-

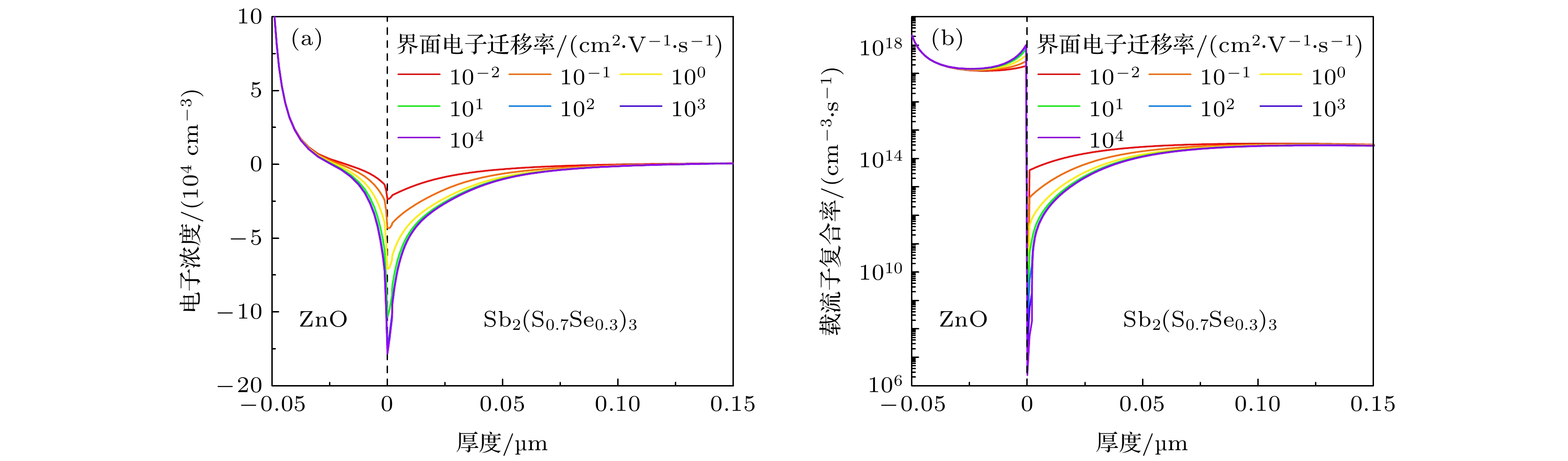

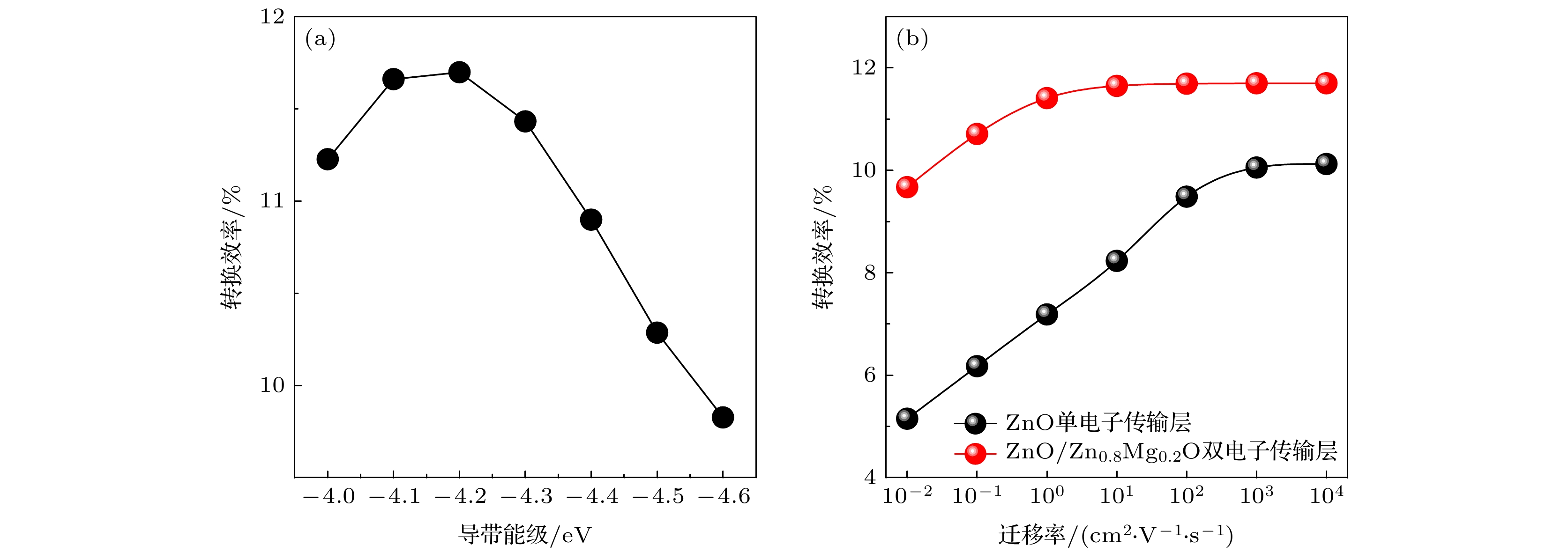

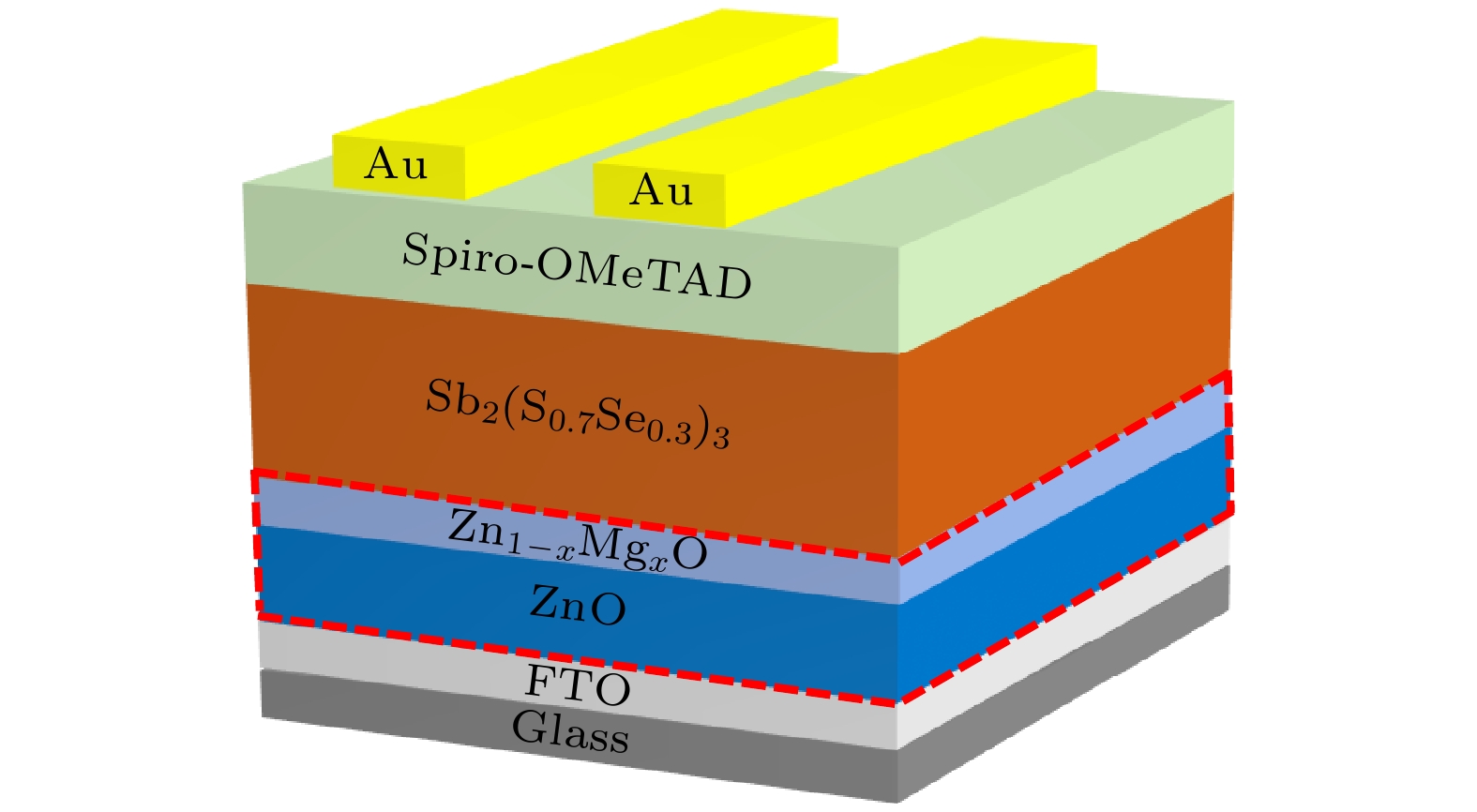

硫硒化锑薄膜太阳电池因其制备方法简单、原材料丰富无毒、光电性质稳定等优点, 成为了光伏领域的研究热点. 经过近几年的发展, 硫硒化锑太阳电池的光电转换效率已经突破10%, 极具发展潜力. 本文针对硫硒化锑太阳电池中n/i界面引起的载流子复合进行了深入研究. 发现硫硒化锑太阳电池的界面特性会受到界面电子迁移能力和能带结构两方面的影响. 界面电子迁移率的提高能使电子更有效地传输至电子传输层, 实现器件短路电流密度和填充因子的有效提升. 在此基础上, 引入ZnO/Zn1–xMgxO双电子传输层结构能够进一步优化硫硒化锑太阳电池性能. 其中, Zn1–xMgxO能级位置的改变可以同时调节界面和吸光层的能级分布, 在Zn1–xMgxO导带能级为–4.2 eV, 对应Mg含量为20%时, 抑制载流子复合的效果最为明显, 硫硒化锑太阳电池也获得了最佳的器件性能. 在去除缺陷态的理想情况下, 双电子传输层结构硫硒化锑太阳电池在600 nm厚时获得了20.77%的理论光电转换效率, 该研究结果为硫硒化锑太阳电池的进一步优化和发展提供了理论与技术支持.Antimony sulfide selenide thin film solar cells have drawn great interest in the field of photovoltaic due to their advantages of simple preparation method, abundant raw materials, non-toxic and stable photoelectric properties. After the development in recent years, the photoelectric conversion efficiency of antimony sulfide selenide solar cells has exceeded 10%, which has great development potential. In this work, the carrier recombination near n/i interface in antimony sulfide selenide solar cells is studied. It is found that the characteristics of the n/i interface are affected by the interfacial electron mobility and energy band structure. The improvement of the interface electron mobility can make the electrons more effectively transferred to the electron transport layer, and realize the effective improvement of the short circuit current density and fill factor of the device. Moreover, the introduction of ZnO/Zn1–xMgxO double electron transport layer structure can further optimize the performance of antimony sulfide selenide solar cells. The change of Zn1–xMgxO energy level position can adjust the energy level distribution of the interface and light absorption layer simultaneously. When the conduction band energy level of Zn1–xMgxO is –4.2 eV and the corresponding Mg content is 20%, the effect of restraining the carrier recombination is the most obvious, and the antimony sulfide selenide solar cell also obtains the best device performance. Finally, under the ideal condition of removing the defect state, the antimony sulfide selenide solar cells with 600 nm in thickness can achieve 20.77% theoretical photoelectric conversion efficiency. The research results provide theoretical and technical support for further optimizing and developing the antimony sulfide selenide solar cells.

-

Keywords:

- thin film solar cells /

- antimony sulfide selenide /

- interface characteristics /

- double electron transport layer

[1] Righetto M, Lim S S, Giovanni D, Lim J W M, Zhang Q, Ramesh S, Tay Y K E, Sum T C 2020 Nat. Commun. 11 1

[2] Metzger W K, Grover S, Lu D, Colegrove E, Moseley J, Perkins C L, Li X, Mallick R, Zhang W, Malik R, Kephart J, Jiang C S, Kuciauskas D, Albin D S, Al-Jassim M M, Xiong G, Gloeckler M 2019 Nat. Energy. 4 837

Google Scholar

Google Scholar

[3] 曹宇, 蒋家豪, 刘超颖, 凌同, 孟丹, 周静, 刘欢, 王俊尧 2021 70 128802

Google Scholar

Google Scholar

Cao Y, Jiang J H, Liu C Y, Ling T, Meng D, Zhou J, Liu H, Wang J Y 2021 Acta Phys. Sin. 70 128802

Google Scholar

Google Scholar

[4] Birant G, Wild J De, Kohl T, Buldu D G, Brammertz G, Meuris M, Poortmans J, Vermang B 2020 Sol. Energy 207 1002

Google Scholar

Google Scholar

[5] Chen Y, Song K, Xu X L, Yao G, Wu Z Y 2020 Sol. Energy 195 121

Google Scholar

Google Scholar

[6] Li D B, Bista S S, Song Z N, Awni R A, Subedi K K, Shrestha N, Pradhan P, Chen L, Bastola E, Grice C R, Phillips A B, Heben M J, Ellingson R J, Yan Y F 2020 Nano Energy 73 104835

Google Scholar

Google Scholar

[7] Wang Y R, Gu S, Liu G L, Zhang L P, Liu Z, Lin R X, Xiao K, Luo X, Shi J H, Du J L, Meng F Y, Li L D, Liu Z X, Tan H R 2021 Sci. China Chem. 64 1

[8] Cao Y, Zhu X Y, Jiang J H, Liu C Y, Zhou J, Ni J, Zhang J J, Pang J B 2020 Sol. Energy Mater. Sol. Cells 206 110279

Google Scholar

Google Scholar

[9] Zhou J, Chen H B, Zhang X T, Chi K L, Cai Y M, Cao Y, Pang J B 2021 J. Alloys Compd. 862 158703

Google Scholar

Google Scholar

[10] 薛丁江, 石杭杰, 唐江 2015 64 038406

Google Scholar

Google Scholar

Xue D J, Shi H J, Tang J 2015 Acta Phys. Sin. 64 038406

Google Scholar

Google Scholar

[11] Li K H, Li F, Chen C, Jiang P F, Lu S C, Wang S Y, Lu Y, Tu G L, Guo J J, Shui L Q, Liu Z, Song B X, Tang J 2021 Nano Energy 86 106101

Google Scholar

Google Scholar

[12] Lian W T, Jiang C H, Yin Y W, Tang R F, Li G, Zhang L J, Che B, Chen T 2021 Nat. Commun. 12 1

Google Scholar

Google Scholar

[13] Lee S J, Sung S J, Yang K J, Kang J K, Kim J Y, Do Y S, Kim D H 2020 ACS Appl. Energy Mater. 3 12644

Google Scholar

Google Scholar

[14] Luo J T, Xiong W, Liang G X, Liu Y K, Yang H Z, Zheng Z H, Zhang X H, Fan P, Chen S 2020 J. Alloys Compd. 826 154235

Google Scholar

Google Scholar

[15] Xiao Y P, Wang H P, Kuang H 2020 Opt. Mater. 108 110414

Google Scholar

Google Scholar

[16] Wang X M, Tang R F, Jiang C H, Lian W T, Ju H X, Jiang G S, Li Z Q, Zhu C F, Chen T 2020 Adv. Energy Mater. 10 2002341

Google Scholar

Google Scholar

[17] Li Z Q, Liang X Y, Li G, Liu H X, Zhang H Y, Guo J X, Chen J W, Shen K, San X Y, Yu W, Schropp R E I, Mai Y H 2019 Nat. Commun. 10 1

Google Scholar

Google Scholar

[18] Islam M T, Thakur A K 2020 Sol. Energy 202 304

Google Scholar

Google Scholar

[19] Ning H, Guo H F, Zhang J Y, Wang X, Jia X G, Qiu J H, Yuan N Y, Ding J N 2021 Sol. Energy Mater. Sol. Cells 221 110816

Google Scholar

Google Scholar

[20] Cai Z H, Dai C M, Chen S Y 2020 Sol. RRL 4 1900503

Google Scholar

Google Scholar

[21] Ishaq M, Chen S, Farooq U, Azam M, Deng H, Su Z H, Zheng Z H, Fan P, Song H S, Liang G X 2020 Sol. RRL 4 2000551

Google Scholar

Google Scholar

[22] Lei H W, Chen J J, Tan Z J, Fang G J 2019 Sol. RRL 3 1900026

Google Scholar

Google Scholar

[23] Cao Y, Liu C Y, Jiang J H, Zhu X Y, Zhou J, Ni J, Zhang J J, Pang J B, Rummeli M H, Zhou J W, Liu H, Cuniberti G 2021 Sol. RRL 5 2000800

Google Scholar

Google Scholar

[24] Yang B, Qin S K, Xue D J, Chen C, He YS, Niu D M, Huang H, Tang J 2017 Prog. Photovolt:Res. Appl. 25 113

Google Scholar

Google Scholar

[25] Wu C Y, Zhang L J, Ding H H, Ju H X, Jin X, Wang X M, Zhu C F, Chen T 2018 Sol. Energy Mater. Sol. Cells 183 52

Google Scholar

Google Scholar

[26] Lu S C, Zhao Y, Wen X X, Xue D J, Chen C, Li K H, Kondrotas R, Wang C, Tang J 2019 Sol. RRL 3 1800280

Google Scholar

Google Scholar

[27] Tang R F, Wang X M, Lian W T, Huang J L, Wei Q, Huang M L, Yin Y W, Jiang C H, Yang S F, Xing G C, Chen S Y, Zhu C F, Hao X J, Green M A, Chen T 2020 Nat. Energy. 5 587

Google Scholar

Google Scholar

[28] Li K H, Lu Y, Ke X X, Li S, Lu S C, Wang C, Wang S Y, Chen C, Tang J 2020 Sol. RRL 4 2000220

Google Scholar

Google Scholar

[29] 曹宇, 祝新运, 陈翰博, 王长刚, 张鑫童, 侯秉东, 申明仁, 周静 2018 67 247301

Google Scholar

Google Scholar

Cao Y, Zhu X X, Chen H B, Wang C G, Zhang X T, Hou B D, Shen M R, Zhou J 2018 Acta Phys. Sin. 67 247301

Google Scholar

Google Scholar

[30] Weng T F, Yan M, Yu X, Qiao Q, Zhou Y T, Li Z H, Wei J, Yu X M 2021 Opt. Mater. 121 111516

Google Scholar

Google Scholar

[31] Wang W H, Wang X M, Chen G L, Chen B W, Cai H L, Chen T, Chen S Y, Huang Z G, Zhu C F, Zhang Y 2018 Sol. RRL 2 1800208

Google Scholar

Google Scholar

[32] Ishaq M, Deng H, Yuan S J, Zhang H, Khan J, Farooq U, Song H S, Tang J 2018 Sol. RRL 2 1800144

Google Scholar

Google Scholar

[33] Gharibshahian I, Orouji A A, Sharbati S 2020 Sol. Energy Mater. Sol. Cells 212 110581

Google Scholar

Google Scholar

[34] Li K H, Kondrotas R, Chen C, Lu S C, Wen X X, Li D B, Luo J J, Zhao Y, Tang J 2018 Sol. Energy 167 10

Google Scholar

Google Scholar

[35] Liu Y M, Sun Y, Rockett A 2012 Sol. Energy Mater. Sol. Cells 98 124

Google Scholar

Google Scholar

[36] Cao Y, Zhu X Y, Chen H B, Zhang X T, Zhou J, Hu Z Y, Pang J B 2019 Sol. Energy Mater. Sol. Cells 200 109945

Google Scholar

Google Scholar

[37] Chen C, Tang J 2020 ACS Energy Lett. 5 2294

Google Scholar

Google Scholar

-

图 4 不同Zn1–xMgxO层导带能级硫硒化锑太阳电池的器件性能 (a) J-V曲线; (b) 能带图; (c) 电子浓度分布; (d) 载流子复合率分布

Fig. 4. Device performance of the Sb2(S0.7Se0.3)3 solar cells with different conduction band energy levels of Zn1–xMgxO layer: (a) J-V curves; (b) energy band diagram; (c) electron density distribution; (d) carrier recombination rate distribution.

表 1 不同Zn1–xMgxO层导带能级硫硒化锑太阳电池的器件性能参数

Table 1. Device performance of Sb2(S1–xSex)3 solar cells with different conduction band energy levels of Zn1–xMgxO layer.

导带能级/eV Voc/V Jsc/(mA·cm–2) FF/% PCE/% –4.0 1.08 17.27 60.44 11.23 –4.2 1.08 17.73 61.28 11.70 –4.4 1.08 17.42 58.10 10.90 –4.6 1.07 16.94 54.39 9.83 -

[1] Righetto M, Lim S S, Giovanni D, Lim J W M, Zhang Q, Ramesh S, Tay Y K E, Sum T C 2020 Nat. Commun. 11 1

[2] Metzger W K, Grover S, Lu D, Colegrove E, Moseley J, Perkins C L, Li X, Mallick R, Zhang W, Malik R, Kephart J, Jiang C S, Kuciauskas D, Albin D S, Al-Jassim M M, Xiong G, Gloeckler M 2019 Nat. Energy. 4 837

Google Scholar

Google Scholar

[3] 曹宇, 蒋家豪, 刘超颖, 凌同, 孟丹, 周静, 刘欢, 王俊尧 2021 70 128802

Google Scholar

Google Scholar

Cao Y, Jiang J H, Liu C Y, Ling T, Meng D, Zhou J, Liu H, Wang J Y 2021 Acta Phys. Sin. 70 128802

Google Scholar

Google Scholar

[4] Birant G, Wild J De, Kohl T, Buldu D G, Brammertz G, Meuris M, Poortmans J, Vermang B 2020 Sol. Energy 207 1002

Google Scholar

Google Scholar

[5] Chen Y, Song K, Xu X L, Yao G, Wu Z Y 2020 Sol. Energy 195 121

Google Scholar

Google Scholar

[6] Li D B, Bista S S, Song Z N, Awni R A, Subedi K K, Shrestha N, Pradhan P, Chen L, Bastola E, Grice C R, Phillips A B, Heben M J, Ellingson R J, Yan Y F 2020 Nano Energy 73 104835

Google Scholar

Google Scholar

[7] Wang Y R, Gu S, Liu G L, Zhang L P, Liu Z, Lin R X, Xiao K, Luo X, Shi J H, Du J L, Meng F Y, Li L D, Liu Z X, Tan H R 2021 Sci. China Chem. 64 1

[8] Cao Y, Zhu X Y, Jiang J H, Liu C Y, Zhou J, Ni J, Zhang J J, Pang J B 2020 Sol. Energy Mater. Sol. Cells 206 110279

Google Scholar

Google Scholar

[9] Zhou J, Chen H B, Zhang X T, Chi K L, Cai Y M, Cao Y, Pang J B 2021 J. Alloys Compd. 862 158703

Google Scholar

Google Scholar

[10] 薛丁江, 石杭杰, 唐江 2015 64 038406

Google Scholar

Google Scholar

Xue D J, Shi H J, Tang J 2015 Acta Phys. Sin. 64 038406

Google Scholar

Google Scholar

[11] Li K H, Li F, Chen C, Jiang P F, Lu S C, Wang S Y, Lu Y, Tu G L, Guo J J, Shui L Q, Liu Z, Song B X, Tang J 2021 Nano Energy 86 106101

Google Scholar

Google Scholar

[12] Lian W T, Jiang C H, Yin Y W, Tang R F, Li G, Zhang L J, Che B, Chen T 2021 Nat. Commun. 12 1

Google Scholar

Google Scholar

[13] Lee S J, Sung S J, Yang K J, Kang J K, Kim J Y, Do Y S, Kim D H 2020 ACS Appl. Energy Mater. 3 12644

Google Scholar

Google Scholar

[14] Luo J T, Xiong W, Liang G X, Liu Y K, Yang H Z, Zheng Z H, Zhang X H, Fan P, Chen S 2020 J. Alloys Compd. 826 154235

Google Scholar

Google Scholar

[15] Xiao Y P, Wang H P, Kuang H 2020 Opt. Mater. 108 110414

Google Scholar

Google Scholar

[16] Wang X M, Tang R F, Jiang C H, Lian W T, Ju H X, Jiang G S, Li Z Q, Zhu C F, Chen T 2020 Adv. Energy Mater. 10 2002341

Google Scholar

Google Scholar

[17] Li Z Q, Liang X Y, Li G, Liu H X, Zhang H Y, Guo J X, Chen J W, Shen K, San X Y, Yu W, Schropp R E I, Mai Y H 2019 Nat. Commun. 10 1

Google Scholar

Google Scholar

[18] Islam M T, Thakur A K 2020 Sol. Energy 202 304

Google Scholar

Google Scholar

[19] Ning H, Guo H F, Zhang J Y, Wang X, Jia X G, Qiu J H, Yuan N Y, Ding J N 2021 Sol. Energy Mater. Sol. Cells 221 110816

Google Scholar

Google Scholar

[20] Cai Z H, Dai C M, Chen S Y 2020 Sol. RRL 4 1900503

Google Scholar

Google Scholar

[21] Ishaq M, Chen S, Farooq U, Azam M, Deng H, Su Z H, Zheng Z H, Fan P, Song H S, Liang G X 2020 Sol. RRL 4 2000551

Google Scholar

Google Scholar

[22] Lei H W, Chen J J, Tan Z J, Fang G J 2019 Sol. RRL 3 1900026

Google Scholar

Google Scholar

[23] Cao Y, Liu C Y, Jiang J H, Zhu X Y, Zhou J, Ni J, Zhang J J, Pang J B, Rummeli M H, Zhou J W, Liu H, Cuniberti G 2021 Sol. RRL 5 2000800

Google Scholar

Google Scholar

[24] Yang B, Qin S K, Xue D J, Chen C, He YS, Niu D M, Huang H, Tang J 2017 Prog. Photovolt:Res. Appl. 25 113

Google Scholar

Google Scholar

[25] Wu C Y, Zhang L J, Ding H H, Ju H X, Jin X, Wang X M, Zhu C F, Chen T 2018 Sol. Energy Mater. Sol. Cells 183 52

Google Scholar

Google Scholar

[26] Lu S C, Zhao Y, Wen X X, Xue D J, Chen C, Li K H, Kondrotas R, Wang C, Tang J 2019 Sol. RRL 3 1800280

Google Scholar

Google Scholar

[27] Tang R F, Wang X M, Lian W T, Huang J L, Wei Q, Huang M L, Yin Y W, Jiang C H, Yang S F, Xing G C, Chen S Y, Zhu C F, Hao X J, Green M A, Chen T 2020 Nat. Energy. 5 587

Google Scholar

Google Scholar

[28] Li K H, Lu Y, Ke X X, Li S, Lu S C, Wang C, Wang S Y, Chen C, Tang J 2020 Sol. RRL 4 2000220

Google Scholar

Google Scholar

[29] 曹宇, 祝新运, 陈翰博, 王长刚, 张鑫童, 侯秉东, 申明仁, 周静 2018 67 247301

Google Scholar

Google Scholar

Cao Y, Zhu X X, Chen H B, Wang C G, Zhang X T, Hou B D, Shen M R, Zhou J 2018 Acta Phys. Sin. 67 247301

Google Scholar

Google Scholar

[30] Weng T F, Yan M, Yu X, Qiao Q, Zhou Y T, Li Z H, Wei J, Yu X M 2021 Opt. Mater. 121 111516

Google Scholar

Google Scholar

[31] Wang W H, Wang X M, Chen G L, Chen B W, Cai H L, Chen T, Chen S Y, Huang Z G, Zhu C F, Zhang Y 2018 Sol. RRL 2 1800208

Google Scholar

Google Scholar

[32] Ishaq M, Deng H, Yuan S J, Zhang H, Khan J, Farooq U, Song H S, Tang J 2018 Sol. RRL 2 1800144

Google Scholar

Google Scholar

[33] Gharibshahian I, Orouji A A, Sharbati S 2020 Sol. Energy Mater. Sol. Cells 212 110581

Google Scholar

Google Scholar

[34] Li K H, Kondrotas R, Chen C, Lu S C, Wen X X, Li D B, Luo J J, Zhao Y, Tang J 2018 Sol. Energy 167 10

Google Scholar

Google Scholar

[35] Liu Y M, Sun Y, Rockett A 2012 Sol. Energy Mater. Sol. Cells 98 124

Google Scholar

Google Scholar

[36] Cao Y, Zhu X Y, Chen H B, Zhang X T, Zhou J, Hu Z Y, Pang J B 2019 Sol. Energy Mater. Sol. Cells 200 109945

Google Scholar

Google Scholar

[37] Chen C, Tang J 2020 ACS Energy Lett. 5 2294

Google Scholar

Google Scholar

计量

- 文章访问数: 7166

- PDF下载量: 133

- 被引次数: 0

下载:

下载: