-

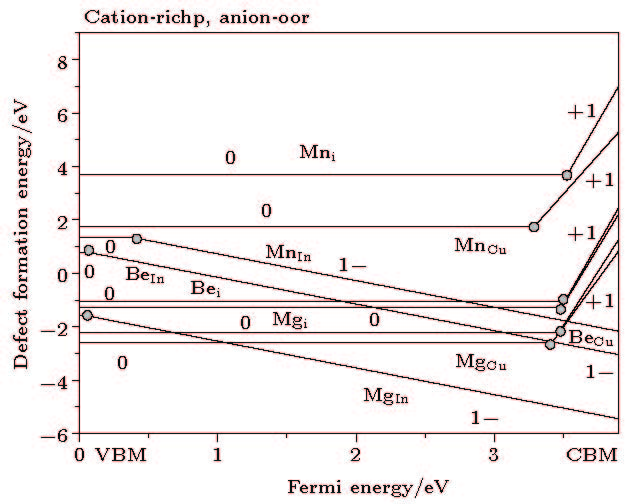

Exploring new type of optoelectronic materials has fundamental scientific and practical significance in the development of society and economy. Recently, intense research has focused on the use of the wide band-gap bipolarity semiconductor material CuInO2 which will allow to the fabrication of that total transparent optoelectronic materials. However, the conductivity of CuInO2 is significantly lower than other n-type conductivity of other TCOs. As a result, one of the key question is how to improve the electric properties of CuInO2 by doping method. Motivated by this observation, in this paper, using the first-principles methods, the formation energetics properties of dopant (Be, Mg, Mn) in transparent conducting oxides CuInO2 were studied within the local-density approximation. Substituting dopant (Be, Mg, Mn) for In, substituting dopant (Be, Mg, Mn) for Cu and dopant as interstitial in their relevant charge state are considered. By systematically calculating formation energies and transition energy level of defect, the calculated results show that, substituting Mg for In does not induce the large structural relaxation. in CuInO2. One can expect that substituting the Mg and Mn for In introduces acceptor because the relative lower formation energies, furthermore, Be atoms would be substitute for In atoms when the Ef move to CBM. In addition, the donor-type extrinsic defects(such as substituting dopant for Cu and dopant as interstitial) have difficulty in inducing n-conductivity in CuInO2 because of their deep transition energy level or the higher formation energies. Considering the transition energy level position, BeIn, MgIn, and MnIn have transition energy levels at 0.06, 0.05, and 0.40 eV above the VBM, respectively. Thus, for all the acceptor-type extrinsic defects, substituting Mg for In is the most prominent doping acceptor with relative shallow transition energy levels in CuInO2 under O-rich condition. Based on our calculated results and discussion mentioned above, in order to increase p-type conductivity in CuInO2, we could substitute Mg atoms for In atoms by the sit-selective doping method through atomic layer epitaxy growth or controlling the oxygen partial pressure in the molecular beam epitaxy or metal-organic chemical vapor deposition crystal growth process. The calculation results will not only provide the guide for design of new type In-based optoelectronic materials, but will also further understand the potential properties in CuInO2.

-

Keywords:

- CuInO2 /

- doping /

- formation energy

[1] Ginley D S, Bright C 2000 MRS Bull. 25 8

[2] Wang L J, Wang W Z, Chen Y L, Yao L Z, Zhao X, Shi H L, Cao M S, Liang Y J 2018 ACS Appl. Mat. Interfaces 10 11652

Google Scholar

Google Scholar

[3] Cao M S, Wang X X, Cao W Q, Fang X Y, Wen B, Yuan J 2018 Small 14 1

[4] Chen Y L, Wang L Y, Wang W Z, Cao M S 2017 Appl. Catal. B 209 110

Google Scholar

Google Scholar

[5] Kawazoe H, Yasukawa M, Hyodo H 1997 Nature 389 939

Google Scholar

Google Scholar

[6] Yanagi H, Inoue S, Ueda K, Kawazoe H, Hosono H 2000 J. Appl. Phys. 88 4159

Google Scholar

Google Scholar

[7] Nakanishi A, Katayama-Yoshida H, Ishikawa T, Shimizu K 2016 J. Phys. Soc. Jpn. 85 094711

Google Scholar

Google Scholar

[8] Jedidi A, Rasul S, Masih D, Cavallo L, Takanabe K 2015 J. Mater. Chem. A 3 19085

Google Scholar

Google Scholar

[9] Nie X, Wei S H, Zhang S B 2002 Phys. Rev. Lett. 88 066405

Google Scholar

Google Scholar

[10] Hamada I, Katayama-Yoshida H 2006 Physsica B 377 808

[11] Jiang H F, Zhu X B, Lei H C, Li G, Yang Z R 2011 Thin Solids Film 519 2559

Google Scholar

Google Scholar

[12] Shimode M, Sasaki M, Mukaida K 2000 J. Soli. Stat. Chem. 151 16

Google Scholar

Google Scholar

[13] Liu Q J, Liu Z T, Feng L P 2010 Physica B 405 2028

Google Scholar

Google Scholar

[14] Singh M, Mehta B R, Varandani D, Singh V N 2009 J. Appl. Phys. 106 053709

Google Scholar

Google Scholar

[15] Ye F, Cai X M, Dai F P, Zhang D P, Fan P, Liu L J 2011 Adv. Mater. Res. 239 242

[16] Shin D, Foord J S, Payne D J 2009 Phys. Rev. B 80 233105

Google Scholar

Google Scholar

[17] Varandani D, Singh B, Mehta B, Singh M, Singh V, Nand G D 2010 J. Appl. Phys. 107 103703

Google Scholar

Google Scholar

[18] Roland G, John R 2011 Phys. Rev. B 84 035125

Google Scholar

Google Scholar

[19] Godinho K G, Morgan B J, Allen J P, Scanlon D O, Watson G W 2011 J. Phys.: Cond. Matter 23 334201

Google Scholar

Google Scholar

[20] Yao Y, Xie G, Song N, Yu X H, Li R X 2011 Adv. Mater. Res. 399 401

[21] Liu L, Bai K W, Gong H, Wu P 2005 Phys. Rev. B 72 125204

Google Scholar

Google Scholar

[22] Blouchl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[23] Kresse G, Joubert J 1999 Phys. Rev. B 59 1758

[24] Hohenberg P, Kohn W 1964 Phys. Rev. B 136 864

Google Scholar

Google Scholar

[25] Kohn W, Sham L J 1965 Phys. Rev. A 140 1133

Google Scholar

Google Scholar

[26] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[27] Kresse G, Furthmüller J 1996 Comp. Mater. Sci. 6 15

Google Scholar

Google Scholar

[28] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[29] Pack J D, Monkhorst H J 1977 Phys. Rev. B 16 1748

Google Scholar

Google Scholar

[30] Murnaghan F D, Natl P 1944 Acad. Sci. USA 30 244

Google Scholar

Google Scholar

[31] Chu S, Hollberg L, Bjorkholm J E, Cable A, Ashkin A 1985 Phys. Rev. Lett. 55 48

Google Scholar

Google Scholar

[32] Wei S H 2004 Comput. Mat. Sci. 30 337

Google Scholar

Google Scholar

-

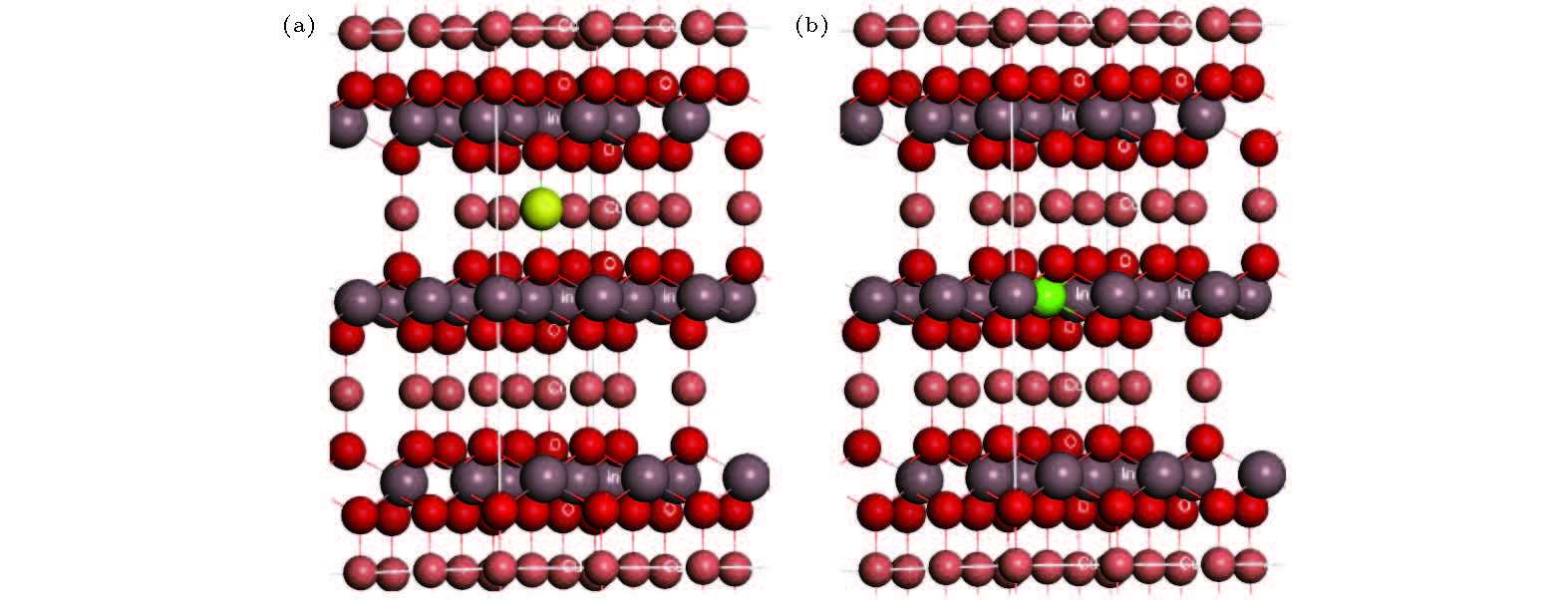

图 1 CuInO2晶体结构图, 图中红色原子为O原子, 灰色原子为In原子, 棕色原子为Cu原子 (a)黄色掺杂原子替代Cu原子的情况; (b)绿色掺杂原子替代In原子的情况

Fig. 1. The crystal structure of the CuInO2, the red atoms are O atoms, the brown atoms are Cu atoms, the purple atoms are In atoms: (a) Substituting yellow dopant atom for Cu atom; (b) substituting green dopant atom for In atom.

表 1 CuInO2晶格常数理论计算值与实验值

Table 1. Theoretical values and experimental values of lattice constants in CuInO2.

CuInO2 晶格常数理论计算值 晶格常数实验值 a 3.297 Å a 3.292 Å c 17.192 Å c 17.388 Å u 0.1047 Å u 0.1061 Å c/a 5.214 c/a 5.282 表 2 掺杂元素周围的弛豫变化情况, 键距后括号为掺杂原子的近邻原子种类和个数

Table 2. The surrounding atoms of dopant, kinds and numbers of dopantxs nearest neighbor atoms in parentheses.

掺杂种类 最近邻键距 掺杂种类 最近邻键距 掺杂种类 最近邻键距 BeCu 1.49 Å(O, 2) MgCu 1.85 Å(O, 2) MnCu 1.77Å(O, 2) BeIn 1.96 Å(O, 6) MgIn 2.12 Å(O, 6) MnIn 1.93Å(O, 6) Bei 1.62 Å(O, 3) Mgi 2.04 Å(O, 3) Mni 1.99Å(O, 3) 表 3 CuInO2的掺杂元素形成能

Table 3. The calculated formation energies of dopants in CuInO2.

掺杂类型 形成能 掺杂类型 总能/eV 形成能 掺杂类型 总能/eV 形成能 BeCu –2.20 MgCu –650.87 –2.58 MnCu –654.63 1.76 BeIn 0.79 MgIn –651.36 –1.59 MnIn –656.54 1.33 Bei –1.05 Mgi –654.27 –1.27 Mni –657.39 3.71 -

[1] Ginley D S, Bright C 2000 MRS Bull. 25 8

[2] Wang L J, Wang W Z, Chen Y L, Yao L Z, Zhao X, Shi H L, Cao M S, Liang Y J 2018 ACS Appl. Mat. Interfaces 10 11652

Google Scholar

Google Scholar

[3] Cao M S, Wang X X, Cao W Q, Fang X Y, Wen B, Yuan J 2018 Small 14 1

[4] Chen Y L, Wang L Y, Wang W Z, Cao M S 2017 Appl. Catal. B 209 110

Google Scholar

Google Scholar

[5] Kawazoe H, Yasukawa M, Hyodo H 1997 Nature 389 939

Google Scholar

Google Scholar

[6] Yanagi H, Inoue S, Ueda K, Kawazoe H, Hosono H 2000 J. Appl. Phys. 88 4159

Google Scholar

Google Scholar

[7] Nakanishi A, Katayama-Yoshida H, Ishikawa T, Shimizu K 2016 J. Phys. Soc. Jpn. 85 094711

Google Scholar

Google Scholar

[8] Jedidi A, Rasul S, Masih D, Cavallo L, Takanabe K 2015 J. Mater. Chem. A 3 19085

Google Scholar

Google Scholar

[9] Nie X, Wei S H, Zhang S B 2002 Phys. Rev. Lett. 88 066405

Google Scholar

Google Scholar

[10] Hamada I, Katayama-Yoshida H 2006 Physsica B 377 808

[11] Jiang H F, Zhu X B, Lei H C, Li G, Yang Z R 2011 Thin Solids Film 519 2559

Google Scholar

Google Scholar

[12] Shimode M, Sasaki M, Mukaida K 2000 J. Soli. Stat. Chem. 151 16

Google Scholar

Google Scholar

[13] Liu Q J, Liu Z T, Feng L P 2010 Physica B 405 2028

Google Scholar

Google Scholar

[14] Singh M, Mehta B R, Varandani D, Singh V N 2009 J. Appl. Phys. 106 053709

Google Scholar

Google Scholar

[15] Ye F, Cai X M, Dai F P, Zhang D P, Fan P, Liu L J 2011 Adv. Mater. Res. 239 242

[16] Shin D, Foord J S, Payne D J 2009 Phys. Rev. B 80 233105

Google Scholar

Google Scholar

[17] Varandani D, Singh B, Mehta B, Singh M, Singh V, Nand G D 2010 J. Appl. Phys. 107 103703

Google Scholar

Google Scholar

[18] Roland G, John R 2011 Phys. Rev. B 84 035125

Google Scholar

Google Scholar

[19] Godinho K G, Morgan B J, Allen J P, Scanlon D O, Watson G W 2011 J. Phys.: Cond. Matter 23 334201

Google Scholar

Google Scholar

[20] Yao Y, Xie G, Song N, Yu X H, Li R X 2011 Adv. Mater. Res. 399 401

[21] Liu L, Bai K W, Gong H, Wu P 2005 Phys. Rev. B 72 125204

Google Scholar

Google Scholar

[22] Blouchl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[23] Kresse G, Joubert J 1999 Phys. Rev. B 59 1758

[24] Hohenberg P, Kohn W 1964 Phys. Rev. B 136 864

Google Scholar

Google Scholar

[25] Kohn W, Sham L J 1965 Phys. Rev. A 140 1133

Google Scholar

Google Scholar

[26] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[27] Kresse G, Furthmüller J 1996 Comp. Mater. Sci. 6 15

Google Scholar

Google Scholar

[28] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[29] Pack J D, Monkhorst H J 1977 Phys. Rev. B 16 1748

Google Scholar

Google Scholar

[30] Murnaghan F D, Natl P 1944 Acad. Sci. USA 30 244

Google Scholar

Google Scholar

[31] Chu S, Hollberg L, Bjorkholm J E, Cable A, Ashkin A 1985 Phys. Rev. Lett. 55 48

Google Scholar

Google Scholar

[32] Wei S H 2004 Comput. Mat. Sci. 30 337

Google Scholar

Google Scholar

计量

- 文章访问数: 18004

- PDF下载量: 986

- 被引次数: 0

下载:

下载: