-

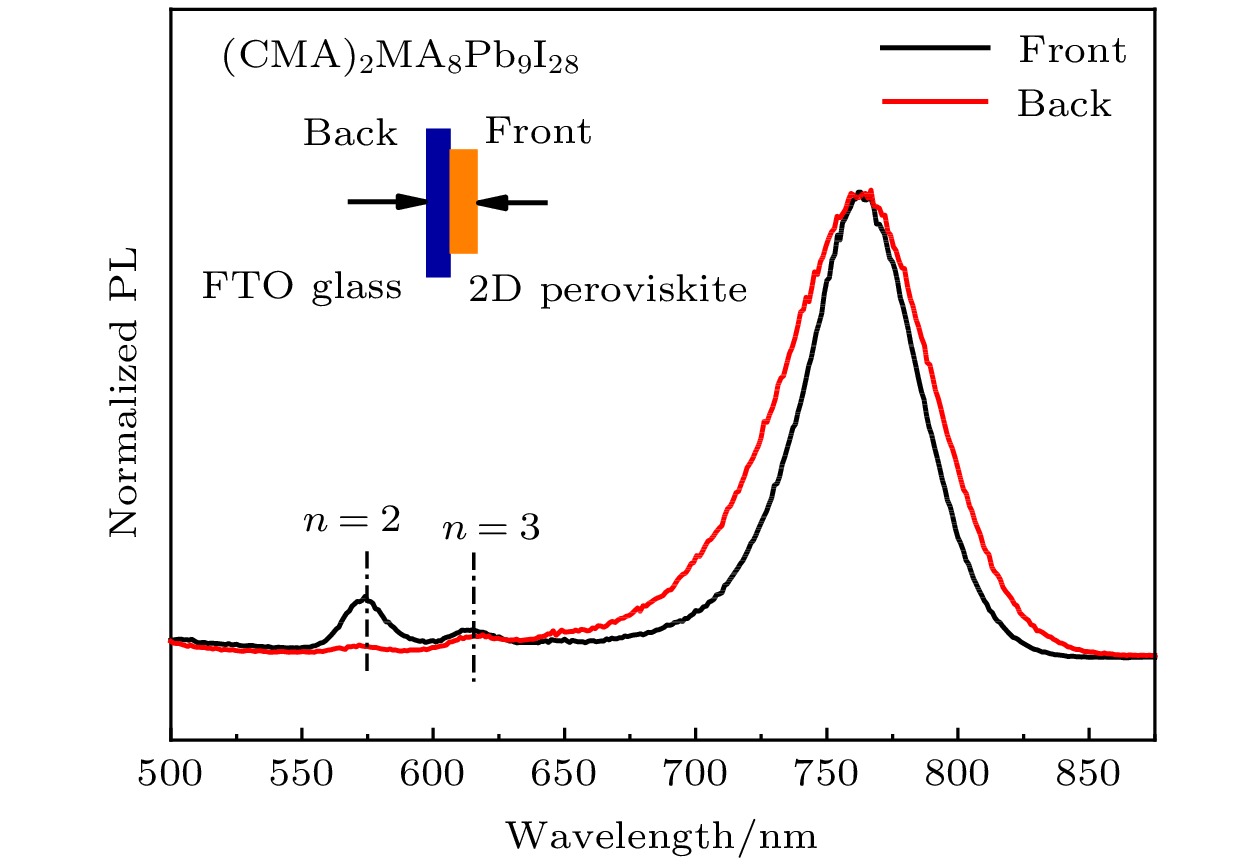

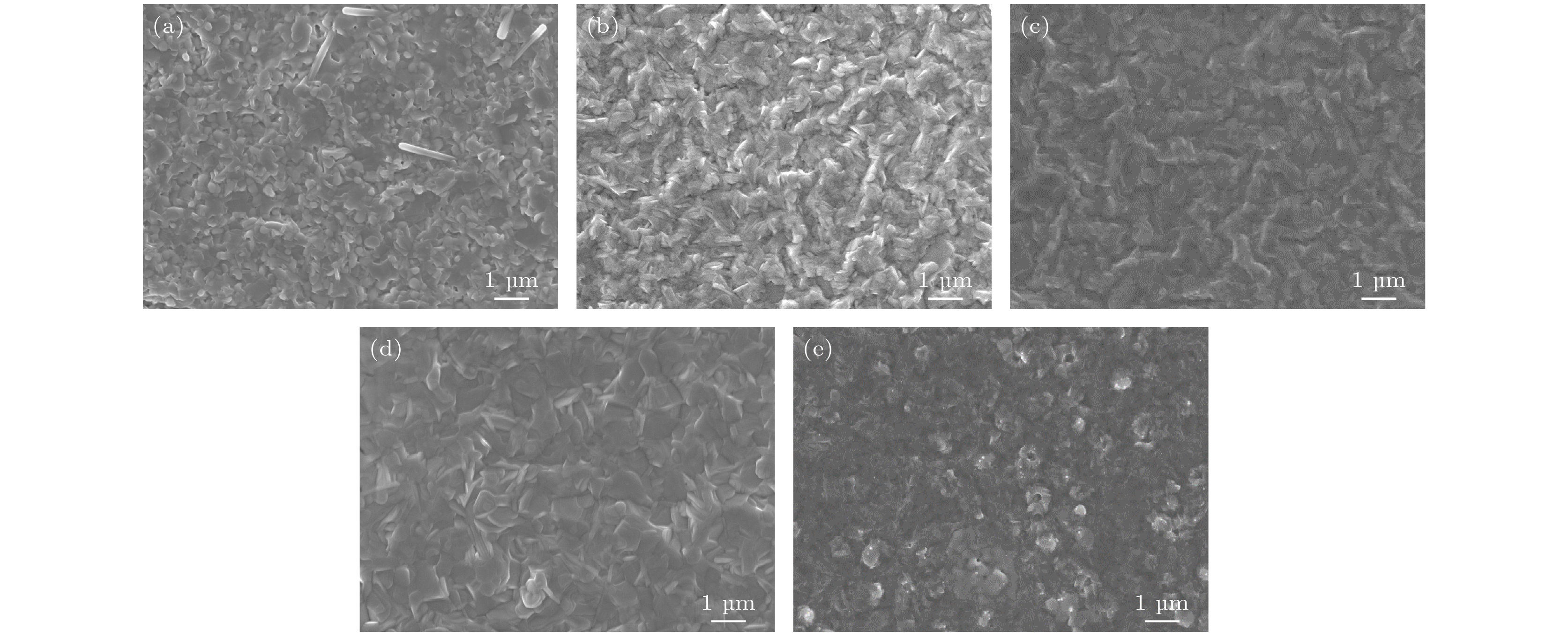

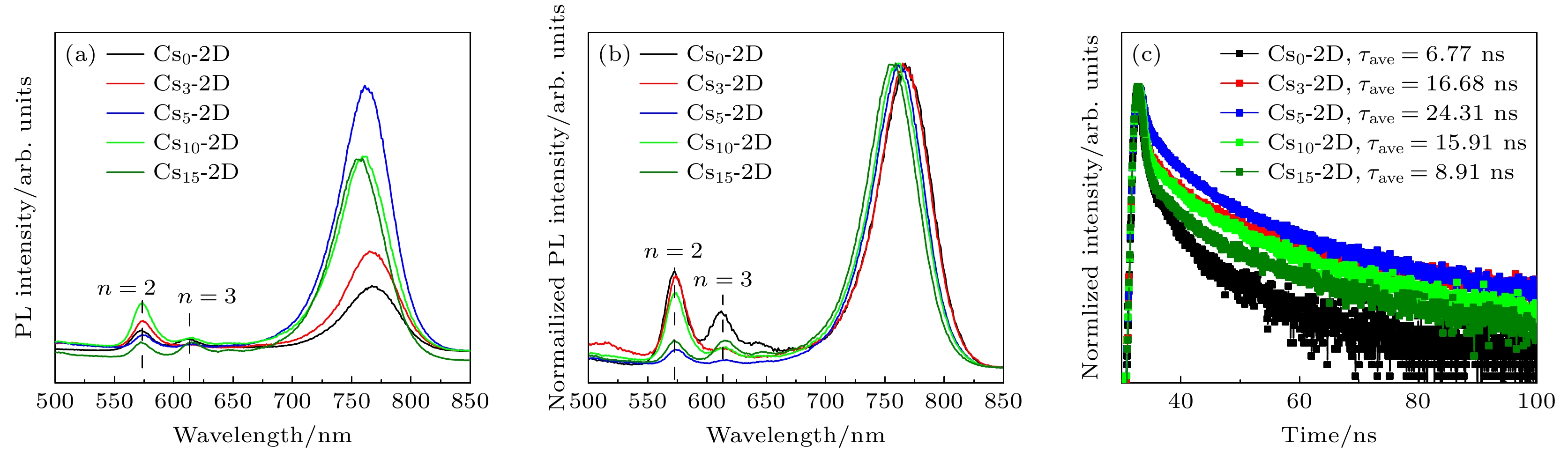

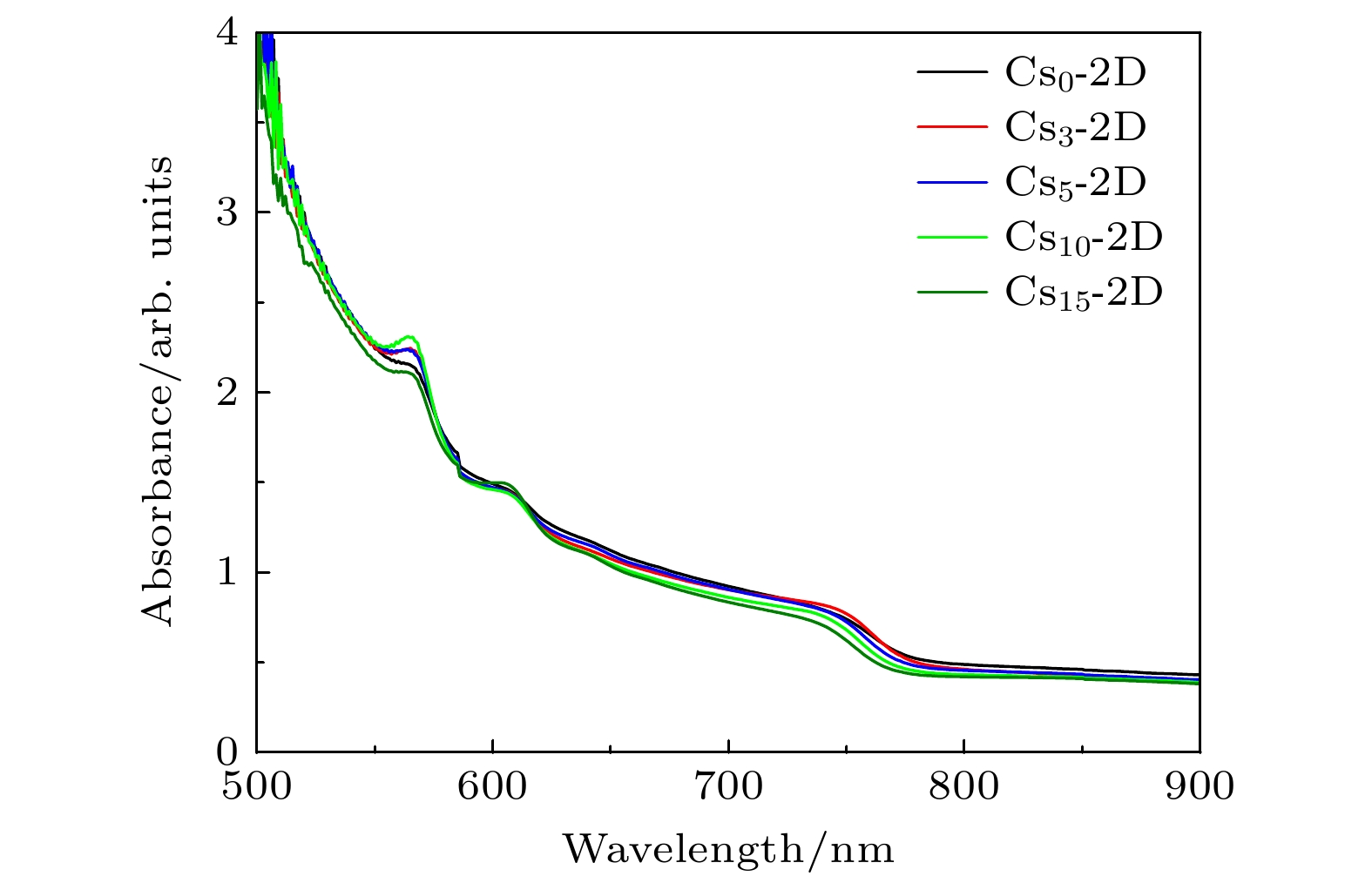

Compared with three-dimensional (3D) perovskites, two-dimensional (2D) perovskites have excellent environmental stability. However, the efficiency of 2D perovskite solar cells is still lower than that of their 3D counterparts owing to the poor carrier transport. In order to improve the efficiency of 2D perovskite solar cells, the cesium (Cs) doping 2D (CMA)2MA8Pb9I28 films with an inverse gradient structure (small n quantum well (QW) located at the surface and large n QW at the bottom) are prepared. The inverse gradient QW structure has the advantages of being more moisture-resistant (small n QW protects the vulnerable large n QW from being attacked by water molecules) and favoring self-driven charge transport (type-II band alignment between different phases). The results show that the quality and thermal stability of 2D (CMA)2MA8Pb9I28 film can be effectively improved by using Cs doping. The SEM images show that the film grains become larger, and the surface is smoother and more compact with CsI content increasing. When CsI increases to 15%, the surface becomes coarse. From the XRD, it can be seen that the crystallinity of perovskite is improved with CsI doping, and it reaches saturation when CsI content increases to 10%. The PL intensity of the film with 5% CsI is higher than the others’, implying a relatively low non-radiative recombination loss and low defect state in that film. Therefore, the minority carrier average lifetime of film doped with 5% CsI is the longest. The absorption is almost unchanged when CsI is doped. The thermal stability of film can be effectively improved when CsI exceeds 10%. Considering the SEM images, crystallinity, PL intensity, light absorption and thermal stability of perovskite, the optimized CsI doped concentration is 10% in our work. Finally, the highest efficiency of (CMA)2MA8Pb9I28 perovskite solar cells doped with 10% CsI content reaches to 14.67%, with a short-circuit current density (JSC) of 23.16 mA/cm2, an open-circuit voltage (Voc) of 1.05 V and a fill factor (FF) of 60.75%. The efficiency of the undoped cells is 10.06%, which is lower than that of CsI doped cells (10%). Therefore, CsI doping is an effective method to further improve the efficiency and thermal stability of 2D perovskite solar cells.

-

Keywords:

- Cs doping /

- solar cells /

- 2D perovskite films /

- stability

[1] Burschka J, Pellet N, Moon S J, Humphry-Baker R, Gao P, Nazeeruddin M K, Grätzel M 2013 Nature 499 316

Google Scholar

Google Scholar

[2] Stranks S D, Snaith Henry J 2015 Nat. Nanotechnol. 10 391

Google Scholar

Google Scholar

[3] Lee M M, Teuscher J, Miyasaka T, Murakami T N, Snaith H J 2012 Science 338 643

Google Scholar

Google Scholar

[4] Kim H S, Lee C R, Im J H, et al. 2012 Sci. Rep. 2 591

Google Scholar

Google Scholar

[5] Wang M, Tan S, Zhao Y, et al. 2021 Adv. Funct. Mater. 31 2007520

Google Scholar

Google Scholar

[6] Ponseca C S, Savenije T J, Abdellah M, et al. 2014 J. Am. Chem. Soc. 136 5189

Google Scholar

Google Scholar

[7] Brenner T M, Egger D A, Kronik L, Hodes G, Cahen D 2016 Nat. Rev. Mater. 1 15007

Google Scholar

Google Scholar

[8] Stoumpos C C, Malliakas C D, Kanatzidis M G 2013 Inorg. Chem. 52 9019

Google Scholar

Google Scholar

[9] Zhao Y, Zhu K 2016 Chem. Soc. Rev. 45 655

Google Scholar

Google Scholar

[10] Wolf S D, Holovsky J, Moon S J, et al. 2014 J. Phys. Chem. Lett. 5 1035

Google Scholar

Google Scholar

[11] Hao F, Stoumpos C C, Cao D H, Chang R P H, Kanatzidis M G 2014 Nat. Photonics 8 489

Google Scholar

Google Scholar

[12] Wu Z W, Bai S, Xiang J, Yuan Z C, Yang Y G, Cui W, Gao X Y, Liu Z, Jin Y Z, Sun B Q 2014 Nanoscale 6 10505

Google Scholar

Google Scholar

[13] Kim H S, Seo J Y, Park N G 2016 Chem. Sus. Chem 9 2528

Google Scholar

Google Scholar

[14] Leijtens T, Eperon G E, Noel N K, Habisreutinger S N, Petrozza A, Snaith H J 2015 Adv. Energy Mater. 5 1500963

Google Scholar

Google Scholar

[15] Jeon N, Noh J, Yang W, Kim Y, Ryu S, Seo J, Seok S 2015 Nature 517 476

Google Scholar

Google Scholar

[16] Tan H, Jain A, Voznyy O, et al. 2017 Science 355 722

Google Scholar

Google Scholar

[17] Raghavan C M, Chen T P, Li S S, et al. 2018 Nano Lett. 18 3221

Google Scholar

Google Scholar

[18] Wei Y, Chu H L, Tian Y Y, Chen B Q, Wu K F, Wang J H, Yang X C, Cai B, Zhang Y F, Zhao J J 2019 Adv. Energy Mater. 1 900612

Google Scholar

Google Scholar

[19] Wu Y H, Ding Y, Liu X Y, Ding X H, Liu X P, Pan X, Dai S Y 2020 Sci. China Mater. 63 47

Google Scholar

Google Scholar

[20] Chang R G, Yan Y T, Zhang J Y, Zhu Z L, Gu J H 2020 Thin Solid Films. 712 138279

Google Scholar

Google Scholar

-

表 1 不同CsI掺杂浓度(CMA)2MA8Pb9I28钙钛矿太阳电池光伏参数

Table 1. Photovoltaic performance of (CMA)2MA8Pb9I28 perovskite solar cells doped with different CsI content.

Sample Jsc/(mA·cm–2) Voc/V FF/% PCE/% Cs0-2D 21.05 1.01 48.40 10.06 a) (21.33±0.28) (1.00±0.01) (45.67±2.73) (9.43±0.63) b) Cs3-2D 21.36 1.03 49.18 10.68 a) (20.74±1.29) (1.02±0.01) (45.66±3.52) (9.66±1.02) b) Cs5-2D 22.08 1.04 56.96 13.08 a) (22.62±0.54) (1.04±0) (49.39±7.57) (11.56±1.52) b) Cs10-2D 23.16 1.05 60.75 14.67 a) (21.90±1.26) (1.04±0.01) (56.07±4.68) (13.49±1.18) b) Cs15-2D 22.71 1.03 58.58 14.12 a) (21.59±1.12) (1.00±0.03) (55.20±3.38) (12.23±1.89) b) 注: a)为最高效率; b)为平均值. -

[1] Burschka J, Pellet N, Moon S J, Humphry-Baker R, Gao P, Nazeeruddin M K, Grätzel M 2013 Nature 499 316

Google Scholar

Google Scholar

[2] Stranks S D, Snaith Henry J 2015 Nat. Nanotechnol. 10 391

Google Scholar

Google Scholar

[3] Lee M M, Teuscher J, Miyasaka T, Murakami T N, Snaith H J 2012 Science 338 643

Google Scholar

Google Scholar

[4] Kim H S, Lee C R, Im J H, et al. 2012 Sci. Rep. 2 591

Google Scholar

Google Scholar

[5] Wang M, Tan S, Zhao Y, et al. 2021 Adv. Funct. Mater. 31 2007520

Google Scholar

Google Scholar

[6] Ponseca C S, Savenije T J, Abdellah M, et al. 2014 J. Am. Chem. Soc. 136 5189

Google Scholar

Google Scholar

[7] Brenner T M, Egger D A, Kronik L, Hodes G, Cahen D 2016 Nat. Rev. Mater. 1 15007

Google Scholar

Google Scholar

[8] Stoumpos C C, Malliakas C D, Kanatzidis M G 2013 Inorg. Chem. 52 9019

Google Scholar

Google Scholar

[9] Zhao Y, Zhu K 2016 Chem. Soc. Rev. 45 655

Google Scholar

Google Scholar

[10] Wolf S D, Holovsky J, Moon S J, et al. 2014 J. Phys. Chem. Lett. 5 1035

Google Scholar

Google Scholar

[11] Hao F, Stoumpos C C, Cao D H, Chang R P H, Kanatzidis M G 2014 Nat. Photonics 8 489

Google Scholar

Google Scholar

[12] Wu Z W, Bai S, Xiang J, Yuan Z C, Yang Y G, Cui W, Gao X Y, Liu Z, Jin Y Z, Sun B Q 2014 Nanoscale 6 10505

Google Scholar

Google Scholar

[13] Kim H S, Seo J Y, Park N G 2016 Chem. Sus. Chem 9 2528

Google Scholar

Google Scholar

[14] Leijtens T, Eperon G E, Noel N K, Habisreutinger S N, Petrozza A, Snaith H J 2015 Adv. Energy Mater. 5 1500963

Google Scholar

Google Scholar

[15] Jeon N, Noh J, Yang W, Kim Y, Ryu S, Seo J, Seok S 2015 Nature 517 476

Google Scholar

Google Scholar

[16] Tan H, Jain A, Voznyy O, et al. 2017 Science 355 722

Google Scholar

Google Scholar

[17] Raghavan C M, Chen T P, Li S S, et al. 2018 Nano Lett. 18 3221

Google Scholar

Google Scholar

[18] Wei Y, Chu H L, Tian Y Y, Chen B Q, Wu K F, Wang J H, Yang X C, Cai B, Zhang Y F, Zhao J J 2019 Adv. Energy Mater. 1 900612

Google Scholar

Google Scholar

[19] Wu Y H, Ding Y, Liu X Y, Ding X H, Liu X P, Pan X, Dai S Y 2020 Sci. China Mater. 63 47

Google Scholar

Google Scholar

[20] Chang R G, Yan Y T, Zhang J Y, Zhu Z L, Gu J H 2020 Thin Solid Films. 712 138279

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 4566

- PDF Downloads: 77

- Cited By: 0

DownLoad:

DownLoad: