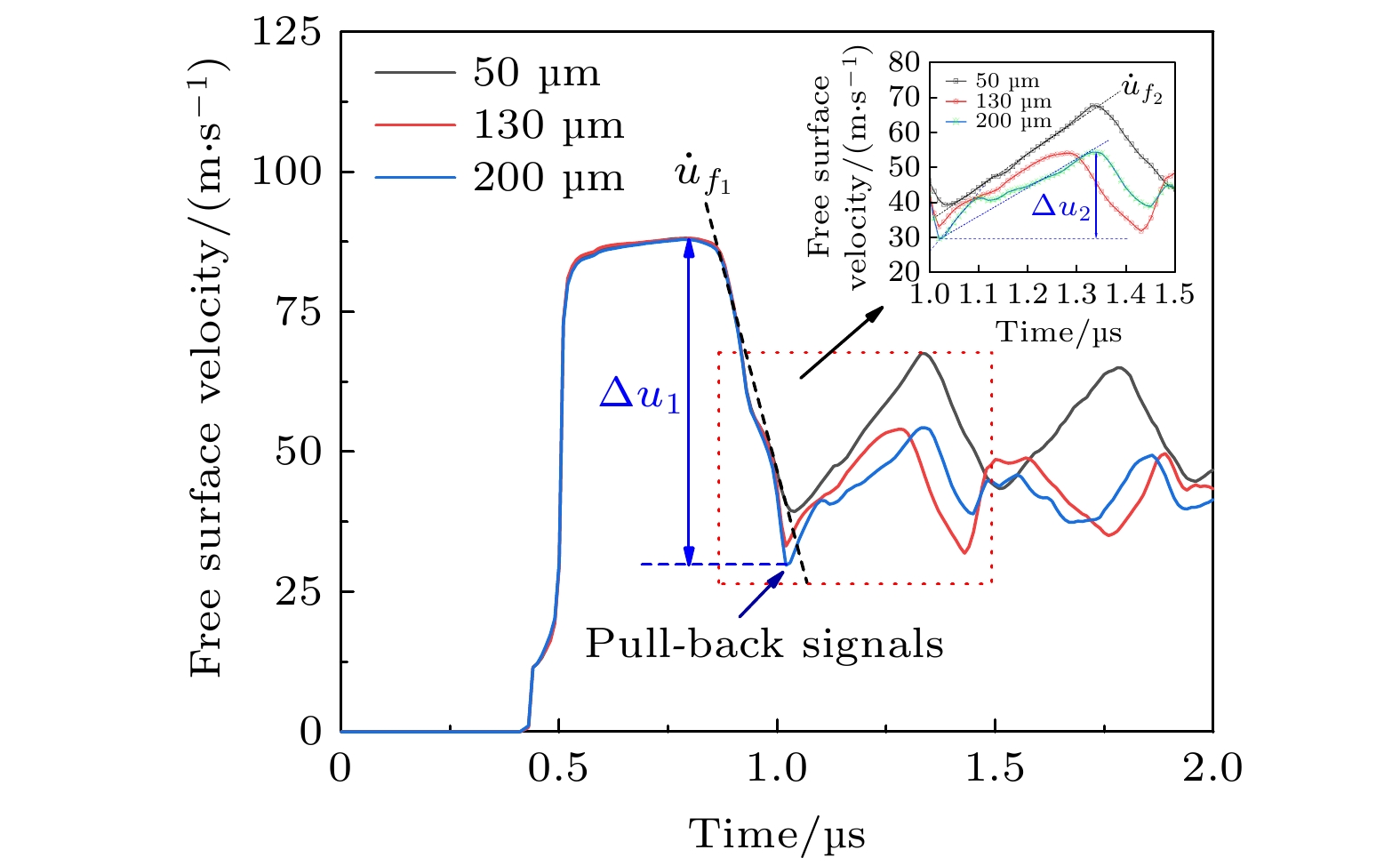

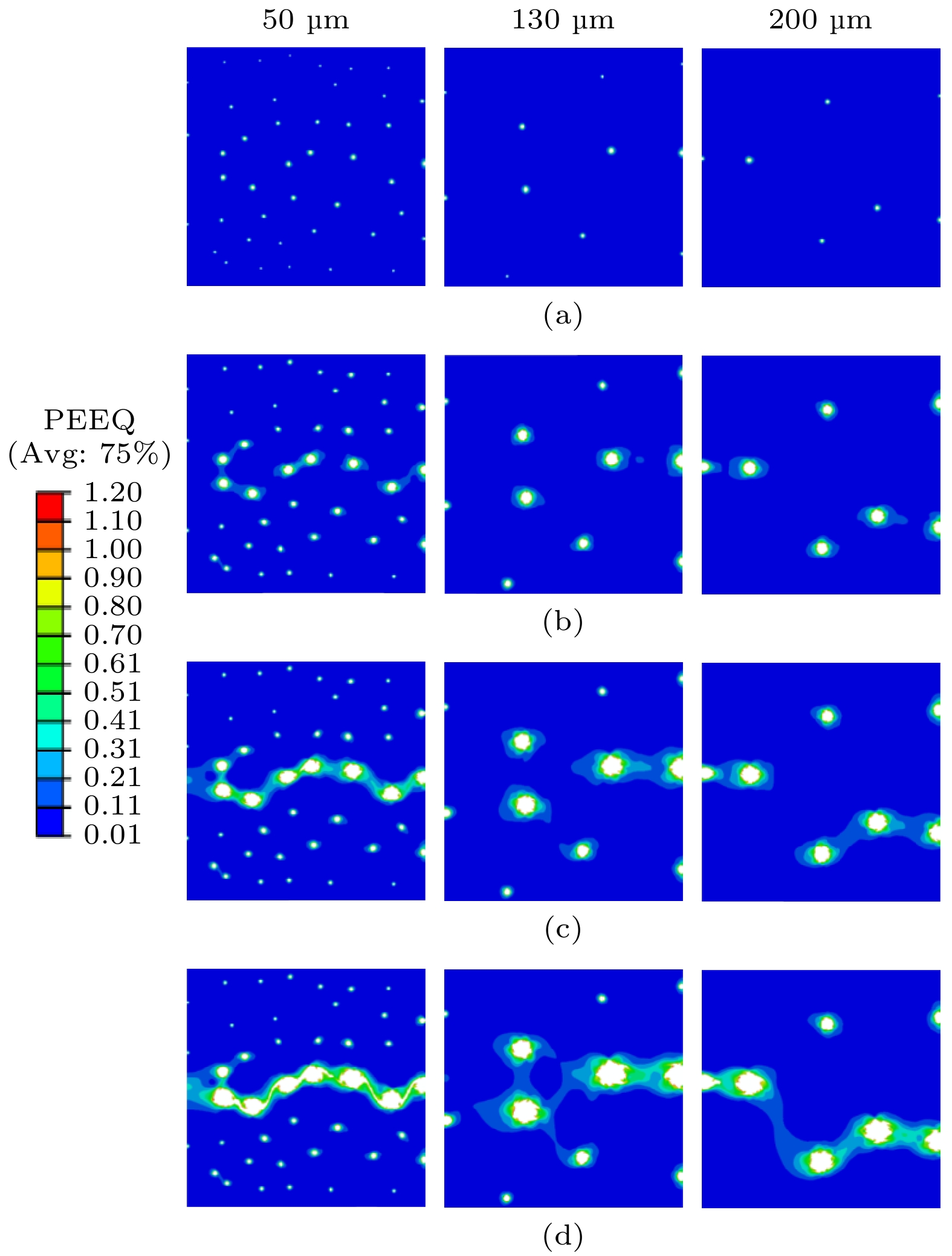

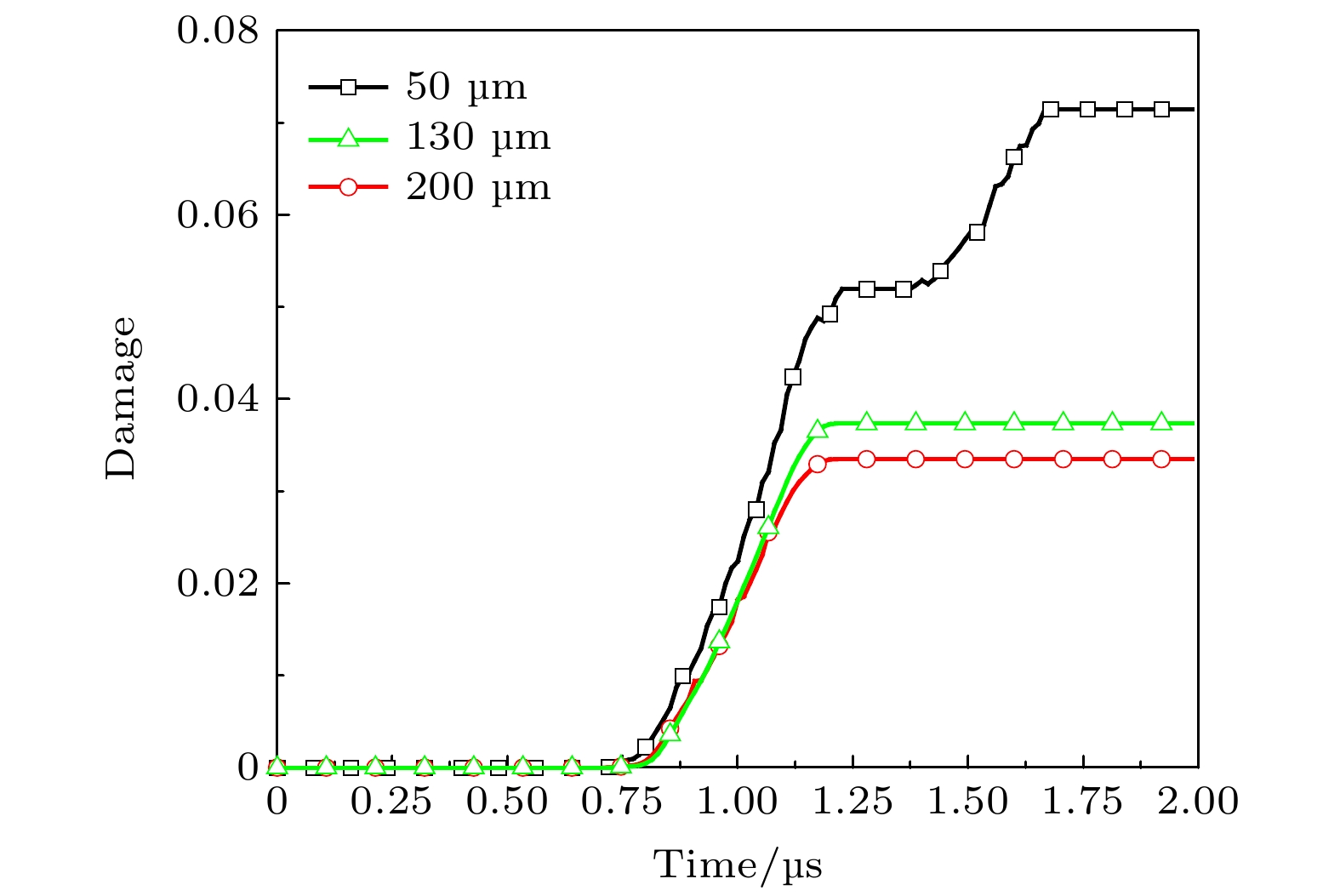

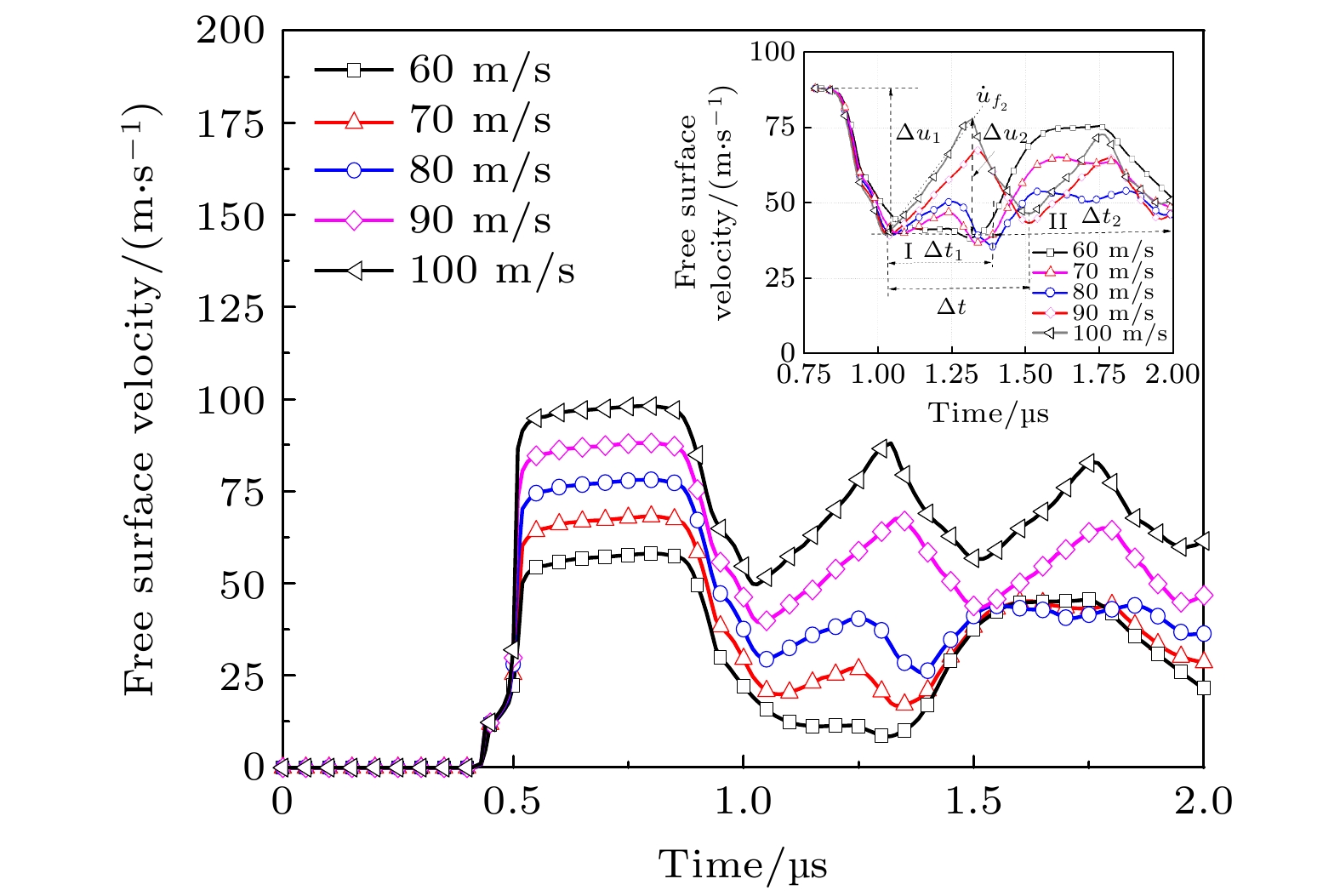

采用Voronoi方法构建了50, 130和200 µm三种晶粒度的高纯铜靶板, 在晶界处随机预制损伤成核点, 建立了平板撞击高纯铜靶板的二维轴对称计算模型, 研究了晶粒度和加载应力对高纯铜层裂宏观力学响应和细观损伤演化的影响. 基于自由面速度剖面特征分析, 揭示了晶粒度和加载应力幅值对Pull-back速度回跳点位置、速度回跳斜率及回跳幅值的影响规律, 论证了层裂强度与损伤区拉伸应力峰值相对应 本质上表征微损伤早期长大临界应力; 基于损伤演化云图特征分析, 讨论了长大和聚集过程中微孔洞周围局域化塑性应变场的演变, 揭示了晶粒度和加载应力对微孔洞聚集和应力松弛行为的影响. 计算结果再现了层裂实验中材料内部的微孔洞长大、聚集的细观物理过程, 进一步揭示其与宏观力学响应之间的内禀关系, 这对认识层裂损伤演化机制和理论模型构建具有重要的意义.High-purity (HP) copper targets with grain sizes of 50, 130 and 200 μm are constructed by using the Voronoi method. Damage nucleation points are randomly prefabricated at the grain boundaries. A two-dimensional axisymmetric finite element model is established to simulate the spallation experiment of HP copper target. The effects of grain size and loading stress on the macro- mechanical response and meso-damage evolution of HP copper spallation are studied and compared with the relevant experimental results. Based on the analysis of free surface velocity profiles, the effects of grain size on the location of pull back velocity rebound point, velocity rebound slope and velocity rebound amplitude are revealed. It is demonstrated that the spalling strength corresponds to the peak value of tensile stress in the damage zone, which essentially represents the critical stress of micro damage nucleation or early growth. Based on the characteristic analysis of damage evolution nephogram, the evolution process of localized plastic strain field around the micro-voids in the growth and coalescence process is reproduced, and the strong dependence of micro-void coalescence behavior on grain size is clarified. The loading stress amplitude has little effect on the location of pull back velocity rebound point, but has a significant effect on the growth and coalescence behavior of micro-voids. The slope and amplitude of pull back velocity rebound increase with loading stress increasing, which is consistent with the relevant experimental result. With the increase of the loading stress, the micro-voids grow from independent growth to coalescence, thus forming spalling surface. The physical process of damage evolution determines the wave oscillation characteristics after the pull-back rebound point. The numerical simulation results reproduce the physical process of damage evolution and its influence on the macroscopic mechanical response, which is of great significance for further understanding spall damage evolution mechanism and theoretical model construction.

-

Keywords:

- spall fracture /

- grain size /

- numerical simulation /

- damage evolution

[1] Antoun T H, Seaman L, Curran D R, Kanel G I, Razorenov S V, Utkin A V 2003 Spall Fracture (New York: Springer-Verlag)

[2] Koller D D, Hixson R S 2005 J. Appl. Phys. 98 103518

Google Scholar

Google Scholar

[3] 彭辉, 李平, 裴晓阳, 贺红亮, 程和平, 祁美兰 2014 63 196202

Google Scholar

Google Scholar

Peng H, Li P, Pei X Y, He H L, Cheng H P, Qi M L 2014 Acta Phys. Sin. 63 196202

Google Scholar

Google Scholar

[4] Johnson J N, Gray G T, Bourne N K 1999 J. Appl. Phys. 86 4892

Google Scholar

Google Scholar

[5] Kanel G, Razorenov S, Bogatch A, Utkin A, Grady D 1997 Int. J. Impact. Eng. 20 467

Google Scholar

Google Scholar

[6] Escobedo J P, Dennis-Koller D, Ceretta E K, Patterson B M, Bronkhorst C A, Hanson BL, Tonks D, Lebensohn R A 2011 J. Appl. Phys. 110 033513

Google Scholar

Google Scholar

[7] Wang Y G, Qi M L, He H L, Wang L L 2014 Mech. Mater. 69 270

Google Scholar

Google Scholar

[8] 裴晓阳, 彭辉, 贺红亮, 李平 2015 64 054601

Google Scholar

Google Scholar

Pei X Y, Peng H, He H L, Li P 2015 Acta Phys. Sin. 64 054601

Google Scholar

Google Scholar

[9] Lieberman E J, Lebensohn R A, Menasche D B, Bronkhorst C A, Rollett A D 2016 Acta Mater. 116 270

Google Scholar

Google Scholar

[10] Turley W D, Fensin S J, Hixson R S, Jones R D, La Lone M B, Stevens G D, Thomas S A, Veeser L R 2018 J. Appl. Phys. 123 055102

Google Scholar

Google Scholar

[11] Johnson J N 1981 J. Appl. Phys. 52 2812

Google Scholar

Google Scholar

[12] Moninari A, Wright TW 2005 J. Mech. Phys. Solids 53 1476

Google Scholar

Google Scholar

[13] Lubarda V A, Schneider M S, Kalantar D H, Remington B R, Meyers M A 2004 Acta Mater. 52 1397

Google Scholar

Google Scholar

[14] Jacques N, Czarnota C, Mercier S, Molinari A 2015 Int. J. Fract. 162 159

[15] Wilkerson J W, Ramesh K T 2016 J. Mech. Phys. Solids 86 94

Google Scholar

Google Scholar

[16] Wilkerson J W 2017 Int J. Plast. 95 21

Google Scholar

Google Scholar

[17] Zurek A K, Thissell W R, Johnson J N, Tonks D L, Hixson R 1996 J. Mater. Process. Technol. 60 261

Google Scholar

Google Scholar

[18] Wang Y G, He H L, Wang L L 2013 Mech. Mater. 56 131

Google Scholar

Google Scholar

[19] Seppälä ET, Belak J, Rudd R E 2004 Phys. Rev. B 69 134101

Google Scholar

Google Scholar

[20] Lou S N, Germann T C, Tonks D L 2009 J. Appl. Phys. 106 123518

Google Scholar

Google Scholar

[21] 邓小良, 祝文军, 宋振飞, 贺红亮, 经福谦 2009 58 4772

Google Scholar

Google Scholar

Deng X L, Zhu W J, Song Z F, He H L, Jing F Q 2009 Acta Phys. Sin. 58 4772

Google Scholar

Google Scholar

[22] Becker R, LeBlanc M M, Cazamias J U 2007 J. Appl. Phys. 102 093512

Google Scholar

Google Scholar

[23] Becker R 2017 Int. J. Fract. 208 5

Google Scholar

Google Scholar

[24] Becker R, Callaghan K 2018 Int. J. Fract. 209 235

Google Scholar

Google Scholar

[25] Trivedi P B, Asay J R, Gupta Y M, Field D P 2007 J. Appl. Phys. 102 083513

Google Scholar

Google Scholar

[26] Schwartz A J, Cazamias J U, Fiske P S, Minich R W 2002 AIP Conf. Proc. 620 491

Google Scholar

Google Scholar

[27] Chen T, Jiang Z X, Peng H, He H L, Wang L L, Wang Y G 2015 Strain 51 190

Google Scholar

Google Scholar

[28] 张凤国, 周洪强 2013 62 164601

Google Scholar

Google Scholar

Zhang F G, Zhou H Q 2013 Acta Phys. Sin. 62 164601

Google Scholar

Google Scholar

[29] Johnson G R, Cook W H 1983 Eng. Fract. Mech. 21 541

[30] Novikov S A 1967 J. Appl. Meth. Tech. Phys. 3 109

[31] Chen D N, Yu Y Y, Yin Z H, Wang H R, Liu G Q 2005 Int. J. Impact Eng. 31 811

Google Scholar

Google Scholar

[32] Kanel G I 2010 Int. J. Fract. 163 173

Google Scholar

Google Scholar

[33] Seppälä ET, Belak J, Rudd R E 2004 Phys. Rev. Lett. 93 245503

Google Scholar

Google Scholar

[34] 王永刚, 胡剑东, 祁美兰, 贺红亮 2011 60 126201

Google Scholar

Google Scholar

Wang Y G, Hu J D, Qi M L, He H L 2011 Acta Phys. Sin. 60 126201

Google Scholar

Google Scholar

-

ρ/(kg·m–3) A/MPa B/MPa C m n $ {\dot{\varepsilon }}_{0} $ Troom Tmelt 8910 90 292 0.025 1.09 0.31 1 300 1356 $ {c}_{0} $/(m·s–1) s $ {\varGamma }_{0} $ $ G/\mathrm{G}\mathrm{P}\mathrm{a} $ d1 d2 d3 d4 d5 3910 1.51 2 47 1.08 4.89 3.03 0.014 1.12 -

[1] Antoun T H, Seaman L, Curran D R, Kanel G I, Razorenov S V, Utkin A V 2003 Spall Fracture (New York: Springer-Verlag)

[2] Koller D D, Hixson R S 2005 J. Appl. Phys. 98 103518

Google Scholar

Google Scholar

[3] 彭辉, 李平, 裴晓阳, 贺红亮, 程和平, 祁美兰 2014 63 196202

Google Scholar

Google Scholar

Peng H, Li P, Pei X Y, He H L, Cheng H P, Qi M L 2014 Acta Phys. Sin. 63 196202

Google Scholar

Google Scholar

[4] Johnson J N, Gray G T, Bourne N K 1999 J. Appl. Phys. 86 4892

Google Scholar

Google Scholar

[5] Kanel G, Razorenov S, Bogatch A, Utkin A, Grady D 1997 Int. J. Impact. Eng. 20 467

Google Scholar

Google Scholar

[6] Escobedo J P, Dennis-Koller D, Ceretta E K, Patterson B M, Bronkhorst C A, Hanson BL, Tonks D, Lebensohn R A 2011 J. Appl. Phys. 110 033513

Google Scholar

Google Scholar

[7] Wang Y G, Qi M L, He H L, Wang L L 2014 Mech. Mater. 69 270

Google Scholar

Google Scholar

[8] 裴晓阳, 彭辉, 贺红亮, 李平 2015 64 054601

Google Scholar

Google Scholar

Pei X Y, Peng H, He H L, Li P 2015 Acta Phys. Sin. 64 054601

Google Scholar

Google Scholar

[9] Lieberman E J, Lebensohn R A, Menasche D B, Bronkhorst C A, Rollett A D 2016 Acta Mater. 116 270

Google Scholar

Google Scholar

[10] Turley W D, Fensin S J, Hixson R S, Jones R D, La Lone M B, Stevens G D, Thomas S A, Veeser L R 2018 J. Appl. Phys. 123 055102

Google Scholar

Google Scholar

[11] Johnson J N 1981 J. Appl. Phys. 52 2812

Google Scholar

Google Scholar

[12] Moninari A, Wright TW 2005 J. Mech. Phys. Solids 53 1476

Google Scholar

Google Scholar

[13] Lubarda V A, Schneider M S, Kalantar D H, Remington B R, Meyers M A 2004 Acta Mater. 52 1397

Google Scholar

Google Scholar

[14] Jacques N, Czarnota C, Mercier S, Molinari A 2015 Int. J. Fract. 162 159

[15] Wilkerson J W, Ramesh K T 2016 J. Mech. Phys. Solids 86 94

Google Scholar

Google Scholar

[16] Wilkerson J W 2017 Int J. Plast. 95 21

Google Scholar

Google Scholar

[17] Zurek A K, Thissell W R, Johnson J N, Tonks D L, Hixson R 1996 J. Mater. Process. Technol. 60 261

Google Scholar

Google Scholar

[18] Wang Y G, He H L, Wang L L 2013 Mech. Mater. 56 131

Google Scholar

Google Scholar

[19] Seppälä ET, Belak J, Rudd R E 2004 Phys. Rev. B 69 134101

Google Scholar

Google Scholar

[20] Lou S N, Germann T C, Tonks D L 2009 J. Appl. Phys. 106 123518

Google Scholar

Google Scholar

[21] 邓小良, 祝文军, 宋振飞, 贺红亮, 经福谦 2009 58 4772

Google Scholar

Google Scholar

Deng X L, Zhu W J, Song Z F, He H L, Jing F Q 2009 Acta Phys. Sin. 58 4772

Google Scholar

Google Scholar

[22] Becker R, LeBlanc M M, Cazamias J U 2007 J. Appl. Phys. 102 093512

Google Scholar

Google Scholar

[23] Becker R 2017 Int. J. Fract. 208 5

Google Scholar

Google Scholar

[24] Becker R, Callaghan K 2018 Int. J. Fract. 209 235

Google Scholar

Google Scholar

[25] Trivedi P B, Asay J R, Gupta Y M, Field D P 2007 J. Appl. Phys. 102 083513

Google Scholar

Google Scholar

[26] Schwartz A J, Cazamias J U, Fiske P S, Minich R W 2002 AIP Conf. Proc. 620 491

Google Scholar

Google Scholar

[27] Chen T, Jiang Z X, Peng H, He H L, Wang L L, Wang Y G 2015 Strain 51 190

Google Scholar

Google Scholar

[28] 张凤国, 周洪强 2013 62 164601

Google Scholar

Google Scholar

Zhang F G, Zhou H Q 2013 Acta Phys. Sin. 62 164601

Google Scholar

Google Scholar

[29] Johnson G R, Cook W H 1983 Eng. Fract. Mech. 21 541

[30] Novikov S A 1967 J. Appl. Meth. Tech. Phys. 3 109

[31] Chen D N, Yu Y Y, Yin Z H, Wang H R, Liu G Q 2005 Int. J. Impact Eng. 31 811

Google Scholar

Google Scholar

[32] Kanel G I 2010 Int. J. Fract. 163 173

Google Scholar

Google Scholar

[33] Seppälä ET, Belak J, Rudd R E 2004 Phys. Rev. Lett. 93 245503

Google Scholar

Google Scholar

[34] 王永刚, 胡剑东, 祁美兰, 贺红亮 2011 60 126201

Google Scholar

Google Scholar

Wang Y G, Hu J D, Qi M L, He H L 2011 Acta Phys. Sin. 60 126201

Google Scholar

Google Scholar

计量

- 文章访问数: 6735

- PDF下载量: 90

- 被引次数: 0

下载:

下载: