-

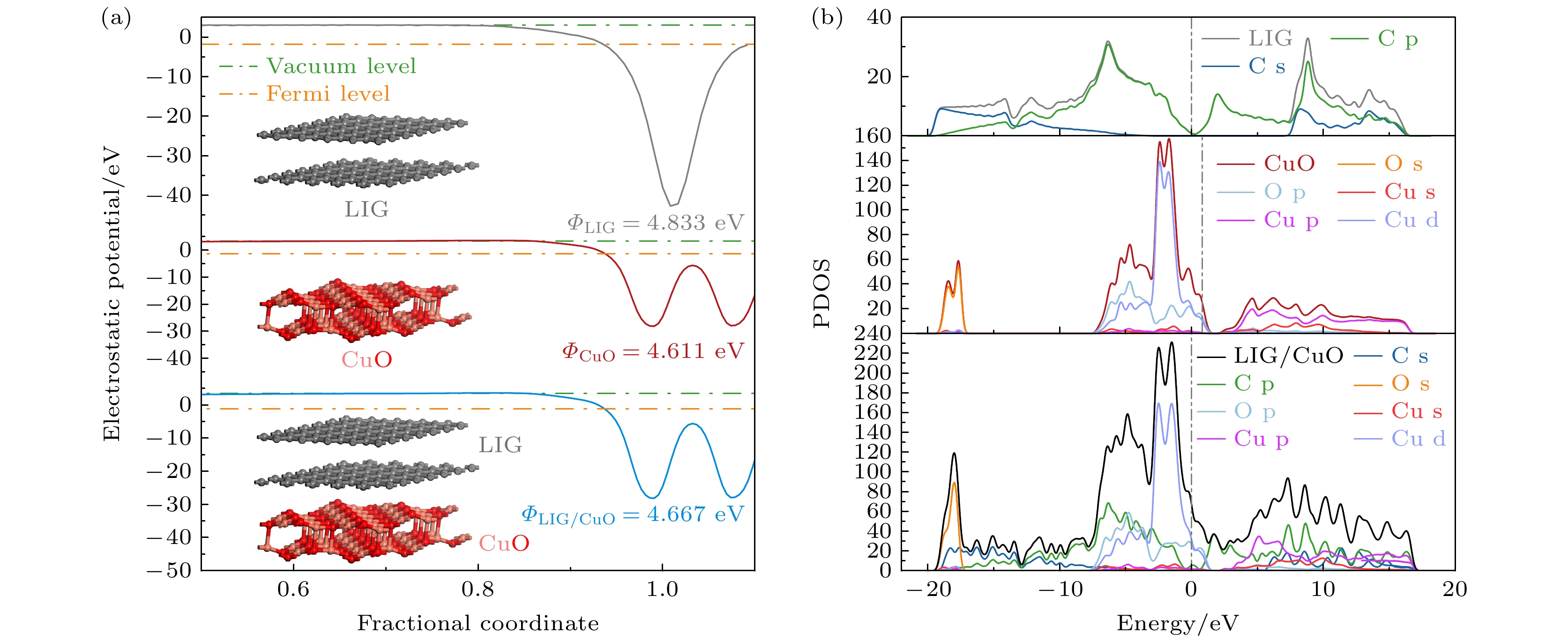

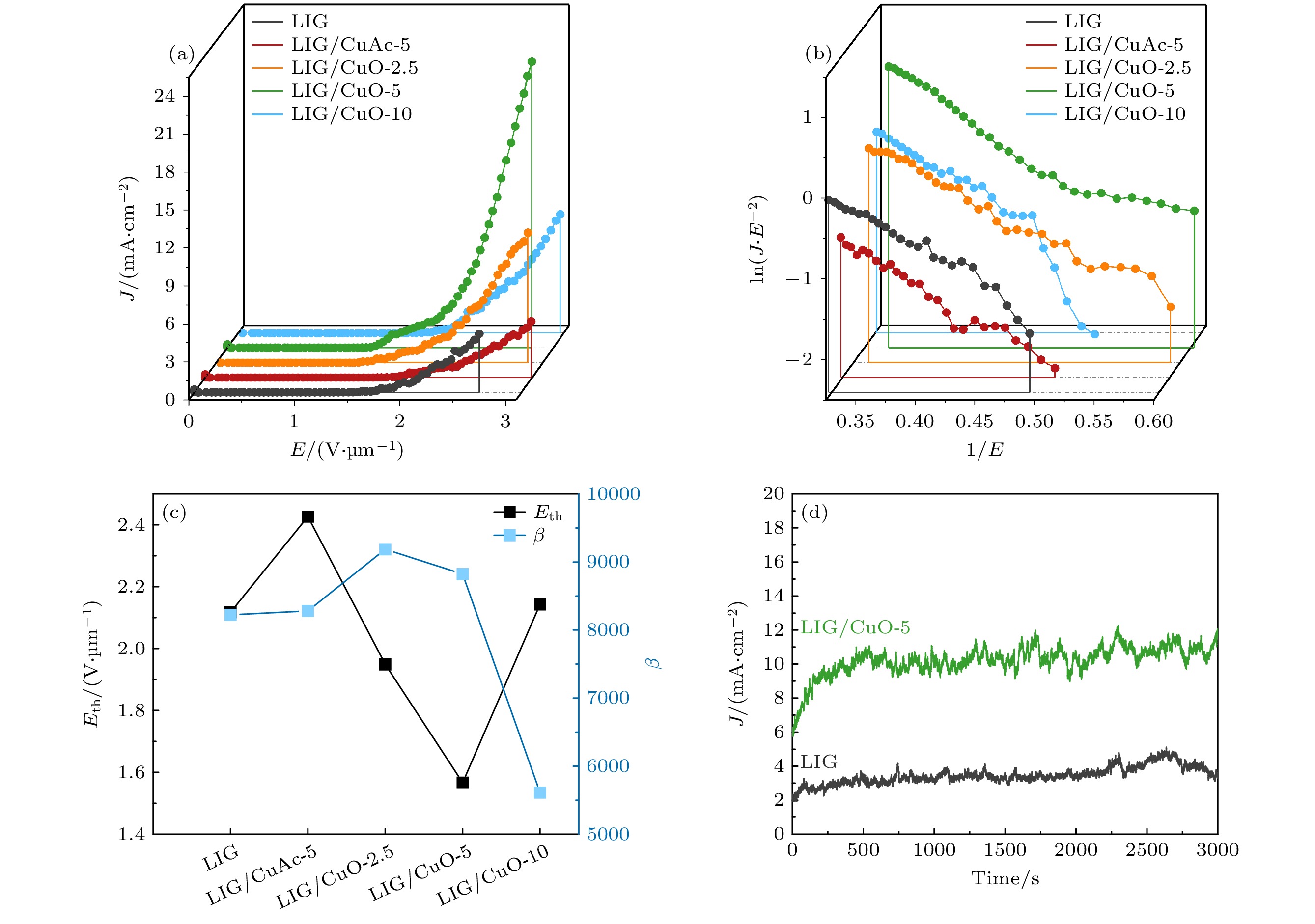

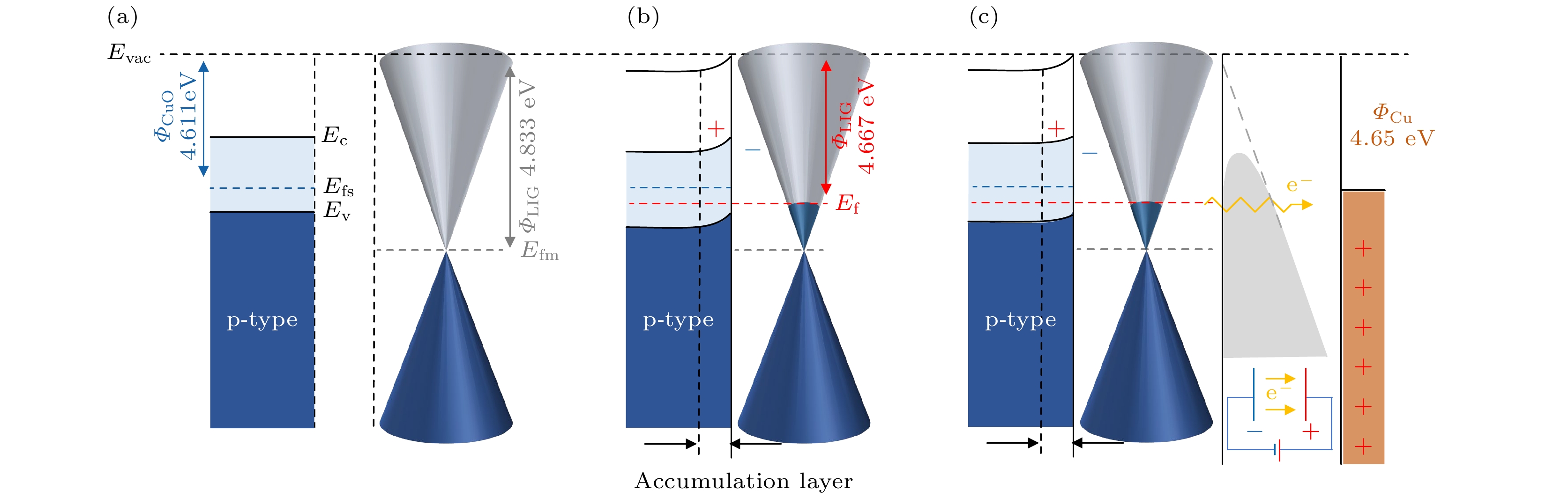

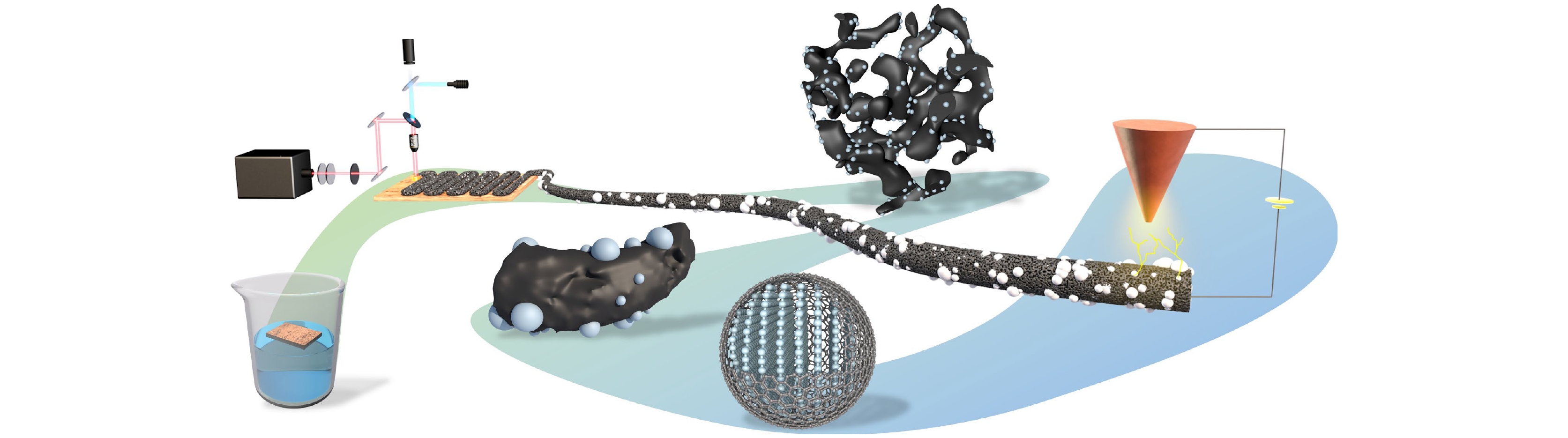

Three-dimensional (3D) graphene materials have excellent electronic emission performance and mechanical stability, showing significant advantages in the field of high current density field emitters. In this study, copper oxide modified three-dimensional graphene composites (LIG/CuO) are prepared in situ by a femtosecond laser one-step method, which realizes the simultaneous regulation of cork carbonization and copper oxidation. Shallow copper-rich precursors are constructed by copper salt infiltration and ascorbic acid reduction. Laser irradiation is used to synchronously induce the carbonization of cellulose into few-layer graphene and the transformation of Cu into CuO, forming a three-dimensional fiber network of microcrystalline graphene coated with CuO nanoparticles (30–80 nm). The structure exhibits excellent field emission performance: the threshold field of preparing pure laser- induced graphene (LIG) is ~2.12 V/μm and the field enhancement factor is ~8223. After optimizing CuO loading, the threshold field of LIG/CuO-5 is reduced to 1.57 V/μm, the field enhancement factor rises up to ~8823, and the ultra-high current density of 22.71 mA/cm2 is achieved at 2.89 V/μm. The density functional theory (DFT) calculations show that the electrons at the heterojunction interface transfer from CuO to graphene, which reduces the work function of graphene from 4.833 eV to 4.677 eV, and the band bending of CuO surface synergistically reduces the tunneling barrier. In addition, the local electric field enhancement effect of CuO nanoparticles and the optimized distribution density synergistically increase the effective emission point density. The performance improvement is mainly attributed to three synergistic effects: 1) the three-dimensional porous graphene network provides abundant tip emission sites; 2) the introduction of CuO nanoparticles reduces the work function of the composite material from 4.833 eV to 4.667 eV, effectively reducing the electron escape barrier; 3) the heterojunction interface forms a directional electron migration channel under a positive bias electric field, combined with the excellent conductivity of LIG, which significantly improves the electron tunneling efficiency.

-

Keywords:

- laser-induced graphene /

- CuO nanoparticles /

- composite cathode /

- field emission

[1] Zhang H, Tang J, Yuan J S, Yamauchi Y, Suzuki T T, Shinya N, Nakajima K, Qin L C 2016 Nat. Nanotechnol. 11 273

Google Scholar

Google Scholar

[2] Deka N, Subramanian V 2020 IEEE Trans. Electron Devices 67 3753

Google Scholar

Google Scholar

[3] Xing Y, Zhang Y, Xu N S, Huang H J, Ke Y L, Li B H, Chen J, She J C, Deng S Z 2018 IEEE Trans. Electron Devices 65 1146

Google Scholar

Google Scholar

[4] Cao G, Lee Y Z, Peng R, Liu Z, Rajaram R, Calderon-Colon X, An L, Wang P, Phan T, Sultana S, Lalush D S, Lu J P, Zhou O 2009 Phys. Med. Biol. 54 2323

Google Scholar

Google Scholar

[5] Heer W, Châtelain A, Ugarte D 1995 Science 270 1179

Google Scholar

Google Scholar

[6] 郑钦仁, 詹涪至, 折俊艺, 王建宇, 石若立, 孟国栋 2024 73 086101

Google Scholar

Google Scholar

Zheng Q R, Zhan B Z, Zhe J Y, Wang J Y, Shi R L, Meng G D 2024 Acta Phys. Sin. 73 086101

Google Scholar

Google Scholar

[7] Bhopale S R, Jagtap K K, Phatangare A, Kamble S, Dhole S D, Mathe V L, More M A 2023 Appl. Surf. Sci. 619 156752

Google Scholar

Google Scholar

[8] Guo X, Li Y L, Ding Y Q, Chen Q, Li J S 2019 Mater. Des. 162 293

Google Scholar

Google Scholar

[9] Deng J H, Liu R N, Zhang Y, Zhu W X, Han A L, Cheng G A 2017 J. Alloys Compd. 723 75

Google Scholar

Google Scholar

[10] Huang Y X, Zhao H, Li Z L, Hu L L, Wu Y L, Sun F, Meng S, Zhao J M 2023 Adv. Mater. 35 2208362

Google Scholar

Google Scholar

[11] 黄逸轩, 赵继民 2024 光散射学报 36 52

Google Scholar

Google Scholar

Huang Y X, Zhao J M 2024 J. Light Scat. 36 52

Google Scholar

Google Scholar

[12] Hasaien J, Wu Y L, Shi M Z, Zhai Y N, Wu Q, Liu Z, Zhou Y, Chen X. H, Zhao J M 2025 PNAS 122 e2406464122

Google Scholar

Google Scholar

[13] Jiang L T, Jiang C Y, Tian Y C, Zhao H, Zhang J, Tian Z Y, Fu S H, Liang E J, Wang X C, Jin C Q, Zhao J M 2024 Chin. Phys. Lett. 41 047802

Google Scholar

Google Scholar

[14] Wu L M, Dong Y Z, Zhao J L, Ma D T, Huang W C, Zhang Y, Wang Y Z, Jiang X T, Xiang Y J, Li J Q, Feng Y Q, Xu J L, Zhang H 2019 Adv. Mater. 31 1807981

Google Scholar

Google Scholar

[15] You Z H, Qiu Q M, Chen H Y, Feng Y Y, Wang X, Wang Y X, Ying Y B 2020 Biosens. Bioelectron. 150 111896

Google Scholar

Google Scholar

[16] Zhang J B, Ren M Q, Li Y L, Tour J M 2018 ACS Energy Lett. 3 677

Google Scholar

Google Scholar

[17] Yoon H, Nah J, Kim H, Ko S, Sharifuzzaman M, Barman S C, Xuan X, Kim J Y, Park J Y 2020 Sensor Actuat. B 311 127866

Google Scholar

Google Scholar

[18] Lin J, Peng Z W, Liu Y Y, Zepeda F R, Ye R Q, Samuel E L, Yacaman M J, Yakobson B I, Tour J M 2014 Nat. Commun. 5 5714

Google Scholar

Google Scholar

[19] Chyan Y, Ye R Q, Li Y L, Singh S P, Arnusch C J, Tour J M 2018 ACS Nano 12 2176

Google Scholar

Google Scholar

[20] Le T S D, Park S B, An J N, Lee P S, Kim Y J 2019 Adv. Funct. Mater. 29 1902771

Google Scholar

Google Scholar

[21] Wu W B, Liang R X, Lu L S, Wang W T, Ran X, Yue D D 2020 Surf. Coat. Technol. 393 125744

Google Scholar

Google Scholar

[22] Cheng J F, Lin Z X, Wu D, Liu C L, Cao Z 2022 J. Hazard. Mater. 436 129150.

Google Scholar

Google Scholar

[23] Ryu C, Do H M, In J B 2024 Appl. Surf. Sci. 643 158696

Google Scholar

Google Scholar

[24] Rodrigues J, Zanoni J, Gaspar G, Fernandes A J S, Carvalho A F, Santos N F, Monteiro T, Costa F M 2019 Nanoscale Adv. 1 3252

Google Scholar

Google Scholar

[25] Lal A, Porat H, Hirsch L O, Cahan R, Borenstein A 2024 Appl. Surf. Sci. 643 158660

Google Scholar

Google Scholar

[26] Ma L A, Chen Y B, Ye X Y, Sun L, Wei Z H, Huang L, Chen H X, Wang Q T, Chen E G 2021 Ceram. Int. 47 27487

Google Scholar

Google Scholar

[27] Huang X, Chen S, Pan J, Wei Z H, Ye X Y, Wang Q T, Ma L A 2024 Ceram. Int. 50 24205

Google Scholar

Google Scholar

[28] Perdew J P, Burke K, Wang Y 1996 Phys. Rev. B Condens. Matter 54 16533

Google Scholar

Google Scholar

[29] Sun Z L, Shao Z G, Wang C L, Yang L 2016 Carbon 110 313

Google Scholar

Google Scholar

[30] Zhang H W, Sun Y S, Li Q W, Wan C X 2022 ACS Sustainable Chem. Eng. 10 11501

Google Scholar

Google Scholar

[31] Raveendran K, Ganesh A, Khilar K C 1996 Fuel 75 987

Google Scholar

Google Scholar

[32] Babinszki B, Sebestyén Z, Jakab E, Kőhalmi L, Bozi J, Várhegyi G, Wang L, Skreiberg Ø, Czégéy Z 2021 Bioresour. Technol. 338 125567

Google Scholar

Google Scholar

[33] Sugioka K, Cheng Y 2014 Light Sci. Appl. 3 e149

Google Scholar

Google Scholar

[34] Chen L F, Yu H, Zhong J S, Wu J, Su W T 2018 J. Alloys Compd. 749 60

Google Scholar

Google Scholar

[35] Keiluweit M, Nico P S, Johnson M G, Kleber M 2010 Environ. Sci. Technol. 44 1247

Google Scholar

Google Scholar

[36] Yu S J, Wang L Z, Li Q H, Zhang Y G, Zhou H 2022 Mater. Today Sustain. 19 100209

Google Scholar

Google Scholar

[37] Miao M, Zuo S L, Zhao Y Y, Wang Y F, Xia H A, Tan C, Gao H 2018 Carbon 140 504

Google Scholar

Google Scholar

[38] Wu J B, Lin M L, Cong X, Liu H N, Tan P H 2018 Chem. Soc. Rev. 47 1822

Google Scholar

Google Scholar

[39] Arulkumar E, Shree S S, Thanikaikarasan S 2024 J. Mater Sci. Mater. EL 35 198

Google Scholar

Google Scholar

[40] 杨孟骐, 姬宇航, 梁琦, 王长昊, 张跃飞, 张铭, 王波, 王如志 2020 69 167805

Google Scholar

Google Scholar

Yang M Q, Ji Y H, Liang Q, Wang C H, Zhang Y F, Zhang M, Wang B, Wang R Z 2020 Acta Phys. Sin. 69 167805

Google Scholar

Google Scholar

[41] Zhang Y H, Ding H, Liu C X, Zhang J C, Wang C B, Guo W H, Ji Q Y, Zhao J Y, Zi Y Y 2024 Diamond Relat. Mater. 144 110972

Google Scholar

Google Scholar

[42] Chu Y L, Young S J, Cai D Y, Chu T T 2021 IEEE J. Electron. Devi. 9 1076

Google Scholar

Google Scholar

[43] Meng G D, Zhan F Z, She J Y, Xie J N, Zheng Q R, Cheng Y H, Yin Z Y 2023 Nanoscale 15 15994

Google Scholar

Google Scholar

[44] Fan L N, Chen W, Zhou K, Zheng H, Zheng P, Zheng L, Zhang Y 2023 ACS Appl. Electron. Mater. 5 123

Google Scholar

Google Scholar

-

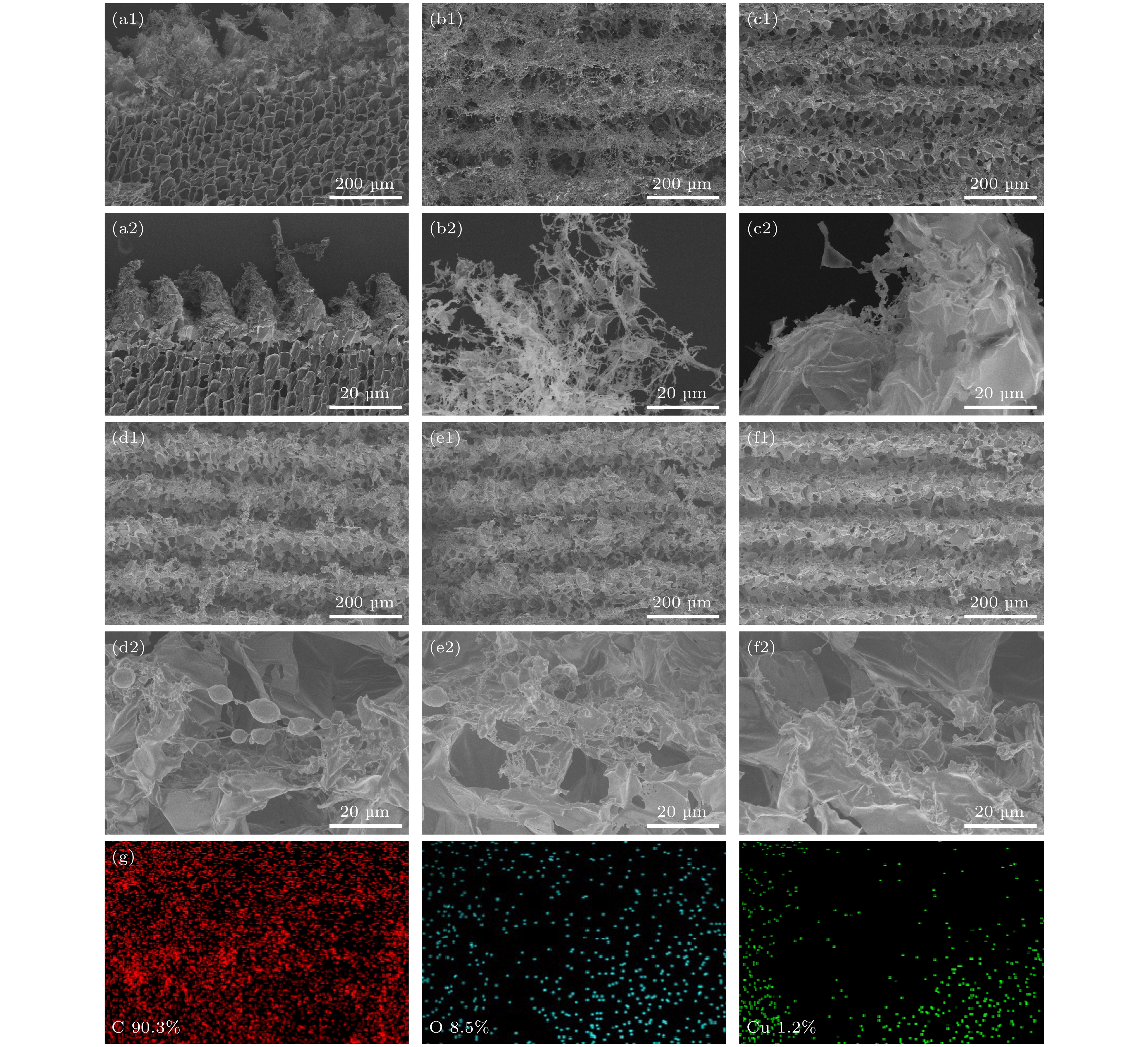

图 2 不同样品的场发射电子显微镜照片 (a1) LIG(截面图); (a2) LIG/CuO-5(截面图); (b1), (b2) LIG; (c1), (c2) LIG/CuAc-5; (d1), (d2) LIG/CuO-2.5; (e1), (e2) LIG/CuO-5; (f1), (f2) LIG/CuO-10; (g) LIG/CuO-5的元素分布图

Figure 2. Field emission electron microscopy images of different samples: (a1) LIG (cross section); (a2) LIG/CuO-5 (cross section); (b1), (b2) LIG; (c1), (c2) LIG/CuAc-5; (d1), (d2) LIG/CuO-2.5; (e1), (e2) LIG/CuO-5; (f1), (f2) LIG/CuO-10; (g) mapping images of LIG/CuO-5.

图 7 (a)样品LIG, LIG/CuAc-5, LIG/CuO-2.5, LIG/CuO-5和LIG/CuO-10的J-E曲线; (b) $\ln(J/E^2) \text{-}1/E $曲线; (c)样品相对应的开启阈值(Eth, 对应电流密度1 mA/cm2)和场增减因子(β)关系曲线; (d)样品LIG和LIG/CuO-5场发射稳定性曲线

Figure 7. (a) J-E plots of LIG, LIG/CuAc-5, LIG/CuO-2.5, LIG/CuO-5 and LIG/CuO-10; (b) $\ln(J/E^2) \text{-}1/E $ plots; (c) relationship plots of Eth (corresponding to a current density of 1 mA/cm2) and β versus the samples; (d) stability plots of LIG and LIG/CuO-5.

-

[1] Zhang H, Tang J, Yuan J S, Yamauchi Y, Suzuki T T, Shinya N, Nakajima K, Qin L C 2016 Nat. Nanotechnol. 11 273

Google Scholar

Google Scholar

[2] Deka N, Subramanian V 2020 IEEE Trans. Electron Devices 67 3753

Google Scholar

Google Scholar

[3] Xing Y, Zhang Y, Xu N S, Huang H J, Ke Y L, Li B H, Chen J, She J C, Deng S Z 2018 IEEE Trans. Electron Devices 65 1146

Google Scholar

Google Scholar

[4] Cao G, Lee Y Z, Peng R, Liu Z, Rajaram R, Calderon-Colon X, An L, Wang P, Phan T, Sultana S, Lalush D S, Lu J P, Zhou O 2009 Phys. Med. Biol. 54 2323

Google Scholar

Google Scholar

[5] Heer W, Châtelain A, Ugarte D 1995 Science 270 1179

Google Scholar

Google Scholar

[6] 郑钦仁, 詹涪至, 折俊艺, 王建宇, 石若立, 孟国栋 2024 73 086101

Google Scholar

Google Scholar

Zheng Q R, Zhan B Z, Zhe J Y, Wang J Y, Shi R L, Meng G D 2024 Acta Phys. Sin. 73 086101

Google Scholar

Google Scholar

[7] Bhopale S R, Jagtap K K, Phatangare A, Kamble S, Dhole S D, Mathe V L, More M A 2023 Appl. Surf. Sci. 619 156752

Google Scholar

Google Scholar

[8] Guo X, Li Y L, Ding Y Q, Chen Q, Li J S 2019 Mater. Des. 162 293

Google Scholar

Google Scholar

[9] Deng J H, Liu R N, Zhang Y, Zhu W X, Han A L, Cheng G A 2017 J. Alloys Compd. 723 75

Google Scholar

Google Scholar

[10] Huang Y X, Zhao H, Li Z L, Hu L L, Wu Y L, Sun F, Meng S, Zhao J M 2023 Adv. Mater. 35 2208362

Google Scholar

Google Scholar

[11] 黄逸轩, 赵继民 2024 光散射学报 36 52

Google Scholar

Google Scholar

Huang Y X, Zhao J M 2024 J. Light Scat. 36 52

Google Scholar

Google Scholar

[12] Hasaien J, Wu Y L, Shi M Z, Zhai Y N, Wu Q, Liu Z, Zhou Y, Chen X. H, Zhao J M 2025 PNAS 122 e2406464122

Google Scholar

Google Scholar

[13] Jiang L T, Jiang C Y, Tian Y C, Zhao H, Zhang J, Tian Z Y, Fu S H, Liang E J, Wang X C, Jin C Q, Zhao J M 2024 Chin. Phys. Lett. 41 047802

Google Scholar

Google Scholar

[14] Wu L M, Dong Y Z, Zhao J L, Ma D T, Huang W C, Zhang Y, Wang Y Z, Jiang X T, Xiang Y J, Li J Q, Feng Y Q, Xu J L, Zhang H 2019 Adv. Mater. 31 1807981

Google Scholar

Google Scholar

[15] You Z H, Qiu Q M, Chen H Y, Feng Y Y, Wang X, Wang Y X, Ying Y B 2020 Biosens. Bioelectron. 150 111896

Google Scholar

Google Scholar

[16] Zhang J B, Ren M Q, Li Y L, Tour J M 2018 ACS Energy Lett. 3 677

Google Scholar

Google Scholar

[17] Yoon H, Nah J, Kim H, Ko S, Sharifuzzaman M, Barman S C, Xuan X, Kim J Y, Park J Y 2020 Sensor Actuat. B 311 127866

Google Scholar

Google Scholar

[18] Lin J, Peng Z W, Liu Y Y, Zepeda F R, Ye R Q, Samuel E L, Yacaman M J, Yakobson B I, Tour J M 2014 Nat. Commun. 5 5714

Google Scholar

Google Scholar

[19] Chyan Y, Ye R Q, Li Y L, Singh S P, Arnusch C J, Tour J M 2018 ACS Nano 12 2176

Google Scholar

Google Scholar

[20] Le T S D, Park S B, An J N, Lee P S, Kim Y J 2019 Adv. Funct. Mater. 29 1902771

Google Scholar

Google Scholar

[21] Wu W B, Liang R X, Lu L S, Wang W T, Ran X, Yue D D 2020 Surf. Coat. Technol. 393 125744

Google Scholar

Google Scholar

[22] Cheng J F, Lin Z X, Wu D, Liu C L, Cao Z 2022 J. Hazard. Mater. 436 129150.

Google Scholar

Google Scholar

[23] Ryu C, Do H M, In J B 2024 Appl. Surf. Sci. 643 158696

Google Scholar

Google Scholar

[24] Rodrigues J, Zanoni J, Gaspar G, Fernandes A J S, Carvalho A F, Santos N F, Monteiro T, Costa F M 2019 Nanoscale Adv. 1 3252

Google Scholar

Google Scholar

[25] Lal A, Porat H, Hirsch L O, Cahan R, Borenstein A 2024 Appl. Surf. Sci. 643 158660

Google Scholar

Google Scholar

[26] Ma L A, Chen Y B, Ye X Y, Sun L, Wei Z H, Huang L, Chen H X, Wang Q T, Chen E G 2021 Ceram. Int. 47 27487

Google Scholar

Google Scholar

[27] Huang X, Chen S, Pan J, Wei Z H, Ye X Y, Wang Q T, Ma L A 2024 Ceram. Int. 50 24205

Google Scholar

Google Scholar

[28] Perdew J P, Burke K, Wang Y 1996 Phys. Rev. B Condens. Matter 54 16533

Google Scholar

Google Scholar

[29] Sun Z L, Shao Z G, Wang C L, Yang L 2016 Carbon 110 313

Google Scholar

Google Scholar

[30] Zhang H W, Sun Y S, Li Q W, Wan C X 2022 ACS Sustainable Chem. Eng. 10 11501

Google Scholar

Google Scholar

[31] Raveendran K, Ganesh A, Khilar K C 1996 Fuel 75 987

Google Scholar

Google Scholar

[32] Babinszki B, Sebestyén Z, Jakab E, Kőhalmi L, Bozi J, Várhegyi G, Wang L, Skreiberg Ø, Czégéy Z 2021 Bioresour. Technol. 338 125567

Google Scholar

Google Scholar

[33] Sugioka K, Cheng Y 2014 Light Sci. Appl. 3 e149

Google Scholar

Google Scholar

[34] Chen L F, Yu H, Zhong J S, Wu J, Su W T 2018 J. Alloys Compd. 749 60

Google Scholar

Google Scholar

[35] Keiluweit M, Nico P S, Johnson M G, Kleber M 2010 Environ. Sci. Technol. 44 1247

Google Scholar

Google Scholar

[36] Yu S J, Wang L Z, Li Q H, Zhang Y G, Zhou H 2022 Mater. Today Sustain. 19 100209

Google Scholar

Google Scholar

[37] Miao M, Zuo S L, Zhao Y Y, Wang Y F, Xia H A, Tan C, Gao H 2018 Carbon 140 504

Google Scholar

Google Scholar

[38] Wu J B, Lin M L, Cong X, Liu H N, Tan P H 2018 Chem. Soc. Rev. 47 1822

Google Scholar

Google Scholar

[39] Arulkumar E, Shree S S, Thanikaikarasan S 2024 J. Mater Sci. Mater. EL 35 198

Google Scholar

Google Scholar

[40] 杨孟骐, 姬宇航, 梁琦, 王长昊, 张跃飞, 张铭, 王波, 王如志 2020 69 167805

Google Scholar

Google Scholar

Yang M Q, Ji Y H, Liang Q, Wang C H, Zhang Y F, Zhang M, Wang B, Wang R Z 2020 Acta Phys. Sin. 69 167805

Google Scholar

Google Scholar

[41] Zhang Y H, Ding H, Liu C X, Zhang J C, Wang C B, Guo W H, Ji Q Y, Zhao J Y, Zi Y Y 2024 Diamond Relat. Mater. 144 110972

Google Scholar

Google Scholar

[42] Chu Y L, Young S J, Cai D Y, Chu T T 2021 IEEE J. Electron. Devi. 9 1076

Google Scholar

Google Scholar

[43] Meng G D, Zhan F Z, She J Y, Xie J N, Zheng Q R, Cheng Y H, Yin Z Y 2023 Nanoscale 15 15994

Google Scholar

Google Scholar

[44] Fan L N, Chen W, Zhou K, Zheng H, Zheng P, Zheng L, Zhang Y 2023 ACS Appl. Electron. Mater. 5 123

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 343

- PDF Downloads: 11

- Cited By: 0

DownLoad:

DownLoad: