-

近年来, 有机无机杂化钙钛矿太阳能电池光电转换效率不断提升, 成为了太阳能电池领域的研究热点. 但是, 有机阳离子甲胺离子(CH3NH

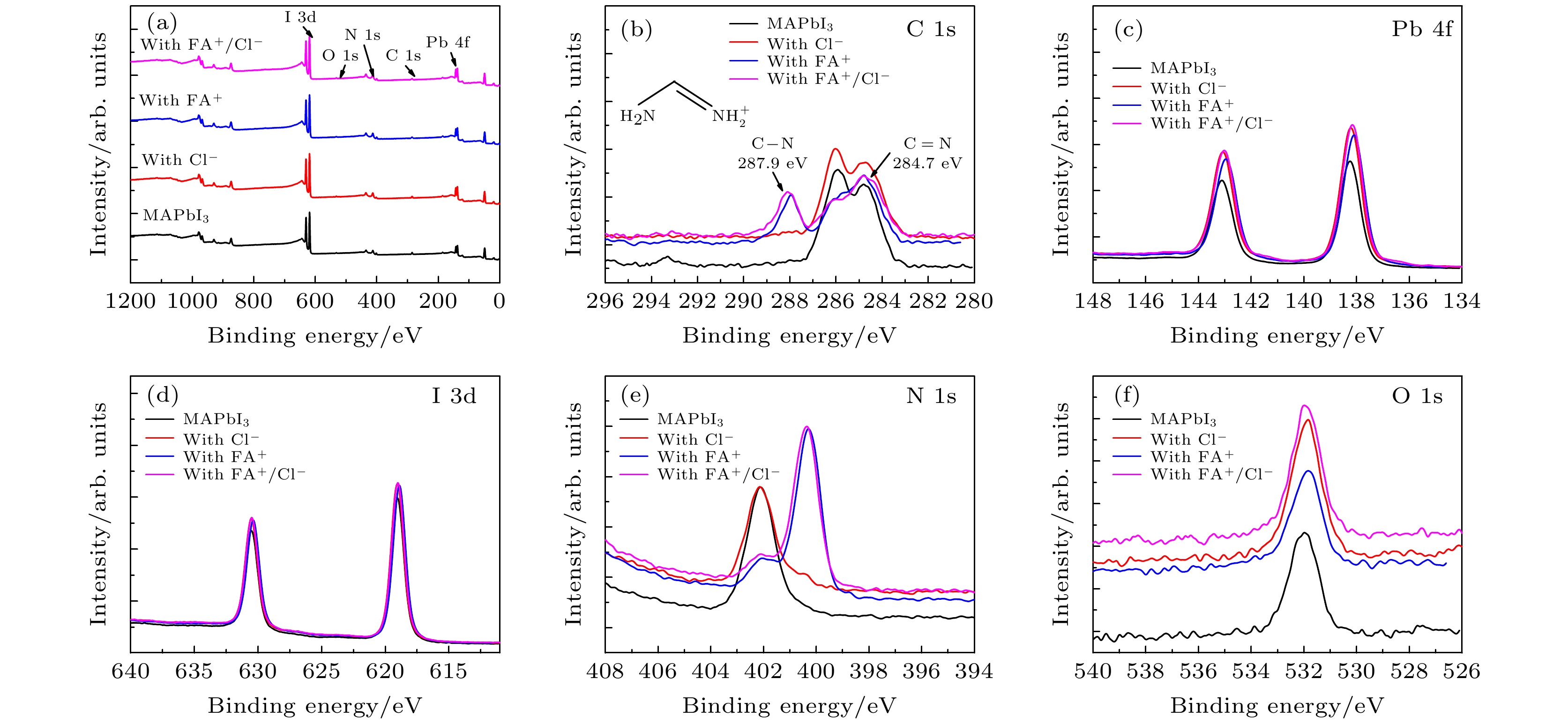

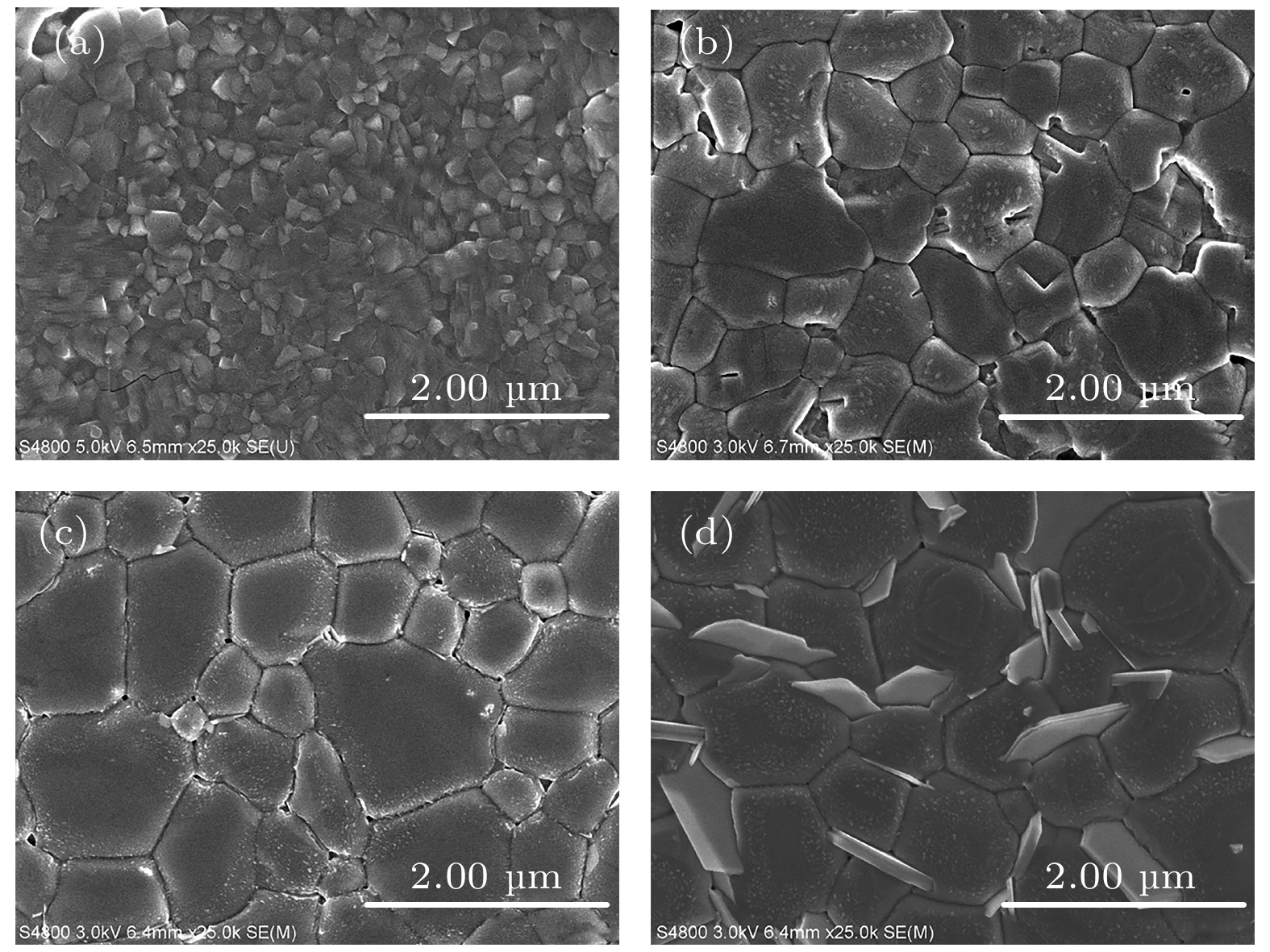

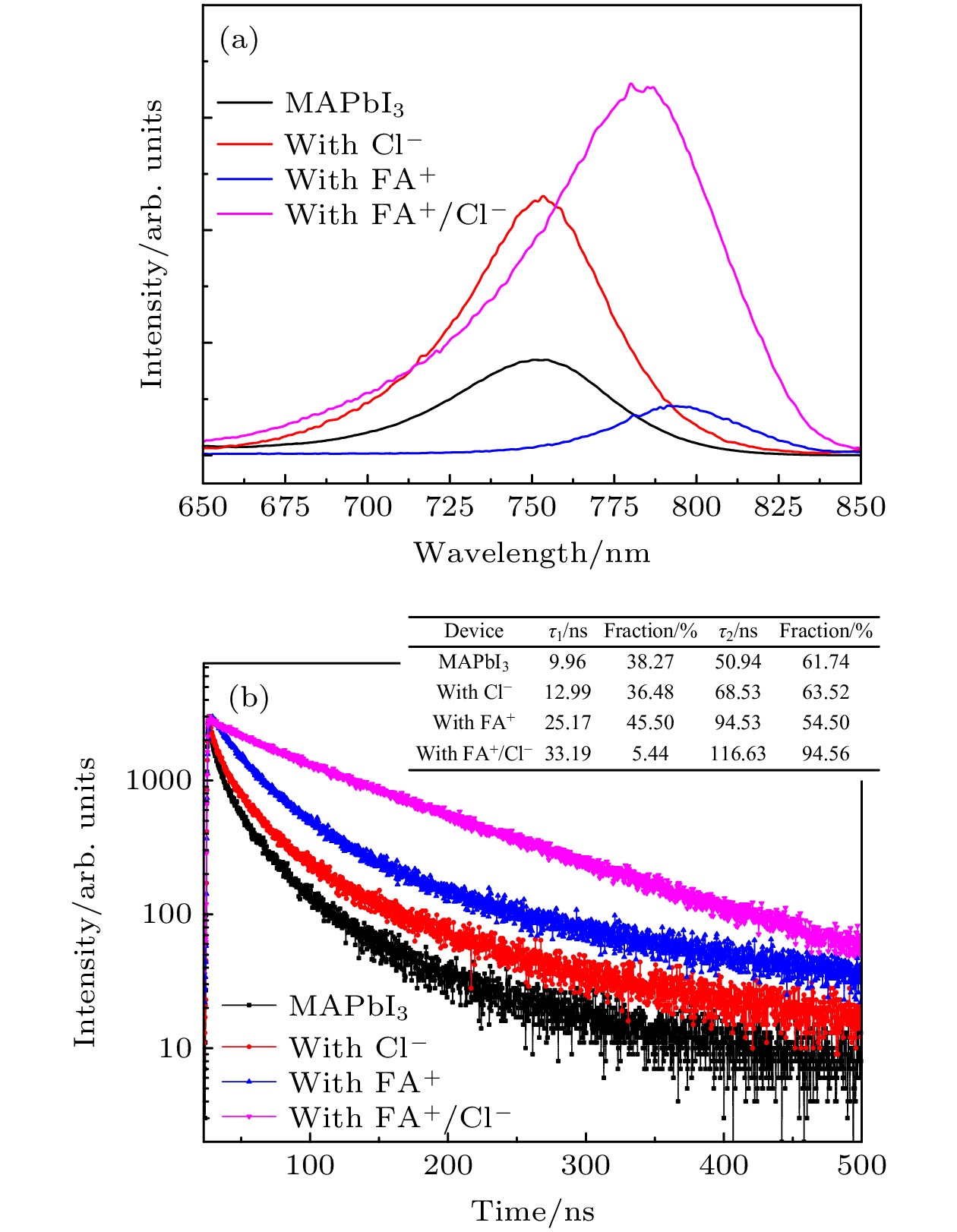

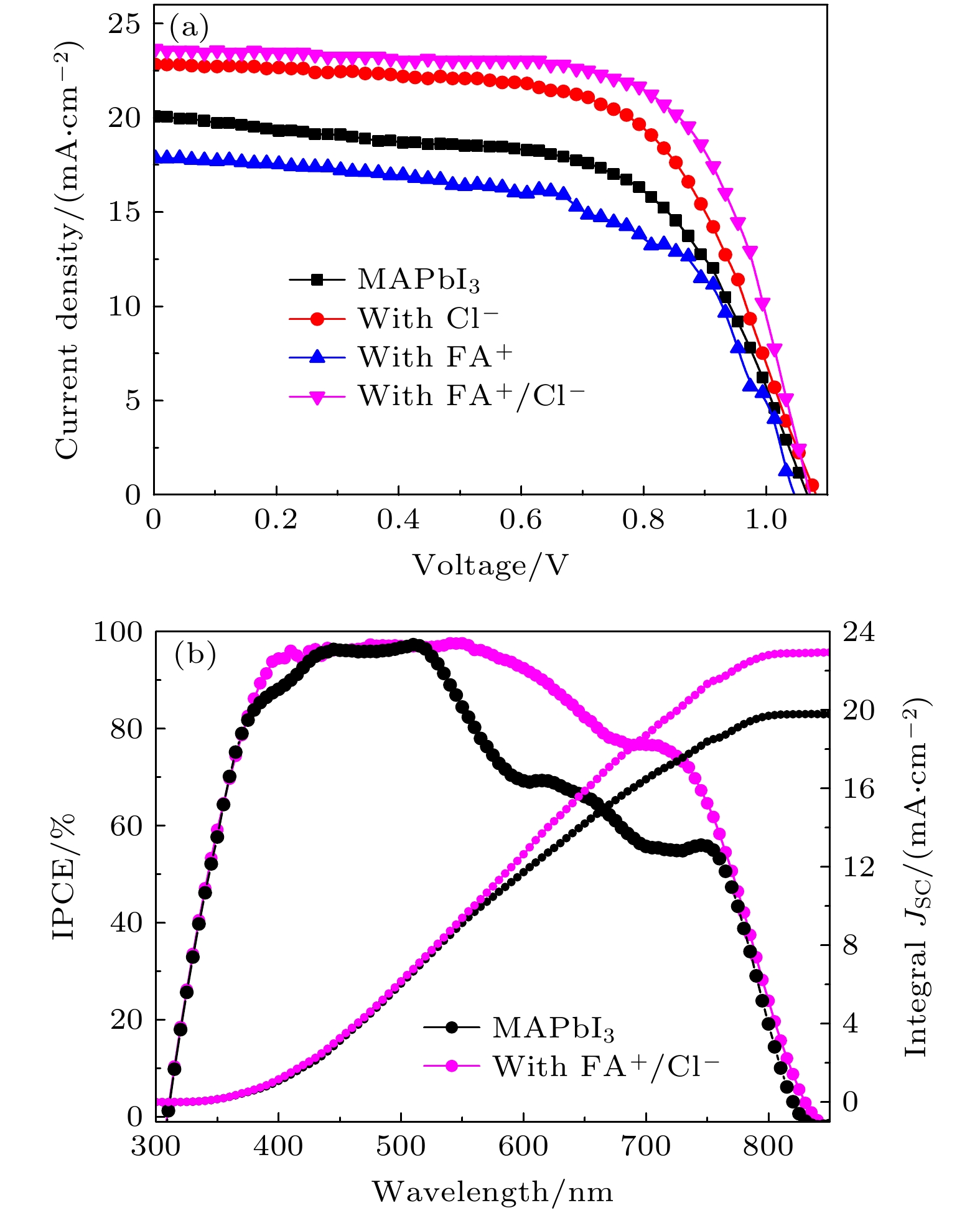

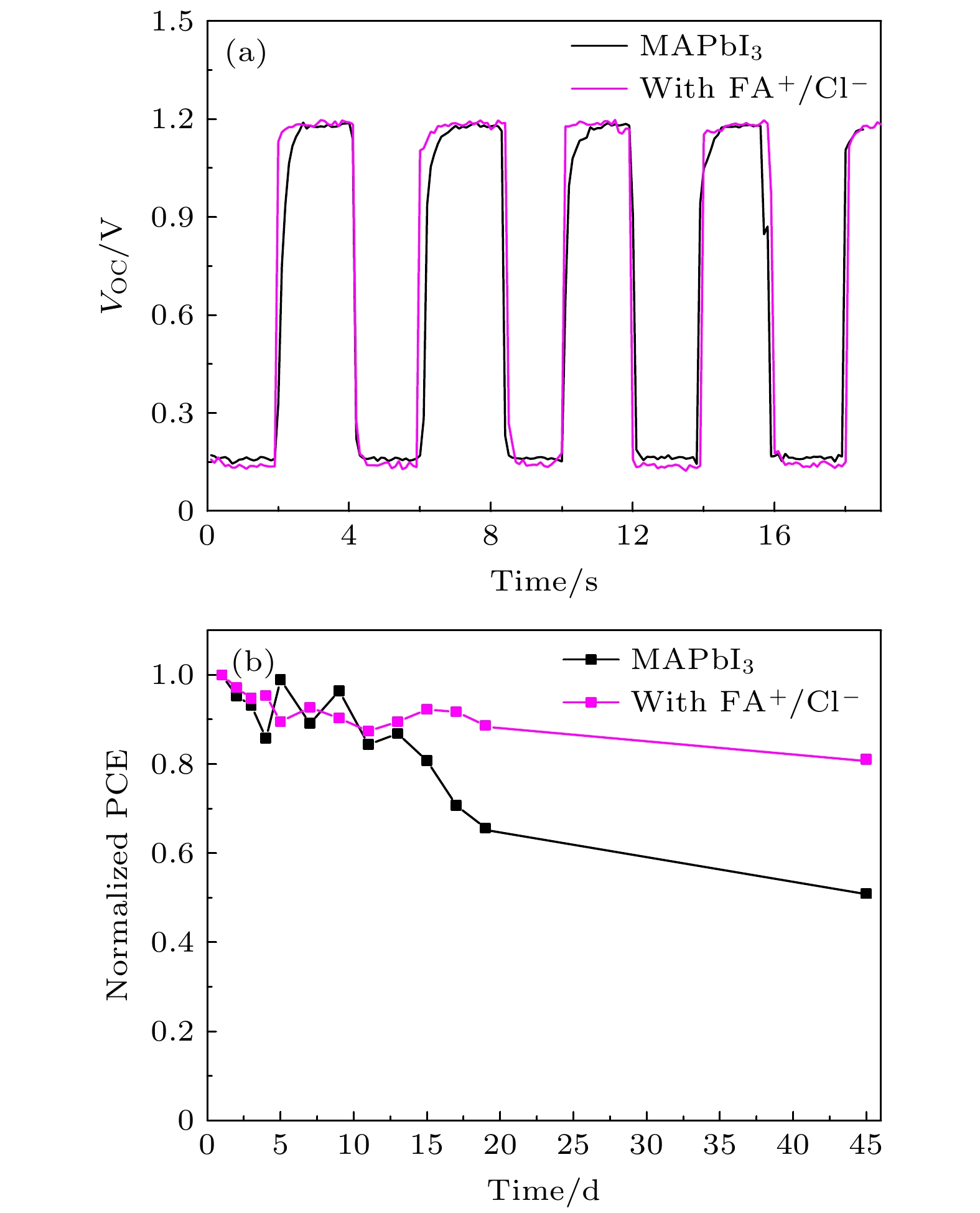

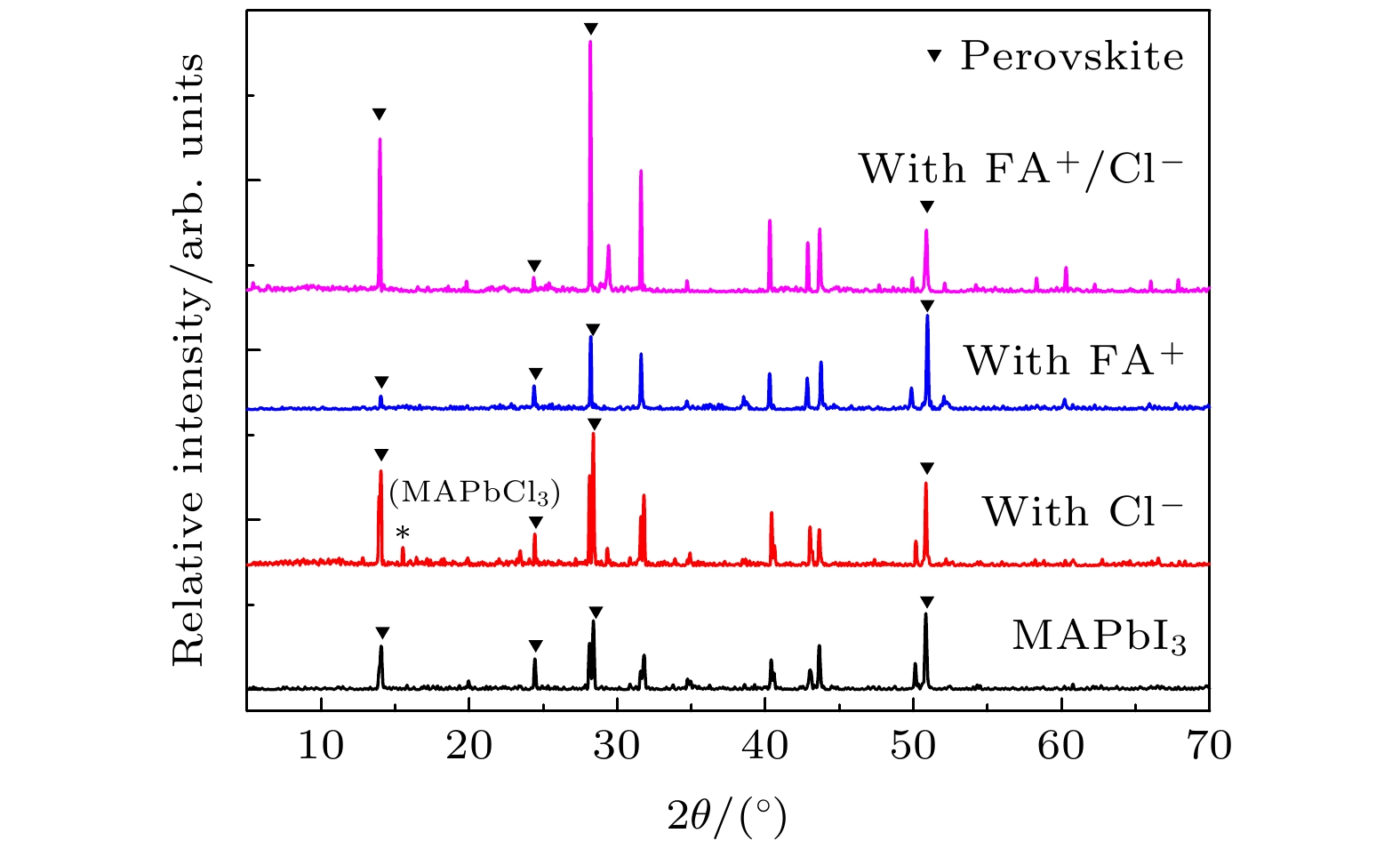

${}_3^+ $ , MA+)和甲脒离子(CH(NH2)${}_2^+ $ , FA+)在水、氧等环境因素作用下极其不稳定, 从而大大阻碍了有机无机杂化钙钛矿太阳能电池的商业应用. 因此, 如何提升其稳定性成为了目前亟待解决的难题. 本文借助离子掺杂工艺, Cl– 掺杂、FA+ 掺杂以及 Cl–, FA+共掺, 对传统 MAPbI3 钙钛矿吸收层材料进行改进, 以提升其稳定性. 结果发现, Cl– 掺杂有利于提升器件载流子迁移能力, FA+ 掺杂可以拓宽吸光范围, Cl–, FA+ 共掺可以促进 α 相钙钛矿的结晶, 从而得到高质量的钙钛矿薄膜. 基于 Cl–, FA+ 共掺的 FAyMA1–yPbI3–xClx钙钛矿薄膜, 在空气中制备出了最高光电转换效率为17.29%的器件, 该器件在空气中储存1000h后, 仍可保持80%的原始效率.ABX3 crystalline perovskite material has many advantages: good photoelectric absorption property, high charge carrier mobility, good film formation, long charge carrier lifetime, and easy bandgap adjustment for absorption layer of perovskite solar cells. As a result, the power conversion efficiency (PCE) of the organic-inorganic halide perovskite solar cells (PSCs) has taken a tremendous step forward, from 3.9% in 2009 to a recently reported value over 25.5%. Thus, it shows great potential to compete with traditional silicon solar cells. However, PSCs preparing conditions are harsh and susceptible to environmental influences, thus leading to instability. Therefore, it is essential to prepare high-performance and stable PSCs in an air environment. This study aims to use the ion doping method to improve the performance and stability of PSCs and analyze the mechanism. This work focuses on enhancing PSCs efficiency and stability by performing FA+ and Cl– doping experiments on MAPbI3 films in air. The results show that a single Cl–-doping increases the carrier diffusion length, reducing the recombination of electrons and holes, and inducing the perovskite intermediate hydrate (CH3NH3)4PbI6·2H2O to form, promoting the crystallization of the thin film, and improving the device performance. On the other hand, a single FA+-doping will reduce the bandgap of perovskite and increase the short-circuit current density (JSC) of the device, and FA+ is susceptible to the influence of water vapor to induce a yellow δ-FAPbI3 perovskite film to form, which leads the device performance to degrade. However, the prepared co-doping Cl–, FA+ significantly improves overall PSCs device performance, yielding the highest PCE of 17.29%, and showing excellent stability by maintaining over 80% of the original PCE without any encapsulation after 1000-hour storage in ambient air.-

Keywords:

- perovskite solar cells /

- organic-inorganic hybrid /

- ion doping /

- stability

[1] Jeon N J, Noh J H, Yang W S, Kim Y C, Ryu S, Seo J, Sang I S 2015 Nature 517 476

Google Scholar

Google Scholar

[2] Zhang X, Jin Z, Zhang J, Bai D, Bian H, Wang K, Sun J, Wang Q, Liu S 2018 ACS Appl. Mater. Interfaces 10 7145

Google Scholar

Google Scholar

[3] Dong Q, Fang Y, Shao Y, Mulligan P, Qiu J, Cao L, Huang J 2015 Science 347 967

Google Scholar

Google Scholar

[4] Jeon N J, Na H, Jung E H, Yang T Y, Seo J 2018 Nat. Energy 3 682

Google Scholar

Google Scholar

[5] D'Innocenzo V, Grancini G, Alcocer M, Kandada A, Petrozza A 2014 Nat. Commun. 5 3586

Google Scholar

Google Scholar

[6] Stranks S D, Eperon G E, Grancini G, et al. 2013 Science 342 341

Google Scholar

Google Scholar

[7] Michael M L, Joel T, Tsutomu M, Takurou N M, Henry J S 2012 Science 338 643

Google Scholar

Google Scholar

[8] Akihiro K, Kenjiro T, Yasuo S, Tsutomu M 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[9] NREL, National Renewable Energy Laboratory. Best Research-Cell Efficiencies, 2021. https://www.nrel.gov/pv/assets/pdfs/cell-pv-eff-emergingpv-rev210726.pdf.

[10] Nenon D P, Christians J A, Wheeler L M, et al. 2016 Energy Environ. Sci. 9 2072

Google Scholar

Google Scholar

[11] Habisreutinger S N, Leijtens T, Eperon G E, Stranks S D, Nicholas R J, Snaith H J 2014 Nano Lett. 14 5561

Google Scholar

Google Scholar

[12] Wu J, Dong J J, Chen S X, Hao H Y, Xing J, Liu H 2018 Nanoscale Res. Lett. 13 293

Google Scholar

Google Scholar

[13] Niu Q, Deng Y, Cui D, Lv H, Min Y 2019 J. Mater. Sci. 54 22

Google Scholar

Google Scholar

[14] Chen S, Dong J, Wu J, Hou S, Hao H 2019 Sol. Energy Mater. Sol. Cells 201 110110

Google Scholar

Google Scholar

[15] Wang C, Long Y, Liu X, Fu S, Wang J, Zhang J, Hu Z, Zhu Y 2020 J. Mater. Chem. C 8 48

[16] Xiang Y, Ma Z, Zhuang J, Lu H, Jia C, Luo J, Li H, Cheng X 2017 J. Phys. Chem. C 121 37

Google Scholar

Google Scholar

[17] Li X, Yang J, Jiang Q, Chu W, Zhang D, Zhou Z, Ren Y, Xin J 2017 Electrochim. Acta 247 460

Google Scholar

Google Scholar

[18] Xu Y Z, Zhu L F, Shi J J, Xu X, Xiao J Y 2016 Chemphyschem 17 112

Google Scholar

Google Scholar

[19] Zhao Y, Tan H, Yuan H, Yang Z, Fan J Z, Kim J, Voznyy O, Gong X, Quan L N, Tan C S 2018 Nat. Commun. 9 1607

Google Scholar

Google Scholar

[20] 李晓娥, 陈秀娟, 张淼, 祖庸 1995 稀有金属材料与工程 24 65

Google Scholar

Google Scholar

Li X E, Chen X J, Zhang M, Zu Y 1995 Rare Met. Mater. Eng. 24 65

Google Scholar

Google Scholar

[21] Isikgor F, Li B, Zhu H, Xu Q H, Ouyang J 2016 J. Mater. Chem. A 4 12543

Google Scholar

Google Scholar

[22] Mu C, Pan J, Feng S, Li Q, Xu D 2017 Adv. Energy Mater. 7 1601297

Google Scholar

Google Scholar

[23] Xie F, Chen C C, Wu Y, Li X, Cai M, Liu X, Yang X, Han L 2017 Energy Environ. Sci. 10 1942

Google Scholar

Google Scholar

[24] Lee Y M, Yun J H, Matsuyama A, et al. 2019 Appl. Phys. Express 12 051003

Google Scholar

Google Scholar

[25] Kim M, Kim G H, Lee T K, Choi I W, Dong S K 2019 Joule 3 2179

Google Scholar

Google Scholar

[26] Liu Z, Shi T, Tang Z, Bo S, Liao G 2016 Nanoscale 8 7017

Google Scholar

Google Scholar

[27] Luo J, Jia C, Wan Z, Han F, Zhao B, Wang R 2017 J. Power Sources 342 886

Google Scholar

Google Scholar

[28] Peng J, Wu Y L, Ye W, et al. 2017 Energy Environ. Sci. 10 1792

Google Scholar

Google Scholar

-

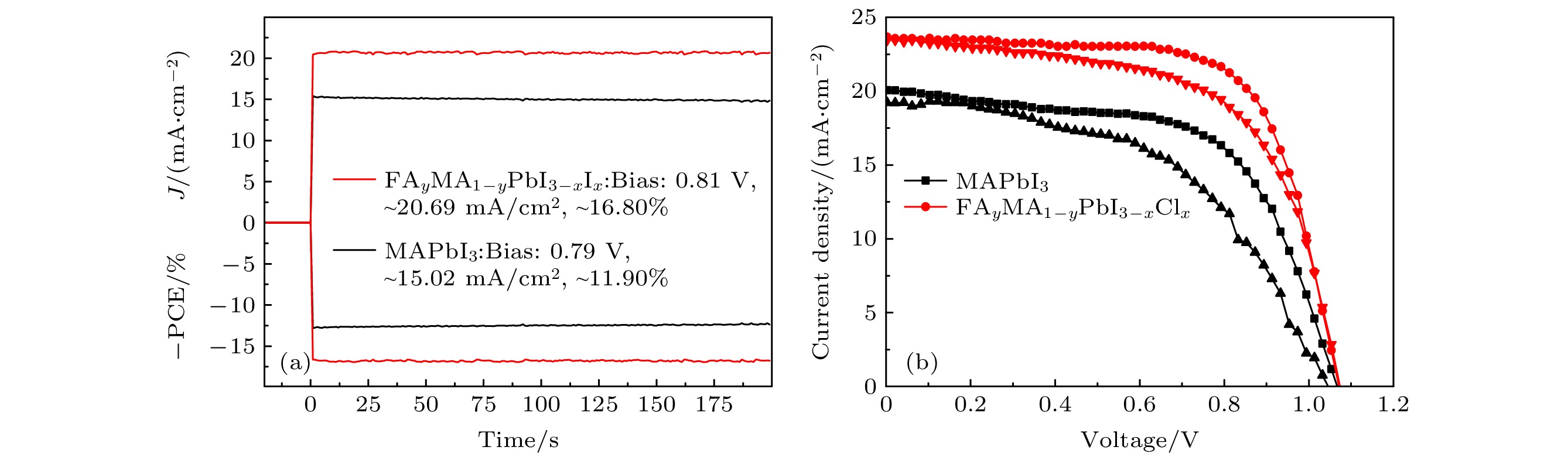

图 8 基于MAPbI3薄膜与FAyMA1–yPbI3–xClx薄膜制备的最优器件的(a)最大功率点稳态输出图和(b)正反扫J-V曲线测试

Fig. 8. (a) Steady-state photocurrent and PCE outputs at a voltage close to the maximum output point (b) J-V curves under reverse and forward scanning of the optimal device prepared based on MAPbI3 film and FAyMA1–yPbI3–xClx film.

表 1 不同掺杂条件下钙钛矿薄膜PSCs的光伏参数

Table 1. Photovoltaic parameters of perovskite film PSCs under different doping conditions.

器件薄膜种类 开路电压 短路电流 填充因子 功率转换效率 VOC/V JSC/(mA·cm–2) FF/% PCE/% MAPbI3 1.04 20.16 60.33 12.94 MAPbI3–xClx 1.08 22.88 62.90 15.67 FAyMA1–yPbI3 1.04 17.91 53.91 11.10 FAyMA1–y PbI3–xClx 1.07 23.67 68.52 17.29 表 2 不同掺杂条件下钙钛矿薄膜PSCs的光伏参数

Table 2. Photovoltaic parameters of perovskite film PSCs under different doping conditions.

组分含量/(mg·mL–1) 开路电压 短路电流 填充因子 功率转换效率 PbI2 MAI FAI MACl VOC/V JSC/(mA·cm–2) FF/% PCE/% 1.4 mol/L 70 0 0 1.04 20.16 60.33 12.94 63 0 7 1.08 22.88 62.90 15.67 56 0 14 1.05 21.79 61.53 14.08 21 49 0 0.98 15.40 47.50 7.17 28 42 0 1.04 17.91 53.91 11.10 35 35 0 1.04 17.35 56.21 10.24 25 38 7 1.07 23.67 68.52 17.29 22 34 14 1.06 21.34 65.07 14.72 -

[1] Jeon N J, Noh J H, Yang W S, Kim Y C, Ryu S, Seo J, Sang I S 2015 Nature 517 476

Google Scholar

Google Scholar

[2] Zhang X, Jin Z, Zhang J, Bai D, Bian H, Wang K, Sun J, Wang Q, Liu S 2018 ACS Appl. Mater. Interfaces 10 7145

Google Scholar

Google Scholar

[3] Dong Q, Fang Y, Shao Y, Mulligan P, Qiu J, Cao L, Huang J 2015 Science 347 967

Google Scholar

Google Scholar

[4] Jeon N J, Na H, Jung E H, Yang T Y, Seo J 2018 Nat. Energy 3 682

Google Scholar

Google Scholar

[5] D'Innocenzo V, Grancini G, Alcocer M, Kandada A, Petrozza A 2014 Nat. Commun. 5 3586

Google Scholar

Google Scholar

[6] Stranks S D, Eperon G E, Grancini G, et al. 2013 Science 342 341

Google Scholar

Google Scholar

[7] Michael M L, Joel T, Tsutomu M, Takurou N M, Henry J S 2012 Science 338 643

Google Scholar

Google Scholar

[8] Akihiro K, Kenjiro T, Yasuo S, Tsutomu M 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[9] NREL, National Renewable Energy Laboratory. Best Research-Cell Efficiencies, 2021. https://www.nrel.gov/pv/assets/pdfs/cell-pv-eff-emergingpv-rev210726.pdf.

[10] Nenon D P, Christians J A, Wheeler L M, et al. 2016 Energy Environ. Sci. 9 2072

Google Scholar

Google Scholar

[11] Habisreutinger S N, Leijtens T, Eperon G E, Stranks S D, Nicholas R J, Snaith H J 2014 Nano Lett. 14 5561

Google Scholar

Google Scholar

[12] Wu J, Dong J J, Chen S X, Hao H Y, Xing J, Liu H 2018 Nanoscale Res. Lett. 13 293

Google Scholar

Google Scholar

[13] Niu Q, Deng Y, Cui D, Lv H, Min Y 2019 J. Mater. Sci. 54 22

Google Scholar

Google Scholar

[14] Chen S, Dong J, Wu J, Hou S, Hao H 2019 Sol. Energy Mater. Sol. Cells 201 110110

Google Scholar

Google Scholar

[15] Wang C, Long Y, Liu X, Fu S, Wang J, Zhang J, Hu Z, Zhu Y 2020 J. Mater. Chem. C 8 48

[16] Xiang Y, Ma Z, Zhuang J, Lu H, Jia C, Luo J, Li H, Cheng X 2017 J. Phys. Chem. C 121 37

Google Scholar

Google Scholar

[17] Li X, Yang J, Jiang Q, Chu W, Zhang D, Zhou Z, Ren Y, Xin J 2017 Electrochim. Acta 247 460

Google Scholar

Google Scholar

[18] Xu Y Z, Zhu L F, Shi J J, Xu X, Xiao J Y 2016 Chemphyschem 17 112

Google Scholar

Google Scholar

[19] Zhao Y, Tan H, Yuan H, Yang Z, Fan J Z, Kim J, Voznyy O, Gong X, Quan L N, Tan C S 2018 Nat. Commun. 9 1607

Google Scholar

Google Scholar

[20] 李晓娥, 陈秀娟, 张淼, 祖庸 1995 稀有金属材料与工程 24 65

Google Scholar

Google Scholar

Li X E, Chen X J, Zhang M, Zu Y 1995 Rare Met. Mater. Eng. 24 65

Google Scholar

Google Scholar

[21] Isikgor F, Li B, Zhu H, Xu Q H, Ouyang J 2016 J. Mater. Chem. A 4 12543

Google Scholar

Google Scholar

[22] Mu C, Pan J, Feng S, Li Q, Xu D 2017 Adv. Energy Mater. 7 1601297

Google Scholar

Google Scholar

[23] Xie F, Chen C C, Wu Y, Li X, Cai M, Liu X, Yang X, Han L 2017 Energy Environ. Sci. 10 1942

Google Scholar

Google Scholar

[24] Lee Y M, Yun J H, Matsuyama A, et al. 2019 Appl. Phys. Express 12 051003

Google Scholar

Google Scholar

[25] Kim M, Kim G H, Lee T K, Choi I W, Dong S K 2019 Joule 3 2179

Google Scholar

Google Scholar

[26] Liu Z, Shi T, Tang Z, Bo S, Liao G 2016 Nanoscale 8 7017

Google Scholar

Google Scholar

[27] Luo J, Jia C, Wan Z, Han F, Zhao B, Wang R 2017 J. Power Sources 342 886

Google Scholar

Google Scholar

[28] Peng J, Wu Y L, Ye W, et al. 2017 Energy Environ. Sci. 10 1792

Google Scholar

Google Scholar

计量

- 文章访问数: 7715

- PDF下载量: 137

- 被引次数: 0

下载:

下载: