-

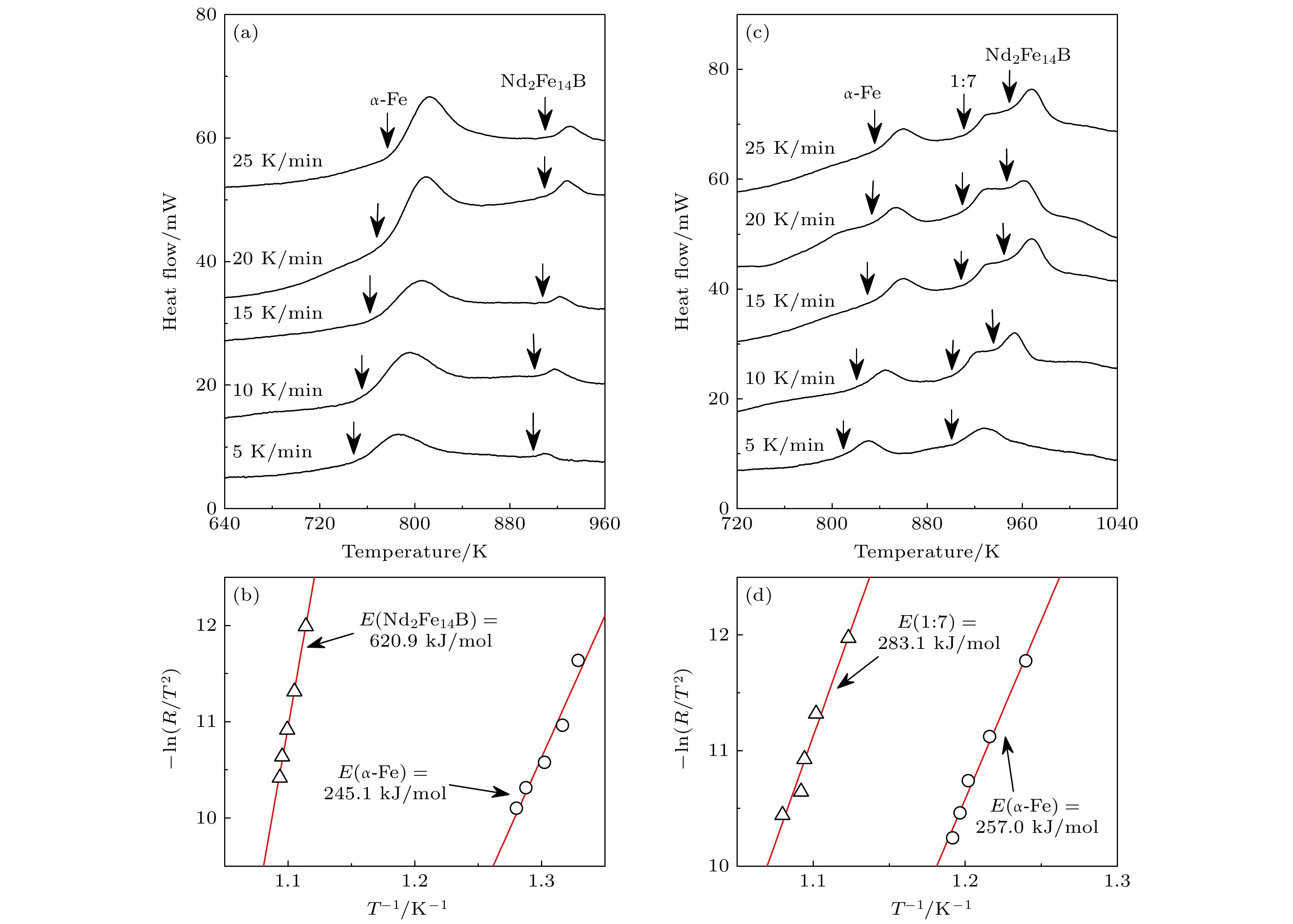

纳米双相复合稀土永磁材料, 利用硬磁相高磁晶各向异性和软磁相高饱和磁化强度的优点, 通过铁磁交换耦合作用获得优异的磁性能. 但是如何解决软硬磁双相纳米微结构不匹配的问题, 控制软硬磁相同时达到理想的纳米尺度复合是关键. 本文研究了掺杂合金元素Ti对熔体快淬法制备的Nd2Fe14B/α-Fe快淬薄带晶化过程的影响. 结果表明, 掺杂合金元素Ti能影响Nd2Fe14B/α-Fe交换耦合磁体整个晶化动力学过程, 使α-Fe相的晶化激活能升高, 抑制其从非晶相中析出. 同时, 降低1∶7亚稳相的晶化激活能, 起到稳定亚稳相的作用. 而且随着晶化温度的进一步提高, α-Fe和Nd2Fe14B两相由1∶7亚稳相分解产生, 从而有效避免了α-Fe相的优先析出. 显微组织观察表明, 掺杂Ti的样品晶粒细小、分布均匀, 平均晶粒尺寸在20 nm左右, 没有特别大的α-Fe粒子出现. 当Ti的掺杂量原子百分数为1.0%时, 获得了最佳磁性能(BH)max = 12 MG·Oe (1 G = 10–4 T, 1 Oe = 79.57795 A/m).Nanocomposite magnet consisting of a fine mixture of magnetically hard and soft phase has received much attention for potential permanent magnet development. One of the important requirements for alloys to exhibit excellent magnetic properties is a nanocrystalline grain size. The soft and hard magnetic phases can simultaneously achieve ideal nanoscale composites. The effect of Ti additions in the amorphous crystallization process of the exchange-coupled nanocomposite Nd2Fe14B/α-Fe magnet prepared by melt spinning is investigated. The results show that Ti can change the crystallization kinetics of the NdFeB melt-spun ribbons. The Ti can increase the activation energy of α-Fe and contrarily reduce the activation energy of a metastable 1∶7 phase, so the growth speed of α-Fe decreases and the metastable 1∶7 phase can stably precipitate from the amorphous phase. When the annealing temperature increases, a metastable 1∶7 phase is decomposed into the α-Fe phase and the Nd2Fe14B phase. The microstructure observation shows that the grains of the alloys doped with Ti are fine and uniform, with an average grain size of about 20 nm, and no particularly large α-Fe particles appear. The optimal magnetic property is (BH)max = 12 MG·Oe (1 G = 10–4 T, 1 Oe = 79.57795 A/m) when Ti addition is 1.0%.

-

Keywords:

- permanent magnet /

- crystallization process /

- doping /

- nanocomposite

[1] Zeng H, Li J, Liu J P, Wang Z L, Sun S 2002 Nature 420 395

Google Scholar

Google Scholar

[2] Liu Z, He J, Ramanujan R V 2021 Mater. Des. 209 110004

Google Scholar

Google Scholar

[3] Quesada A, Granados-Miralles C, López-Ortega A, Erokhin S, Lottini E, Pedrosa J, Bollero A, Aragón A M, Rubio-Marcos F, Stingaciu M, Bertoni G, Fernández C de J, Sangregorio C, Fernández J F, Berkov D, Christensen M 2016 Adv. Electron. Mater. 2 1500365

Google Scholar

Google Scholar

[4] 庞利佳, 孙光飞, 陈菊芳, 强文江, 张锦标, 黎文安 2006 55 3049

Google Scholar

Google Scholar

Pang L J, Sun G F, Chen J F, Qiang W J, Zhang J B, Li W A 2006 Acta Phys. Sin. 55 3049

Google Scholar

Google Scholar

[5] Hernando A, Gonzalez J M 2000 Hyperfine Interact. 130 221

Google Scholar

Google Scholar

[6] 夏静, 张溪超, 赵国平 2013 62 227502

Google Scholar

Google Scholar

Xia J, Zhang X C, Zhao G P 2013 Acta Phys. Sin. 62 227502

Google Scholar

Google Scholar

[7] Yang C J, Park E B 1997 J. Magn. Magn. Mater. 168 278

Google Scholar

Google Scholar

[8] Mohseni F, Pullar R C, Vieira J M, Amaral J S 2020 J. Phys. D:Appl. Phys. 53 494003

Google Scholar

Google Scholar

[9] Kuma J, Kitajima N, Kanai Y, Fukunaga H 1998 J. Appl. Phys. 83 6623

[10] Attyabi S N, Radmanesh S M A, Seyyed Ebrahimi S A, Dehghan H 2022 J. Supercond. Novel Magn. 35 1229

Google Scholar

Google Scholar

[11] Skomski R, Coey J M D 1993 Phys. Rev. B 48 15812

Google Scholar

Google Scholar

[12] Bauer J, Seager M, Zerm A, Kronmüller H 1996 J. Appl. Phys. 80 1667

Google Scholar

Google Scholar

[13] Deng W K, Wei B N, Shan W K, Hua Y X, Li X, Guo D F 2021 Physica B 620 413263

Google Scholar

Google Scholar

[14] Ma Y, Yin X, Shao B, Yang Q, Shen Q, Zhou X, Sun J, Guo D, Li K 2019 J. Mater. Sci. 54 2658

Google Scholar

Google Scholar

[15] Yang S, Song X P, Li S, Liu X, Tian Z, Gu B, Du Y 2003 J. Magn. Magn. Mater. 263 134

[16] Ngo H M, Lee G, Haider S K, Pal U, Hawari T, Kim K M, Kim J, Kwon H, Kang Y S 2021 RSC Adv. 11 32376

Google Scholar

Google Scholar

[17] Kim C, Ding S L, O Y J, Zha L, Yun C, Yang W Y, Han J Z, Liu S Q, Du H L, Wang C S, Yang J B 2021 J. Phys. D:Appl. Phys. 54 245003

Google Scholar

Google Scholar

[18] 何学敏, 钟伟, 都有为 2018 67 227501

Google Scholar

Google Scholar

He X M, Zhong W, Du Y W 2018 Acta Phys. Sin. 67 227501

Google Scholar

Google Scholar

[19] Semaida A M, Bordyuzhin I G, El-Dek S I, Kutzhanov M K, Menushenkov V P, Savchenko A G 2021 Mater. Res. Express 8 076101

Google Scholar

Google Scholar

[20] Wang Y, Song W, Huang G 2022 J. Supercond. Novel Magn. 35 1261

Google Scholar

Google Scholar

[21] Pan M, Li Z, Wu Q, Ge H, Xu H 2019 J. Magn. Magn. Mater. 471 457

Google Scholar

Google Scholar

[22] Zhang S Y, Xu H, Ni J S, Wang H L, Hou X L, Dong Y D 2007 Physica B 393 153

Google Scholar

Google Scholar

[23] Zhang W, Zhang S, Yan A, Zhang H, Shen B 2001 J. Magn. Magn. Mater. 225 389

Google Scholar

Google Scholar

[24] Yang S, Song X, Gu B, Du Y 2005 J. Alloys Compd. 394 1

Google Scholar

Google Scholar

[25] Hono K, Ping D H, Ohnuma M, Onodera H 1999 Acta Mater. 47 997

Google Scholar

Google Scholar

[26] Ping D H, Hono K, Kanekiyo H, Hirosawa S 1999 Acta Mater. 47 4641

Google Scholar

Google Scholar

[27] Yang S, Song X, Du Y 2003 Microelectron. Eng. 66 121

Google Scholar

Google Scholar

[28] Kelly P E, O’Grady K, Chantrell R W 1989 IEEE Trans. Magn. 25 3881

Google Scholar

Google Scholar

[29] Wohlfarth E P 1958 J. Appl. Phys. 29 595

-

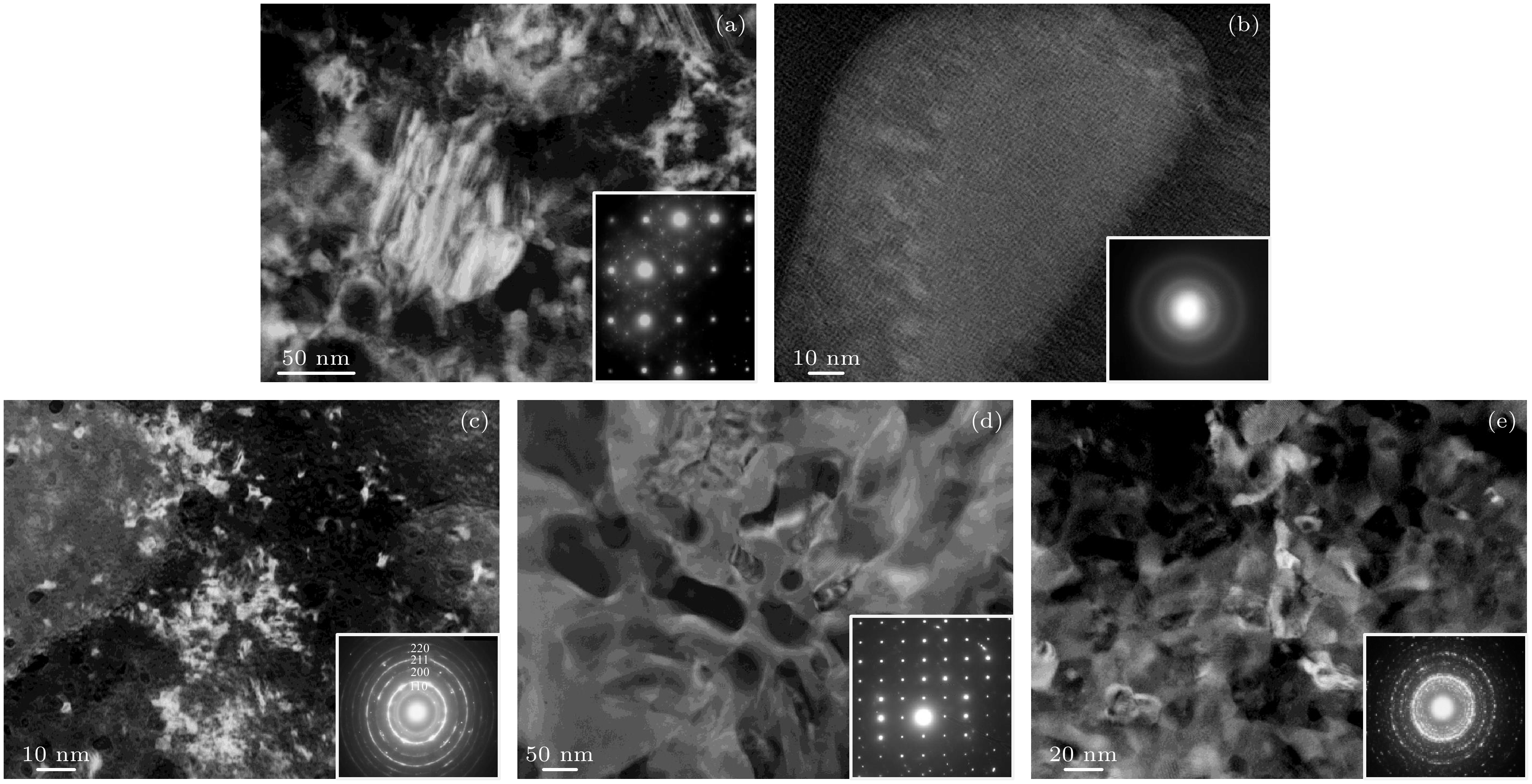

图 3 (a) Nd8Fe86B6合金快淬带650 ℃晶化10 min后局部TEM图谱; Nd8Fe85Ti1B6合金快淬带在不同温度下晶化3 min后的TEM图谱 (b) 快淬; (c) 600 ℃; (d) 650 ℃; (e) 700 ℃. 插图为对应的高分辨电子衍射谱

Fig. 3. TEM micrographs of (a) Nd8Fe86B6 ribbons annealed at 650 ℃ for 10 min, and Nd8Fe85Ti1B6 ribbons annealed at different temperature for 3 min: (b) as-spun; (c) 600 ℃; (d) 650 ℃; (e) 700 ℃. The insets are the corresponding electron diffraction patterns.

-

[1] Zeng H, Li J, Liu J P, Wang Z L, Sun S 2002 Nature 420 395

Google Scholar

Google Scholar

[2] Liu Z, He J, Ramanujan R V 2021 Mater. Des. 209 110004

Google Scholar

Google Scholar

[3] Quesada A, Granados-Miralles C, López-Ortega A, Erokhin S, Lottini E, Pedrosa J, Bollero A, Aragón A M, Rubio-Marcos F, Stingaciu M, Bertoni G, Fernández C de J, Sangregorio C, Fernández J F, Berkov D, Christensen M 2016 Adv. Electron. Mater. 2 1500365

Google Scholar

Google Scholar

[4] 庞利佳, 孙光飞, 陈菊芳, 强文江, 张锦标, 黎文安 2006 55 3049

Google Scholar

Google Scholar

Pang L J, Sun G F, Chen J F, Qiang W J, Zhang J B, Li W A 2006 Acta Phys. Sin. 55 3049

Google Scholar

Google Scholar

[5] Hernando A, Gonzalez J M 2000 Hyperfine Interact. 130 221

Google Scholar

Google Scholar

[6] 夏静, 张溪超, 赵国平 2013 62 227502

Google Scholar

Google Scholar

Xia J, Zhang X C, Zhao G P 2013 Acta Phys. Sin. 62 227502

Google Scholar

Google Scholar

[7] Yang C J, Park E B 1997 J. Magn. Magn. Mater. 168 278

Google Scholar

Google Scholar

[8] Mohseni F, Pullar R C, Vieira J M, Amaral J S 2020 J. Phys. D:Appl. Phys. 53 494003

Google Scholar

Google Scholar

[9] Kuma J, Kitajima N, Kanai Y, Fukunaga H 1998 J. Appl. Phys. 83 6623

[10] Attyabi S N, Radmanesh S M A, Seyyed Ebrahimi S A, Dehghan H 2022 J. Supercond. Novel Magn. 35 1229

Google Scholar

Google Scholar

[11] Skomski R, Coey J M D 1993 Phys. Rev. B 48 15812

Google Scholar

Google Scholar

[12] Bauer J, Seager M, Zerm A, Kronmüller H 1996 J. Appl. Phys. 80 1667

Google Scholar

Google Scholar

[13] Deng W K, Wei B N, Shan W K, Hua Y X, Li X, Guo D F 2021 Physica B 620 413263

Google Scholar

Google Scholar

[14] Ma Y, Yin X, Shao B, Yang Q, Shen Q, Zhou X, Sun J, Guo D, Li K 2019 J. Mater. Sci. 54 2658

Google Scholar

Google Scholar

[15] Yang S, Song X P, Li S, Liu X, Tian Z, Gu B, Du Y 2003 J. Magn. Magn. Mater. 263 134

[16] Ngo H M, Lee G, Haider S K, Pal U, Hawari T, Kim K M, Kim J, Kwon H, Kang Y S 2021 RSC Adv. 11 32376

Google Scholar

Google Scholar

[17] Kim C, Ding S L, O Y J, Zha L, Yun C, Yang W Y, Han J Z, Liu S Q, Du H L, Wang C S, Yang J B 2021 J. Phys. D:Appl. Phys. 54 245003

Google Scholar

Google Scholar

[18] 何学敏, 钟伟, 都有为 2018 67 227501

Google Scholar

Google Scholar

He X M, Zhong W, Du Y W 2018 Acta Phys. Sin. 67 227501

Google Scholar

Google Scholar

[19] Semaida A M, Bordyuzhin I G, El-Dek S I, Kutzhanov M K, Menushenkov V P, Savchenko A G 2021 Mater. Res. Express 8 076101

Google Scholar

Google Scholar

[20] Wang Y, Song W, Huang G 2022 J. Supercond. Novel Magn. 35 1261

Google Scholar

Google Scholar

[21] Pan M, Li Z, Wu Q, Ge H, Xu H 2019 J. Magn. Magn. Mater. 471 457

Google Scholar

Google Scholar

[22] Zhang S Y, Xu H, Ni J S, Wang H L, Hou X L, Dong Y D 2007 Physica B 393 153

Google Scholar

Google Scholar

[23] Zhang W, Zhang S, Yan A, Zhang H, Shen B 2001 J. Magn. Magn. Mater. 225 389

Google Scholar

Google Scholar

[24] Yang S, Song X, Gu B, Du Y 2005 J. Alloys Compd. 394 1

Google Scholar

Google Scholar

[25] Hono K, Ping D H, Ohnuma M, Onodera H 1999 Acta Mater. 47 997

Google Scholar

Google Scholar

[26] Ping D H, Hono K, Kanekiyo H, Hirosawa S 1999 Acta Mater. 47 4641

Google Scholar

Google Scholar

[27] Yang S, Song X, Du Y 2003 Microelectron. Eng. 66 121

Google Scholar

Google Scholar

[28] Kelly P E, O’Grady K, Chantrell R W 1989 IEEE Trans. Magn. 25 3881

Google Scholar

Google Scholar

[29] Wohlfarth E P 1958 J. Appl. Phys. 29 595

计量

- 文章访问数: 5842

- PDF下载量: 92

- 被引次数: 0

下载:

下载: