-

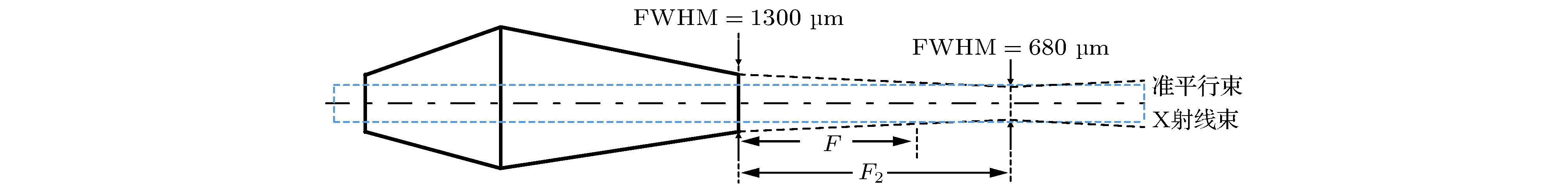

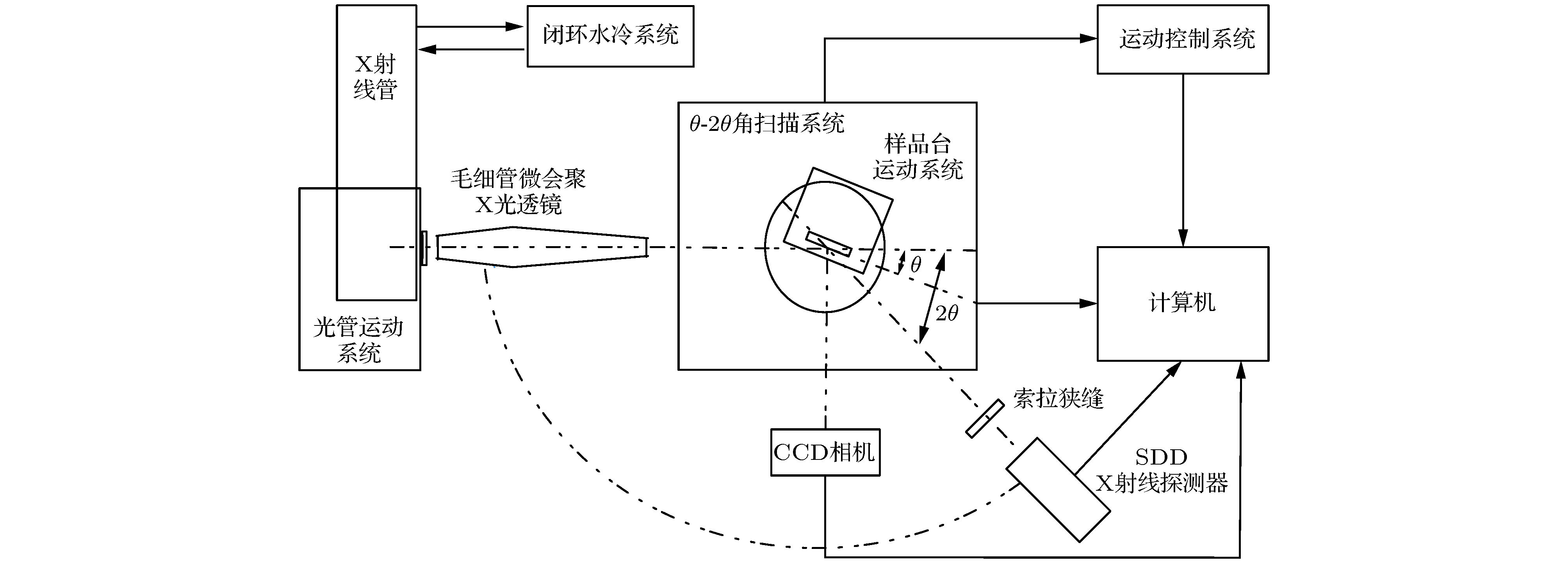

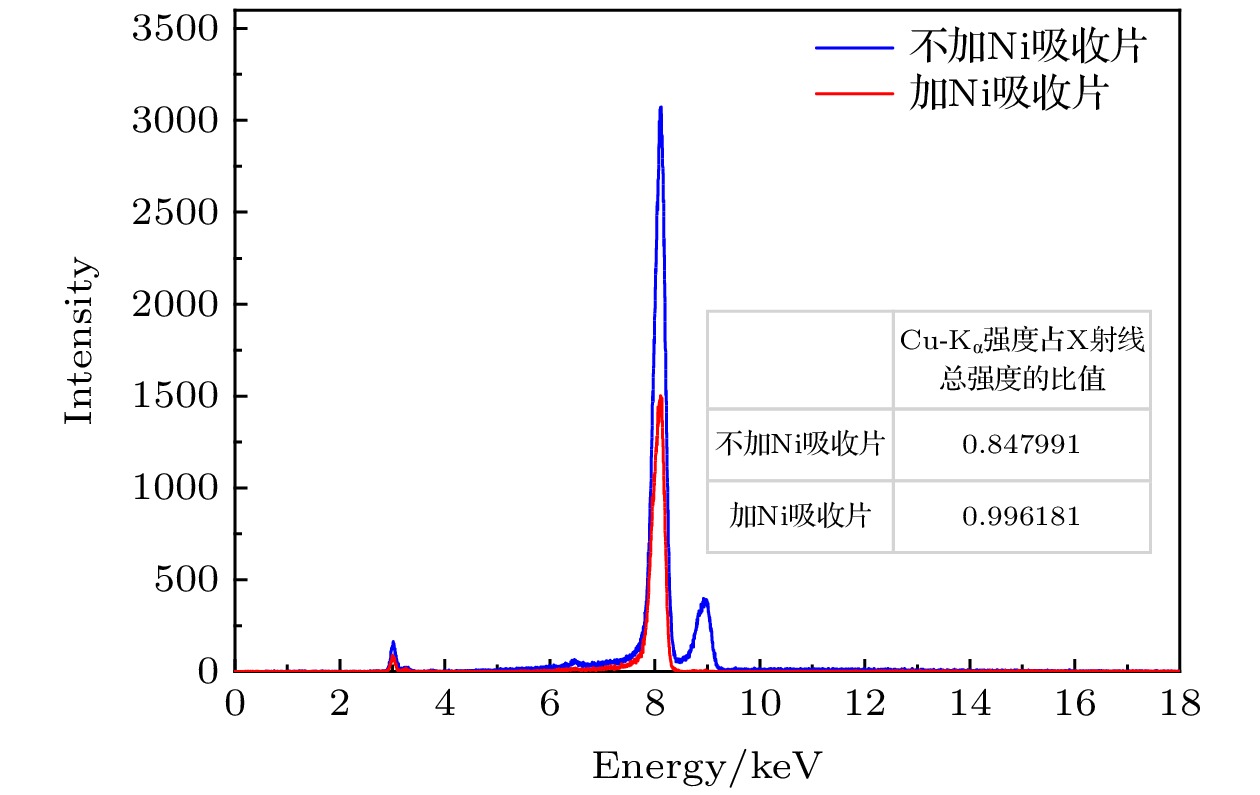

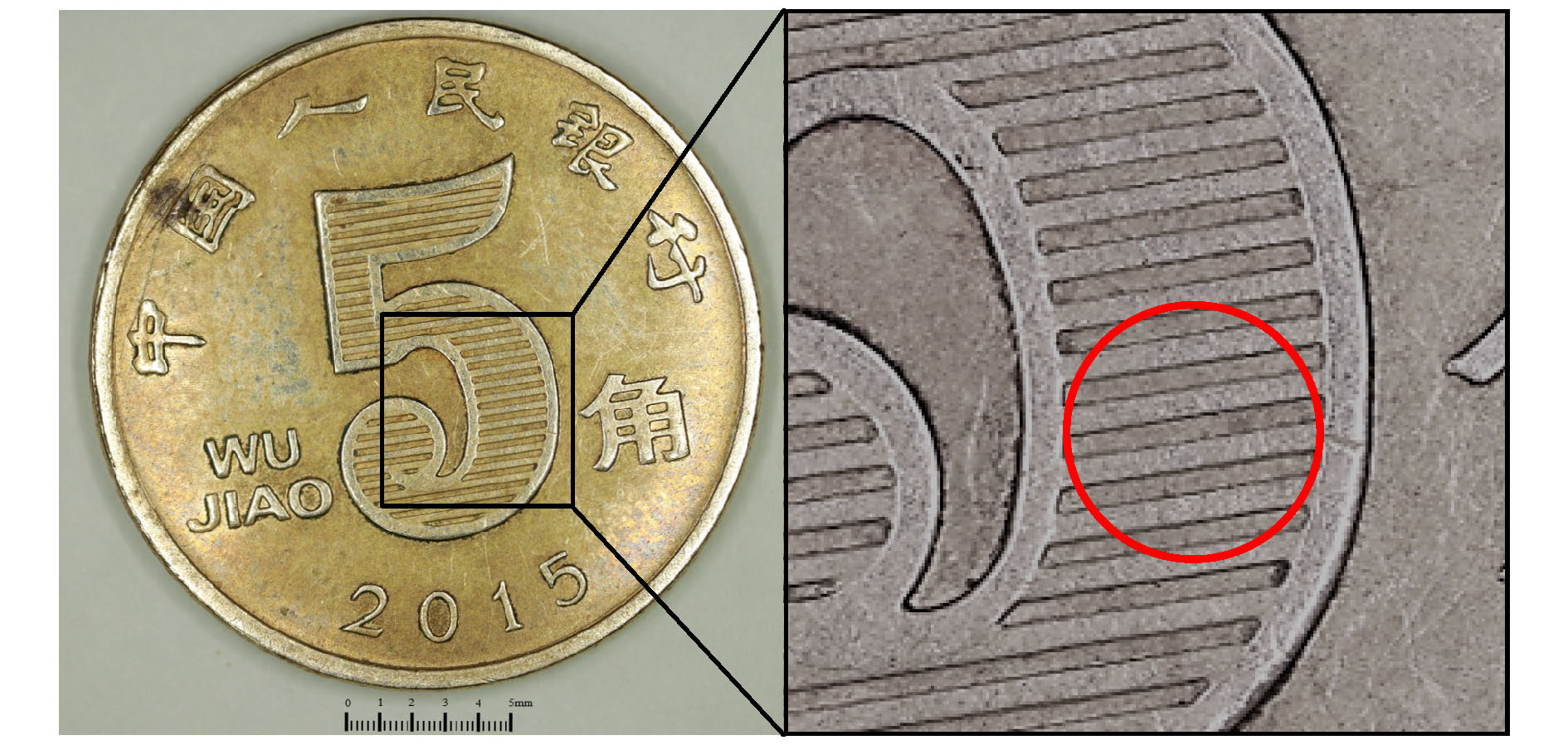

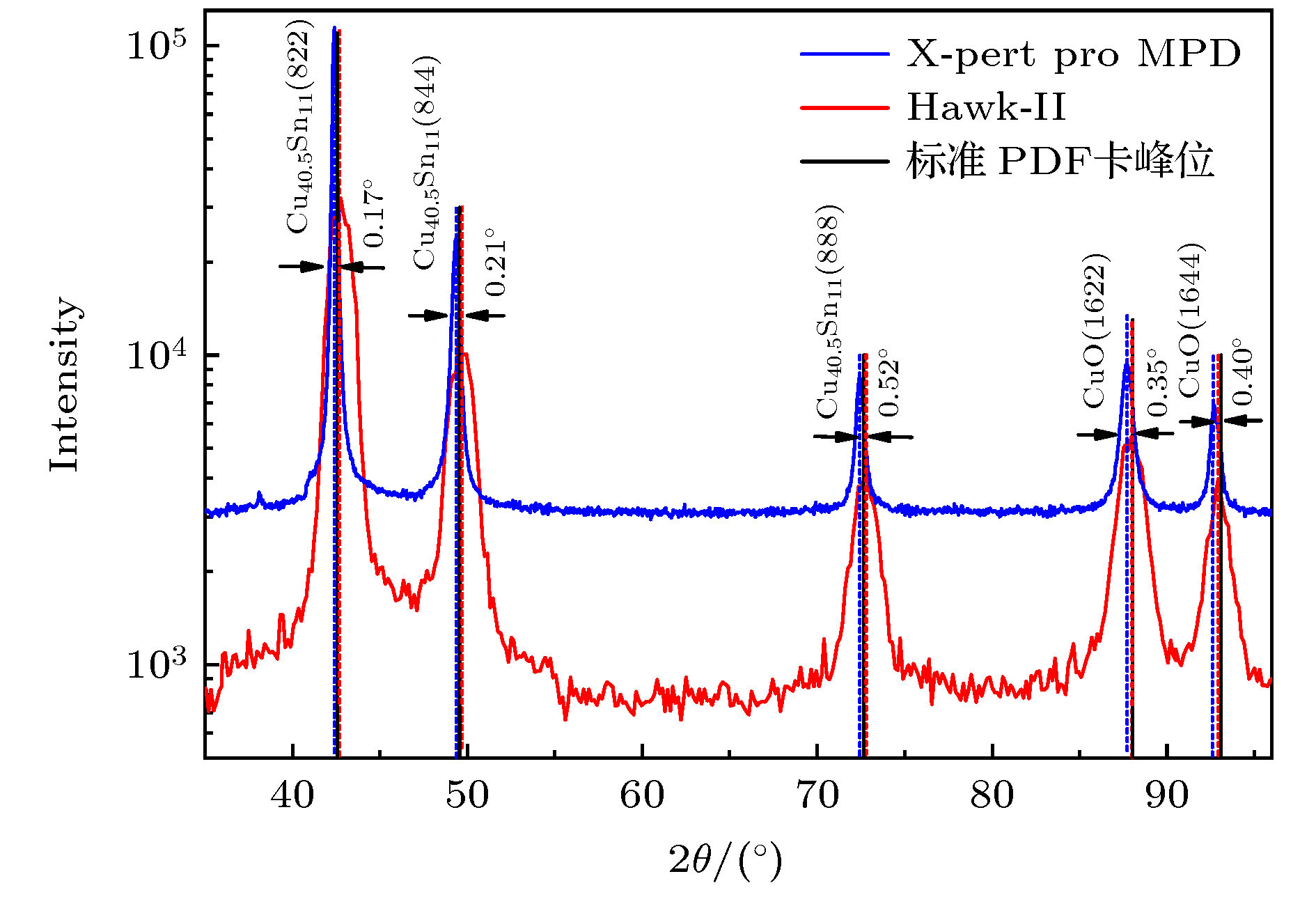

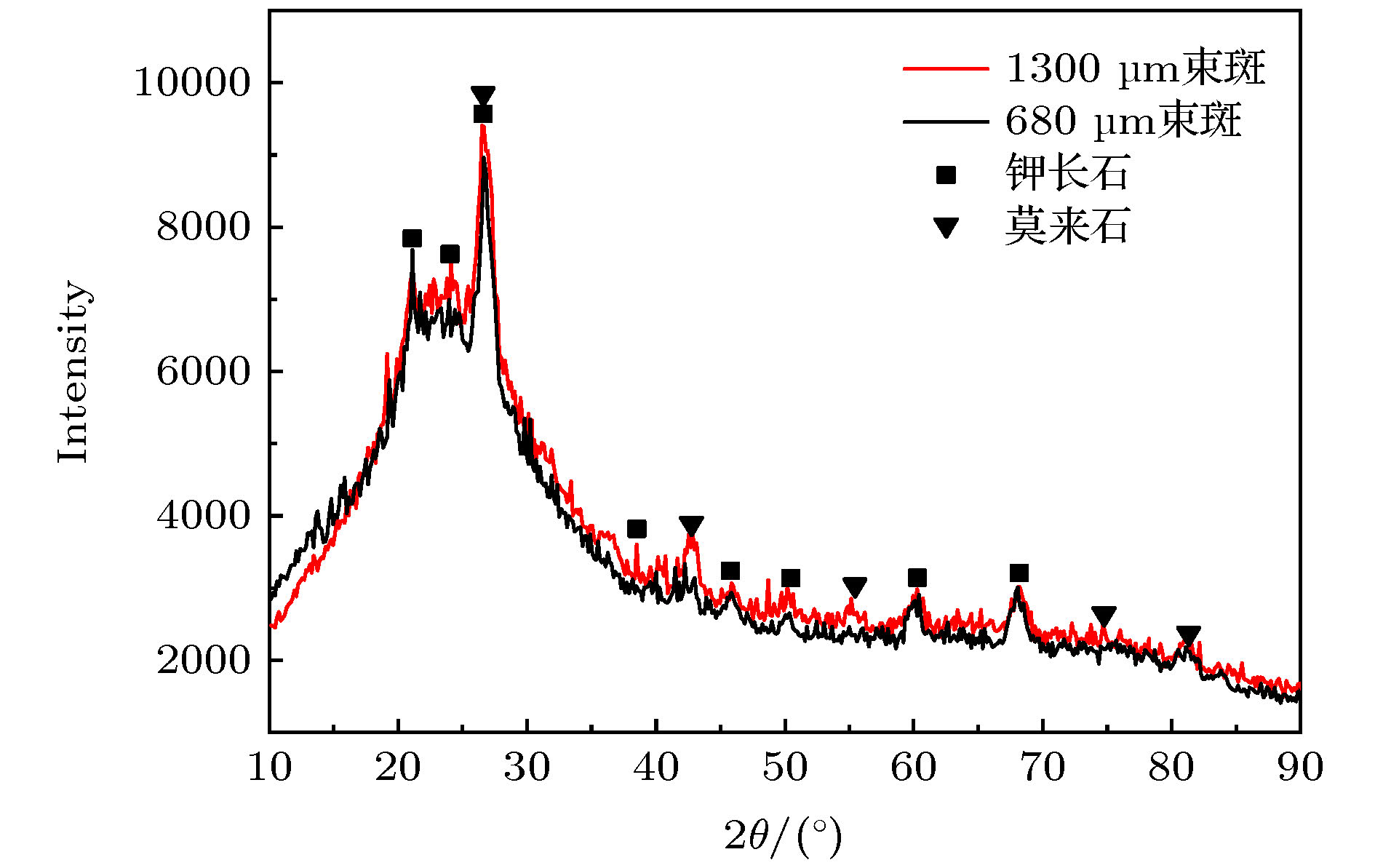

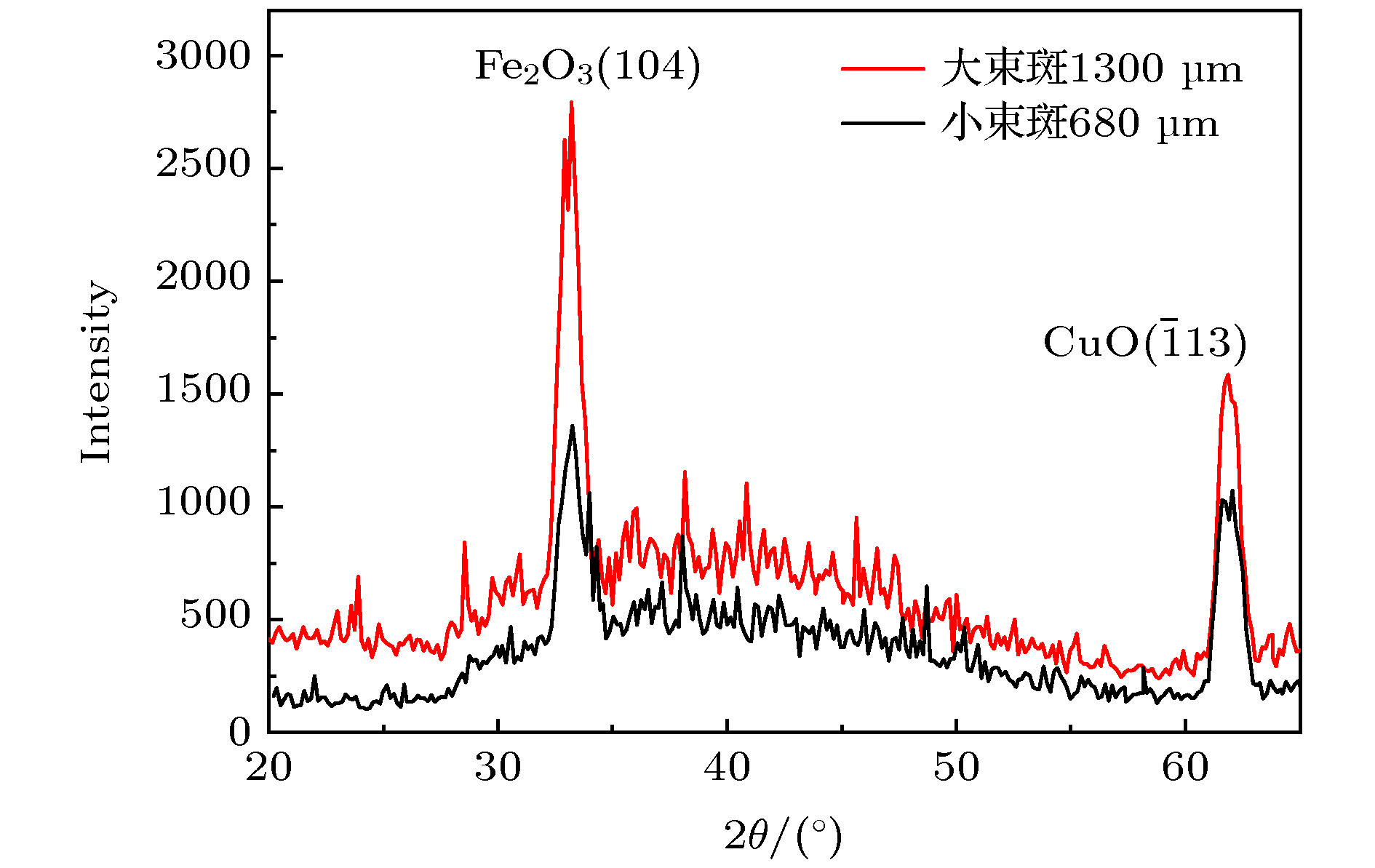

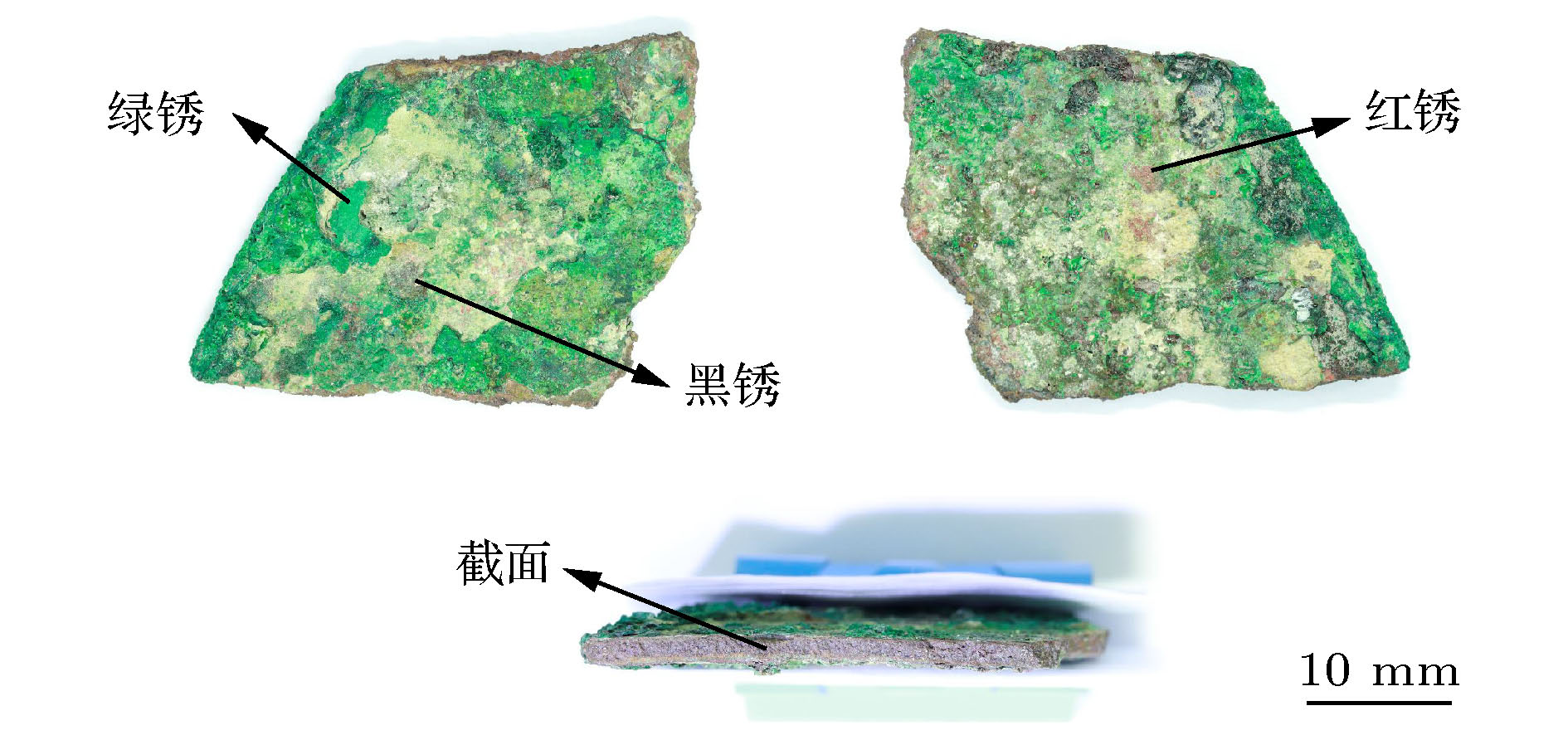

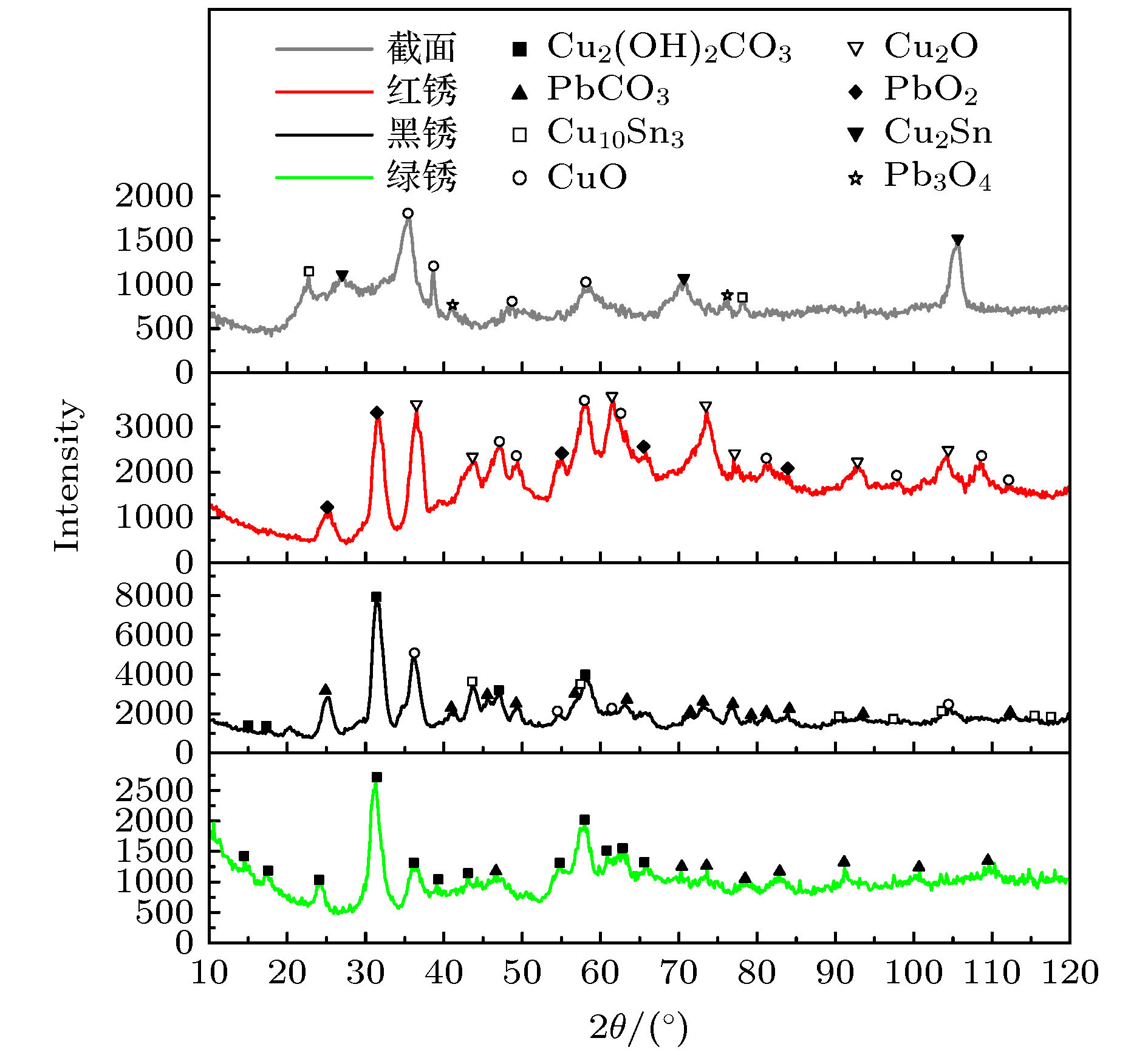

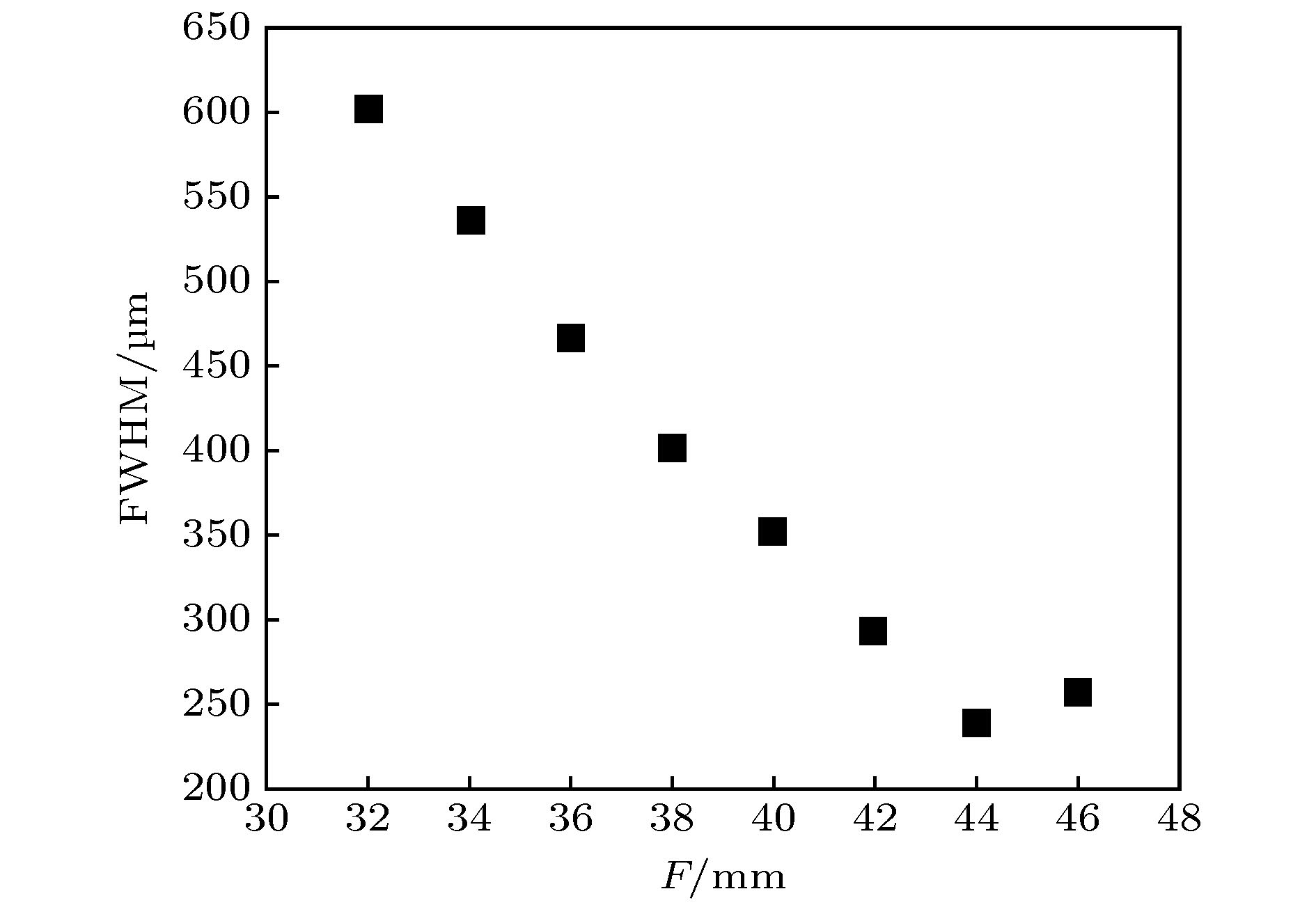

为同时实现微米量级待测区域和毫米量级待测区域的物相分析, 以及对表面不平整样品准确的物相分析, 本实验室结合X射线衍射技术、CCD相机成像技术和毛细管微会聚X光调控技术, 研制了一款能根据待测区域大小自适应调节照射X射线束斑直径的点光源X射线衍射仪Hawk-II,其主要组成包括X射线源系统、六维联动运动系统、CCD相机、X射线探测系统和基于LabVIEW的软件控制系统. 为验证设备的可行性, 对表面不平整的人民币五角硬币进行分析, 发现Hawk-II测得的衍射图与标准PDF卡基本一致, 而帕纳科X-Pert Pro MPD测得的衍射图最大偏移角度高达0.52°. 对清代红绿彩瓷白釉和表面镀Cu, Fe的纳米材料采用不同直径的X射线束进行分析, 发现白釉的晶体分布较为均匀, 而纳米材料的表面镀膜不均匀. 应用Hawk-II分析一片西汉青铜, 根据其锈蚀点的大小自适应调节照射X射线束斑直径, 从而实现了物相的精确分析. 由分析结果可知, Hawk-II不仅拥有准确分析不规则样品的能力, 而且拥有从微米级到毫米级待测区域的物相分析能力, 并兼具能量色散X射线荧光分析功能, 在诸多领域具有广泛的应用前景.In order to realize micron scale to millimeter scale phase structure analysis, as well as accurate phase structure analysis of surface uneven samples, X-ray diffractometer named Hawk-II, which can adaptively adjust the diameter of irradiated X-ray beam spot according to the diameter of internal tangential circle at the measured point, is developed by combining X-ray diffraction technology, CCD camera imaging technology and slightly-focusing ploycapillary X-ray control technology. The X-ray source system, six-dimensional linkage motion system, CCD camera, detection system and control system based on LabVIEW are the main components of the Hawk-II. Compared with the 3°–5° divergence of the conventional X-ray source, the divergence of the X-ray emitted by the slightly-focusing polycapillary X-ray optics is only about 0.15° and also the intensity within the beam spot range is dozens of times stronger. Therefore, the shift of peak position will not appear due to the pores, curvature or uneven surface of the sample, when Hawk-II is used to analyze the samples with irregular surface. The diffraction pattern of the uneven Ren Min Bi five-cent coin are collected in the Hawk-II and PANalytical X-Pert Pro MPD conventional X-ray diffractometer respectively. By comparing the analysis results, it is found that the diffraction peaks measured by the X-Pert Pro MPD are shifted seriously, with a maximum deviation angle of 0.52°. While the diffraction peaks detected by the Hawk-II are basically consistent with the data from the standard PDF card, which verifies the advantages of the analysis of irregular samples by the Hawk-II. In order to explore the difference between different beam spots used for analysis at the same point, red and green porcelain fired in Qing dynasty and GaAs-based Cu and Fe plated films are analyzed by the Hawk-II. It is found that when the samples are relatively uniform, the intensities of diffraction peaks of different beam spots are relatively close, while when the samples are not uniform, the diffraction peaks vary greatly. Especially, some microcrystalline phases can be detected only with large beam spots. In addition, to verify the adaptive functionality of the Hawk-II, a bronze from the Western Han Dynasty, with different rust spots on it, is tested. It is found that the Hawk-II can adjust the beam spot size according to the different corrosion points, making the irradiation area coincide with the area to be analysed and the phase structure detected more accurately. Therefore, the Hawk-II is a general purpose X-ray diffractometer, which has the analytical capability from micron scale to millimeter scale and the energy dispersive X-ray fluorescence analysis function. Moreover, it has the advantages of the accurate analysis of irregular samples, fast detection speed, simple operation, etc. Based on the above analysis, the Hawk-II will be widely used in different fields.

[1] Dikmen G, Alver Ö, Parlak C 2018 Chem. Phys. Lett. 698 114

[2] Zhou X, Liu D, Bu H, Deng L, Liu H, Yuan P, Du P, Song H 2018 Solid Earth 3 16

[3] Thota S, Kashyap S C, Sharma S K, Reddy V R 2016 Mater. Sci. Eng., B 206 69

[4] Dappe V, Uzu G, Schreck E, Wu L, Li X, Dumat C, Moreau M, Hanoune B, Ro C, Sobanska S 2018 Atmos. Pollut. Res. 9 697

[5] Liu Z, Jia C, Li L, Li X L, Ji L Y, Wang L H, Lei Y, Wei X J 2018 J. Amer. Chem. Soc. 101 5229

Google Scholar

Google Scholar

[6] Gordillo-Cruz E, Alvarez-Ramirez J, González F, Reyes J A 2018 Physica A 512 635

[7] Myoung J H, Lee D R, Sung H I, Jeong A Y, Chang Y S, Kim H J, Sun W J, Young W C, Young T H, Myung J K 2018 Eur. J. Pharm. Biopharm. 130 143

[8] Nakai I, Abe Y 2012 Appl. Phys. A 106 279

Google Scholar

Google Scholar

[9] 姜其立, 段泽明, 帅麒麟, 李融武, 潘秋丽, 程琳 2019 68 124

Google Scholar

Google Scholar

Jiang Q L, Duan Z M, Shuai Q L, Li R W, Pan Q L, Cheng L 2019 Acta Phys. Sin. 68 124

Google Scholar

Google Scholar

[10] Noyan I C, Wang P C, Kaldor S K, Jordan-Sweet J L, Liniger E G 2000 Rev. Sci. Instrum. 71 1991

[11] 陈俊, 赫业军, 李玉德, 魏富忠, 王大椿, 罗萍, 颜一鸣 1999 核技术 22 3

Google Scholar

Google Scholar

Chen J, He Y J, Li Y D, Wei F Z, Wang D C, Luo P, Yan Y M 1999 Nucl. Tech. 22 3

Google Scholar

Google Scholar

[12] Pradell T, Molera J, Salvadó N, Labrador A 2010 Appl. Phys. A 99 407

Google Scholar

Google Scholar

[13] Alfeld M, Janssens K, Dik J, Nolf W, Snickt G 2011 J. Anal. Atom. Spect. 26 899

Google Scholar

Google Scholar

[14] 段泽明, 刘俊, 姜其立, 潘秋丽, 李融武, 程琳 2019 光谱学与光谱分析 39 303

Google Scholar

Google Scholar

Duan Z M, Liu J, Jiang Q L, Pan Q L, Li R W, Cheng L 2019 Spectroscopy and Spectral Analysis 39 303

Google Scholar

Google Scholar

[15] Hodoroaba V D, Radtke M, Reinholz U, Riesemeier H, Vincze L, Reuter D 2011 Nucl. Instrum. Methods Phys. Res., Sect. B 269 1493

Google Scholar

Google Scholar

[16] 徐晓明, 苗伟, 陶琨 2014 63 136001

Google Scholar

Google Scholar

Xu X M, Miao W, Tao K 2014 Acta Phys. Sin. 63 136001

Google Scholar

Google Scholar

[17] Yang J, Tsuji K C, Lin X Y, Han D Y, Ding X L 2009 Thin Solid Films 517 3357

Google Scholar

Google Scholar

[18] 罗武干, 秦颍, 黄凤春, 胡雅丽, 王昌燧 2007 腐蚀科学与防护技术 19 157

Google Scholar

Google Scholar

Luo W G, Qin Y, Huang F C, Hu Y L, Wang C S 2007 Corros. Sci. Prot. Technol. 19 157

Google Scholar

Google Scholar

[19] 金普军, 秦颍, 龚明, 李涛, 朱铁权, 胡雅丽, 王昌燧 2007 中国腐蚀与防护学报 27 162

Google Scholar

Google Scholar

Jin P J, Qin Y, Gong M, Li T, Zhu T Q, Hu Y L, Wang C S 2007 Corros. Sci. Prot. Technol. 27 162

Google Scholar

Google Scholar

[20] Bastidas J M, Alonso M P, Mora E M, Chico B 1995 Mater. Corros. 46 515

[21] 钟家让 2004 山西大学学报(自然科学版) 27 47

Google Scholar

Google Scholar

Zhong J R 2004 J. Shanxi Univ. (Nat. Sci. Ed.) 27 47

Google Scholar

Google Scholar

[22] 祝鸿范, 周浩 1999 电化学 5 314

Google Scholar

Google Scholar

Zhu H F, Zhou H 1999 Electrochemistry 5 314

Google Scholar

Google Scholar

[23] 周浩, 祝鸿范, 蔡兰坤 2005 文物保护与考古科学 17 22

Google Scholar

Google Scholar

Zhou H, Zhu H F, Cai L K 2005 Sci. Conserv. Archaeol 17 22

Google Scholar

Google Scholar

-

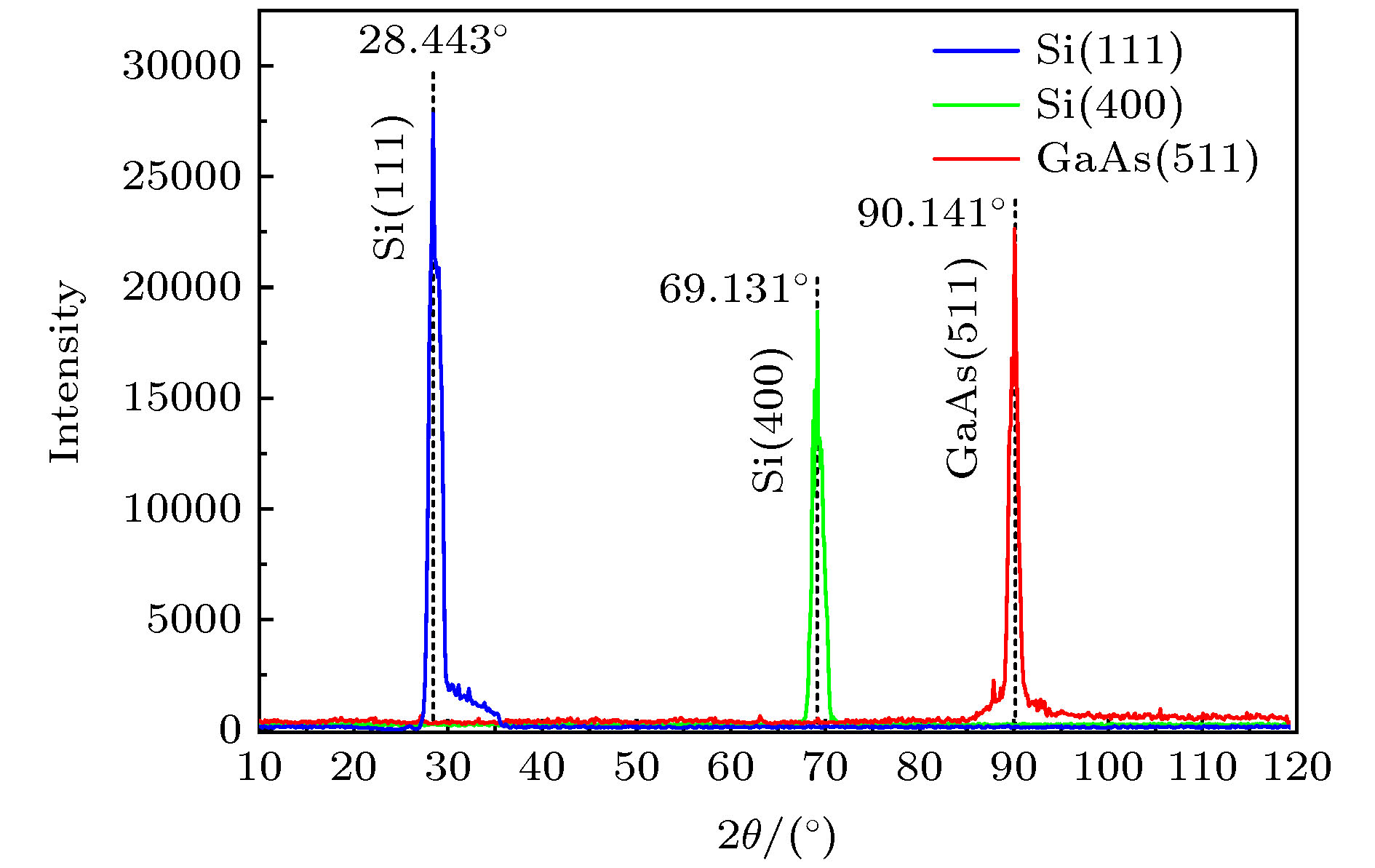

表 1 Si (1 1 1), Si (4 0 0)和GaAs (4 1 1)的测量数据对比

Table 1. The comparison of measurement data of Si (1 1 1), Si (4 0 0) and GaAs (4 1 1).

参考数据 测量数据 PDF卡 2θ/(°) (h k l) 2θ/(°) Si(JCPDS 75-0590) 28.443 (1 1 1) 28.441 Si(JCPDS 75-0590) 69.131 (4 0 0) 69.136 GaAs(JCPDS 29-0615) 90.141 (5 1 1) 90.132 表 2 两种衍射仪的实验条件对比

Table 2. Measurement conditions of two diffractometers.

Hawk-II X-pert-pro-MPD 靶材料 Cu Cu 单色器 Ni吸收片 Ni吸收片 束斑尺寸/mm 1.3 × 1.3 1 × 10 电压/kV 40 40 电流/mA 40 40 步距角/(°) 0.15 0.03 探测时间/s 2 20 表 3 各探测点的X射线束斑直径

Table 3. X-ray Beam diameter of each detected points.

锈蚀点 照射X射线束斑直径/μm 绿锈 1300 红锈 680 黑锈 1000 截面 800 -

[1] Dikmen G, Alver Ö, Parlak C 2018 Chem. Phys. Lett. 698 114

[2] Zhou X, Liu D, Bu H, Deng L, Liu H, Yuan P, Du P, Song H 2018 Solid Earth 3 16

[3] Thota S, Kashyap S C, Sharma S K, Reddy V R 2016 Mater. Sci. Eng., B 206 69

[4] Dappe V, Uzu G, Schreck E, Wu L, Li X, Dumat C, Moreau M, Hanoune B, Ro C, Sobanska S 2018 Atmos. Pollut. Res. 9 697

[5] Liu Z, Jia C, Li L, Li X L, Ji L Y, Wang L H, Lei Y, Wei X J 2018 J. Amer. Chem. Soc. 101 5229

Google Scholar

Google Scholar

[6] Gordillo-Cruz E, Alvarez-Ramirez J, González F, Reyes J A 2018 Physica A 512 635

[7] Myoung J H, Lee D R, Sung H I, Jeong A Y, Chang Y S, Kim H J, Sun W J, Young W C, Young T H, Myung J K 2018 Eur. J. Pharm. Biopharm. 130 143

[8] Nakai I, Abe Y 2012 Appl. Phys. A 106 279

Google Scholar

Google Scholar

[9] 姜其立, 段泽明, 帅麒麟, 李融武, 潘秋丽, 程琳 2019 68 124

Google Scholar

Google Scholar

Jiang Q L, Duan Z M, Shuai Q L, Li R W, Pan Q L, Cheng L 2019 Acta Phys. Sin. 68 124

Google Scholar

Google Scholar

[10] Noyan I C, Wang P C, Kaldor S K, Jordan-Sweet J L, Liniger E G 2000 Rev. Sci. Instrum. 71 1991

[11] 陈俊, 赫业军, 李玉德, 魏富忠, 王大椿, 罗萍, 颜一鸣 1999 核技术 22 3

Google Scholar

Google Scholar

Chen J, He Y J, Li Y D, Wei F Z, Wang D C, Luo P, Yan Y M 1999 Nucl. Tech. 22 3

Google Scholar

Google Scholar

[12] Pradell T, Molera J, Salvadó N, Labrador A 2010 Appl. Phys. A 99 407

Google Scholar

Google Scholar

[13] Alfeld M, Janssens K, Dik J, Nolf W, Snickt G 2011 J. Anal. Atom. Spect. 26 899

Google Scholar

Google Scholar

[14] 段泽明, 刘俊, 姜其立, 潘秋丽, 李融武, 程琳 2019 光谱学与光谱分析 39 303

Google Scholar

Google Scholar

Duan Z M, Liu J, Jiang Q L, Pan Q L, Li R W, Cheng L 2019 Spectroscopy and Spectral Analysis 39 303

Google Scholar

Google Scholar

[15] Hodoroaba V D, Radtke M, Reinholz U, Riesemeier H, Vincze L, Reuter D 2011 Nucl. Instrum. Methods Phys. Res., Sect. B 269 1493

Google Scholar

Google Scholar

[16] 徐晓明, 苗伟, 陶琨 2014 63 136001

Google Scholar

Google Scholar

Xu X M, Miao W, Tao K 2014 Acta Phys. Sin. 63 136001

Google Scholar

Google Scholar

[17] Yang J, Tsuji K C, Lin X Y, Han D Y, Ding X L 2009 Thin Solid Films 517 3357

Google Scholar

Google Scholar

[18] 罗武干, 秦颍, 黄凤春, 胡雅丽, 王昌燧 2007 腐蚀科学与防护技术 19 157

Google Scholar

Google Scholar

Luo W G, Qin Y, Huang F C, Hu Y L, Wang C S 2007 Corros. Sci. Prot. Technol. 19 157

Google Scholar

Google Scholar

[19] 金普军, 秦颍, 龚明, 李涛, 朱铁权, 胡雅丽, 王昌燧 2007 中国腐蚀与防护学报 27 162

Google Scholar

Google Scholar

Jin P J, Qin Y, Gong M, Li T, Zhu T Q, Hu Y L, Wang C S 2007 Corros. Sci. Prot. Technol. 27 162

Google Scholar

Google Scholar

[20] Bastidas J M, Alonso M P, Mora E M, Chico B 1995 Mater. Corros. 46 515

[21] 钟家让 2004 山西大学学报(自然科学版) 27 47

Google Scholar

Google Scholar

Zhong J R 2004 J. Shanxi Univ. (Nat. Sci. Ed.) 27 47

Google Scholar

Google Scholar

[22] 祝鸿范, 周浩 1999 电化学 5 314

Google Scholar

Google Scholar

Zhu H F, Zhou H 1999 Electrochemistry 5 314

Google Scholar

Google Scholar

[23] 周浩, 祝鸿范, 蔡兰坤 2005 文物保护与考古科学 17 22

Google Scholar

Google Scholar

Zhou H, Zhu H F, Cai L K 2005 Sci. Conserv. Archaeol 17 22

Google Scholar

Google Scholar

计量

- 文章访问数: 10039

- PDF下载量: 112

- 被引次数: 0

下载:

下载: