-

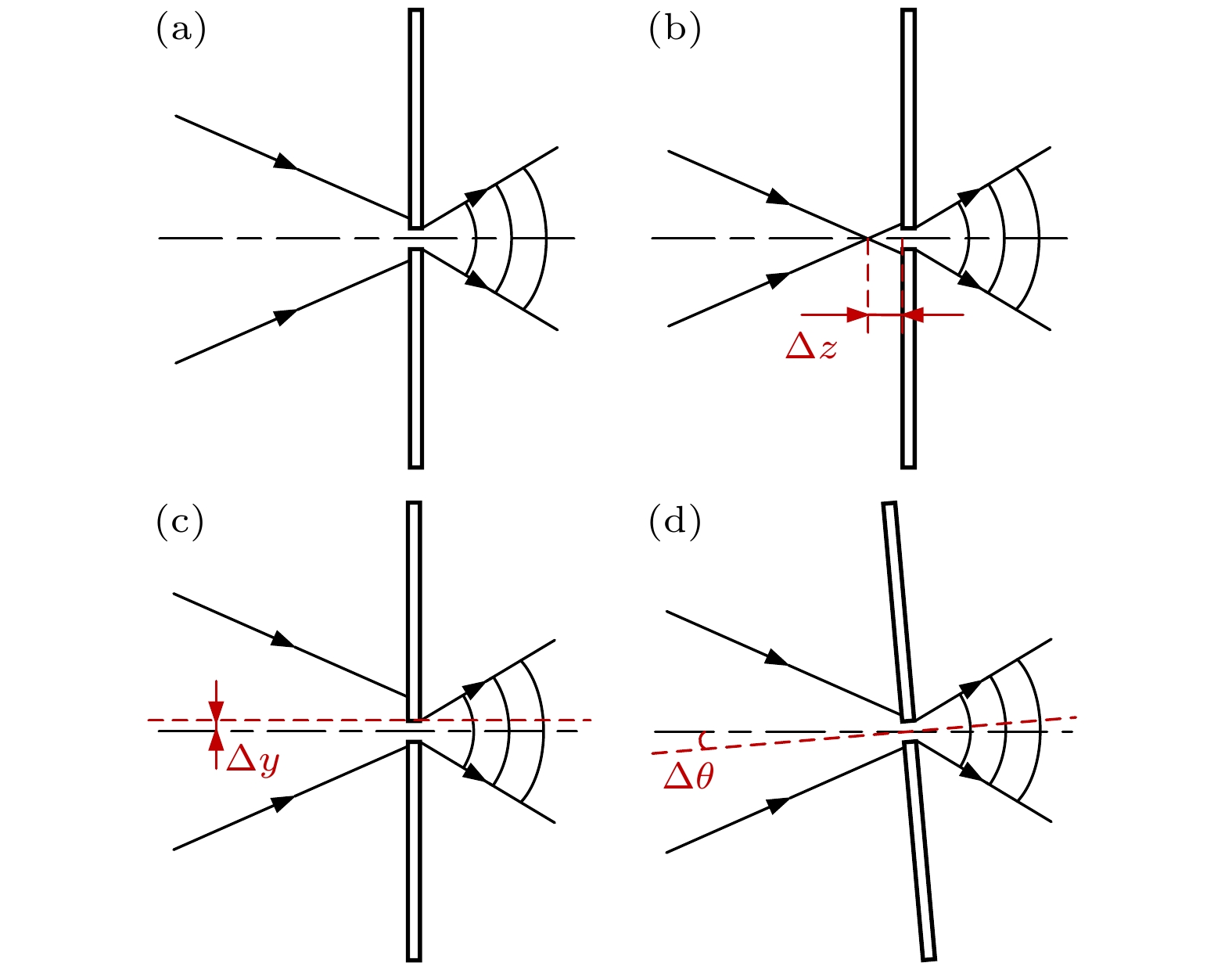

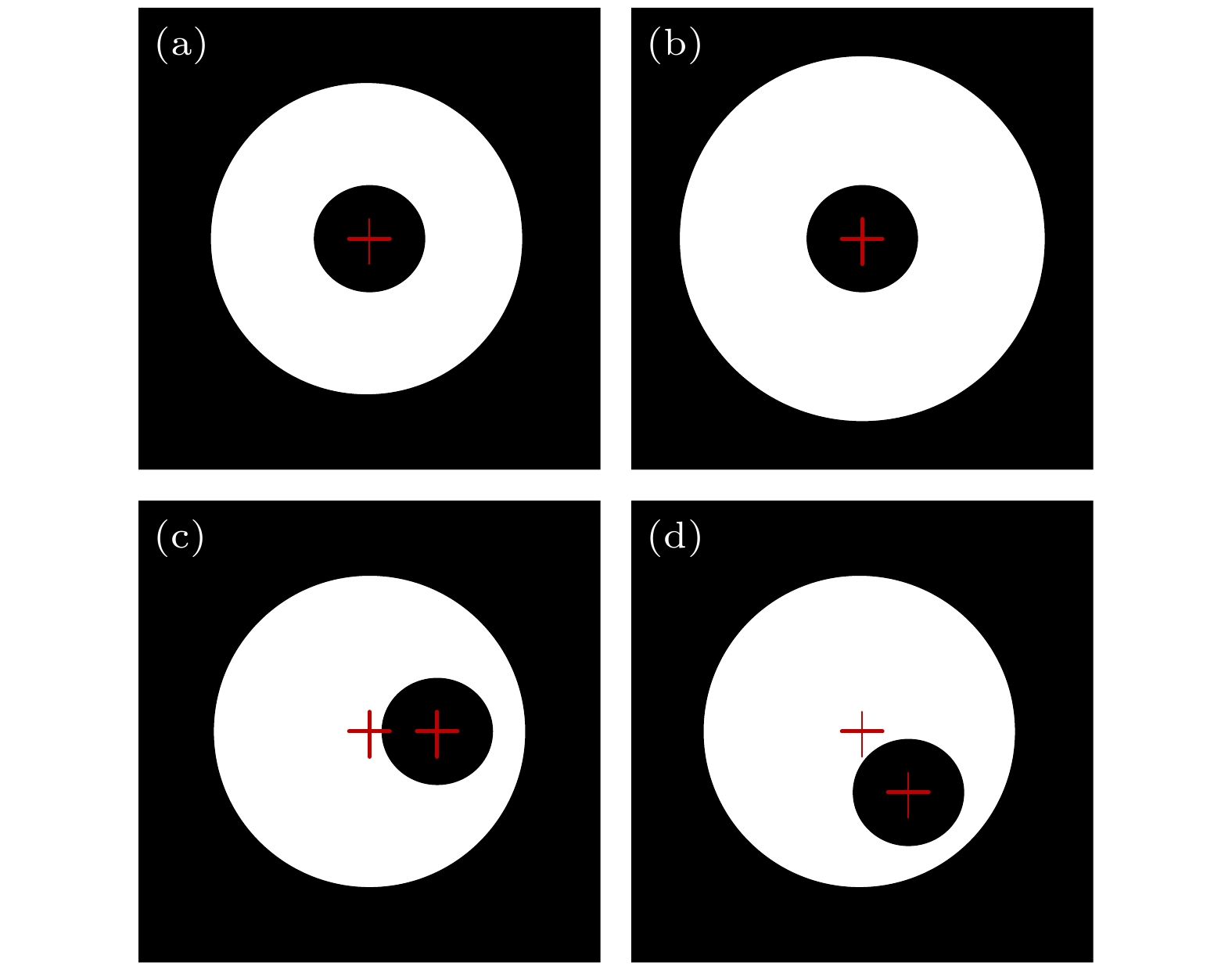

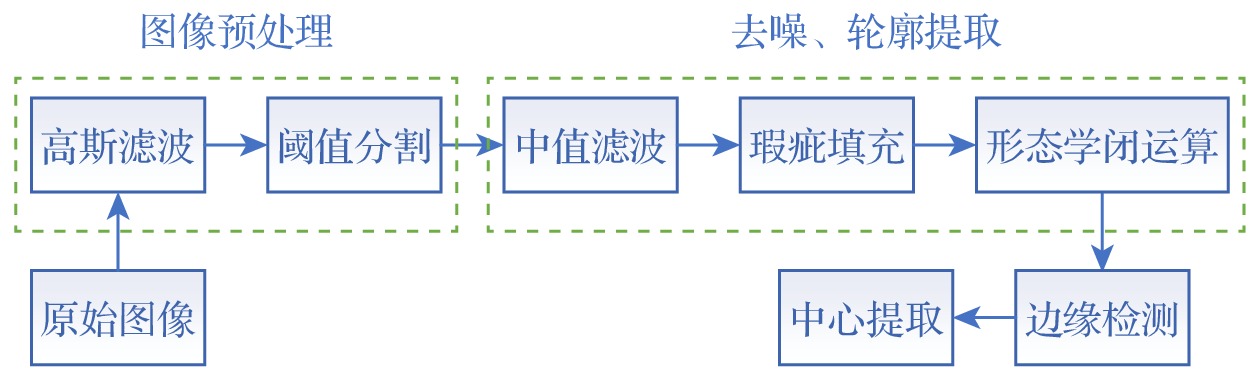

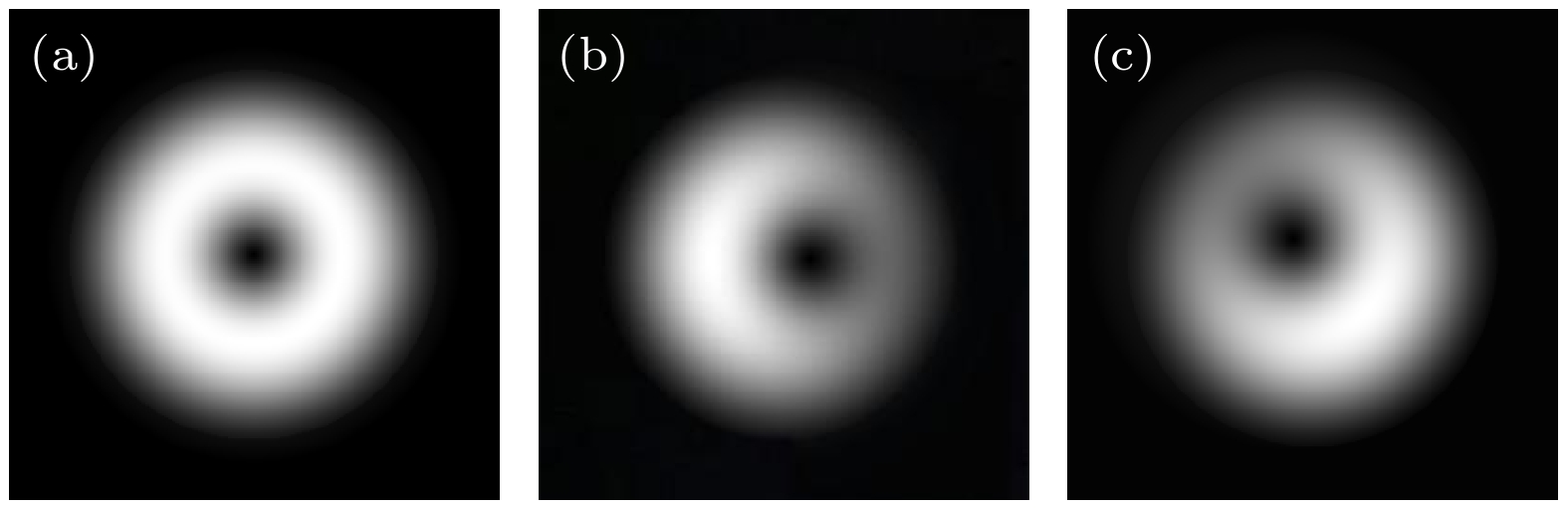

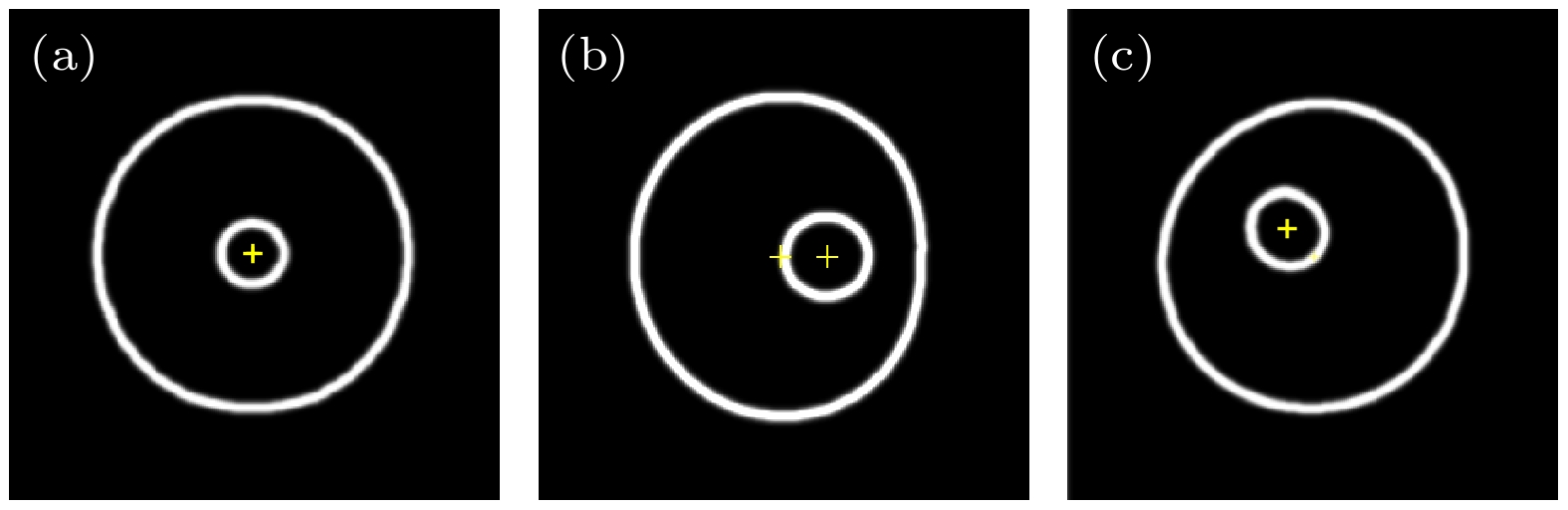

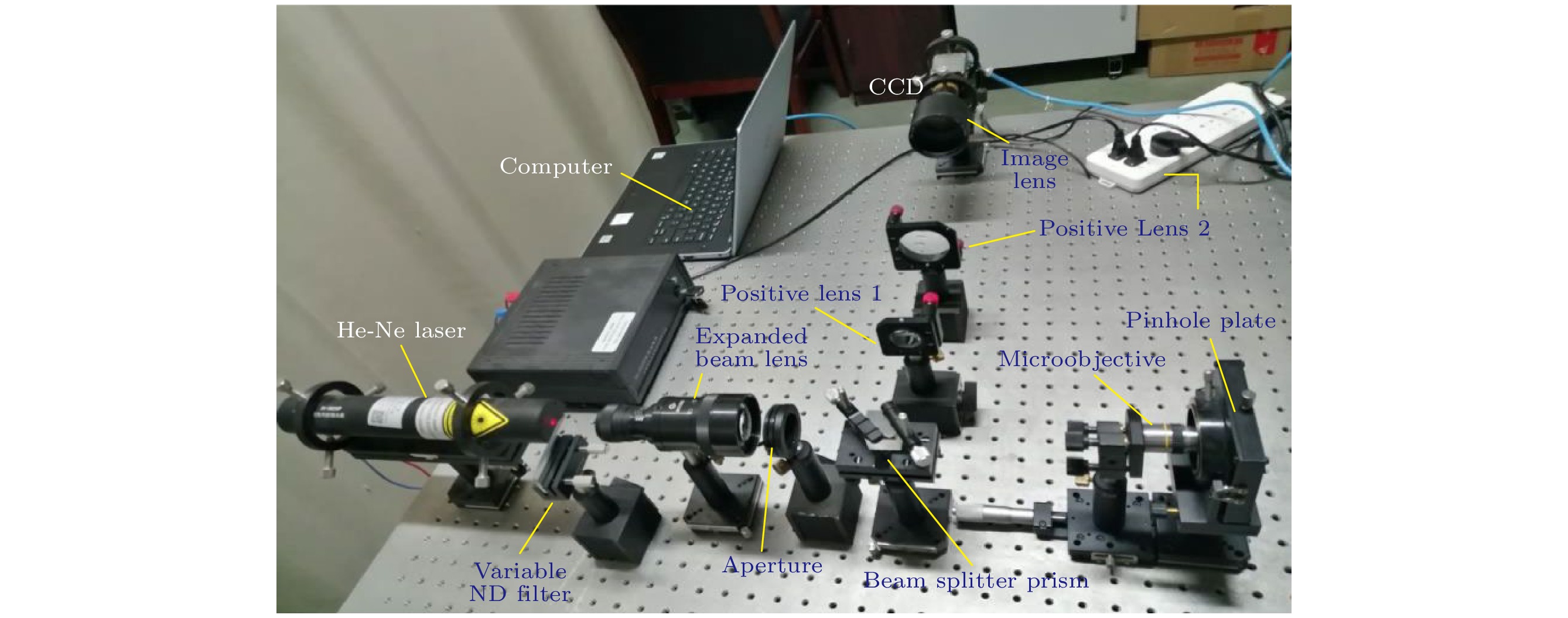

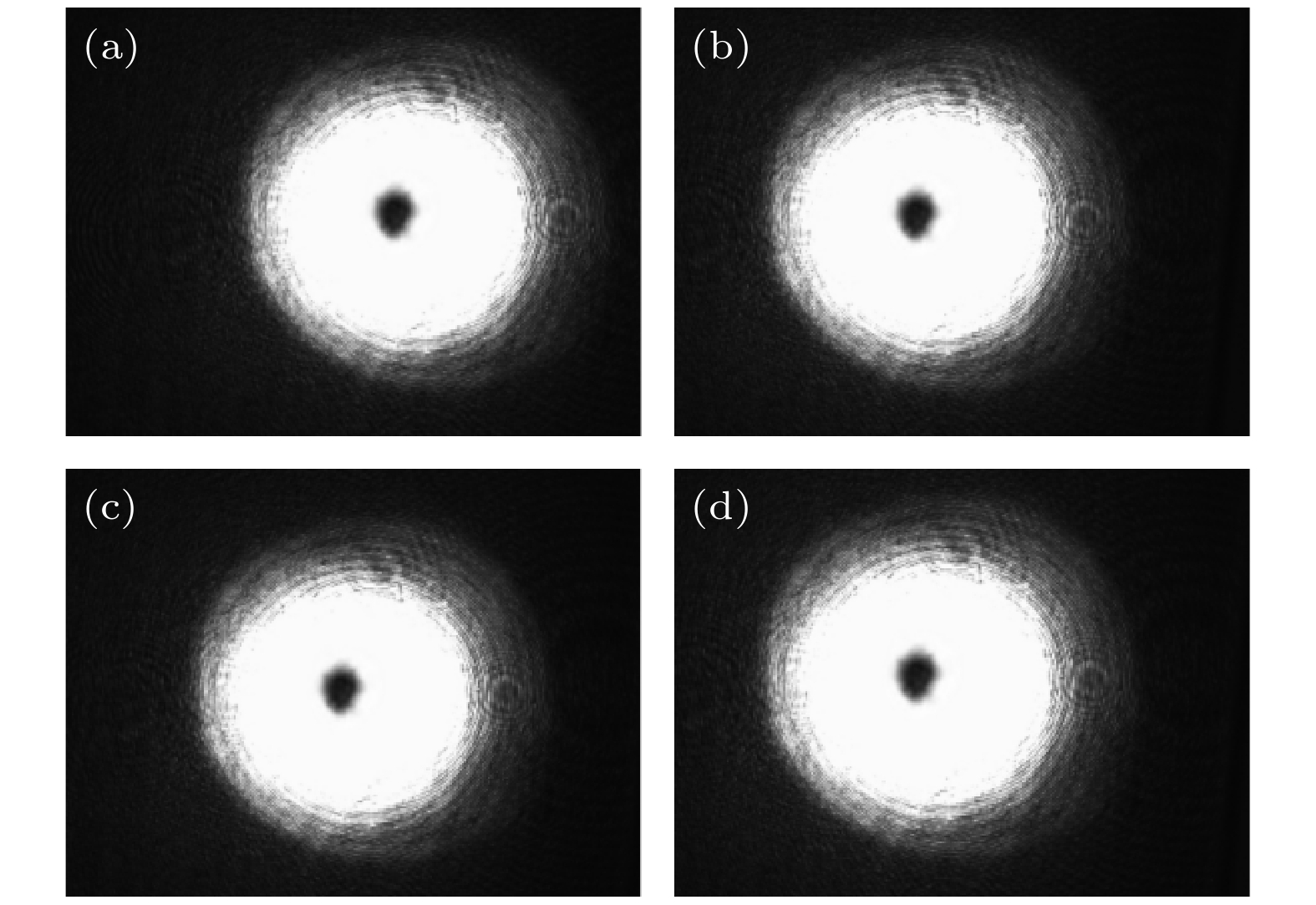

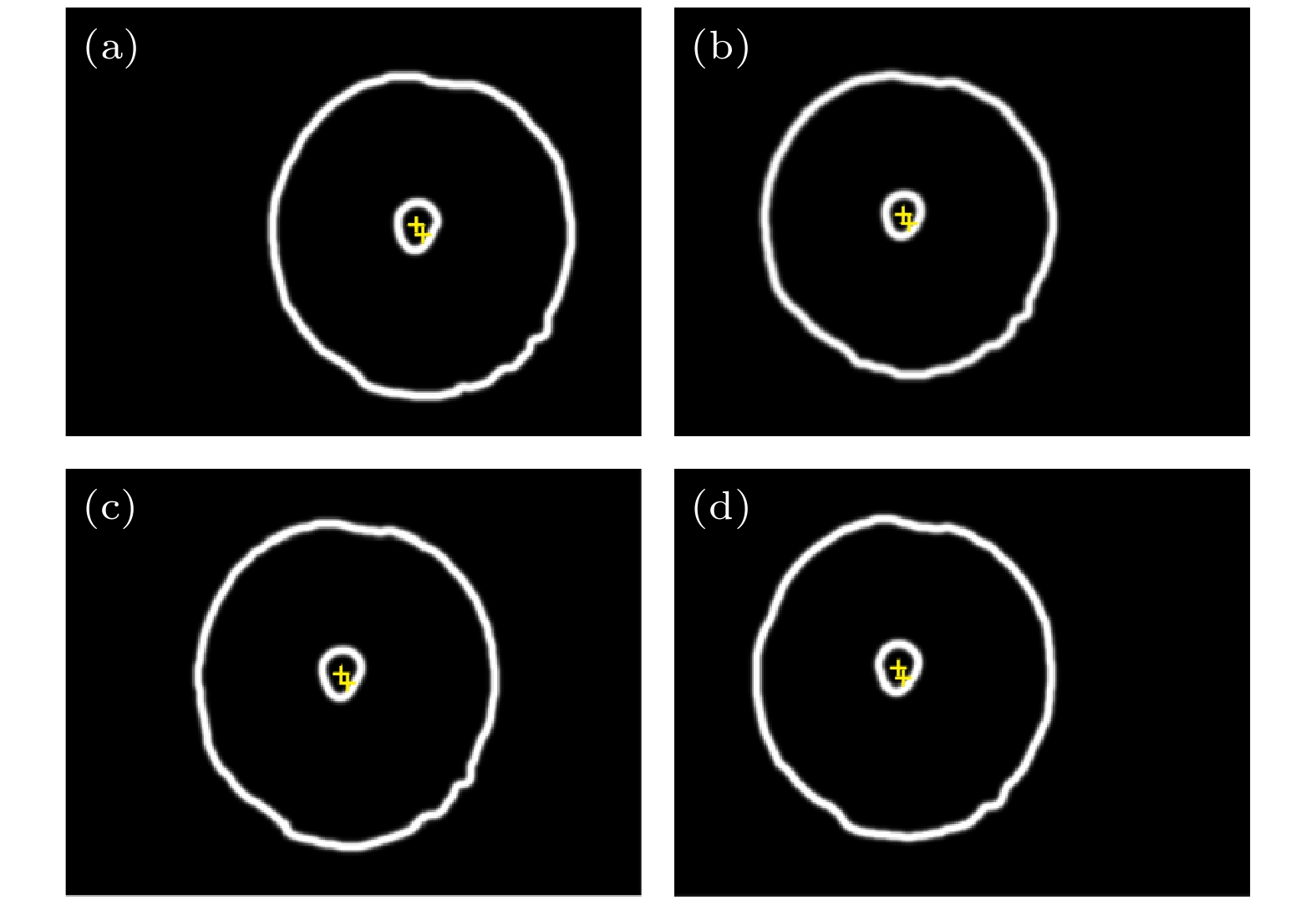

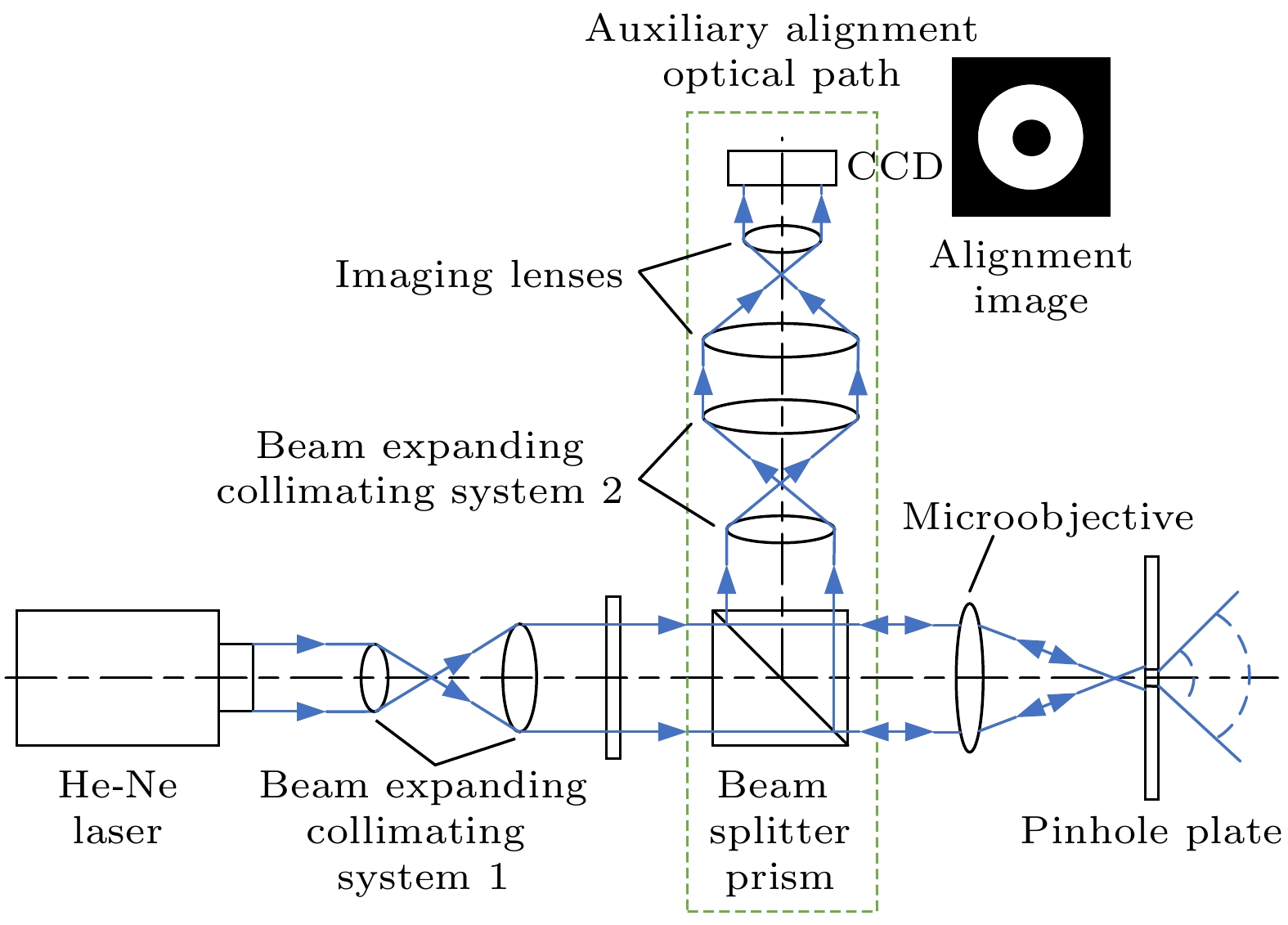

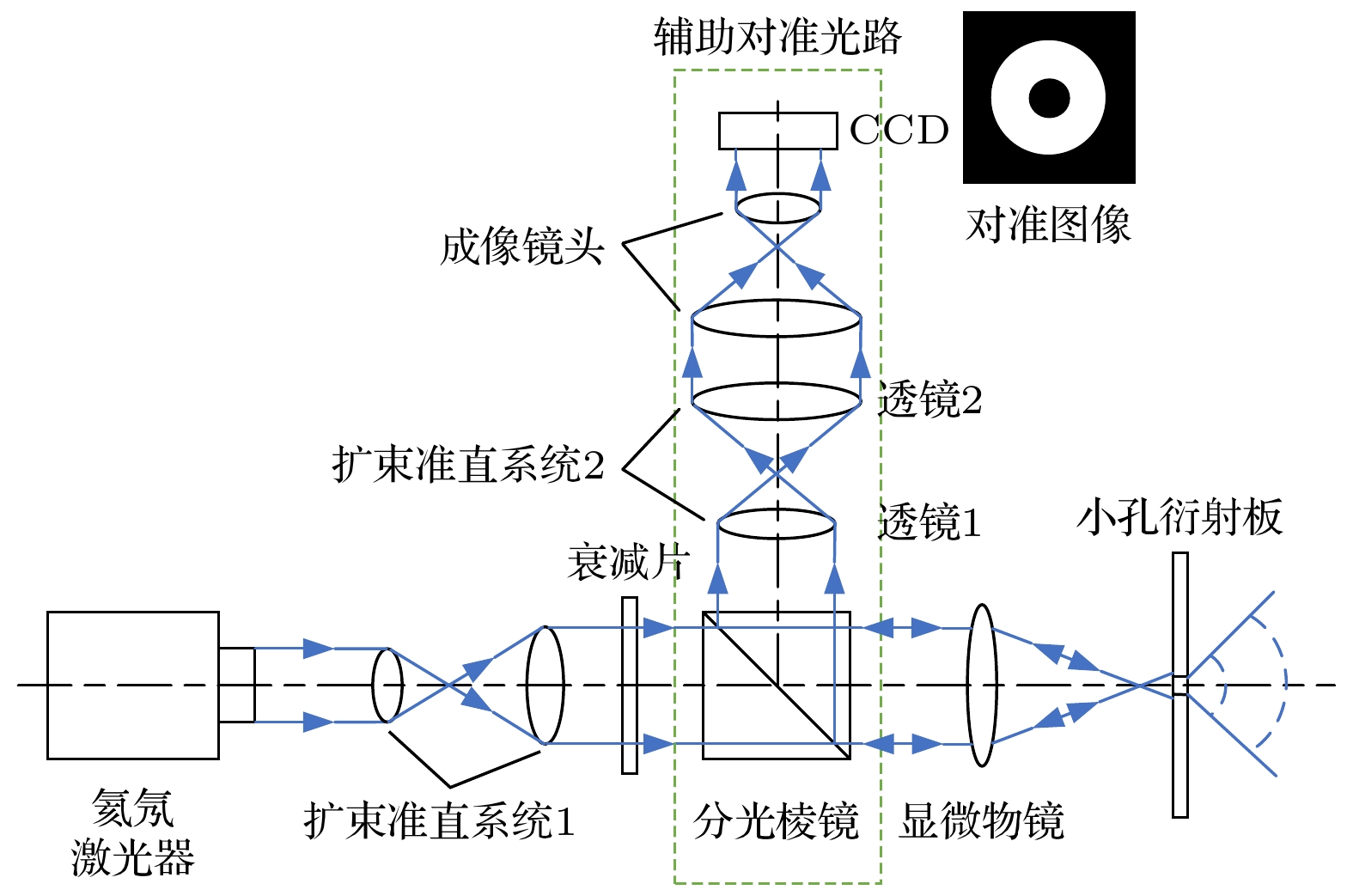

In the construction of the pinhole point diffraction interferometer, the alignment error between the convergent spot of the microscopic objective lens and the diffraction hole in the front end of the pinhole diffraction will lead to problems such as diffraction wavefront error, diffraction intensity reduction, and interference fringe contrast reduction, which will affect the actual measurement accuracy. In order to solve the problem of inaccurate alignment between the convergent spot of the microscopic objective lens and the diffraction hole, a diffraction hole visual alignment method based on the auxiliary optical path is proposed in this work. An auxiliary alignment optical path is built at the front end of the pinhole diffraction, and the beam reflected by the pinhole diffraction plate is mainly reflected by the beam splitter prism, and then received by a charge coupled device (CCD). By collecting and processing the spot image reflected by the small hole diffraction plate, the alignment state of the small hole is monitored and the alignment error is calculated. In this work, a visual-precision optical path alignment scheme is designed, and the visual performance of the alignment image under three typical alignment deviations of translation, tilt and defocus is simulated and analyzed. The mathematical model of the object-image relationship between the alignment image and the alignment error is constructed, and the alignment image error measurement and processing algorithm is studied. The experimental results show that the auxiliary optical path alignment method and the alignment image processing algorithm proposed in this work are feasible, and the alignment accuracy can reach 0.05 μm. The research results are helpful in improving the alignment efficiency and accuracy of point diffraction interferometer, and can lay a certain technical foundation for the development of practical point diffraction interferometer.

-

Keywords:

- point diffraction interferometer /

- diffraction pinhole /

- visual alignment /

- alignment error

[1] Patrick P N, Kenneth A G, Sang H L 1999 Appl. Opt. 38 7252

Google Scholar

Google Scholar

[2] 王同盟, 高芬, 李兵 2024 光学精密工程 32 208

Google Scholar

Google Scholar

Wang T M, Gao F, Li B 2024 Opt. Precis. Eng. 32 208

Google Scholar

Google Scholar

[3] 张金鹏, 高芬, 李兵 2022 光子学报 51 0412004

Google Scholar

Google Scholar

Zhang J P, Gao F, Li B 2022 Acta Photonica Sin. 51 0412004

Google Scholar

Google Scholar

[4] Shan M G, Yin Z Y, Zhong Z, Liu B, Yu L, Liu L 2024 Phys. Scr. 99 065118

Google Scholar

Google Scholar

[5] Zheng D H, Ma Z Y, Zhang Z, Hu C H 2023 Appl. Opt. 62 745

Google Scholar

Google Scholar

[6] Yang X, Guo R H, Tang X, Yin Z Y, Liu C X, Li J X 2021 Appl. Opt. 60 10988

Google Scholar

Google Scholar

[7] 毛姗姗, 李艳秋, 刘克, 刘丽辉, 郑猛, 闫旭 2019 红外与激光工程 48 0814002

Google Scholar

Google Scholar

Mao S S, Li Y Q, Liu K, Liu L H, Zheng M, Yan X 2019 Infrared Laser Eng. 48 0814002

Google Scholar

Google Scholar

[8] 张宇, 金春水, 马冬梅, 王丽萍 2012 红外与激光工程 41 3384

Zhang Y, Jin C S, Ma D M, Wang L P 2012 Infrared Laser Eng. 41 3384

[9] Feng P, Tang F, Wang X Z, Lu Y J, Xu J H, Guo F D, Zhang G X 2020 Appl. Opt. 59 3093

Google Scholar

Google Scholar

[10] 郑东晖, 李金鹏, 陈磊, 朱文华, 韩志刚, 乌兰图雅, 郭仁慧 2016 65 114203

Google Scholar

Google Scholar

Zheng D H, Li J P, Chen L, Zhu W H, Han Z G, Wulan T Y, Guo R H 2016 Acta Phys. Sin. 65 114203

Google Scholar

Google Scholar

[11] Nicolás D, Ali N B, Marc D, Myers R M 2022 Appl. Opt. 61 4160

Google Scholar

Google Scholar

[12] Lu J S, Li B, Zhao Z, Geng L Q 2022 Opt. Lett. 47 4877

Google Scholar

Google Scholar

[13] Smartt R N, Steel W H 1985 Appl. Opt. 24 1402

Google Scholar

Google Scholar

[14] Otaki K, Yamamoto T, Fukud Y, Ota K, Nishiyama I, Okazaki S 2002 J. Vac. Sci. Technol., B 20 295

Google Scholar

Google Scholar

[15] 卢毅伟, 骆永洁, 刘维, 孔明, 王道档 2023 红外与激光工程 52 20220593

Google Scholar

Google Scholar

Lu Y W, Luo Y J, Liu W, Kong M, Wang D D 2023 Infrared Laser Eng. 52 20220593

Google Scholar

Google Scholar

[16] Sun Y, Shen H, Li X, Li J, Gao J M, Zhu R H 2019 Appl. Opt. 58 1253

Google Scholar

Google Scholar

[17] 冯鹏, 李中梁, 王向朝, 步扬, 卢云君, 郭福东, 李思坤 2022 中国激光 49 2104001

Google Scholar

Google Scholar

Feng P, Li Z L, Wang X C, Bu Y, Lu Y J, Guo F D, Li S K 2022 Chin. J. Lasers 49 2104001

Google Scholar

Google Scholar

[18] Gao F, Jiang Z D, Zhao Z, Li B 2015 Opt. Eng. 54 014102

Google Scholar

Google Scholar

[19] Geng L Q, Li B, Zhao Z, Lu J S 2024 Opt. Laser Eng. 178 108198

Google Scholar

Google Scholar

[20] Ota K, Yamamoto T, Fukuda Y, Otaki K, Nishiyama I, Okazaki S 2001 Proc. SPIE 4343 543

Google Scholar

Google Scholar

[21] Zhao Z, Li B, Kang X Q, Chen L, Wei X 2019 Appl. Opt. 58 3703

Google Scholar

Google Scholar

[22] 高芬, 蒋庄德, 李兵 2014 光学学报 34 0812004

Google Scholar

Google Scholar

Gao F, Jiang Z D, Li B 2014 Acta Opt. Sin. 34 0812004

Google Scholar

Google Scholar

-

表 1 仿真图像中心像素坐标

Table 1. Simulation image center pixel coordinates.

表 2 仿真图像中心提取像素坐标

Table 2. Pixel coordinates extracted from the center of the simulation image.

表 3 实验图像中心点像素坐标

Table 3. Pixel coordinates of the center point of the experimental image.

表 4 实验图像中心点相机靶面坐标

Table 4. Experimental image center point camera target surface coordinates.

-

[1] Patrick P N, Kenneth A G, Sang H L 1999 Appl. Opt. 38 7252

Google Scholar

Google Scholar

[2] 王同盟, 高芬, 李兵 2024 光学精密工程 32 208

Google Scholar

Google Scholar

Wang T M, Gao F, Li B 2024 Opt. Precis. Eng. 32 208

Google Scholar

Google Scholar

[3] 张金鹏, 高芬, 李兵 2022 光子学报 51 0412004

Google Scholar

Google Scholar

Zhang J P, Gao F, Li B 2022 Acta Photonica Sin. 51 0412004

Google Scholar

Google Scholar

[4] Shan M G, Yin Z Y, Zhong Z, Liu B, Yu L, Liu L 2024 Phys. Scr. 99 065118

Google Scholar

Google Scholar

[5] Zheng D H, Ma Z Y, Zhang Z, Hu C H 2023 Appl. Opt. 62 745

Google Scholar

Google Scholar

[6] Yang X, Guo R H, Tang X, Yin Z Y, Liu C X, Li J X 2021 Appl. Opt. 60 10988

Google Scholar

Google Scholar

[7] 毛姗姗, 李艳秋, 刘克, 刘丽辉, 郑猛, 闫旭 2019 红外与激光工程 48 0814002

Google Scholar

Google Scholar

Mao S S, Li Y Q, Liu K, Liu L H, Zheng M, Yan X 2019 Infrared Laser Eng. 48 0814002

Google Scholar

Google Scholar

[8] 张宇, 金春水, 马冬梅, 王丽萍 2012 红外与激光工程 41 3384

Zhang Y, Jin C S, Ma D M, Wang L P 2012 Infrared Laser Eng. 41 3384

[9] Feng P, Tang F, Wang X Z, Lu Y J, Xu J H, Guo F D, Zhang G X 2020 Appl. Opt. 59 3093

Google Scholar

Google Scholar

[10] 郑东晖, 李金鹏, 陈磊, 朱文华, 韩志刚, 乌兰图雅, 郭仁慧 2016 65 114203

Google Scholar

Google Scholar

Zheng D H, Li J P, Chen L, Zhu W H, Han Z G, Wulan T Y, Guo R H 2016 Acta Phys. Sin. 65 114203

Google Scholar

Google Scholar

[11] Nicolás D, Ali N B, Marc D, Myers R M 2022 Appl. Opt. 61 4160

Google Scholar

Google Scholar

[12] Lu J S, Li B, Zhao Z, Geng L Q 2022 Opt. Lett. 47 4877

Google Scholar

Google Scholar

[13] Smartt R N, Steel W H 1985 Appl. Opt. 24 1402

Google Scholar

Google Scholar

[14] Otaki K, Yamamoto T, Fukud Y, Ota K, Nishiyama I, Okazaki S 2002 J. Vac. Sci. Technol., B 20 295

Google Scholar

Google Scholar

[15] 卢毅伟, 骆永洁, 刘维, 孔明, 王道档 2023 红外与激光工程 52 20220593

Google Scholar

Google Scholar

Lu Y W, Luo Y J, Liu W, Kong M, Wang D D 2023 Infrared Laser Eng. 52 20220593

Google Scholar

Google Scholar

[16] Sun Y, Shen H, Li X, Li J, Gao J M, Zhu R H 2019 Appl. Opt. 58 1253

Google Scholar

Google Scholar

[17] 冯鹏, 李中梁, 王向朝, 步扬, 卢云君, 郭福东, 李思坤 2022 中国激光 49 2104001

Google Scholar

Google Scholar

Feng P, Li Z L, Wang X C, Bu Y, Lu Y J, Guo F D, Li S K 2022 Chin. J. Lasers 49 2104001

Google Scholar

Google Scholar

[18] Gao F, Jiang Z D, Zhao Z, Li B 2015 Opt. Eng. 54 014102

Google Scholar

Google Scholar

[19] Geng L Q, Li B, Zhao Z, Lu J S 2024 Opt. Laser Eng. 178 108198

Google Scholar

Google Scholar

[20] Ota K, Yamamoto T, Fukuda Y, Otaki K, Nishiyama I, Okazaki S 2001 Proc. SPIE 4343 543

Google Scholar

Google Scholar

[21] Zhao Z, Li B, Kang X Q, Chen L, Wei X 2019 Appl. Opt. 58 3703

Google Scholar

Google Scholar

[22] 高芬, 蒋庄德, 李兵 2014 光学学报 34 0812004

Google Scholar

Google Scholar

Gao F, Jiang Z D, Li B 2014 Acta Opt. Sin. 34 0812004

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 3043

- PDF Downloads: 69

- Cited By: 0

DownLoad:

DownLoad: