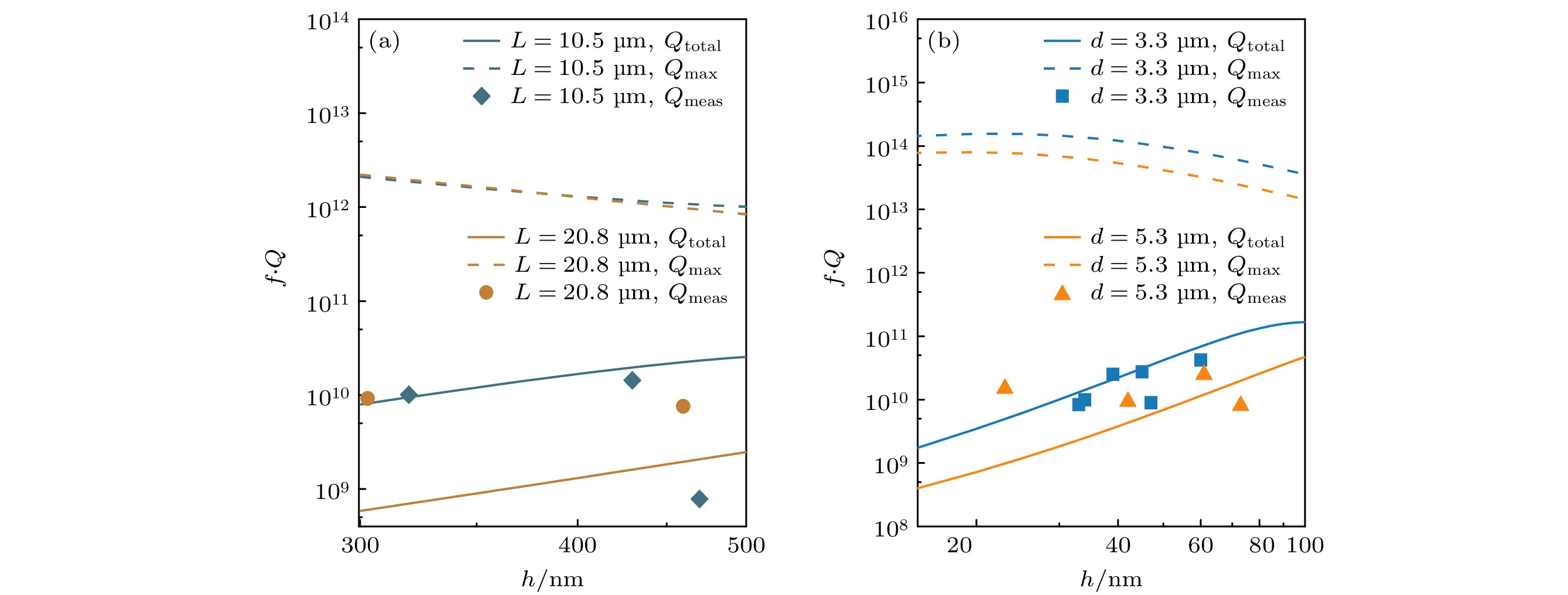

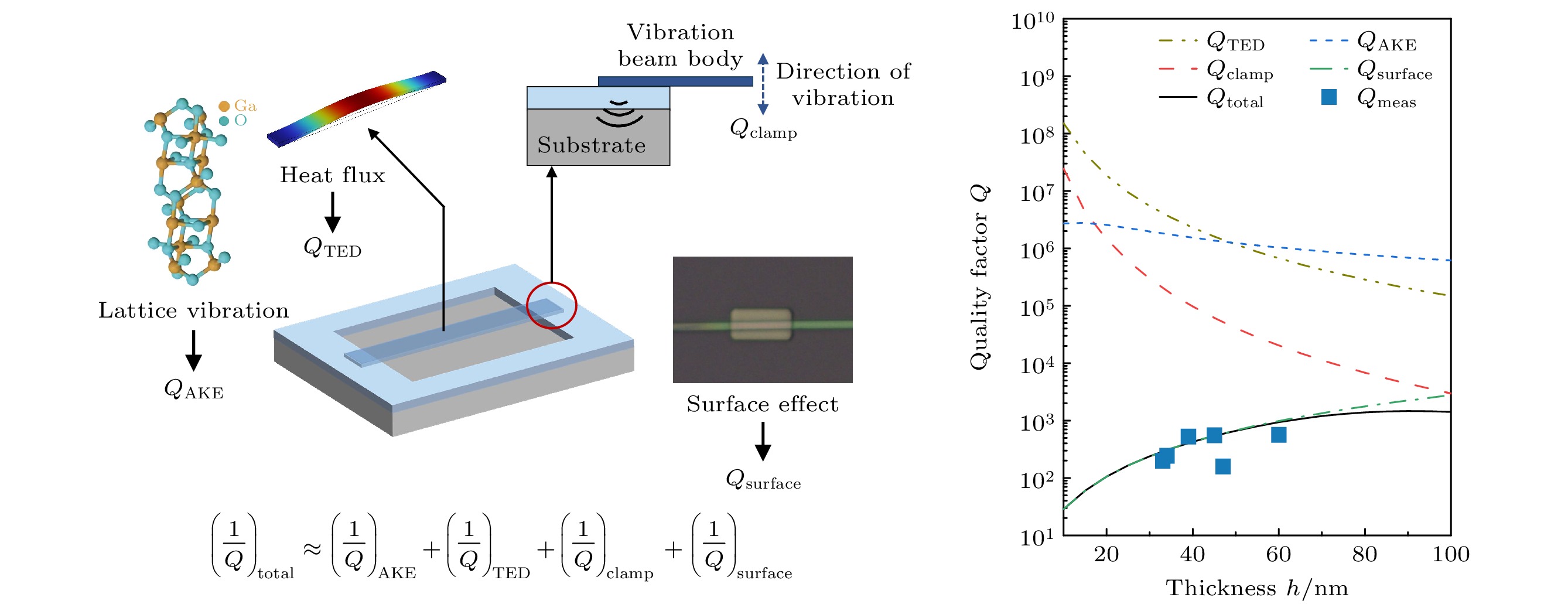

-

Beta-gallium oxide (β-Ga2O3), an emerging ultrawide bandgap (~4.8 eV) semiconductor, exhibits excellent electrical properties and cost advantages, being made as a promising candidate for high-power, high-frequency, and optoelectronic applications. Furthermore, its superior mechanical properties, including a Young’s modulus of 261 GPa, a mass density of 5950 kg/m³, and an acoustic velocity of 6623 m/s, make it particularly attractive for realizing high-frequency micro- and nanoelectromechanical system (M/NEMS) resonators. In this work, the energy dissipation mechanisms are investigated in two different β-Ga2O3 NEMS resonator geometries – doubly-clamped beams (10.5–20.8 μm length) and circular drumheads (3.3–5.3 μm diameter) – through theoretical analysis, finite element model (FEM) simulations, and experimental measurements under vacuum condition (<50 mTorr). The dominant energy dissipation mechanisms in resonators are investigated, including Akhiezer damping (AKE), thermoelastic damping (TED), clamping loss, and surface loss, by using a combined theoretical and FEM approach. Experimentally, the resonators are made by employing mechanical exfoliation combined with dry transfer techniques, yielding device thickness of 30–500 nm as verified by atomic force microscopy (AFM). Subsequently, laser interferometry is used to characterize the resonator dynamics. The resonant frequency f is obtained in a range of 5–75 MHz and the quality factor Q is approximately 200–1700 obtained through Lorentzian fitting of the resonant spectra, thus verifying the theoretical and simulation results. Our analysis indicates that surface loss and clamping loss are the main limiting factors for the Q values of current β-Ga2O3 resonators. Conversely, AKE and TED are mainly affected by material properties and resonator geometry, thus setting an upper limit for the achievable Q values with f×Q product reaching up to 1014 Hz. Our study provides a comprehensive framework integrating both theoretical analysis and experimental validation for understanding the complex energy dissipation mechanism inside a β-Ga2O3 NEMS resonator, and optimizes Q value through strain engineering and phonon crystal anchoring. These findings provide essential guidance for optimizing the performance and modulating the bandwidth of β-Ga2O3 NEMS resonator in high-frequency and high-power applications. [1] Ning S T, Huang S, Zhang Z Y, Zhao B, Zhang R Q, Qi N, Chen Z Q 2022 Phys. Chem. Chem. Phys. 24 12052

Google Scholar

Google Scholar

[2] Zhou M, Zhou H, Huang S, Si M W, Zhang Y H, Luan T T, Yue H Q, Dang K, Wang C L, Liu Z H, Zhang J C, Hao Y 2023 2023 International Electron Devices Meeting Francisco, CA, USA, December 9–13, 2023 p1

[3] Chen H, Li Z, Zhang Z Y L, Liu D H, Zeng L R, Yan Y R, Chen D Z, Feng Q, Zhang J C, Hao Y, Zhang C F 2024 Semicond. Sci. Technol. 39 063001

Google Scholar

Google Scholar

[4] Zheng X Q, Zhao H P, Feng P X L 2022 Appl. Phys. Lett. 120 040502

Google Scholar

Google Scholar

[5] Labed M, Sengouga N, Prasad C V, Henini M, Rim Y S 2023 Mater. Today Phys. 36 101155

Google Scholar

Google Scholar

[6] Liang Y, Yu H, Wang H, Zhang H C, Cui T J 2022 Chip 1 100030

Google Scholar

Google Scholar

[7] Li H, Zhou Z H, Zhao Y Z, Li Y 2023 Chip 2 100049

Google Scholar

Google Scholar

[8] Soref R, Leonardis F D 2022 Chip 1 100011

Google Scholar

Google Scholar

[9] Lu C C, Yuan H Y, Zhang H Y, Zhao W, Zhang N E, Zheng Y J, Elshahat S, Liu Y C 2022 Chip 1 100025

Google Scholar

Google Scholar

[10] Wang L M, Zhang P C, Liu Z H, Wang Z H, Yang R 2023 Chip 2 100038

Google Scholar

Google Scholar

[11] Abdolvand R, Bahreyni B, Lee J E Y, Nabki F 2016 Micromachines 7 160

Google Scholar

Google Scholar

[12] Feng T R, Yuan Q, Yu D L, Wu B, Wang H 2022 Micromachines 13 2195

Google Scholar

Google Scholar

[13] Aoust G, Levy R, Bourgeteau B, Traon O L 2015 Sens. Actuators A: Phys. 230 126

Google Scholar

Google Scholar

[14] Sun Y X, Tohmyoh H 2009 J. Sound Vib. 319 392

Google Scholar

Google Scholar

[15] Schmid S, Hierold C 2008 J. Appl. Phys. 104 093516

Google Scholar

Google Scholar

[16] Imboden M, Mohanty P 2014 Phys. Rep. 534 89

Google Scholar

Google Scholar

[17] Rodriguez J, Chandorkar S A, Watson C A, Glaze G M, Ahn C H, Ng E J, Yang Y S, Kenny T W 2019 Sci. Rep. 9 2244

Google Scholar

Google Scholar

[18] Pearton S J, Yang J C, Cary P H, Ren F, Kim J, Tadjer M J, Mastro M A 2018 Appl. Phys. Rev. 5 011301

Google Scholar

Google Scholar

[19] Bokaian A 1990 J. Sound Vib. 142 481

Google Scholar

Google Scholar

[20] Suzuki H, Yamaguchi N, Izumi H 2009 Acoust. Sci. Technol. 30 348

Google Scholar

Google Scholar

[21] Cimalla V, Foerster C, Will F, Tonisch K, Brueckner K, Stephan R, Hein M E, Ambacher O, Aperathitis E 2006 Appl. Phys. Lett. 88 253501

Google Scholar

Google Scholar

[22] Lee J, Wang Z H, He K L, Shan J, Feng P X L 2014 Appl. Phys. Lett. 105 023104

Google Scholar

Google Scholar

[23] Kunal K, Aluru N R 2011 Phys. Rev. B 84 245450

Google Scholar

Google Scholar

[24] Ghaffari S, Chandorkar S A, Wang S S, Ng E J, Ahn C H, Hong V, Yang Y S, Kenny T W 2013 Sci. Rep. 3 3244

Google Scholar

Google Scholar

[25] Tabrizian R, Rais-Zadeh M, Ayazi F 2009 Solid-state Sensors, Actuators & Microsystems Conference Denver, CO, USA, June 21–25, 2009 p2131

[26] Chen Z J, Jia Q Q, Liu W L, Zhu Y F, Yuan Q, Yang J L, Yang F H 2021 IEEE MEMS 2021 Virtual Conference Gainesville, FL, USA, January 25–29, 2021 p964

[27] Yan S H, Liu Z, Tan C K, Zhang X Y, Li S, Shi L, Guo Y F, Tang W H 2023 Appl. Phys. Lett. 123 142202

Google Scholar

Google Scholar

[28] Guo Z, Verma A, Wu X F, Sun F Y, Hickman A, Masui T, Kuramata A, Higashiwaki M, Jena D, Luo T F 2015 Appl. Phys. Lett. 106 111909

Google Scholar

Google Scholar

[29] Safieddine F, Hassan F E H, Kazan M 2022 J. Solid State Chem. 312 123272

Google Scholar

Google Scholar

[30] Prabhakar S, Vengallatore S 2007 J. Micromech. Microeng. 17 532

Google Scholar

Google Scholar

[31] Lifshitz R, Roukes M L 2000 Phys. Rev. B 61 5600

[32] Sun Y X, Saka M 2010 J. Sound Vib. 329 328

Google Scholar

Google Scholar

[33] Cheng Z Z, Hanke M, Galazka Z, Trampert A 2018 Appl. Phys. Lett. 113 182102

Google Scholar

Google Scholar

[34] Ko J H, Jeong J, Choi J, Cho M 2011 Appl. Phys. Lett. 98 171909

Google Scholar

Google Scholar

[35] Yang J L, Ono T, Esashi M 2002 J. Microelectromech. Syst. 11 775

Google Scholar

Google Scholar

[36] Mohanty P, Harrington D A, Ekinci K L, Yang Y T, Murphy M J, Roukes M L 2002 Phys. Rev. B 66 085416

Google Scholar

Google Scholar

[37] Villanueva L G, Schmid S 2014 Phys. Rev. Lett. 113 227201

Google Scholar

Google Scholar

[38] Zheng X Q, Tharpe T, Enamul Hoque Yousuf S M, Rudawski N G, Feng P X L 2022 ACS Appl. Mater. Interfaces 14 36807

Google Scholar

Google Scholar

[39] Bercioux D, Buchs G, Grabert H, Groning O 2011 Phys. Rev. B 83 165439

Google Scholar

Google Scholar

[40] Wang C H, Ning Y H, Zhao W Y, Yi G X, Huo Y 2023 Sens. Actuator A: Phys. 359 114456

Google Scholar

Google Scholar

[41] Ahamed M J, Senkal D, Shkel A M 2014 2014 International Symposium on Inertial Sensors and Systems (INERTIAL) Laguna Beach, CA, USA, February 25–26, 2014 p59

[42] Zheng X Q, Lee J, Rafique S, Han L, Zorman C A, Zhao H P, Feng P X L 2017 ACS Appl. Mater. Interfaces 9 43090

Google Scholar

Google Scholar

[43] Li S S, Lin Y W, Xie Y, Ren Z Y, Nguyen C T C 2004 17th Int. IEEE Micro Electro Mechanical Systems Conf Maastricht, The Netherlands, January 25–29, 2004 p821

[44] 郑贤德, 甄嘉鹏, 邱静, 刘冠军 2023 仪器仪表学报 44 206

Google Scholar

Google Scholar

Zheng X D, Zhen J P, Qiu J, Liu G J 2023 Chin. J. Sci. Instrum. 44 206

Google Scholar

Google Scholar

-

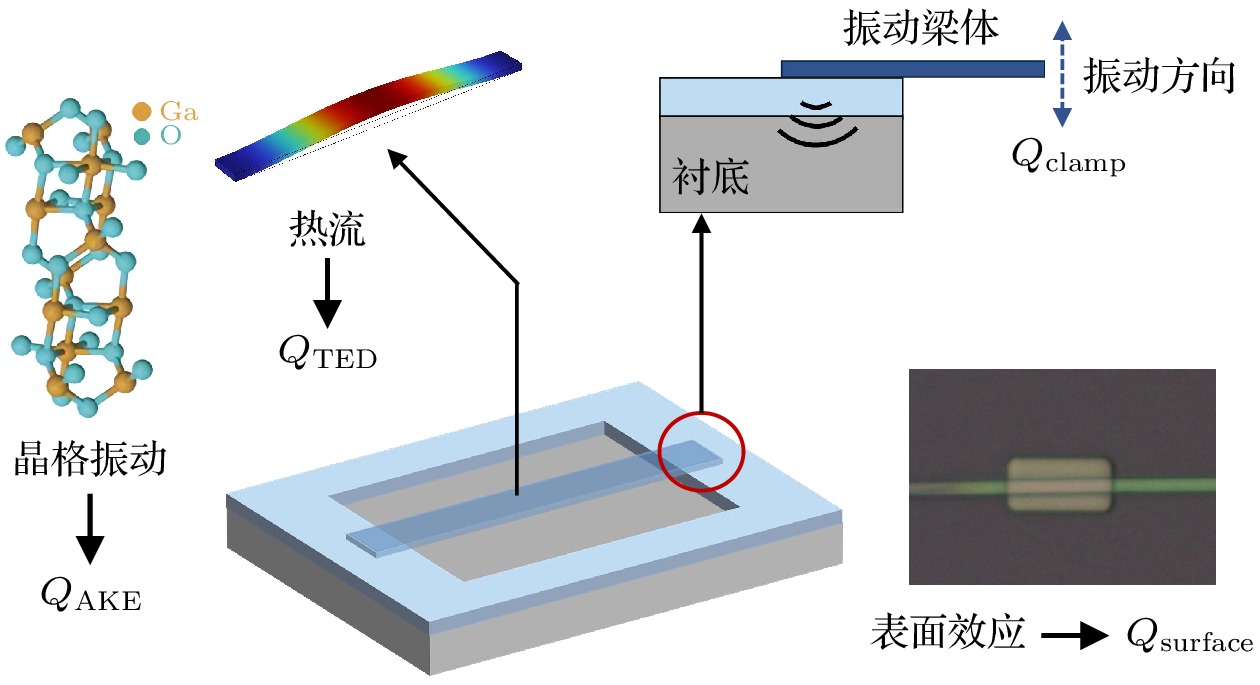

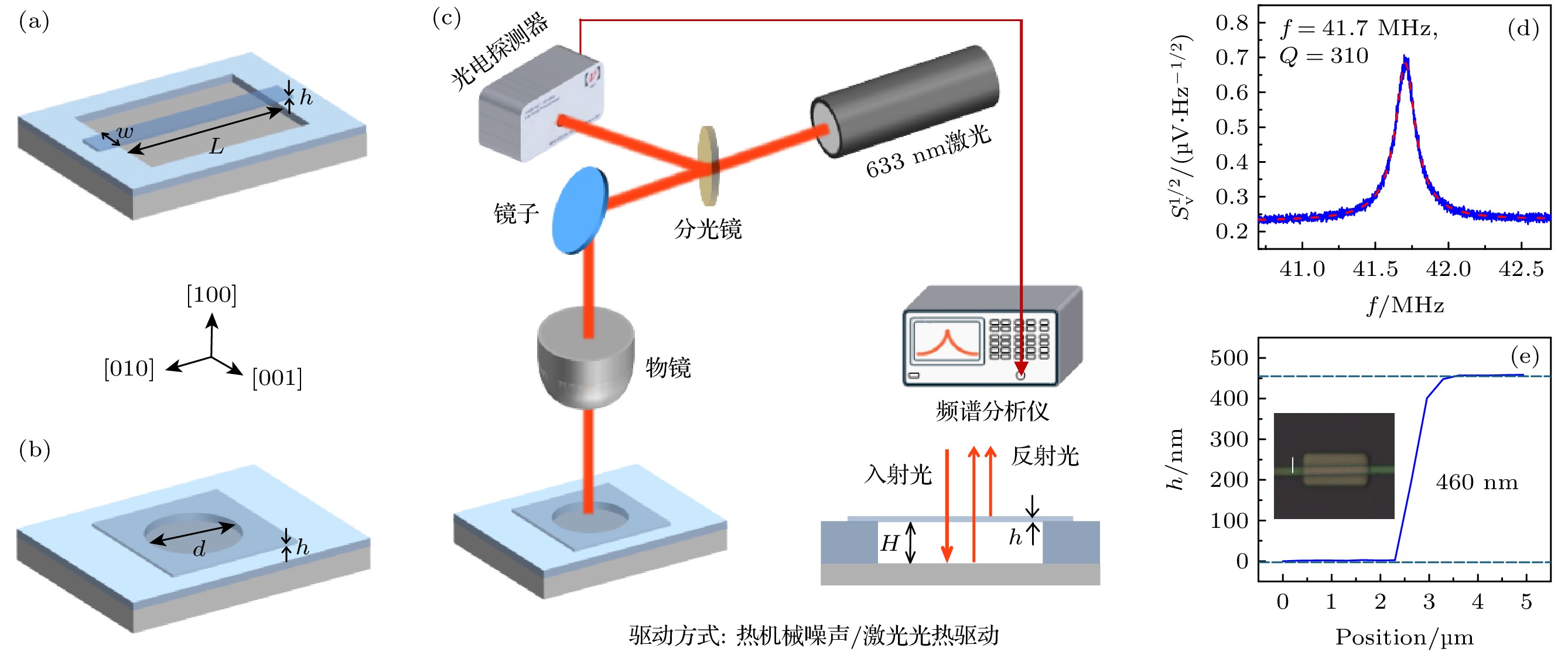

图 1 (a) 双端固支谐振器结构示意图; (b) 圆形鼓面谐振器结构示意图; (c) 激光干涉测量系统原理图, 其中h, H分别表示材料厚度与沟槽深度; (d) 谐振器典型频谱曲线及其洛伦兹拟合, 该器件为d = 3.3 μm, h = 45 nm的圆形鼓面谐振器; (e) AFM扫描曲线, 插图为所测量的双端固支结构谐振器, 其中短实线为AFM探针的扫描路径

Figure 1. (a) Illustration of a doubly-clamped resonator; (b) illustration of a circular drumhead resonator; (c) schematic of the laser interferometry measurement system, where h and H denote the material thickness and trench depth, respectively; (d) typical spectrum of a circular drumhead resonator with d = 3.3 μm, h = 45 nm and its Lorentzian fitting; (e) AFM scanning curve with inset showing the scanning path, where the short solid line is the scanning path of the AFM probe.

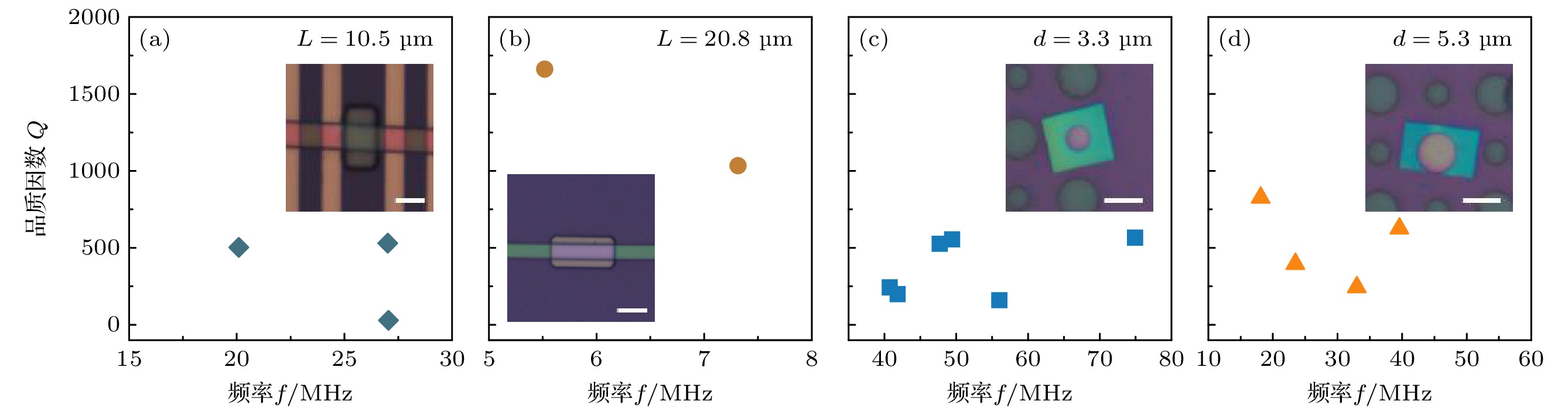

图 3 不同谐振器的f和Q测量值, 插图显示了对应典型器件的显微图, L与d分别表示双端固支悬空结构的长度与圆形鼓面悬空结构的直径 (a), (b) L = 10.5 μm和20.8 μm的双端固支器件, 比例尺为10 μm; (c), (d) d = 3.3 μm和5.3 μm的圆形鼓面器件, 比例尺为5 μm

Figure 3. Measured values of f and Q for various resonators, with the insets showing the corresponding micrographs of typical devices: (a), (b) Doubly-clamped resonators with L = 10.5 μm and 20.8 μm, each with a scale bar of 10 μm; (c), (d) circular drumhead resonators with d = 3.3 μm and 5.3 μm, each with a scale bar of 5 μm.

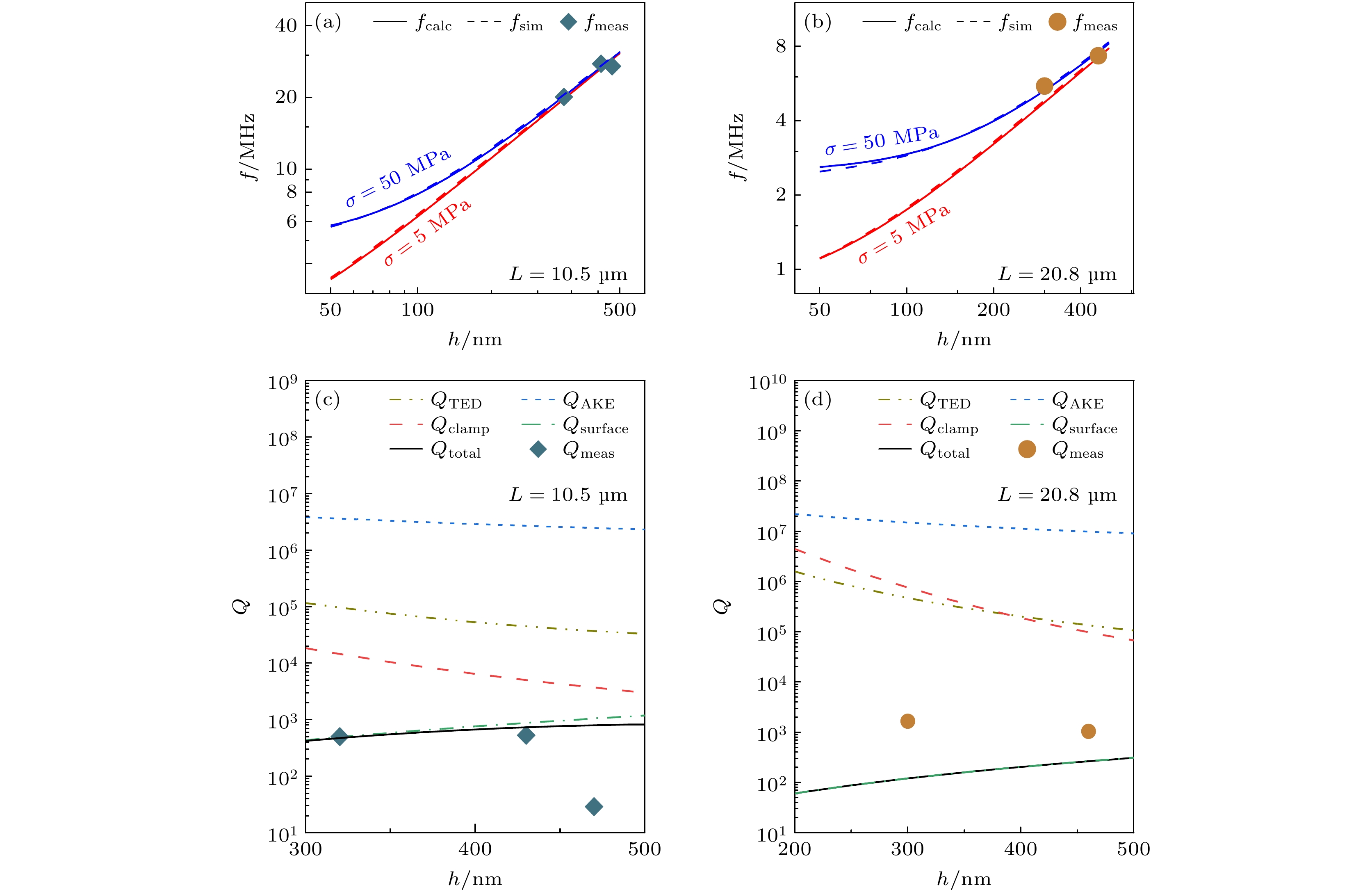

图 4 (a) L = 10.5 μm和(b) L = 20.8 μm两种双端固支器件在不同内应力 (红色曲线为σ = 5 MPa, 蓝色曲线为σ = 50 MPa) 下谐振频率f的计算值fcalc(实线)、仿真值fsim(虚线)与测量值fmeas(散点); (c) L = 10.5 μm和(d) L = 20.8 μm两种双端固支谐振器在不同耗散机制限制下的Q值、通过(1)式计算得到的Qtotal以及测量值Qmeas

Figure 4. Calculated value fcalc (solid line), simulated value fsim (dashed line), and measured value fmeas (scattered symbols) of the resonant frequency f under different internal stresses (σ = 5 MPa for red curve and σ = 50 MPa for blue curve) for doubly-clamped resonators: (a) L = 10.5 μm and (b) L = 20.8 μm, Q values limited by different loss mechanisms, Qtotal calculated by Eq. (1), and measured Qmeas for doubly-clamped resonators of (c) L = 10.5 μm and (d) L = 20.8 μm.

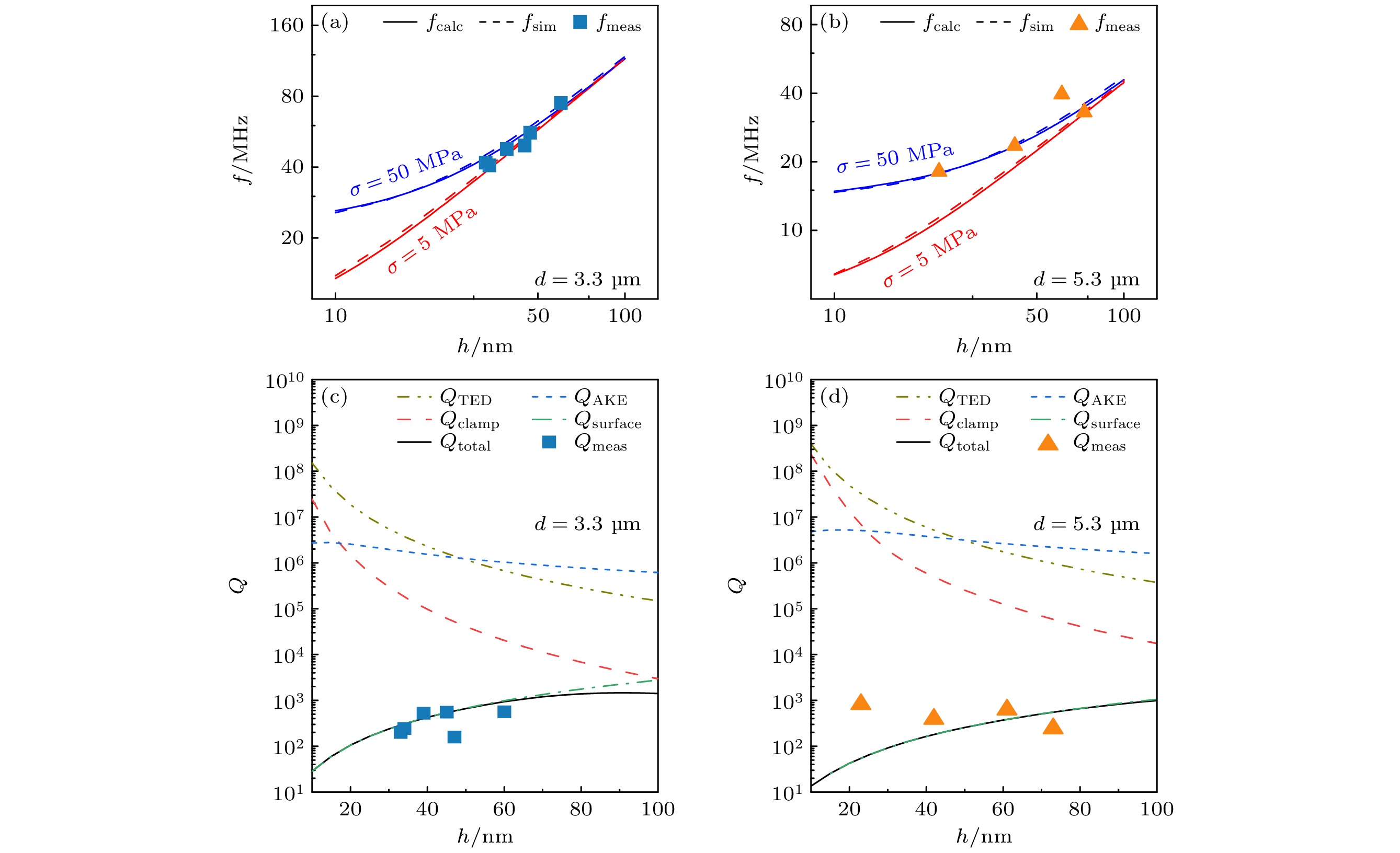

图 5 (a) d = 3.3 μm和(b) d = 5.3 μm两种圆形鼓面器件在不同内应力(红色曲线为σ = 5 MPa, 蓝色曲线为σ = 50 MPa)下谐振频率f的计算值fcalc(实线)、仿真值fsim(虚线)与测量值fmeas(散点), 其中实线为计算值, 虚线为仿真值; (c) d = 3.3 μm和(d) d = 5.3 μm两种圆形鼓面器件在不同耗散机制限制下的Q值、通过(1)式计算得到的Qtotal以及测量值Qmeas

Figure 5. Calculated value fcalc (soild line), simulated value fsim (dashed line), and measured value fmeas (scattered line) of the resonant frequency f under different internal stresses (σ = 5 MPa for red curve and σ = 50 MPa for blue curve) of drumhead resonators: (a) d = 3.3 μm and (b) d = 5.3 μm. Q values limited by different loss mechanisms, Qtotal calculated by Eq. (1), and measured Qmeas for drumhead resonators of (c) d = 3.3 μm and (d) d = 5.3 μm.

表 1 β-Ga2O3的材料性能参数

Table 1. Material properties of β-Ga2O3.

物理量 值 杨氏模量EY[4]/GPa 261 密度ρ[4] /(kg·m–3) 5950 泊松比ν[4] 0.2 声速c[4]/(m·s–1) 6623 声子散射时间τs/s 双端固支: 6.37×10–13

圆形鼓面: 4.89×10–13平均Grüneisen参数γavg[27] 1.018 质量热容Cp[29] /(J·kg–1·K–1) 491 热膨胀系数α[33]/K–1 [100]: 0.10×10–6

[010]: 1.68×10–6

[001]: 1.74×10–6热导率k[28]/(W·m–1·K–1) [100]: 10.9

[010]: 27.0

[001]: 14.5 -

[1] Ning S T, Huang S, Zhang Z Y, Zhao B, Zhang R Q, Qi N, Chen Z Q 2022 Phys. Chem. Chem. Phys. 24 12052

Google Scholar

Google Scholar

[2] Zhou M, Zhou H, Huang S, Si M W, Zhang Y H, Luan T T, Yue H Q, Dang K, Wang C L, Liu Z H, Zhang J C, Hao Y 2023 2023 International Electron Devices Meeting Francisco, CA, USA, December 9–13, 2023 p1

[3] Chen H, Li Z, Zhang Z Y L, Liu D H, Zeng L R, Yan Y R, Chen D Z, Feng Q, Zhang J C, Hao Y, Zhang C F 2024 Semicond. Sci. Technol. 39 063001

Google Scholar

Google Scholar

[4] Zheng X Q, Zhao H P, Feng P X L 2022 Appl. Phys. Lett. 120 040502

Google Scholar

Google Scholar

[5] Labed M, Sengouga N, Prasad C V, Henini M, Rim Y S 2023 Mater. Today Phys. 36 101155

Google Scholar

Google Scholar

[6] Liang Y, Yu H, Wang H, Zhang H C, Cui T J 2022 Chip 1 100030

Google Scholar

Google Scholar

[7] Li H, Zhou Z H, Zhao Y Z, Li Y 2023 Chip 2 100049

Google Scholar

Google Scholar

[8] Soref R, Leonardis F D 2022 Chip 1 100011

Google Scholar

Google Scholar

[9] Lu C C, Yuan H Y, Zhang H Y, Zhao W, Zhang N E, Zheng Y J, Elshahat S, Liu Y C 2022 Chip 1 100025

Google Scholar

Google Scholar

[10] Wang L M, Zhang P C, Liu Z H, Wang Z H, Yang R 2023 Chip 2 100038

Google Scholar

Google Scholar

[11] Abdolvand R, Bahreyni B, Lee J E Y, Nabki F 2016 Micromachines 7 160

Google Scholar

Google Scholar

[12] Feng T R, Yuan Q, Yu D L, Wu B, Wang H 2022 Micromachines 13 2195

Google Scholar

Google Scholar

[13] Aoust G, Levy R, Bourgeteau B, Traon O L 2015 Sens. Actuators A: Phys. 230 126

Google Scholar

Google Scholar

[14] Sun Y X, Tohmyoh H 2009 J. Sound Vib. 319 392

Google Scholar

Google Scholar

[15] Schmid S, Hierold C 2008 J. Appl. Phys. 104 093516

Google Scholar

Google Scholar

[16] Imboden M, Mohanty P 2014 Phys. Rep. 534 89

Google Scholar

Google Scholar

[17] Rodriguez J, Chandorkar S A, Watson C A, Glaze G M, Ahn C H, Ng E J, Yang Y S, Kenny T W 2019 Sci. Rep. 9 2244

Google Scholar

Google Scholar

[18] Pearton S J, Yang J C, Cary P H, Ren F, Kim J, Tadjer M J, Mastro M A 2018 Appl. Phys. Rev. 5 011301

Google Scholar

Google Scholar

[19] Bokaian A 1990 J. Sound Vib. 142 481

Google Scholar

Google Scholar

[20] Suzuki H, Yamaguchi N, Izumi H 2009 Acoust. Sci. Technol. 30 348

Google Scholar

Google Scholar

[21] Cimalla V, Foerster C, Will F, Tonisch K, Brueckner K, Stephan R, Hein M E, Ambacher O, Aperathitis E 2006 Appl. Phys. Lett. 88 253501

Google Scholar

Google Scholar

[22] Lee J, Wang Z H, He K L, Shan J, Feng P X L 2014 Appl. Phys. Lett. 105 023104

Google Scholar

Google Scholar

[23] Kunal K, Aluru N R 2011 Phys. Rev. B 84 245450

Google Scholar

Google Scholar

[24] Ghaffari S, Chandorkar S A, Wang S S, Ng E J, Ahn C H, Hong V, Yang Y S, Kenny T W 2013 Sci. Rep. 3 3244

Google Scholar

Google Scholar

[25] Tabrizian R, Rais-Zadeh M, Ayazi F 2009 Solid-state Sensors, Actuators & Microsystems Conference Denver, CO, USA, June 21–25, 2009 p2131

[26] Chen Z J, Jia Q Q, Liu W L, Zhu Y F, Yuan Q, Yang J L, Yang F H 2021 IEEE MEMS 2021 Virtual Conference Gainesville, FL, USA, January 25–29, 2021 p964

[27] Yan S H, Liu Z, Tan C K, Zhang X Y, Li S, Shi L, Guo Y F, Tang W H 2023 Appl. Phys. Lett. 123 142202

Google Scholar

Google Scholar

[28] Guo Z, Verma A, Wu X F, Sun F Y, Hickman A, Masui T, Kuramata A, Higashiwaki M, Jena D, Luo T F 2015 Appl. Phys. Lett. 106 111909

Google Scholar

Google Scholar

[29] Safieddine F, Hassan F E H, Kazan M 2022 J. Solid State Chem. 312 123272

Google Scholar

Google Scholar

[30] Prabhakar S, Vengallatore S 2007 J. Micromech. Microeng. 17 532

Google Scholar

Google Scholar

[31] Lifshitz R, Roukes M L 2000 Phys. Rev. B 61 5600

[32] Sun Y X, Saka M 2010 J. Sound Vib. 329 328

Google Scholar

Google Scholar

[33] Cheng Z Z, Hanke M, Galazka Z, Trampert A 2018 Appl. Phys. Lett. 113 182102

Google Scholar

Google Scholar

[34] Ko J H, Jeong J, Choi J, Cho M 2011 Appl. Phys. Lett. 98 171909

Google Scholar

Google Scholar

[35] Yang J L, Ono T, Esashi M 2002 J. Microelectromech. Syst. 11 775

Google Scholar

Google Scholar

[36] Mohanty P, Harrington D A, Ekinci K L, Yang Y T, Murphy M J, Roukes M L 2002 Phys. Rev. B 66 085416

Google Scholar

Google Scholar

[37] Villanueva L G, Schmid S 2014 Phys. Rev. Lett. 113 227201

Google Scholar

Google Scholar

[38] Zheng X Q, Tharpe T, Enamul Hoque Yousuf S M, Rudawski N G, Feng P X L 2022 ACS Appl. Mater. Interfaces 14 36807

Google Scholar

Google Scholar

[39] Bercioux D, Buchs G, Grabert H, Groning O 2011 Phys. Rev. B 83 165439

Google Scholar

Google Scholar

[40] Wang C H, Ning Y H, Zhao W Y, Yi G X, Huo Y 2023 Sens. Actuator A: Phys. 359 114456

Google Scholar

Google Scholar

[41] Ahamed M J, Senkal D, Shkel A M 2014 2014 International Symposium on Inertial Sensors and Systems (INERTIAL) Laguna Beach, CA, USA, February 25–26, 2014 p59

[42] Zheng X Q, Lee J, Rafique S, Han L, Zorman C A, Zhao H P, Feng P X L 2017 ACS Appl. Mater. Interfaces 9 43090

Google Scholar

Google Scholar

[43] Li S S, Lin Y W, Xie Y, Ren Z Y, Nguyen C T C 2004 17th Int. IEEE Micro Electro Mechanical Systems Conf Maastricht, The Netherlands, January 25–29, 2004 p821

[44] 郑贤德, 甄嘉鹏, 邱静, 刘冠军 2023 仪器仪表学报 44 206

Google Scholar

Google Scholar

Zheng X D, Zhen J P, Qiu J, Liu G J 2023 Chin. J. Sci. Instrum. 44 206

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 2894

- PDF Downloads: 82

- Cited By: 0

DownLoad:

DownLoad: