-

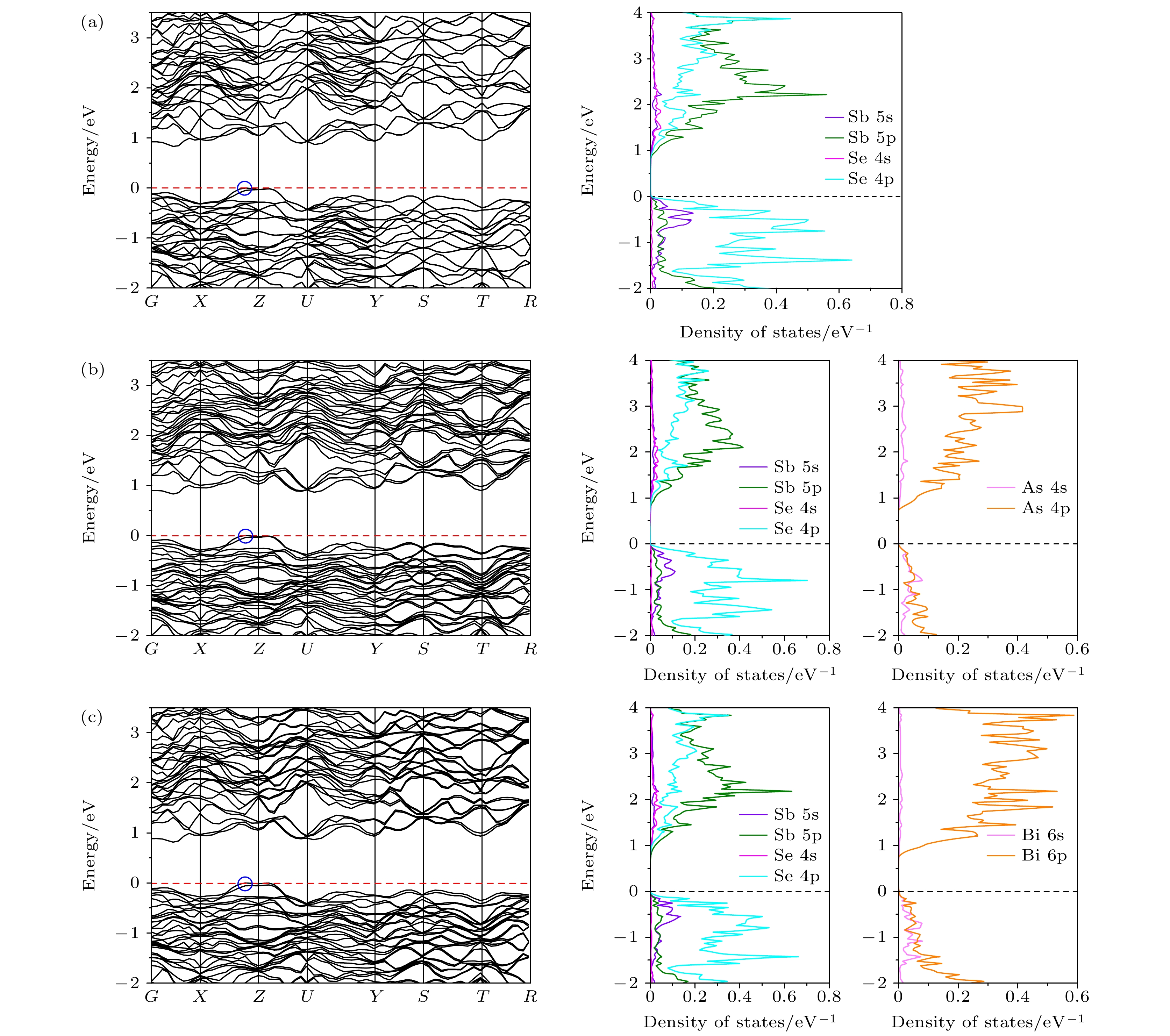

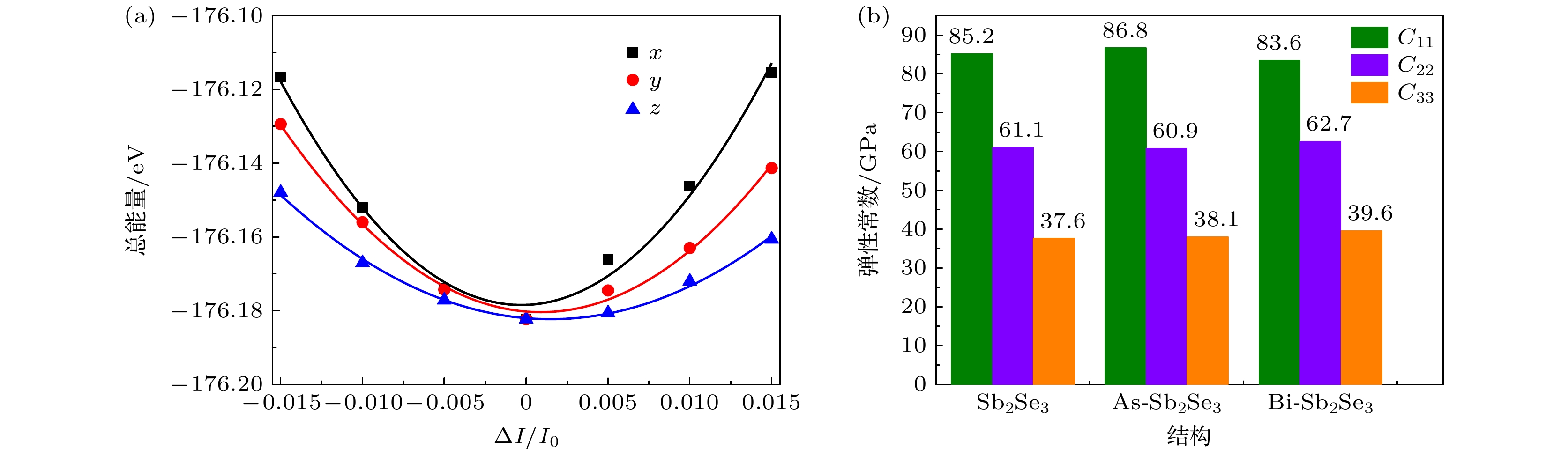

硒化锑(Sb2Se3)是一种元素丰富、经济且无毒的太阳电池吸收层材料. 太阳电池的性能在很大程度上取决于载流子的传输特性, 然而在Sb2Se3中, 这些特性尚未得到很好的理解. 通过密度泛函理论和形变势理论, 本文对纯Sb2Se3以及掺杂了As, Bi的Sb2Se3的空穴传输特性进行研究, 计算并分析了影响迁移率的3个关键参数: 有效质量、形变势和弹性常数. 结果显示, 有效质量对迁移率具有最大影响, 掺杂Bi的Sb2Se3表现出最高的平均迁移率. 同时发现, Sb2Se3的空穴迁移率呈现出明显的各向异性, 其中x方向的迁移率远高于y, z方向, 这应该与x方向的原子主要以较强的共价键连接, 而y, z方向以较弱的范德瓦耳斯力连接有关. 载流子传输能力强的方向有助于有效传输和收集光生载流子, 本研究从理论上强调了控制Sb2Se3沿特定方向生长的重要性.Antimony selenide (Sb2Se3) is an element-rich, cost-effective, and non-toxic material used as an absorber layer in solar cells. The performance of solar cells is significantly influenced by the transport characteristics of charge carriers. However, these characteristics in Sb2Se3 have not been well understood. In this work, through density functional theory and deformation potential theory, we investigate the hole transport properties of pure Sb2Se3 and As-, Bi-doped Sb2Se3. The incorporation of as element and Bi element does not introduce additional impurity levels within the band gap. However, the band gaps are reduced in both As-Sb2Se3 and Bi-Sb2Se3 due to the band shifts of energy levels. This phenomenon is primarily attributed to the interactions between the unoccupied 4p and 6p states of the doping atoms and the unoccupied 4p states of Se atoms, as well as the unoccupied 5p states of Sb atoms. In this study, we calculate and analyze three key parameters affecting mobility: effective mass, deformation potential, and elastic constants. The results indicate that effective mass has the greatest influence on mobility, with Bi-Sb2Se3 exhibiting the highest average mobility. The average effective mass is highest in As-Sb2Se3 and lowest in Bi-Sb2Se3. The elastic constants of the As- and Bi-doped Sb2Se3 structures show minimal differences compared with that of the intrinsic Sb2Se3 structure. By comparing the intrinsic, As-doped, and Bi-doped Sb2Se3, it is evident that doping has a minor influence on deformation potential energy along various directions. The study reveals that the hole mobility in Sb2Se3 displays significant anisotropy, with higher mobilities observed in the x-direction and the y-direction than in the z-direction. This discrepancy is attributed to stronger covalent bonding primarily in the x- and y-direction, while in the z-direction weaker van der Waals forces is dominant. The directions with enhanced charge carrier transport capability contribute to efficient transfer and collection of photo-generated charge carriers. Therefore, our research theoretically underscores the significance of controlling the growth of antimony selenide along specific directions.

-

Keywords:

- Sb2Se3 /

- mobility /

- deformation potential /

- doping

[1] Chen C, Li K H, Tang J 2022 Sol. RRL 6 2200094

Google Scholar

Google Scholar

[2] Zhang X, Li C, Sun K, Zhou J, Zhang Z 2021 Adv. Energy Mater. 11 2002614

Google Scholar

Google Scholar

[3] 薛丁江, 石杭杰, 唐江 2015 64 038406

Google Scholar

Google Scholar

Xue D J, Shi H J, Tang J 2015 Acta Phys. Sin. 64 038406

Google Scholar

Google Scholar

[4] Zhao Y, Wang S, Li C, Che B, Chen X, Chen H, Tang R, Wang X, Chen G, Wang T, Gong J, Chen T, Xiao X 2022 Energy Environ. Sci. 15 5118

Google Scholar

Google Scholar

[5] Li Z, Liang X, Li G, Liu H, Zhang H, Guo J, Chen J, Shen K, San X, Yu W, Schropp R, Mai Y 2019 Nat. Commun. 10 125

Google Scholar

Google Scholar

[6] Wang X, Ganose A M, Kavanagh S R, Walsh A 2022 ACS Energy Lett. 7 2954

Google Scholar

Google Scholar

[7] Spaggiari G, Bersani D, Calestani D, Gilioli E, Gombia E, Mezzadri F, Casappa M, Pattini F, Trevisi G, Rampino S 2022 Int. J. Mol. Sci. 23 15529

Google Scholar

Google Scholar

[8] Huang M, Lu S, Li K, Lu Y, Chen C, Tang J, Chen S 2022 Sol. RRL 6 2100730

Google Scholar

Google Scholar

[9] Liang G, Chen X, Ren D, Jiang X, Tang R, Zheng Z, Su Z, Fan P, Zhang X, Zhang Y, Chen S 2021 J. Materiomics 7 1324

Google Scholar

Google Scholar

[10] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[11] Vadapoo R, Krishnan S, Yilmaz H, Marin C 2011 Phys. Status Solidi B 248 700

Google Scholar

Google Scholar

[12] Bardekn J, Shockley W 1950 Phys. Rev. 80 72

Google Scholar

Google Scholar

[13] Xi J, Long M, Tang L, Wang D, Shuai Z 2012 Nanoscale 4 4348

Google Scholar

Google Scholar

[14] El-Sayad E A, Moustafa A M, Marzouk S Y 2009 Physica B 404 1119

Google Scholar

Google Scholar

[15] Zheng X, Xie Y, Zhu L, Jiang X, Jia Y, Song W, Sun Y 2002 Inorg. Chem. 41 455

Google Scholar

Google Scholar

[16] Effective Mass Calculator for Semiconductors, Fonari A, Sutton C https://github.com/afonari/emc [2013-3-18

[17] Zhang B, Qian X 2022 ACS Appl. Energy Mater. 5 492

Google Scholar

Google Scholar

[18] Wang X, Li Z, Kavanagh S R, Ganose A M, Walsh A 2022 Phys. Chem. Chem. Phys. 24 7195

Google Scholar

Google Scholar

[19] Wang V, Xu N, Liu J C, Tang G, Geng W T 2021 Comput. Phys. Commun. 267 108033

Google Scholar

Google Scholar

[20] Silva E Lora da, Skelton J M, Rodríguez-Hernández P, Muõz A, Santo M C, Martínez-García D, Vilaplana R, Manjón F J 2022 J. Mater. Chem. C 10 15061

Google Scholar

Google Scholar

[21] Zhou Y, Leng M, Xia Z, Zhong J, Song H, Liu X, Yang B, Zhang J, Chen J, Zhou K 2014 Adv. Energy Mater. 4 1301846

Google Scholar

Google Scholar

[22] Madelung O 1996 Semiconductor: Data Handbook (2rd Ed.) (New York: Springer-Verlag Berlin Heidelbergy) p204

[23] Black J, Conwell E, Seigle L, Spencer C 1957 J. Phys. Chem. Solids 2 240

Google Scholar

Google Scholar

[24] Cheng L, Liu Y 2018 J. Am. Chem. Soc. 140 17895

Google Scholar

Google Scholar

-

图 4 (a)本征Sb2Se3在3个不同方向应变下的价带边缘位置, 实线是线性拟合, 其决定了形变势; (b)不同结构的形变势能

Fig. 4. (a) Valence band edge positions of intrinsic Sb2Se3 under strain along three different directions, solid lines represent linear fitting, determining the deformation potential; (b) calculated deformation potential energies of different structures.

表 1 优化后的晶格参数

Table 1. Optimized lattice parameters.

表 2 不同Sb2Se3结构的空穴有效质量

Table 2. Effective mass of holes for different structures of Sb2Se3.

m*/m0 Sb2Se3 As-Sb2Se3 Bi-Sb2Se3 $ {m}_{xx}^{*} $ 0.43 0.45 0.42 $ {m}_{yy}^{*} $ 0.88 0.89 0.67 $ {m}_{zz}^{*} $ 1.08 1.22 1.61 $ {\stackrel{-}{m}}^{*} $ 0.68 0.72 0.67 表 3 三种结构的空穴迁移率

Table 3. Hole mobility of Sb2Se3, As-Sb2Se3 and Bi-Sb2Se3 along three principle directions.

迁移率/(cm2·V–1·s–1) Sb2Se3 As-Sb2Se3 Bi-Sb2Se3 μx 232.62 221.59 240.66 μy 32.78 31.20 66.71 μz 20.02 15.11 8.04 μavg 95.14 89.30 105.13 -

[1] Chen C, Li K H, Tang J 2022 Sol. RRL 6 2200094

Google Scholar

Google Scholar

[2] Zhang X, Li C, Sun K, Zhou J, Zhang Z 2021 Adv. Energy Mater. 11 2002614

Google Scholar

Google Scholar

[3] 薛丁江, 石杭杰, 唐江 2015 64 038406

Google Scholar

Google Scholar

Xue D J, Shi H J, Tang J 2015 Acta Phys. Sin. 64 038406

Google Scholar

Google Scholar

[4] Zhao Y, Wang S, Li C, Che B, Chen X, Chen H, Tang R, Wang X, Chen G, Wang T, Gong J, Chen T, Xiao X 2022 Energy Environ. Sci. 15 5118

Google Scholar

Google Scholar

[5] Li Z, Liang X, Li G, Liu H, Zhang H, Guo J, Chen J, Shen K, San X, Yu W, Schropp R, Mai Y 2019 Nat. Commun. 10 125

Google Scholar

Google Scholar

[6] Wang X, Ganose A M, Kavanagh S R, Walsh A 2022 ACS Energy Lett. 7 2954

Google Scholar

Google Scholar

[7] Spaggiari G, Bersani D, Calestani D, Gilioli E, Gombia E, Mezzadri F, Casappa M, Pattini F, Trevisi G, Rampino S 2022 Int. J. Mol. Sci. 23 15529

Google Scholar

Google Scholar

[8] Huang M, Lu S, Li K, Lu Y, Chen C, Tang J, Chen S 2022 Sol. RRL 6 2100730

Google Scholar

Google Scholar

[9] Liang G, Chen X, Ren D, Jiang X, Tang R, Zheng Z, Su Z, Fan P, Zhang X, Zhang Y, Chen S 2021 J. Materiomics 7 1324

Google Scholar

Google Scholar

[10] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[11] Vadapoo R, Krishnan S, Yilmaz H, Marin C 2011 Phys. Status Solidi B 248 700

Google Scholar

Google Scholar

[12] Bardekn J, Shockley W 1950 Phys. Rev. 80 72

Google Scholar

Google Scholar

[13] Xi J, Long M, Tang L, Wang D, Shuai Z 2012 Nanoscale 4 4348

Google Scholar

Google Scholar

[14] El-Sayad E A, Moustafa A M, Marzouk S Y 2009 Physica B 404 1119

Google Scholar

Google Scholar

[15] Zheng X, Xie Y, Zhu L, Jiang X, Jia Y, Song W, Sun Y 2002 Inorg. Chem. 41 455

Google Scholar

Google Scholar

[16] Effective Mass Calculator for Semiconductors, Fonari A, Sutton C https://github.com/afonari/emc [2013-3-18

[17] Zhang B, Qian X 2022 ACS Appl. Energy Mater. 5 492

Google Scholar

Google Scholar

[18] Wang X, Li Z, Kavanagh S R, Ganose A M, Walsh A 2022 Phys. Chem. Chem. Phys. 24 7195

Google Scholar

Google Scholar

[19] Wang V, Xu N, Liu J C, Tang G, Geng W T 2021 Comput. Phys. Commun. 267 108033

Google Scholar

Google Scholar

[20] Silva E Lora da, Skelton J M, Rodríguez-Hernández P, Muõz A, Santo M C, Martínez-García D, Vilaplana R, Manjón F J 2022 J. Mater. Chem. C 10 15061

Google Scholar

Google Scholar

[21] Zhou Y, Leng M, Xia Z, Zhong J, Song H, Liu X, Yang B, Zhang J, Chen J, Zhou K 2014 Adv. Energy Mater. 4 1301846

Google Scholar

Google Scholar

[22] Madelung O 1996 Semiconductor: Data Handbook (2rd Ed.) (New York: Springer-Verlag Berlin Heidelbergy) p204

[23] Black J, Conwell E, Seigle L, Spencer C 1957 J. Phys. Chem. Solids 2 240

Google Scholar

Google Scholar

[24] Cheng L, Liu Y 2018 J. Am. Chem. Soc. 140 17895

Google Scholar

Google Scholar

计量

- 文章访问数: 4491

- PDF下载量: 119

- 被引次数: 0

下载:

下载: