-

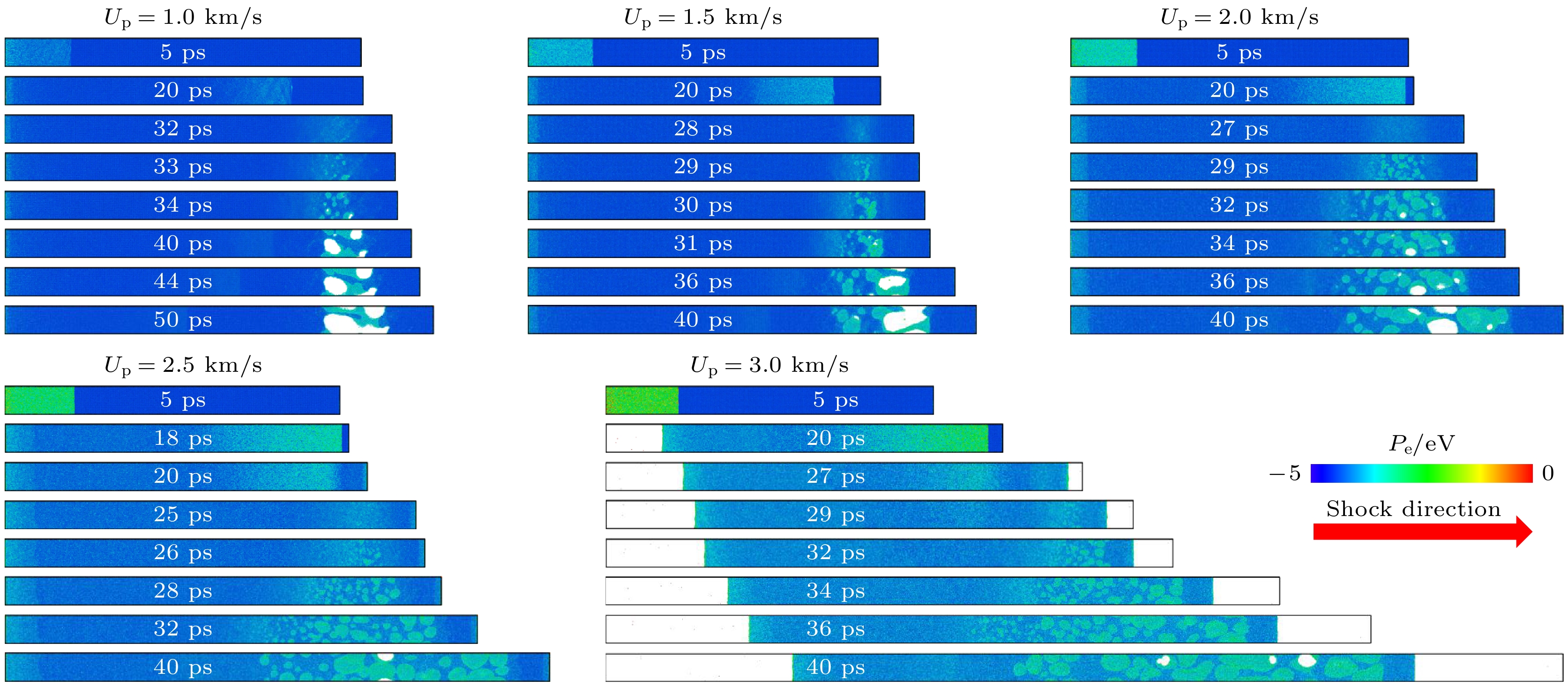

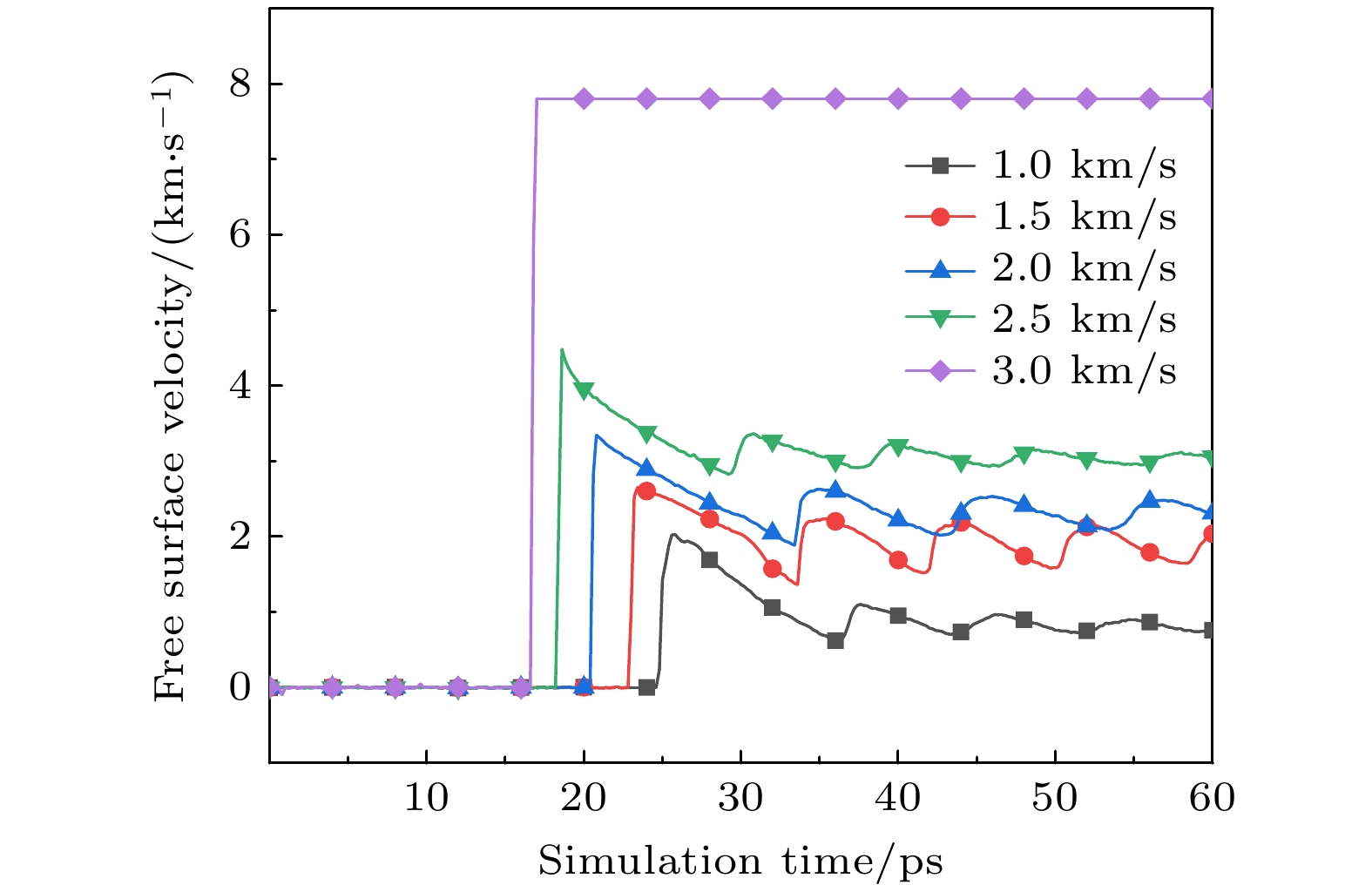

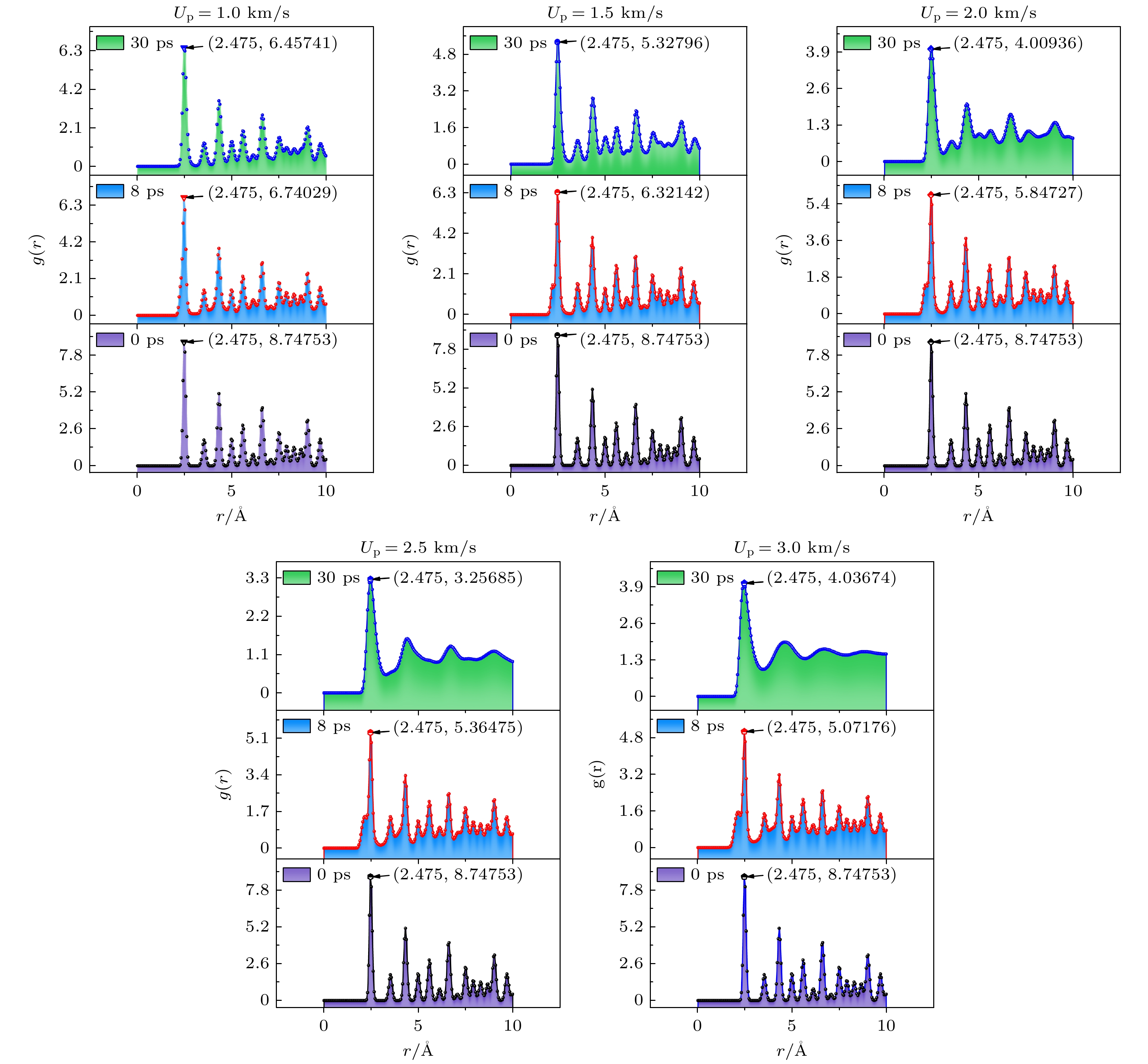

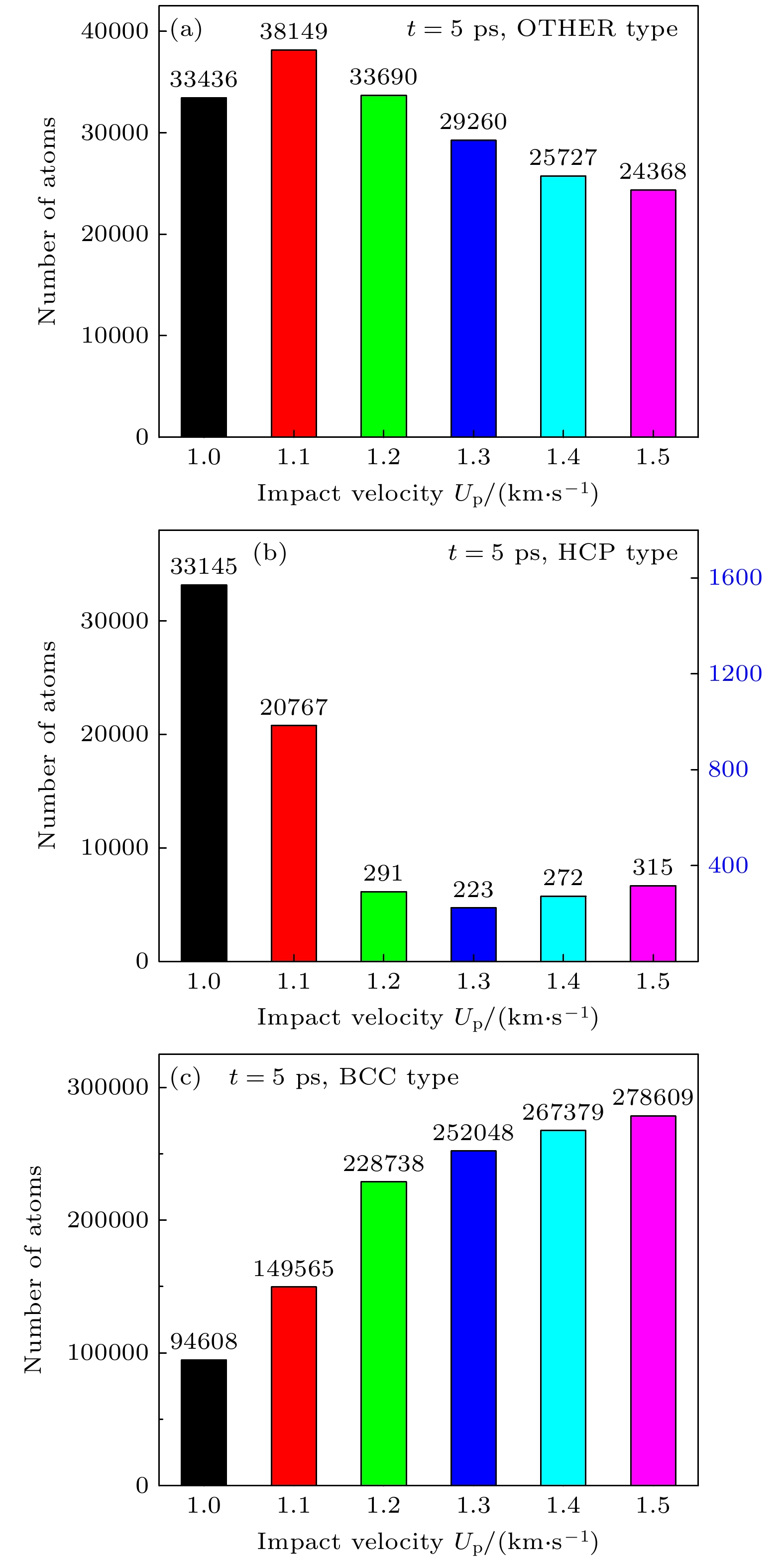

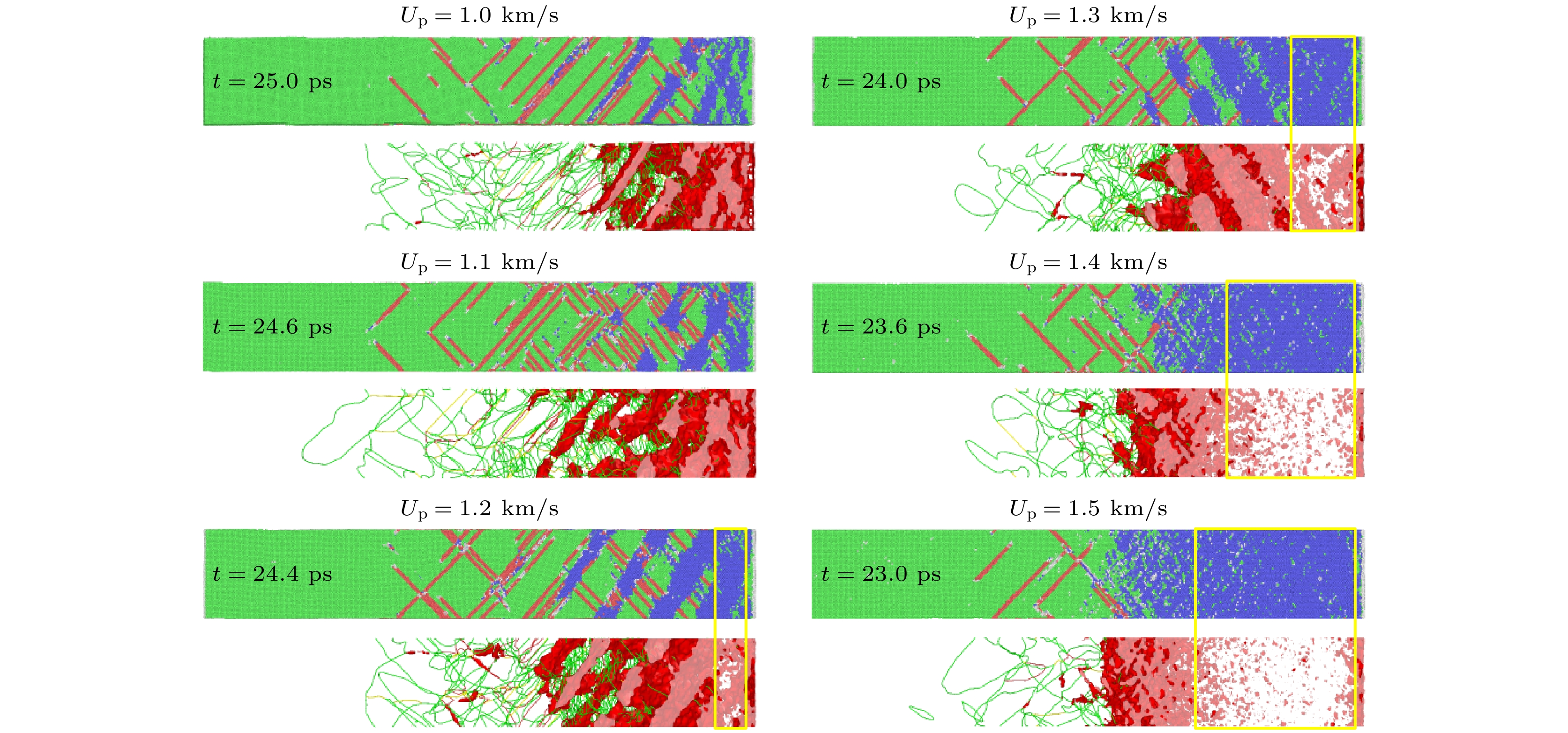

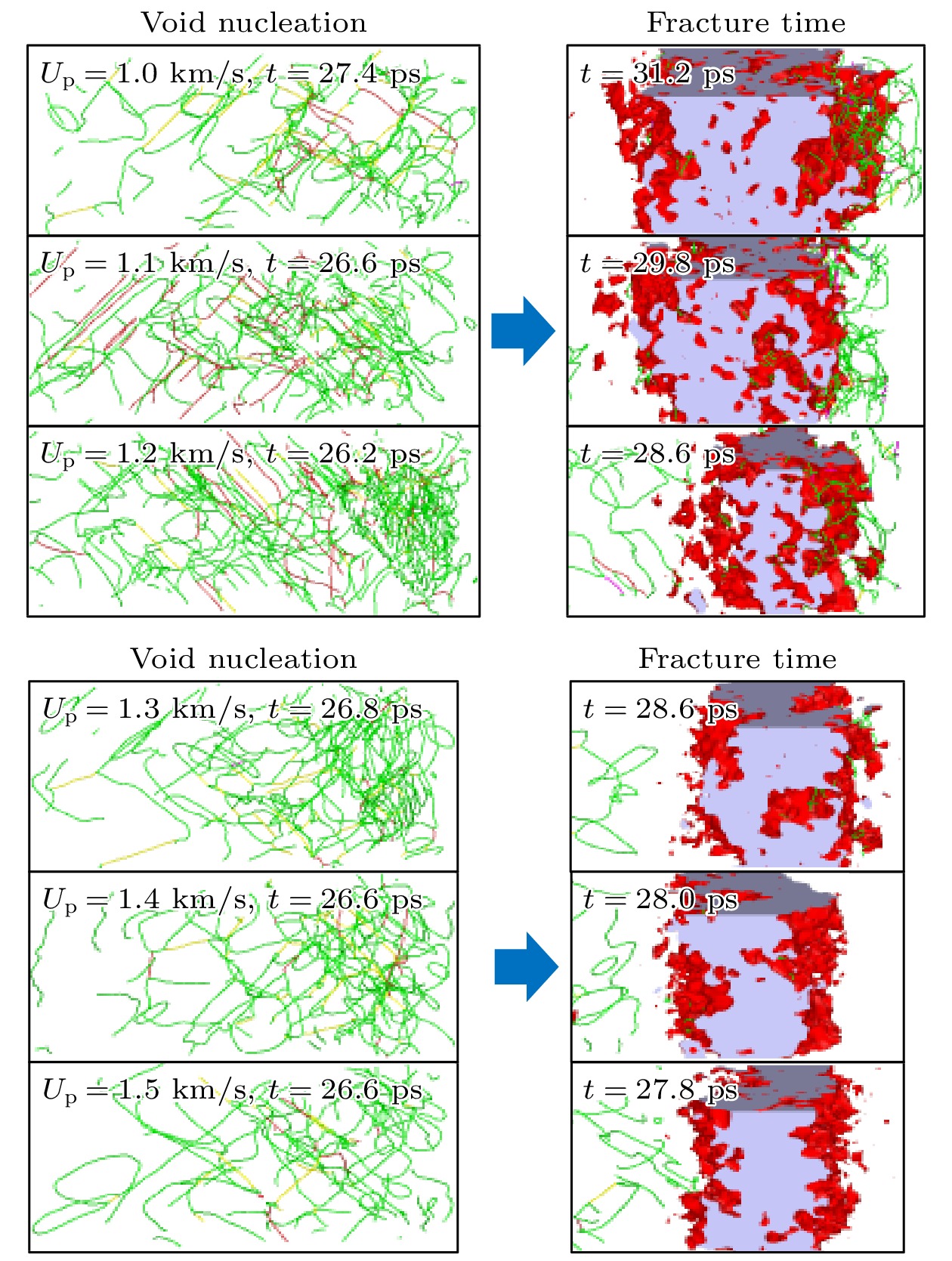

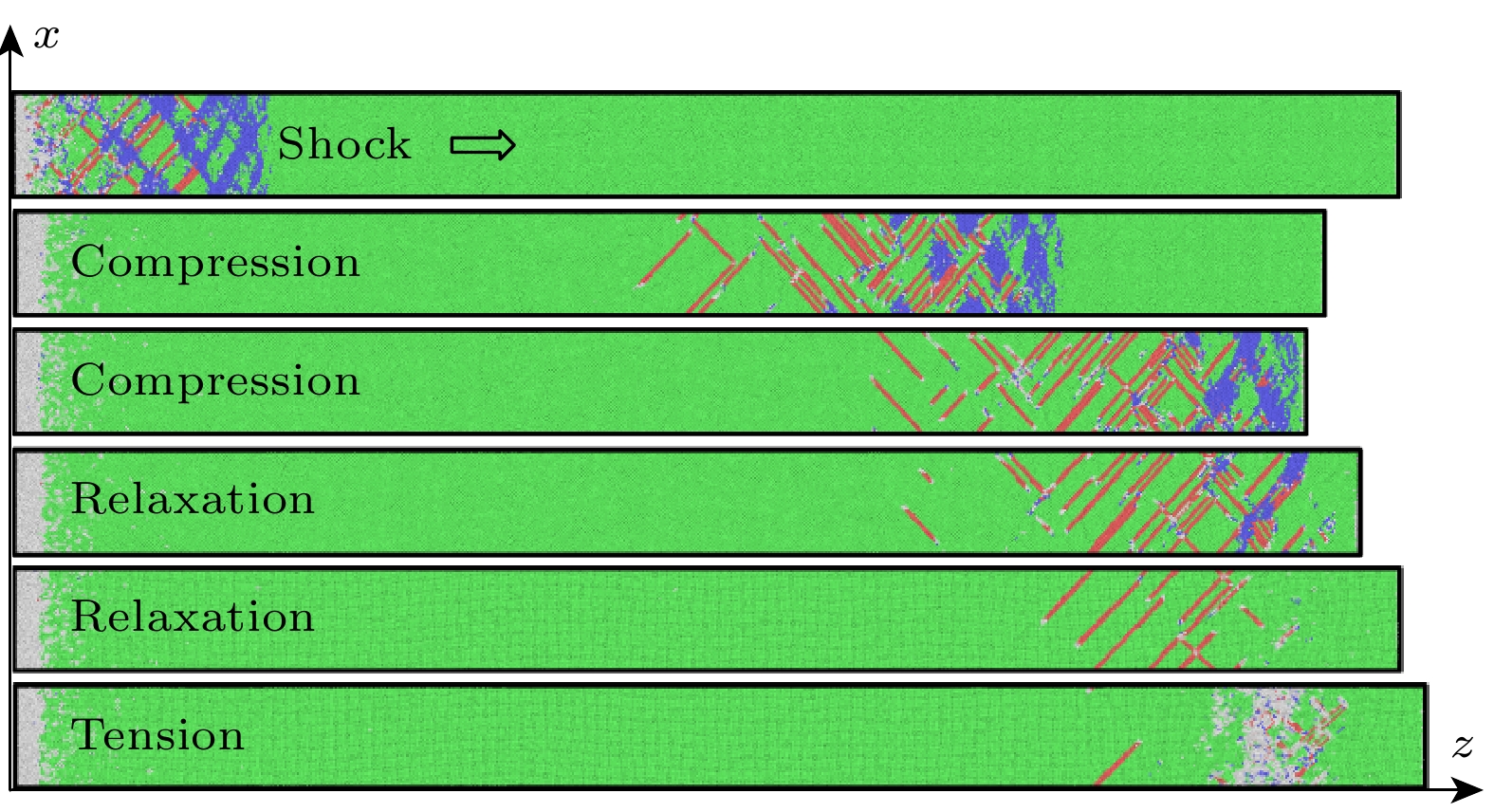

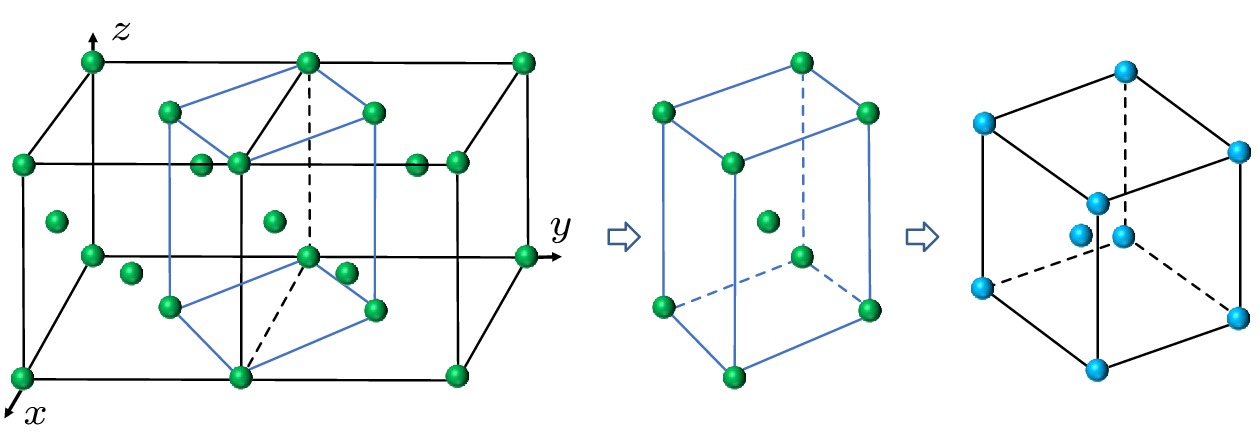

为了阐明冲击速度对单晶镍冲击层裂行为的影响机理, 采用非平衡分子动力学方法获得了不同冲击速度下单晶镍自由面的速度、径向分布函数、原子晶体结构、位错和孔洞演化过程. 结果表明单晶镍层裂行为的临界冲击速度为1.5 km/s, 当冲击速度Up ≤ 1.5 km/s时, 层裂机制为经典层裂损伤, 而Up>1.5 km/s时表现出微层裂损伤. 相比经典层裂, 微层裂下孔洞数量显著增加, 分布更为分散, 应力区域宽. 分析了冲击速度对经典层裂损伤行为(Up ≤ 1.5 km/s)的影响, 并获得了相应的层裂强度, 当Up = 1.3 km/s时, 发生层裂强度突变. 单晶镍的层裂强度与层错、相变和位错机制共同作用. 随着位错形核和发射位错数量增加, 导致层裂强度先下降. 当冲击速度Up < 1.3 km/s时, 层裂损伤主要由层错作用影响; 当Up = 1.3 km/s时, 层裂强度主要受到层错与相变共同竞争作用; 当冲击速度Up > 1.3 km/s, 层裂强度主要由BCC相变机制影响, 其相变机制为相变路径为FCC→BCT→BCC的马氏体相变机制. 本文揭示了冲击速度对层裂损伤和断裂影响规律及作用机制, 可为镍基材料在极端冲击条件下的防护应用提供理论基础.In order to reveal the influence of impact velocity (Up) on the spalling and fracture behavior of single crystal nickel, a non-equilibrium molecular dynamics approach is adopted to investigate the free surface velocity curve, radial distribution function, atomic crystal structures, dislocations, and void evolution process. The results show that the critical impact velocity Up for spalling behavior in single crystal nickel is 1.5 km/s, and when Up ≤ 1.5 km/s the spallation mechanism is classical spallation damage and when Up >1.5 km/s it behaves as micro-spallation damage. The pore number and distribution area, and stress distribution area under micro-spallation damage are much higher than those under classical spallation damage. The influence of impact velocity on the classical spalling damage behavior (Up ≤ 1.5 km/s) is analyzed and the corresponding spalling strength is obtained, indicating that an accident of spalling strength occurs when Up is 1.3 km/s. The spalling strength of single crystal nickel is influenced by the combined effects of stacking faults, phase transformation, and dislocation. As the nucleation and emission of dislocations increase, the spalling strength decreases. When Up < 1.3 km/s, the spalling damage is mainly due to stacking faults. When Up = 1.3 km/s, the spalling strength is mainly affected by the competition between stacking faults and phase transformation. When Up > 1.3 km/s, spalling strength is predominantly influenced by the body-centered cubic (BCC) phase transformation mechanism (transformation path: FCC → BCT → BCC). This study reveals the impact velocity-dependent patterns, mechanisms, and effects on spalling damage and fracture, providing a theoretical basis for realizing the protective application of nickel-based materials under extreme impact conditions.

-

Keywords:

- impact velocity /

- single crystal nickel /

- spallation /

- phase transition /

- molecular dynamics

[1] Tang Y, Wang R X, Xiao B, Zhang Z R, Li S, Qiao J W, Bai S X, Zhang Y, Liaw P K 2023 Prog. Mater. Sci. 135 101090

Google Scholar

Google Scholar

[2] Arcade S, Paul J H, Juan P E, Wang H X, Oromiehie E, Prusty G B, Phillips A W, John N A S 2023 Compos. Part A-Appl. S 173 107674

Google Scholar

Google Scholar

[3] Wang P F, Xu S L 2022 Advances in Experimental Impact Mechanics (Elsevier) pp41–74

[4] 余文韬, 黄佩珍 2018 力学学报 50 828

Google Scholar

Google Scholar

Yu W T, Huang P Z 2018 Chin. J. Theor. Appl. Mech. 50 828

Google Scholar

Google Scholar

[5] Mukherjee T, Elmer J W, Wei H L, Lienert T J, Zhang W, Kou S, DebRoy T 2023 Prog. Mater. Sci. 138 101153

Google Scholar

Google Scholar

[6] Ogorodnikov V A, Mikhaĭlov A L, Burtsev V V, Lobastov S A, Erunov S V, Romanov A V, Rudnev A V, Kulakov E V, Bazarov Y B, Glushikhin V V, Kalashnik I A, Tsyganov V A, Tkachenko B I 2009 J. Exp. Theor. Phys. 109 530

Google Scholar

Google Scholar

[7] Huang L Q, Wang J, Momeni A, Wang S F 2021 Trans. Nonferrous Met. Soc. China 31 2116

Google Scholar

Google Scholar

[8] Curran D R, Seaman L, Shockey D A 1987 Phys. Rep. 147 253

Google Scholar

Google Scholar

[9] Ren K R, Liu H Y, Ma R, Chen S, Zhang S Y, Wang R X, Chen R, Tang Y, Li S, Lu F Y 2023 J. Mater. Sci. Tech. 161 201

Google Scholar

Google Scholar

[10] Luo Q S, Kitchen M, Li J B, Li W B, Li Y Z 2023 Wear 523 204779

Google Scholar

Google Scholar

[11] Zhang W L, Kennedy G B, Muly K, Li P J, Thadhani N N 2020 Int. J. Impact Eng. 146 103725

Google Scholar

Google Scholar

[12] Cheng J C, Chai H W, Fan G L, Li Z Q, Xie H L, Tan Z Q, Bie B X, Huang J Y, Luo S N 2020 Carbon 170 589

Google Scholar

Google Scholar

[13] Ren Y, Li Z, Zhang Z Y, Zhang Z Y, Chen R, Li Z Y, Tan C W, Chen P W 2022 Mater. Sci. Eng. A 860 144320

Google Scholar

Google Scholar

[14] Molinari A, Wright T W 2005 J. Mech. Phys. Solids 53 1476

Google Scholar

Google Scholar

[15] Luo S N, An Q, Germann T C, Han L B 2009 J. Appl. Phys. 106 013502

Google Scholar

Google Scholar

[16] Liao Y, Xiang M Z, Li G M, Wang K, Zhang X Y, Chen J 2018 Mech. Mater. 126 13

Google Scholar

Google Scholar

[17] Wang Y T, Zeng X G, Yang X, Xu T L 2022 Comput. Mater. Sci. 201 110870

Google Scholar

Google Scholar

[18] Liao Y, Xiang M Z, Zeng X G, Chen J 2014 Comput. Mater. Sci. 95 89

Google Scholar

Google Scholar

[19] Schuler H, Mayrhofer C, Thoma K 2006 Int. J. Impact Eng. 32 1635

Google Scholar

Google Scholar

[20] Li P, Wang L S, Yan S L, Meng M, Zhou Y F, Xue K M 2021 Int. J. Refract. Met. H. 94 105376

Google Scholar

Google Scholar

[21] Xiang M Z, Hu H B, Chen J, Long Y 2013 Modell. Simul. Mater. Sci. Eng. 21 055005

Google Scholar

Google Scholar

[22] Kadau K, Germann T C, Lomdahl P S, Holian B L 2002 Science 296 1681

Google Scholar

Google Scholar

[23] Liao Y, Xiang M Z, Zeng X G, Chen J 2015 Mech. Mater. 84 12

Google Scholar

Google Scholar

[24] Li W H, Yao X H 2016 Comput. Mater. Sci. 124 151

Google Scholar

Google Scholar

[25] He L, Wang F, Zeng X G, Yang X, Qi Z P 2020 Mech. Mater. 143 103343

Google Scholar

Google Scholar

[26] Chen B, Li Y L, Şopu D, Eckert J, Wu W P 2023 Int. J. Plasticity 162 103539

Google Scholar

Google Scholar

[27] Jiang D D, Shao J L, Wu B, Wang P, He A M 2022 Scripta Mater. 210 114474

Google Scholar

Google Scholar

[28] Xie H C, Ma Z C, Zhang W, Zhao H W, Ren L Q 2024 J. Mater. Sci. Tech. 175 72

Google Scholar

Google Scholar

[29] 程志达, 朱静, 孙铁昱 2011 60 037504

Google Scholar

Google Scholar

Cheng Z D, Zhu J, Sun T Y 2011 Acta Phys. Sin. 60 037504

Google Scholar

Google Scholar

[30] 徐送宁, 张林, 张彩碚, 祁阳 2007 金属学报 43 379

Xu S N, Zhang L, Zhang C B, Qi Y 2007 Acta Metall. Sin. 43 379

[31] Liu B B, Chen Y C, Guo L, Li X F, Wang K, Deng H Q, Tian Z, Hu W Y, Xiao S F, Yuan D W 2023 Int. J. Mech. Sci. 250 108330

Google Scholar

Google Scholar

[32] 杜欣, 袁福平, 熊启林, 张波, 阚前华, 张旭 2022 力学学报 54 2152

Google Scholar

Google Scholar

Du X, Yuan F P, Xiong Q L, Zhang B, Kan Q H, Zhang X 2022 Chin. J. Theor. Appl. Mech. 54 2152

Google Scholar

Google Scholar

[33] Chen B, Wu W P, Chen M X 2022 Comput. Mater. Sci. 202 111015

Google Scholar

Google Scholar

[34] Zhou X W, Johnson R A, Wadley H N G 2004 Phys. Rev. B 69 144113

Google Scholar

Google Scholar

[35] Kedharnath A, Kapoor R, Sarkar A 2021 Comput. Struct. 254 106614

Google Scholar

Google Scholar

[36] Potirniche G P, Horstemeyer M F, Wagner G J, Gullett P M 2006 Int. J. Plasticity 22 257

Google Scholar

Google Scholar

[37] Wang W D, Yi C L, Fan K Q 2013 Trans. Nonferrous Met. Soc. China 23 3353

Google Scholar

Google Scholar

[38] 周延, 蔡洋, 卢磊 2022 实验力学 37 183

Zhou Y, Cai Y, Lu L 2022 J. Exp. Mech. 37 183

[39] Jian W R, Xie Z C, Xu S Z, Yao X H, Beyerlein I J 2022 Scripta Mater. 209 114379

Google Scholar

Google Scholar

[40] 王云天, 曾祥国, 陈华燕, 杨鑫, 王放, 祁忠鹏 2021 爆炸与冲击 41 139

Google Scholar

Google Scholar

Wang Y T, Zeng X G, Chen H Y, Yang X, Wang F, Qi Z P 2021 Explo. Shock Waves 41 139

Google Scholar

Google Scholar

[41] 杨鑫, 赵晗, 高学军, 陈臻林, 王放, 曾祥国 2023 爆炸与冲击 43 29

Google Scholar

Google Scholar

Yang X, Zhao Han, Gao X J, Chen Z L, Wang F, Zeng X G 2023 Explo. Shock Waves 43 29

Google Scholar

Google Scholar

[42] Zhou T T, He A M, Wang P, Shao J L 2019 Comput. Mater. Sci. 162 255

Google Scholar

Google Scholar

[43] Thürmer D, Zhao S T, Deluigi O R, Stan C, Alhafez I A, Urbassek H M, Meyers M A, Bringa E M, Gunkelmann N 2022 J. Alloys Compd. 895 162567

Google Scholar

Google Scholar

[44] 王嘉楠, 伍鲍, 何安民, 吴凤超, 王裴, 吴恒安 2021 高压 35 4

Google Scholar

Google Scholar

Wang J N, Wu B, He A M, Wu F C, Wang P, Wu H A 2021 Chin. J. High Pressure Phys. 35 4

Google Scholar

Google Scholar

[45] Mescheryakov Y I, Divakov A K, Zhigacheva N I 2000 Shock Waves 10 43

Google Scholar

Google Scholar

[46] Tang J F, Xiao J C, Deng L, Li W, Zhang X M, Wang L, Xiao S F, Deng H Q, Hu W Y 2018 Phys. Chem. Chem. Phys. 20 28039

Google Scholar

Google Scholar

[47] Wang K, Zhu W J, Xiang M Z, Xu Y, Li G M, Chen J 2019 Modell. Simul. Mater. Sc. 27 015001

Google Scholar

Google Scholar

[48] Tuler F R, Butcher B M 1984 International Journal of Fracture 26 322

Google Scholar

Google Scholar

[49] 裴晓阳, 彭辉, 贺红亮, 李平 2015 64 034601

Google Scholar

Google Scholar

Pei X Y, Peng H, He H L, Li P 2015 Acta Phys. Sin. 64 034601

Google Scholar

Google Scholar

[50] Davison L, Stevens A L 1972 J. Appl. Phys. 43 988

Google Scholar

Google Scholar

[51] Kanel G I, Rasorenov S V, Utkin A V 1996 High-Pressure Shock Compression of Solids II (New York: Springer-Verlag) pp1–24

[52] 白以龙, 柯孚久, 夏蒙棼 1991 力学学报 23 290

Google Scholar

Google Scholar

Bai Y L, Ke F J, Xia M F 1991 Chin. J. Theor. Appl. Mech. 23 290

Google Scholar

Google Scholar

[53] Qiu T, Xiong Y N, Xiao S F, Li X F, Hu W Y, Deng H Q 2017 Comput. Mater. Sci. 137 273

Google Scholar

Google Scholar

[54] Stukowski A, Bulatov V V, Arsenlis A 2012 Modell. Simul. Mater. Sc. 20 085007

Google Scholar

Google Scholar

-

表 1 冲击速度为Up = 1.0—1.5 km/s时的加载应力和断裂时间

Table 1. Loading stress and fracture time under the impact velocity of Up = 1.0–1.5 km/s.

冲击速度 Up/(km·s–1) 加载应力 P/GPa 断裂时间 tf/ps 1.0 53.67 3.8 1.1 60.46 3.2 1.2 67.49 2.4 1.3 74.78 1.8 1.4 82.33 1.4 1.5 90.13 1.2 表 2 冲击速度分别为0.9 km/s和1.25 km/s时的加载应力和断裂时间

Table 2. Loading stress and fracture time under the impact velocity of 0.9 km/s and 1.25 km/s.

冲击速度 Up (km/s) 加载应力P/GPa 断裂时间tf/ps 0.9 47.13 5.2 1.25 69.93 2.0 -

[1] Tang Y, Wang R X, Xiao B, Zhang Z R, Li S, Qiao J W, Bai S X, Zhang Y, Liaw P K 2023 Prog. Mater. Sci. 135 101090

Google Scholar

Google Scholar

[2] Arcade S, Paul J H, Juan P E, Wang H X, Oromiehie E, Prusty G B, Phillips A W, John N A S 2023 Compos. Part A-Appl. S 173 107674

Google Scholar

Google Scholar

[3] Wang P F, Xu S L 2022 Advances in Experimental Impact Mechanics (Elsevier) pp41–74

[4] 余文韬, 黄佩珍 2018 力学学报 50 828

Google Scholar

Google Scholar

Yu W T, Huang P Z 2018 Chin. J. Theor. Appl. Mech. 50 828

Google Scholar

Google Scholar

[5] Mukherjee T, Elmer J W, Wei H L, Lienert T J, Zhang W, Kou S, DebRoy T 2023 Prog. Mater. Sci. 138 101153

Google Scholar

Google Scholar

[6] Ogorodnikov V A, Mikhaĭlov A L, Burtsev V V, Lobastov S A, Erunov S V, Romanov A V, Rudnev A V, Kulakov E V, Bazarov Y B, Glushikhin V V, Kalashnik I A, Tsyganov V A, Tkachenko B I 2009 J. Exp. Theor. Phys. 109 530

Google Scholar

Google Scholar

[7] Huang L Q, Wang J, Momeni A, Wang S F 2021 Trans. Nonferrous Met. Soc. China 31 2116

Google Scholar

Google Scholar

[8] Curran D R, Seaman L, Shockey D A 1987 Phys. Rep. 147 253

Google Scholar

Google Scholar

[9] Ren K R, Liu H Y, Ma R, Chen S, Zhang S Y, Wang R X, Chen R, Tang Y, Li S, Lu F Y 2023 J. Mater. Sci. Tech. 161 201

Google Scholar

Google Scholar

[10] Luo Q S, Kitchen M, Li J B, Li W B, Li Y Z 2023 Wear 523 204779

Google Scholar

Google Scholar

[11] Zhang W L, Kennedy G B, Muly K, Li P J, Thadhani N N 2020 Int. J. Impact Eng. 146 103725

Google Scholar

Google Scholar

[12] Cheng J C, Chai H W, Fan G L, Li Z Q, Xie H L, Tan Z Q, Bie B X, Huang J Y, Luo S N 2020 Carbon 170 589

Google Scholar

Google Scholar

[13] Ren Y, Li Z, Zhang Z Y, Zhang Z Y, Chen R, Li Z Y, Tan C W, Chen P W 2022 Mater. Sci. Eng. A 860 144320

Google Scholar

Google Scholar

[14] Molinari A, Wright T W 2005 J. Mech. Phys. Solids 53 1476

Google Scholar

Google Scholar

[15] Luo S N, An Q, Germann T C, Han L B 2009 J. Appl. Phys. 106 013502

Google Scholar

Google Scholar

[16] Liao Y, Xiang M Z, Li G M, Wang K, Zhang X Y, Chen J 2018 Mech. Mater. 126 13

Google Scholar

Google Scholar

[17] Wang Y T, Zeng X G, Yang X, Xu T L 2022 Comput. Mater. Sci. 201 110870

Google Scholar

Google Scholar

[18] Liao Y, Xiang M Z, Zeng X G, Chen J 2014 Comput. Mater. Sci. 95 89

Google Scholar

Google Scholar

[19] Schuler H, Mayrhofer C, Thoma K 2006 Int. J. Impact Eng. 32 1635

Google Scholar

Google Scholar

[20] Li P, Wang L S, Yan S L, Meng M, Zhou Y F, Xue K M 2021 Int. J. Refract. Met. H. 94 105376

Google Scholar

Google Scholar

[21] Xiang M Z, Hu H B, Chen J, Long Y 2013 Modell. Simul. Mater. Sci. Eng. 21 055005

Google Scholar

Google Scholar

[22] Kadau K, Germann T C, Lomdahl P S, Holian B L 2002 Science 296 1681

Google Scholar

Google Scholar

[23] Liao Y, Xiang M Z, Zeng X G, Chen J 2015 Mech. Mater. 84 12

Google Scholar

Google Scholar

[24] Li W H, Yao X H 2016 Comput. Mater. Sci. 124 151

Google Scholar

Google Scholar

[25] He L, Wang F, Zeng X G, Yang X, Qi Z P 2020 Mech. Mater. 143 103343

Google Scholar

Google Scholar

[26] Chen B, Li Y L, Şopu D, Eckert J, Wu W P 2023 Int. J. Plasticity 162 103539

Google Scholar

Google Scholar

[27] Jiang D D, Shao J L, Wu B, Wang P, He A M 2022 Scripta Mater. 210 114474

Google Scholar

Google Scholar

[28] Xie H C, Ma Z C, Zhang W, Zhao H W, Ren L Q 2024 J. Mater. Sci. Tech. 175 72

Google Scholar

Google Scholar

[29] 程志达, 朱静, 孙铁昱 2011 60 037504

Google Scholar

Google Scholar

Cheng Z D, Zhu J, Sun T Y 2011 Acta Phys. Sin. 60 037504

Google Scholar

Google Scholar

[30] 徐送宁, 张林, 张彩碚, 祁阳 2007 金属学报 43 379

Xu S N, Zhang L, Zhang C B, Qi Y 2007 Acta Metall. Sin. 43 379

[31] Liu B B, Chen Y C, Guo L, Li X F, Wang K, Deng H Q, Tian Z, Hu W Y, Xiao S F, Yuan D W 2023 Int. J. Mech. Sci. 250 108330

Google Scholar

Google Scholar

[32] 杜欣, 袁福平, 熊启林, 张波, 阚前华, 张旭 2022 力学学报 54 2152

Google Scholar

Google Scholar

Du X, Yuan F P, Xiong Q L, Zhang B, Kan Q H, Zhang X 2022 Chin. J. Theor. Appl. Mech. 54 2152

Google Scholar

Google Scholar

[33] Chen B, Wu W P, Chen M X 2022 Comput. Mater. Sci. 202 111015

Google Scholar

Google Scholar

[34] Zhou X W, Johnson R A, Wadley H N G 2004 Phys. Rev. B 69 144113

Google Scholar

Google Scholar

[35] Kedharnath A, Kapoor R, Sarkar A 2021 Comput. Struct. 254 106614

Google Scholar

Google Scholar

[36] Potirniche G P, Horstemeyer M F, Wagner G J, Gullett P M 2006 Int. J. Plasticity 22 257

Google Scholar

Google Scholar

[37] Wang W D, Yi C L, Fan K Q 2013 Trans. Nonferrous Met. Soc. China 23 3353

Google Scholar

Google Scholar

[38] 周延, 蔡洋, 卢磊 2022 实验力学 37 183

Zhou Y, Cai Y, Lu L 2022 J. Exp. Mech. 37 183

[39] Jian W R, Xie Z C, Xu S Z, Yao X H, Beyerlein I J 2022 Scripta Mater. 209 114379

Google Scholar

Google Scholar

[40] 王云天, 曾祥国, 陈华燕, 杨鑫, 王放, 祁忠鹏 2021 爆炸与冲击 41 139

Google Scholar

Google Scholar

Wang Y T, Zeng X G, Chen H Y, Yang X, Wang F, Qi Z P 2021 Explo. Shock Waves 41 139

Google Scholar

Google Scholar

[41] 杨鑫, 赵晗, 高学军, 陈臻林, 王放, 曾祥国 2023 爆炸与冲击 43 29

Google Scholar

Google Scholar

Yang X, Zhao Han, Gao X J, Chen Z L, Wang F, Zeng X G 2023 Explo. Shock Waves 43 29

Google Scholar

Google Scholar

[42] Zhou T T, He A M, Wang P, Shao J L 2019 Comput. Mater. Sci. 162 255

Google Scholar

Google Scholar

[43] Thürmer D, Zhao S T, Deluigi O R, Stan C, Alhafez I A, Urbassek H M, Meyers M A, Bringa E M, Gunkelmann N 2022 J. Alloys Compd. 895 162567

Google Scholar

Google Scholar

[44] 王嘉楠, 伍鲍, 何安民, 吴凤超, 王裴, 吴恒安 2021 高压 35 4

Google Scholar

Google Scholar

Wang J N, Wu B, He A M, Wu F C, Wang P, Wu H A 2021 Chin. J. High Pressure Phys. 35 4

Google Scholar

Google Scholar

[45] Mescheryakov Y I, Divakov A K, Zhigacheva N I 2000 Shock Waves 10 43

Google Scholar

Google Scholar

[46] Tang J F, Xiao J C, Deng L, Li W, Zhang X M, Wang L, Xiao S F, Deng H Q, Hu W Y 2018 Phys. Chem. Chem. Phys. 20 28039

Google Scholar

Google Scholar

[47] Wang K, Zhu W J, Xiang M Z, Xu Y, Li G M, Chen J 2019 Modell. Simul. Mater. Sc. 27 015001

Google Scholar

Google Scholar

[48] Tuler F R, Butcher B M 1984 International Journal of Fracture 26 322

Google Scholar

Google Scholar

[49] 裴晓阳, 彭辉, 贺红亮, 李平 2015 64 034601

Google Scholar

Google Scholar

Pei X Y, Peng H, He H L, Li P 2015 Acta Phys. Sin. 64 034601

Google Scholar

Google Scholar

[50] Davison L, Stevens A L 1972 J. Appl. Phys. 43 988

Google Scholar

Google Scholar

[51] Kanel G I, Rasorenov S V, Utkin A V 1996 High-Pressure Shock Compression of Solids II (New York: Springer-Verlag) pp1–24

[52] 白以龙, 柯孚久, 夏蒙棼 1991 力学学报 23 290

Google Scholar

Google Scholar

Bai Y L, Ke F J, Xia M F 1991 Chin. J. Theor. Appl. Mech. 23 290

Google Scholar

Google Scholar

[53] Qiu T, Xiong Y N, Xiao S F, Li X F, Hu W Y, Deng H Q 2017 Comput. Mater. Sci. 137 273

Google Scholar

Google Scholar

[54] Stukowski A, Bulatov V V, Arsenlis A 2012 Modell. Simul. Mater. Sc. 20 085007

Google Scholar

Google Scholar

计量

- 文章访问数: 447

- PDF下载量: 23

- 被引次数: 0

下载:

下载: