-

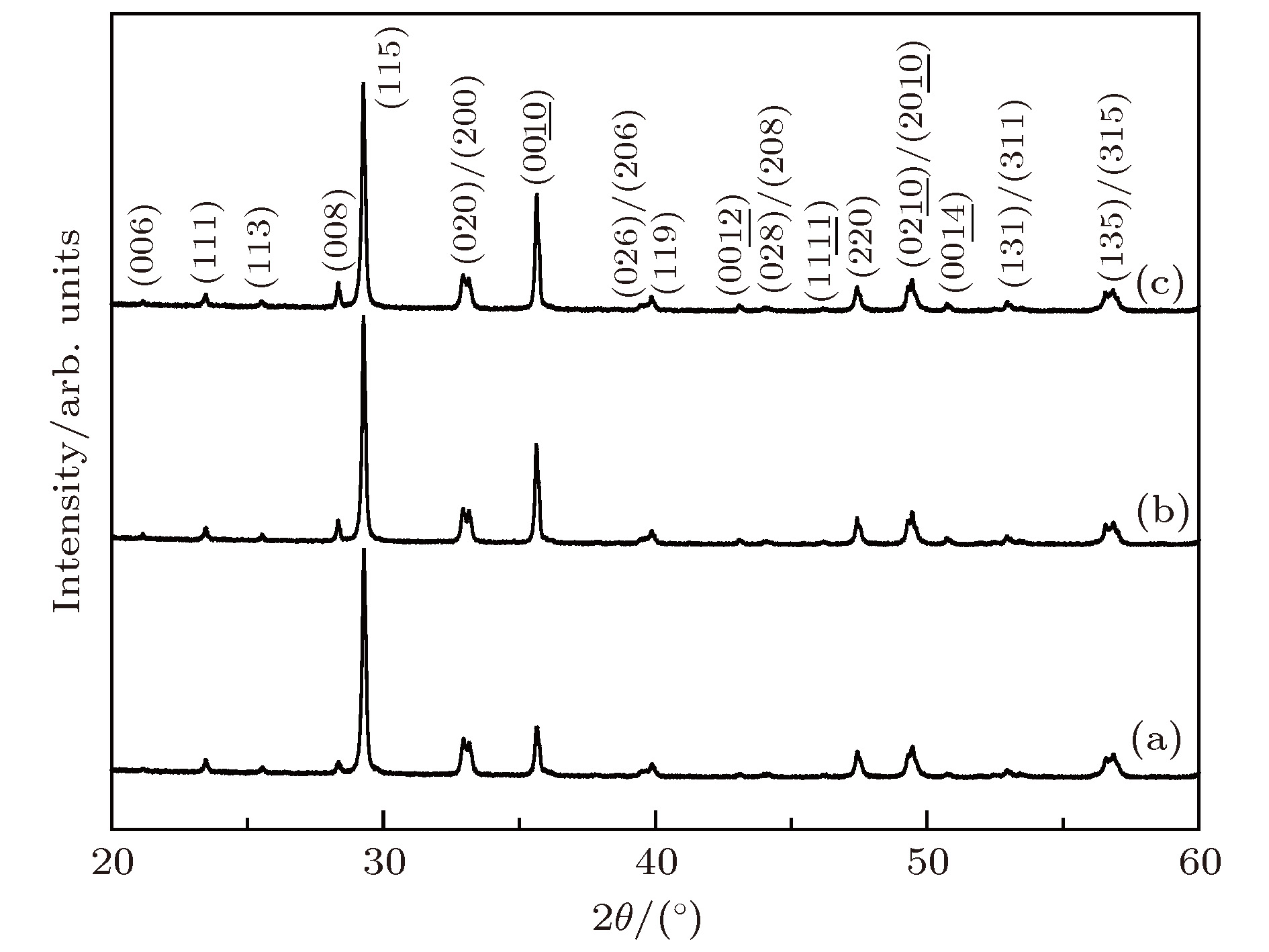

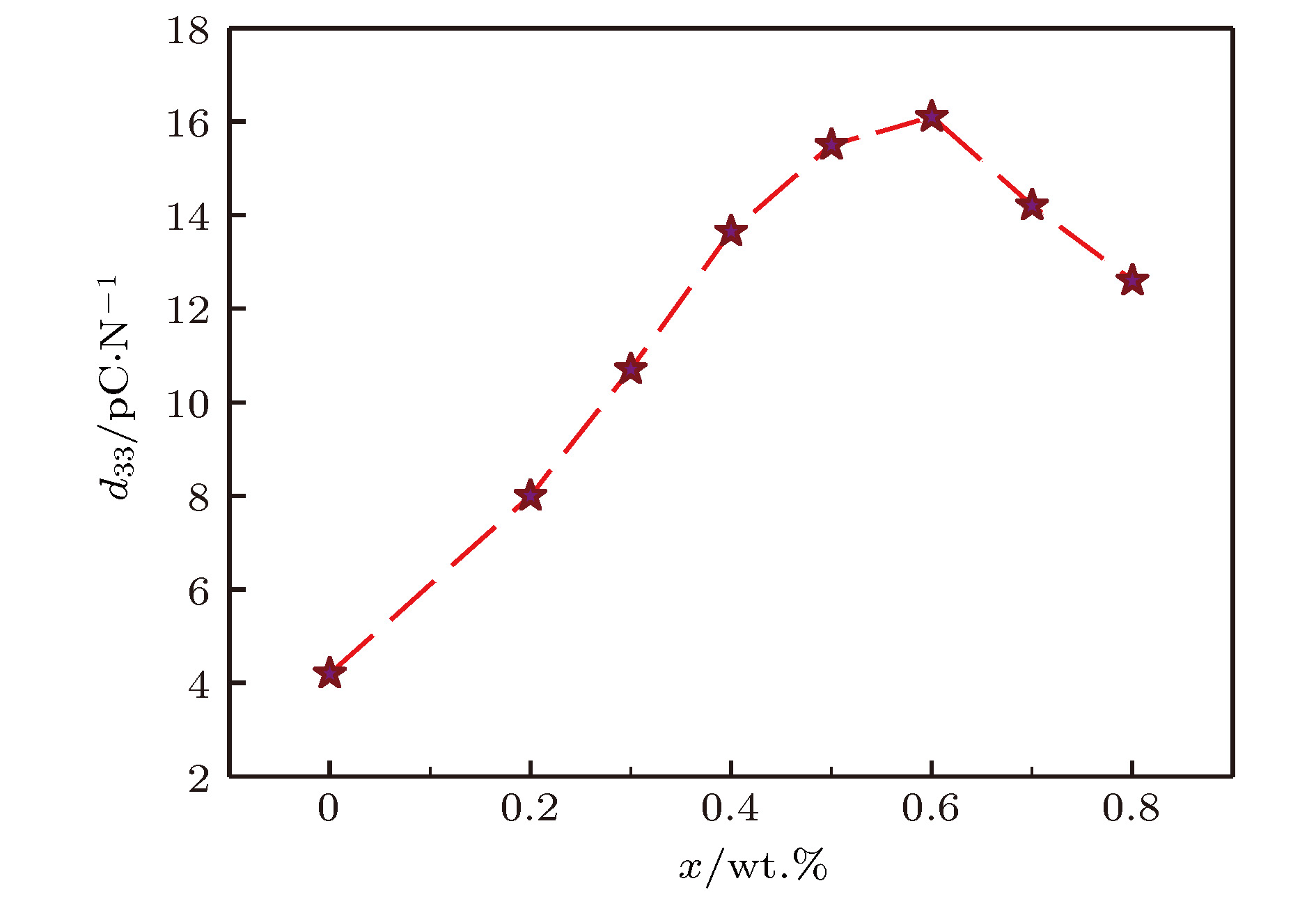

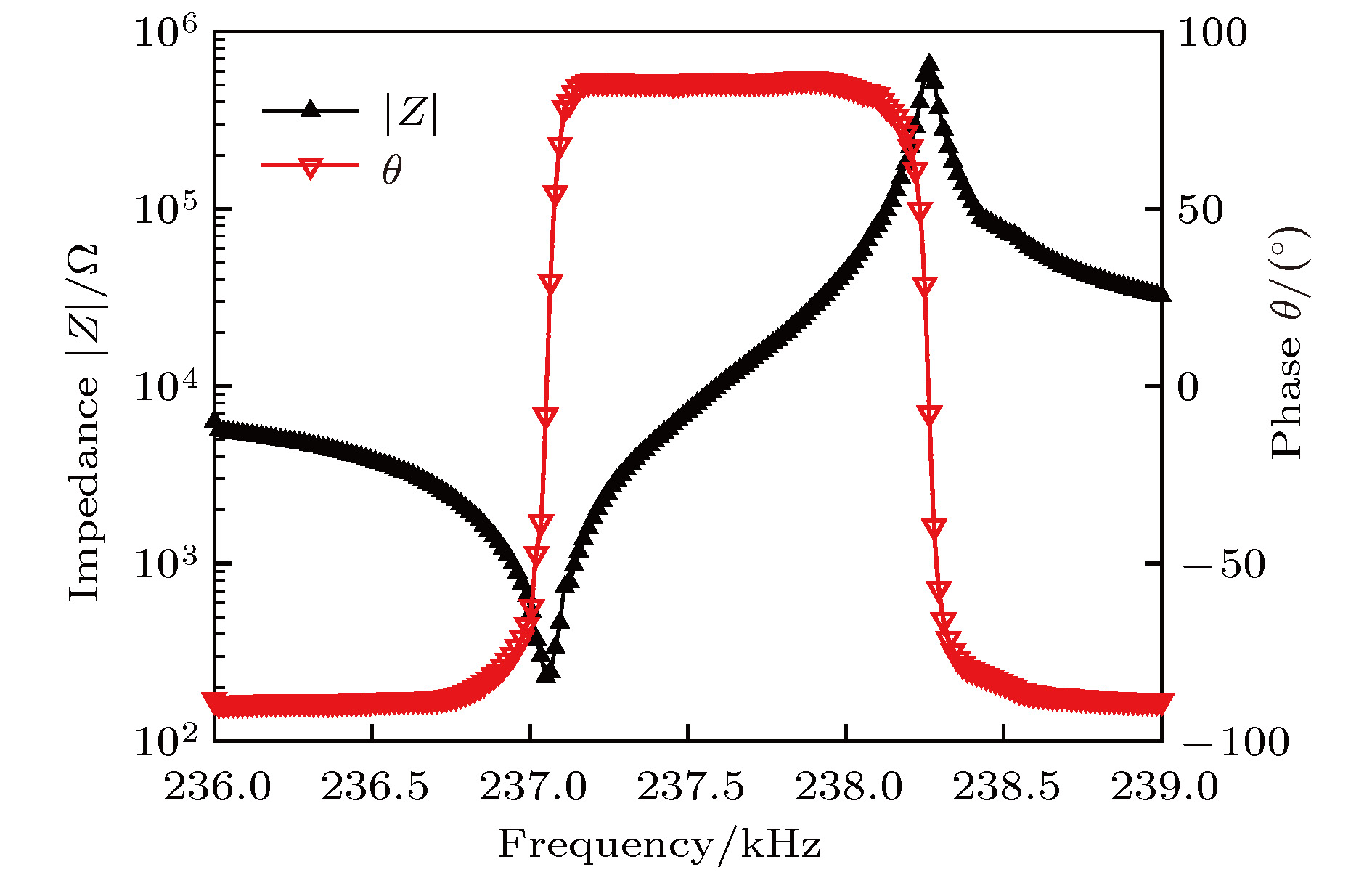

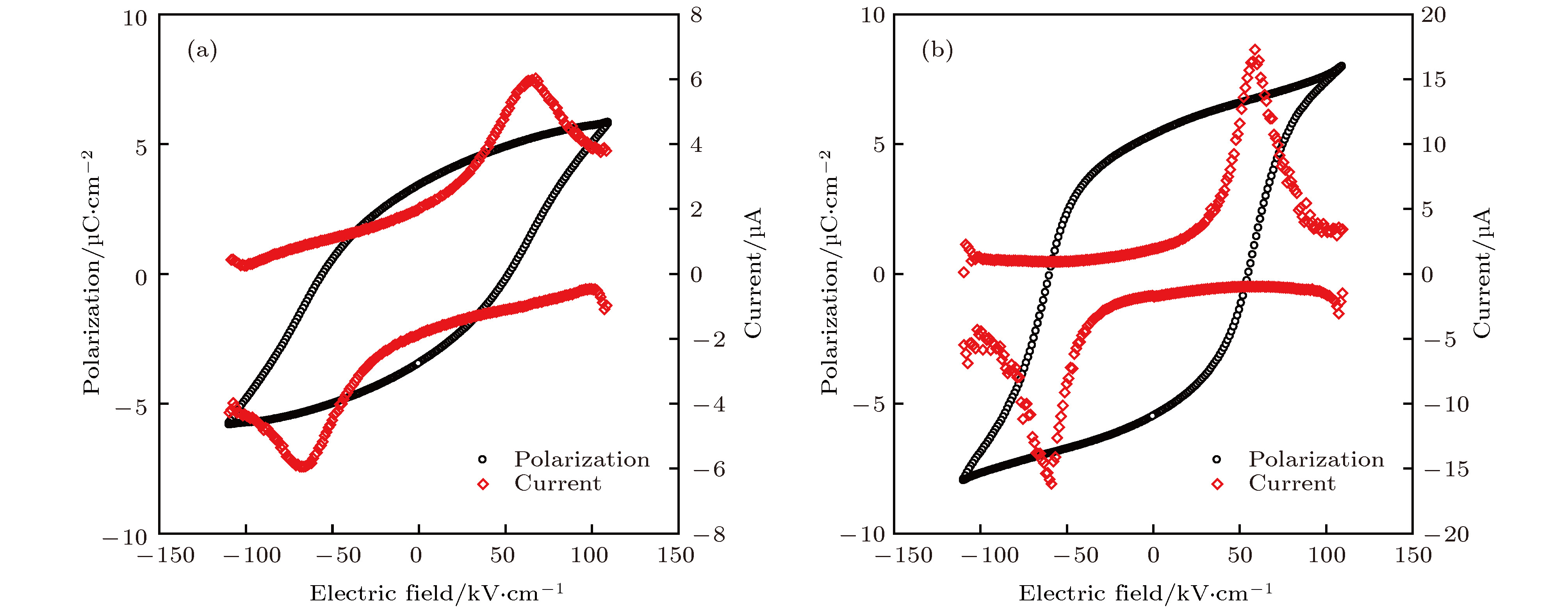

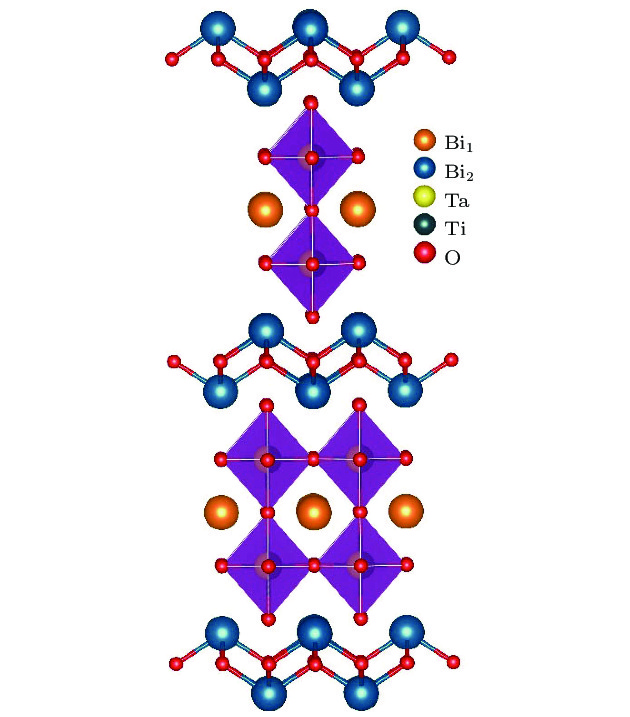

随着现代信息技术的飞速发展, 压电材料的应用范围进一步拓展, 使用的温度环境越来越严苛, 在一些极端环境下对压电材料的服役性能提出了新的挑战. 因此研究具有高居里温度同时具有较强压电性能的压电材料, 是迫切需要解决的问题. 本文利用普通陶瓷工艺制备了高居里温度铋层状结构钛钽酸铋Bi3TiTaO9+x wt.% CeO2 (x = 0—0.8, 简写为BTT-10xCe)压电陶瓷, 研究了钛钽酸铋陶瓷的压电、介电和铁电特性. 压电特性研究表明, 稀土Ce离子的引入可以提高BTT陶瓷的压电性能, BTT-6Ce (x = 0.6)陶瓷具有最大的压电系数d33~16.2 pC/N, 约为纯的BTT陶瓷压电系数(d33~4.2 pC/N)的4倍. 介电特性研究显示, BTT和BTT-6Ce (x = 0.6)陶瓷均具有高的居里温度, TC分别为890 ℃和879 ℃, 同时稀土Ce离子的引入降低了BTT陶瓷的高温介电损耗tanδ. 铁电特性研究表明, 稀土Ce离子的引入提高了BTT陶瓷的极化强度. 在180 ℃温度下和110 kV/cm的电场驱动下, BTT和BTT-6Ce (x = 0.6)陶瓷的矫顽场Ec分别为53.8 kV/cm和57.5 kV/cm, 剩余极化强度Pr分别为3.4 μC/cm2和5.4 μC/cm2. 退火实验显示: 稀土Ce离子组分优化的BTT压电陶瓷经800 ℃的高温退火后, 仍具有优异的压电性能温度稳定性. 研究结果表明, BTT-6Ce (x = 0.6)陶瓷兼具高的居里温度Tc约为879 ℃和强的压电性能d33约为16.2 pC/N、较好的压电性能温度稳定性, 是一类压电性能优异的高温压电陶瓷.Piezoelectric materials have been extensively employed in numerous devices. With the rapid development of modern information technology, the high temperature piezoelectric materials that can work in extreme environments are in great demand. Therefore, it is urgent to investigate piezoelectric materials with high Curie temperature and strong piezoelectric performance. This paper reports the significantly improved piezoelectric properties of high temperature bismuth titanate-tantalate (Bi3TiTaO9, BTT) polycrystalline ceramics. In this work, the rare-earth cerium ions modified Bi3TiTaO9 piezoelectric ceramics are prepared by the conventional ceramic technique. The introduction of Ce ions significantly enhances the piezoelectric performance of BTT ceramics. The BTT-6Ce (BTT+0.6 wt.% CeO2) exhibits optimized piezoelectric properties with a piezoelectric coefficient d33 of 16.2 pC/N, which is four times the value of unmodified BTT (d33~4.2 pC/N). The dielectric and ferroelectric measurements indicate that Ce ions remarkably reduce the dielectric loss tanδ and increase polarizations, which are beneficial to the piezoelectric properties. The BTT and BTT-6Ce (x = 0.6) ceramics each have a high Curie temperature TC: ~890 ℃ and 879 ℃, respectively. The coercive field Ec of BTT and BTT-6Ce ceramics are 53.8 kV/cm and 57.5 kV/cm, respectively, while the remnant polarizations Pr of BTT and BTT-6Ce ceramics are 3.4 μC/cm2 and 5.4 μC/cm2, respectively, at a frequency of 1 Hz, temperature of 180 ℃, and drive field of 110 kV/cm. The thermal annealing measurements indicate that the BTT ceramics still possess stable piezoelectric properties after being annealed at 800 ℃. The results exhibit that the cerium-modified BTT ceramics are good materials for high temperature applications.

-

Keywords:

- bismuth layer-structured ferroelectrics /

- Bi3TiTaO9 /

- piezoelectric ceramics /

- high Curie temperature

[1] 吴金根, 高翔宇, 陈建国, 王春明, 张树君, 董蜀湘 2018 67 207701

Google Scholar

Google Scholar

Wu J G, Gao X Y, Chen J G, Wang C M, Zhang S J, Dong S X 2018 Acta Phys. Sin. 67 207701

Google Scholar

Google Scholar

[2] Zhang S, Yu F 2011 J. Am. Ceram. Soc. 94 3153

Google Scholar

Google Scholar

[3] Zhao T L, Bokov A A, Wu J G, Wang H L, Wang C M, Yu Y, Wang C L, Zeng K, Ye Z G, Dong S X 2019 Adv. Funct. Mater. 29 1807920

Google Scholar

Google Scholar

[4] Zhu X, Fu M, Stennett M C, Vilarinho P M, Levin I, Randall C A, Gardner J, Morrison F D, Reaney I M 2015 Chem. Mater. 27 3250

Google Scholar

Google Scholar

[5] 张丽娜, 赵苏串, 郑嘹赢, 李国荣, 殷庆瑞 2005 54 2346

Google Scholar

Google Scholar

Zhang L N, Zhao S C, Zheng L Y, Li G R, Yin Q R 2005 Acta Phys. Sin. 54 2346

Google Scholar

Google Scholar

[6] 单丹, 朱珺钏, 金灿, 陈小兵 2009 58 7235

Google Scholar

Google Scholar

Shan D, Zhu J C, Jin C, Chen X B 2009 Acta Phys. Sin. 58 7235

Google Scholar

Google Scholar

[7] 孙琳, 褚君浩, 杨平雄, 冯楚德 2009 58 5790

Google Scholar

Google Scholar

Sun L, Chu J H, Yang P X, Feng C D 2009 Acta Phys. Sin. 58 5790

Google Scholar

Google Scholar

[8] Aurivillius B 1949 Ark. Kemi 1 463

[9] Wang C M, Wang J F, Zhang S J, Shrout T R 2009 Phys. Status Solidi (RRL)

3 49  Google Scholar

Google Scholar

[10] Moure A, Pardo L 2005 J. Appl. Phys. 97 084103

Google Scholar

Google Scholar

[11] Muneyasu S, Hajime N, Jin O, Hiroshi F, Tadashi T 2003 Jpn. J. Appl. Phys. 42 6090

Google Scholar

Google Scholar

[12] Noguchi Y, Satoh R, Miyayama M, Kudo T 2001 J. Ceram. Soc. Jpn. 109 29

Google Scholar

Google Scholar

[13] Xie D A N, Zhang Z, Ren T, Liu L 2006 Integr. Ferroelectr. 79 227

Google Scholar

Google Scholar

[14] Suzuki M, Inai S, Tokutsu T, Nagata H, Takenaka T 2007 Ferroelectrics 356 62

Google Scholar

Google Scholar

[15] Nagata H, Itagaki M, Takenaka T 2003 Ferroelectrics 286 85

Google Scholar

Google Scholar

[16] Suzuki M, Nagata H, Funakubo H, Takenaka T 2003 Key Eng. Mater. 248 11

Google Scholar

Google Scholar

[17] Sun Y, Li Z, Zhang H, Yu C, Viola G, Fu S, Koval V, Yan H 2016 Mater. Lett. 175 79

Google Scholar

Google Scholar

[18] Long C, Fan H, Wu Y, Li Y 2014 J. Appl. Phys. 116 074111

Google Scholar

Google Scholar

[19] Long C, Fan H, Li M 2013 Dalton Trans. 42 3561

Google Scholar

Google Scholar

[20] Troyanchuk I O, Karpinsky D V, Bushinsky M V, Mantytskaya O S, Tereshko N V, Shut V N 2011 J. Am. Ceram. Soc. 94 4502

Google Scholar

Google Scholar

[21] Wang C M, Wang J F, Gai Z G 2007 Scripta Mater. 57 789

Google Scholar

Google Scholar

[22] Eitel R E, Randall C A, Shrout T R, Rehrig P W, Hackenberger W, Park S E 2001 Jpn. J. Appl. Phys. 40 5999

Google Scholar

Google Scholar

[23] Shannon R 1976 Acta Cryst. A 32 751

Google Scholar

Google Scholar

[24] Wang C M, Zhao L, Liu Y, Withers R L, Zhang S, Wang Q 2016 Ceram. Int. 42 4268

Google Scholar

Google Scholar

[25] Frit B, Mercurio J P 1992 J. Alloy. Compd. 188 27

Google Scholar

Google Scholar

[26] 许煜寰 1978 铁电与压电材料 (北京: 科学出版社) 第161页

Xu Y H 1978 Ferroelectric and Piezoelectric Materials (Beijing: Science Press) p161 (in Chinese)

[27] Chen J, Cheng J, Dong S 2014 J. Adv. Dielect. 4 1430002

Google Scholar

Google Scholar

[28] Wang C M, Zhang S J, Wang J F, Zhao M L, Wang C L 2009 Mater. Chem. Phys. 118 21

Google Scholar

Google Scholar

[29] Wang Q, Wang C M, Wang J F, Zhang S 2016 Ceram. Int. 42 6993

Google Scholar

Google Scholar

-

表 1 高居里温度(TC~900 ℃)铋层状结构氧化物压电陶瓷的电学性能参数: CaBi2Nb2O9 (CBN), Bi3TiNbO9 (BTN), Bi3TiTaO9 (BTT)

Table 1. Electrical parameters of high Curie temperature (TC~900 ℃) bismuth layer-structured oxide piezoelectric ceramics: CaBi2Nb2O9 (CBN), Bi3TiNbO9 (BTN), Bi3TiTaO9 (BTT)

-

[1] 吴金根, 高翔宇, 陈建国, 王春明, 张树君, 董蜀湘 2018 67 207701

Google Scholar

Google Scholar

Wu J G, Gao X Y, Chen J G, Wang C M, Zhang S J, Dong S X 2018 Acta Phys. Sin. 67 207701

Google Scholar

Google Scholar

[2] Zhang S, Yu F 2011 J. Am. Ceram. Soc. 94 3153

Google Scholar

Google Scholar

[3] Zhao T L, Bokov A A, Wu J G, Wang H L, Wang C M, Yu Y, Wang C L, Zeng K, Ye Z G, Dong S X 2019 Adv. Funct. Mater. 29 1807920

Google Scholar

Google Scholar

[4] Zhu X, Fu M, Stennett M C, Vilarinho P M, Levin I, Randall C A, Gardner J, Morrison F D, Reaney I M 2015 Chem. Mater. 27 3250

Google Scholar

Google Scholar

[5] 张丽娜, 赵苏串, 郑嘹赢, 李国荣, 殷庆瑞 2005 54 2346

Google Scholar

Google Scholar

Zhang L N, Zhao S C, Zheng L Y, Li G R, Yin Q R 2005 Acta Phys. Sin. 54 2346

Google Scholar

Google Scholar

[6] 单丹, 朱珺钏, 金灿, 陈小兵 2009 58 7235

Google Scholar

Google Scholar

Shan D, Zhu J C, Jin C, Chen X B 2009 Acta Phys. Sin. 58 7235

Google Scholar

Google Scholar

[7] 孙琳, 褚君浩, 杨平雄, 冯楚德 2009 58 5790

Google Scholar

Google Scholar

Sun L, Chu J H, Yang P X, Feng C D 2009 Acta Phys. Sin. 58 5790

Google Scholar

Google Scholar

[8] Aurivillius B 1949 Ark. Kemi 1 463

[9] Wang C M, Wang J F, Zhang S J, Shrout T R 2009 Phys. Status Solidi (RRL)

3 49  Google Scholar

Google Scholar

[10] Moure A, Pardo L 2005 J. Appl. Phys. 97 084103

Google Scholar

Google Scholar

[11] Muneyasu S, Hajime N, Jin O, Hiroshi F, Tadashi T 2003 Jpn. J. Appl. Phys. 42 6090

Google Scholar

Google Scholar

[12] Noguchi Y, Satoh R, Miyayama M, Kudo T 2001 J. Ceram. Soc. Jpn. 109 29

Google Scholar

Google Scholar

[13] Xie D A N, Zhang Z, Ren T, Liu L 2006 Integr. Ferroelectr. 79 227

Google Scholar

Google Scholar

[14] Suzuki M, Inai S, Tokutsu T, Nagata H, Takenaka T 2007 Ferroelectrics 356 62

Google Scholar

Google Scholar

[15] Nagata H, Itagaki M, Takenaka T 2003 Ferroelectrics 286 85

Google Scholar

Google Scholar

[16] Suzuki M, Nagata H, Funakubo H, Takenaka T 2003 Key Eng. Mater. 248 11

Google Scholar

Google Scholar

[17] Sun Y, Li Z, Zhang H, Yu C, Viola G, Fu S, Koval V, Yan H 2016 Mater. Lett. 175 79

Google Scholar

Google Scholar

[18] Long C, Fan H, Wu Y, Li Y 2014 J. Appl. Phys. 116 074111

Google Scholar

Google Scholar

[19] Long C, Fan H, Li M 2013 Dalton Trans. 42 3561

Google Scholar

Google Scholar

[20] Troyanchuk I O, Karpinsky D V, Bushinsky M V, Mantytskaya O S, Tereshko N V, Shut V N 2011 J. Am. Ceram. Soc. 94 4502

Google Scholar

Google Scholar

[21] Wang C M, Wang J F, Gai Z G 2007 Scripta Mater. 57 789

Google Scholar

Google Scholar

[22] Eitel R E, Randall C A, Shrout T R, Rehrig P W, Hackenberger W, Park S E 2001 Jpn. J. Appl. Phys. 40 5999

Google Scholar

Google Scholar

[23] Shannon R 1976 Acta Cryst. A 32 751

Google Scholar

Google Scholar

[24] Wang C M, Zhao L, Liu Y, Withers R L, Zhang S, Wang Q 2016 Ceram. Int. 42 4268

Google Scholar

Google Scholar

[25] Frit B, Mercurio J P 1992 J. Alloy. Compd. 188 27

Google Scholar

Google Scholar

[26] 许煜寰 1978 铁电与压电材料 (北京: 科学出版社) 第161页

Xu Y H 1978 Ferroelectric and Piezoelectric Materials (Beijing: Science Press) p161 (in Chinese)

[27] Chen J, Cheng J, Dong S 2014 J. Adv. Dielect. 4 1430002

Google Scholar

Google Scholar

[28] Wang C M, Zhang S J, Wang J F, Zhao M L, Wang C L 2009 Mater. Chem. Phys. 118 21

Google Scholar

Google Scholar

[29] Wang Q, Wang C M, Wang J F, Zhang S 2016 Ceram. Int. 42 6993

Google Scholar

Google Scholar

计量

- 文章访问数: 14818

- PDF下载量: 281

- 被引次数: 0

下载:

下载: