-

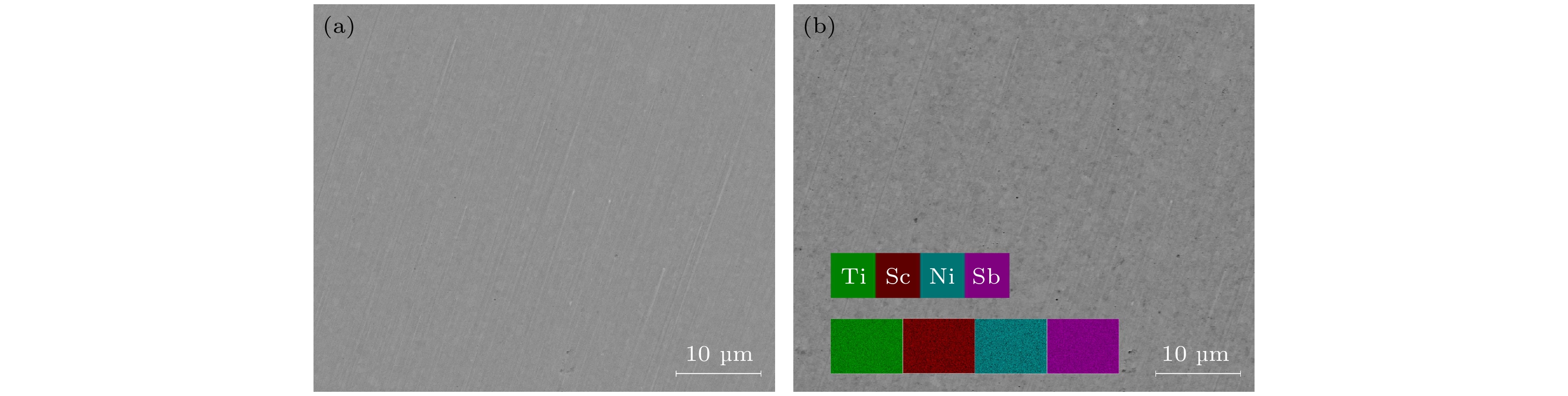

The nominal composition TiNiSb with 19 valence electrons is demonstrated to be composed of off-stoichiometric half-Heusler phase and impurities. In this work, the Ti1–xNiSb (x = 0, 0.10, 0.15, 0.20, 0.25) samples are prepared by ball milling and spark plasma sintering. The single-phase Ti0.9NiSb sample, deviating from the theoretical composition Ti0.75NiSb base on 18-electron rule, is obtained, which might be ascribed to the small defect formation energy of Ti filling the vacancy as well as our ball-milling preparation method. With the single-phase Ti0.9NiSb sample used as the base material, a small amount of Sc is used to partially replace Ti in order to further reduce the carrier concentration. Thus, the Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05) samples are designed to investigate the effect of Sc doping on the thermoelectric properties. The X-ray powder diffraction (XRD) and scanning electron microscopy (SEM) analysis confirm the single-phase nature of the Ti1–x–yScyNiSb samples. Energy-dispersive X-ray spectroscopy (EDS) results indicate that the actual compositions of the Ti1–x–yScyNiSb samples are consistent well with their nominal compositions, and all elements are distributed uniformly in the sample. Moreover, the doping of Sc can increase the content of Ti vacancy while maintaining the single-phase structure, which could be attributed to the higher binding energy between Sc and Sb because the electronegativity of Sc is less than that of Ti. Both the substitution of Sc for Ti and the increase of the Ti vacancies significantly reduce the carrier concentration, which decreases from ~13.6 × 1021 cm–3 for Ti0.9NiSb to ~3.4 × 1021 cm–3 for Ti0.8Sc0.05NiSb. The reduced carrier concentration results in greatly increased Seebeck coefficient, therefore the Ti0.8Sc0.05NiSb sample achieves a power factor as high as 17.7 μW·cm-1·K-2 at 973 K. Although the lattice thermal conductivity of Sc-doped sample increases slightly due to the reduction of electron–phonon scattering and the enhancement of chemical bonds, the total thermal conductivity decreases dramatically due to the electronic thermal conductivity decreasing greatly. Finally, the Ti0.8Sc0.05NiSb sample reaches a ZT value of ~0.42 at 973 K, which is 180% higher than that of Ti0.9NiSb sample. Despite the fact that the thermoelectric performance of our sample is still inferior to those of the state-of-the-art off-stoichiometric 19-electron half-Heusler alloys, this work demonstrates that the thermoelectric performance of Ti1–xNiSb can be further improved by non-isoelectronic doping.

-

Keywords:

- TiNiSb /

- half-Heusler alloy /

- vacancies /

- thermoelectric properties

[1] Bell L E 2008 Science 321 1457

Google Scholar

Google Scholar

[2] Jia N, Cao J, Tan X Y, Dong J F, Liu H F, Tan C K I, Xu J W, Yan Q Y, Loh X J, Suwardi A 2021 Energy Environ. Sci. 21 100519

Google Scholar

Google Scholar

[3] Min R A, Wang Y X, Jiang X, Chen R C, Kang H J, Guo E Y, Chen Z N, Yang X, Wang T M 2022 Chem. Eng. J. 449 137898

Google Scholar

Google Scholar

[4] Joshi G, Dahal T, Chen S, Wang H Z, Shiomi J, Chen G, Ren Z F 2013 Nano Energy 2 82

Google Scholar

Google Scholar

[5] Yu C, Zhu T J, Shi R Z, Zhang Y, Zhao X B, He J 2009 Acta Mater. 57 2757

Google Scholar

Google Scholar

[6] Fu C G, Zhu T J, Liu Y T, Xie H H, Zhao X B 2015 Energy Environ. Sci. 8 216

Google Scholar

Google Scholar

[7] Pei Y Z, Shi X Y, LaLonde A, Wang H, Chen L D, Snyder G J 2011 Nature 473 66

Google Scholar

Google Scholar

[8] Fu C G, Zhu T J, Pei Y Z, Xie H H, Wang H, Snyder G J, Liu Y, Liu Y T, Zhao X B 2014 Adv. Energy Mater. 4 1400600

Google Scholar

Google Scholar

[9] Tan C, Wang H X, Yao J, Chen T T, Wang L, Sun Y Q, Khan M, Wang H C, Wang C L 2022 J. Eur. Ceram. Soc. 42 7010

Google Scholar

Google Scholar

[10] Biswas K, He J Q, Blum I D, Wu C I, Hogan T P, Seidman D N, Dravid V P, Kanatzidis M G 2012 Nature 489 414

Google Scholar

Google Scholar

[11] Sun Y J, Shuai Z G, Wang D 2019 J. Phys. Chem. C 123 12001

Google Scholar

Google Scholar

[12] He R, Gahlawat S, Guo C F, Chen S, Dahal T, Zhang H, Liu W S, Zhang Q, Chere E, White K, Ren Z F 2015 Phys. Status. Solidi. A 212 2191

Google Scholar

Google Scholar

[13] Graf T, Felser C, Parkin S S P 2011 Prog. Solid. State Ch. 39 1

Google Scholar

Google Scholar

[14] Sakurada S, Shutoh N 2005 Appl. Phys. Lett. 86 082105

Google Scholar

Google Scholar

[15] Uher C, Yang J, Hu S, Morelli D T, Meisner G P 1999 Phys. Rev. B 59 8615

Google Scholar

Google Scholar

[16] 王鹏将, 康慧君, 杨雄, 刘颖, 程成, 王同敏 2022 无机材料学报 37 717

Google Scholar

Google Scholar

Wang P J, Kang H J, Yang X, Liu Y, Cheng C, Wang T M 2022 J. Inorg. Mater. 37 717

Google Scholar

Google Scholar

[17] Sekimoto T, Kurosaki K, Muta H, Yamanaka S 2006 Mater. Trans. 47 1445

Google Scholar

Google Scholar

[18] Sekimoto T, Kurosaki K, Muta H, Yamanaka S 2005 Mater. Trans. 46 1481

Google Scholar

Google Scholar

[19] Sekimoto T, Kurosaki K, Muta H, Yamanaka S 2007 Jpn. J. Appl. Phys. 46 L673

Google Scholar

Google Scholar

[20] Huang Y, Hayashi K, Miyazaki Y 2020 Chem. Mater. 32 5173

Google Scholar

Google Scholar

[21] Joshi G, He R, Engber M, Samsonidze G, Pantha T, Dahal E, Dahal K, Yang J, Lan Y C, Kozinsky B, Ren Z F 2014 Energy Environ. Sci. 7 4070

Google Scholar

Google Scholar

[22] Zhu H T, Mao J, Li Y W, et al. 2019 Nat. Commun. 10 270

Google Scholar

Google Scholar

[23] Xia K, Liu Y, Anand S, Snyder G J, Xin J, Yu J, Zhao X, Zhu T 2018 Adv. Funct. Mater. 28 1705845

Google Scholar

Google Scholar

[24] Li S, Bai F X, Wang R F, Chen C, Li X F, Cao F, Yu B, Sui J H, Liu X J, Ren Z F, Zhang Q 2020 Ann. Phys. 532 1900440

Google Scholar

Google Scholar

[25] Miranda J, Gruhn T 2022 J. Electron. Mater. 51 2043

Google Scholar

Google Scholar

[26] Huang L H, Wang J C, Mo X B, Lei X B, Ma S D, Wang C, Zhang Q Y 2019 Materials 12 1637

Google Scholar

Google Scholar

[27] Kainuma R, Umino R, Xu X, Han K, Omori T 2020 J. Phase. Equilibria. Diffus. 41 116

Google Scholar

Google Scholar

[28] Romaka V V, Rogl P, Romaka L, Stadnyk Y, Melnychenko N, Grytsiv A, Falmbigl M, Skryabina N 2013 J. Solid State Chem. 197 103

Google Scholar

Google Scholar

[29] Anand S, Xia K Y, Zhu T J, Wolverton C, Snyder G J 2018 Adv. Energy Mater. 8 1801409

Google Scholar

Google Scholar

[30] Luo F, Wang J, Zhu C, He X, Zhang S, Wang J F, Liu H X, Sun Z G 2022 J. Mater. Chem. A 10 9655

Google Scholar

Google Scholar

[31] Anand S, Xia K Y, Hegde V I, Aydemir U, Kocevski V, Zhu T J, Wolverton C, Snyder G J 2018 Energy Environ. Sci. 11 1480

Google Scholar

Google Scholar

[32] Romaka V V, Rogl G, Grytsiv A, Rogl P 2020 Comput. Mater. Sci. 172 109307

Google Scholar

Google Scholar

[33] Zhou M, Chen L D, Feng C D, Wang D L, Li J F 2007 J. Appl. Phys. 101 113714

Google Scholar

Google Scholar

[34] Zhao D G, Wang L, Bo L, Wu D 2018 Metals 8 61

Google Scholar

Google Scholar

[35] Tavassoli A, Failamani F, Grytsiv A, Rogl G, Heinrich P, Müller H, Bauer E, Zehetbauer M, Rogl P 2017 Acta Mater. 135 263

Google Scholar

Google Scholar

[36] Kim H S, Gibbs Z M, Tang Y L, Wang H, Snyder G J 2015 APL Mater. 3 041506

Google Scholar

Google Scholar

[37] 沈家骏, 方腾, 傅铁铮, 忻佳展, 赵新兵, 朱铁军 2019 无机材料学报 34 260

Google Scholar

Google Scholar

Shen J J, Fang T, Fu T Z, Xin J Z, Zhao X B, Zhu T J 2019 J. Inorg. Mater. 34 260

Google Scholar

Google Scholar

[38] Zhu T J, Yu G T, Xu J, Wu H J, Fu C G, Liu X H, He J Q, Zhao X B 2016 Adv. Electron. Mater. 2 1600171

Google Scholar

Google Scholar

[39] Karati A, Hariharan V S, Ghosh S, Prasad A, Nagini M, Guruvidyathri K, Mallik R C, Shabadi R, Bichler L, Murty B S, Varadaraju U V 2020 Scr. Mater. 186 375

Google Scholar

Google Scholar

[40] Hasan R, Park T, Kim S I, Kim H S, Jo S, Lee K H 2022 Adv. Energy Sustainability Res. 3 2100206

Google Scholar

Google Scholar

[41] Zhang X Y, Bu Z L, Shi X M, Chen Z W, Lin S Q, Shan B, Wood M, Snyder A H, Chen L D, Snyder G J, Pei Y Z 2020 Sci. Adv. 6 eabc0726

Google Scholar

Google Scholar

-

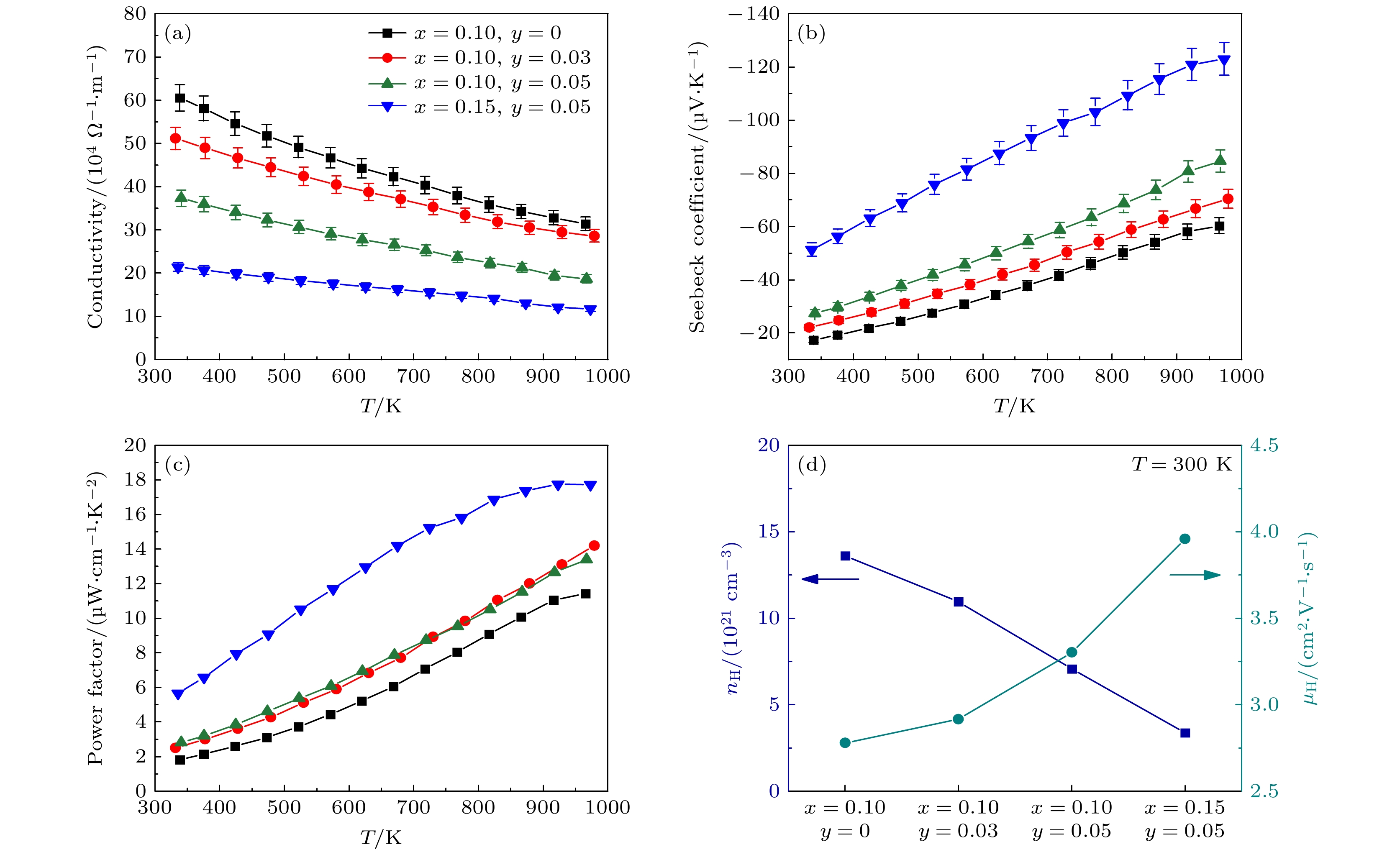

图 4 Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05)的电输运特性随温度的变化 (a) 电导率σ; (b) 塞贝克系数S; (c) 功率因子. (d) Ti1–x–yScyNiSb样品的载流子浓度nH和迁移率μH

Figure 4. Temperature dependent electrical transport properties of Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05) samples: (a) Electrical conductivity σ; (b) Seebeck coefficients S; (c) power factor. (d) Room-temperature Hall carrier concentration nH and mobility μH of Ti1–x-yScyNiSb samples.

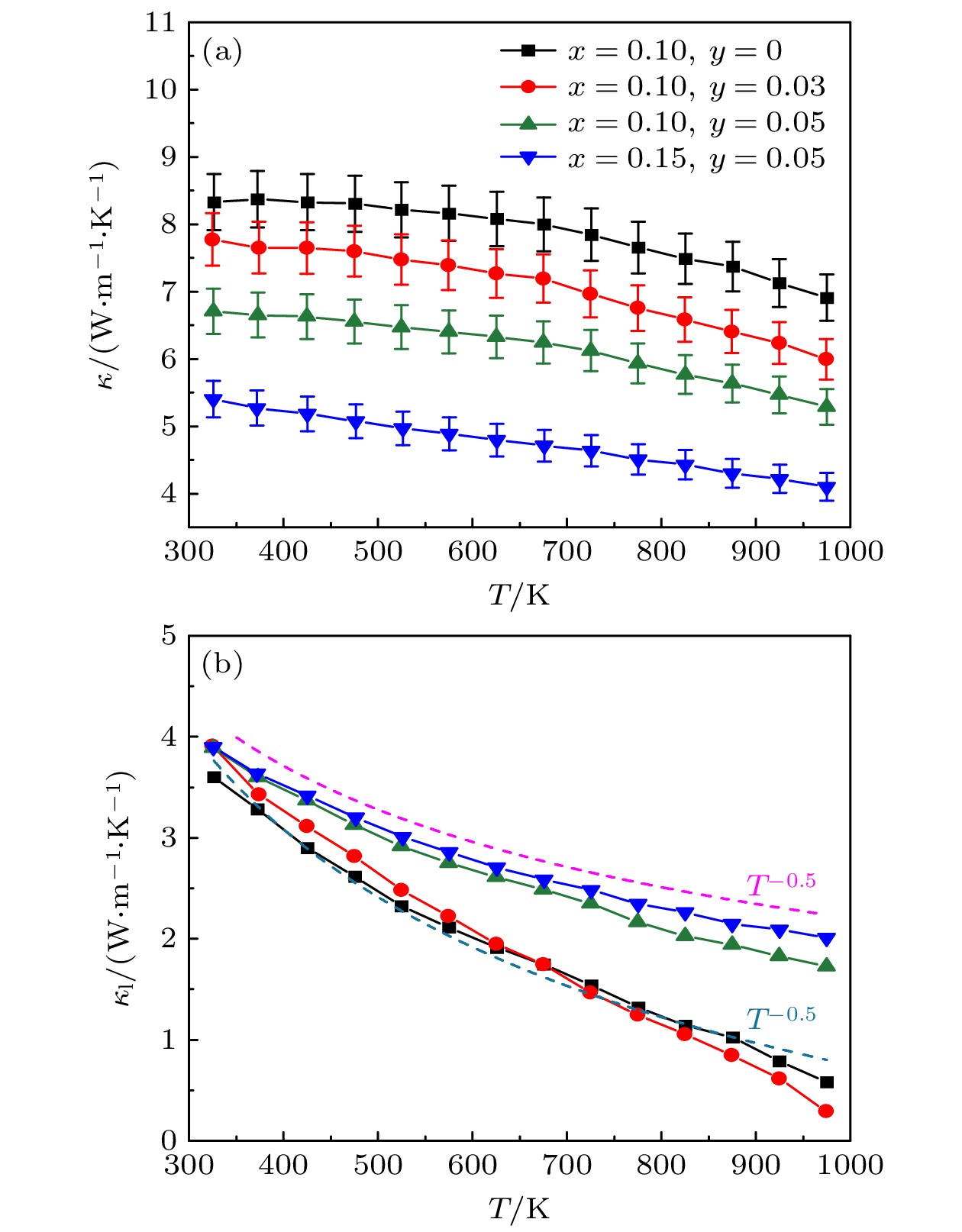

图 6 (a), (b) Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05) 样品的总热导率κ和晶格热导率κl随温度的变化 (图(b)中的虚线为T–0.5关系)

Figure 6. (a), (b) Temperature dependence of total thermal conductivity (κ) and lattice thermal conductivity (κl) of Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05) samples (The dashed lines in Fig. (b) represent the T–0.5 relationship).

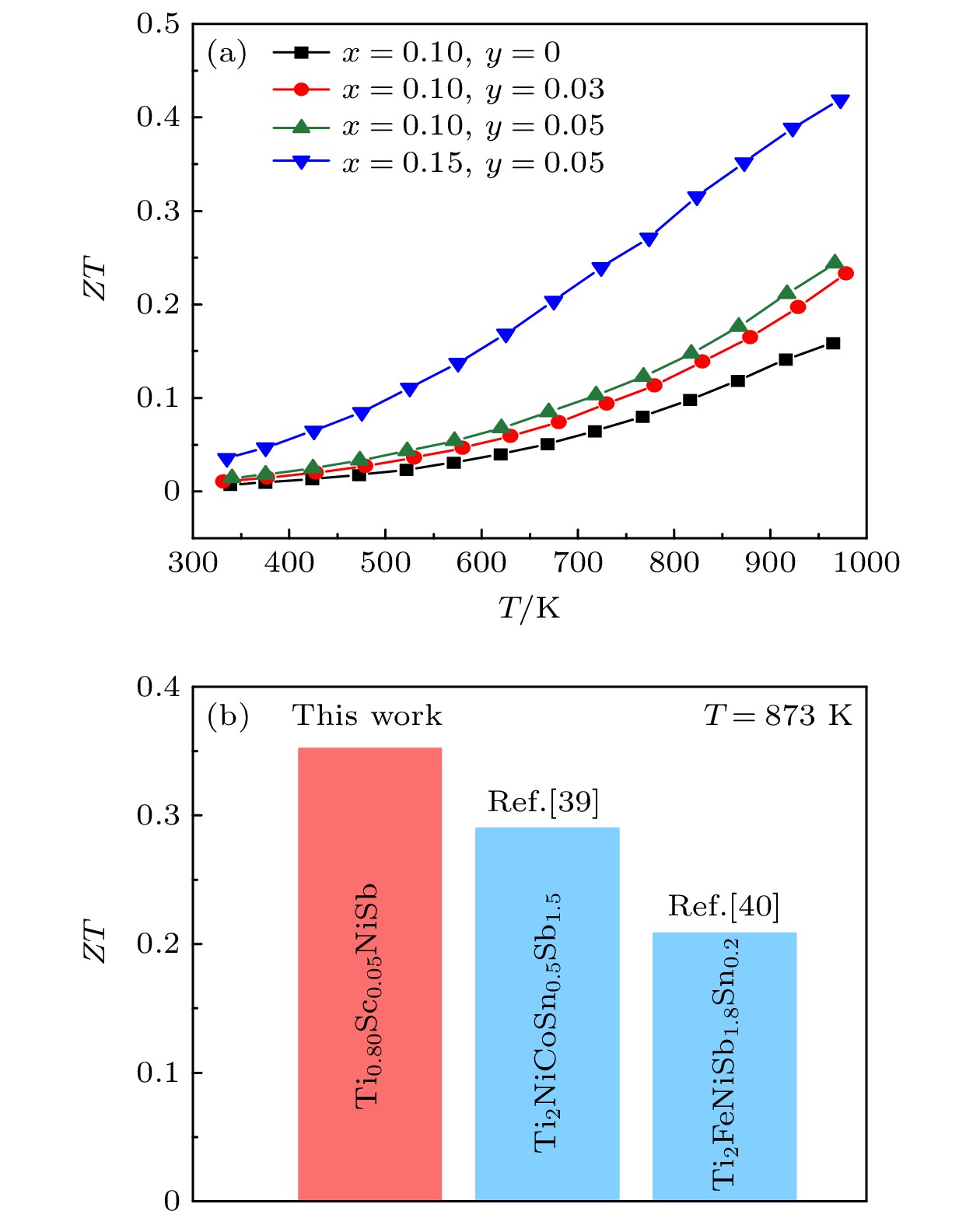

图 7 (a) Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05) 样品的ZT值随温度的变化; (b) Ti0.8Sc0.05NiSb样品的ZT值与文献数据对比[39,40]

Figure 7. (a) Temperature dependence of ZT value for Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05) samples; (b) comparison of ZT value of Ti0.8Sc0.05NiSb sample with literature data[39,40].

表 1 Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05) 样品的名义成分和EDS实际成分

Table 1. Nominal and actual atomic contents for Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05) detected by EDS.

名义成分 实际成分 Ti0.9NiSb Ti0.87NiSb1.04 Ti0.87Sc0.03NiSb Ti0.85Sc0.03NiSb1.02 Ti0.85Sc0.05NiSb Ti0.85Sc0.06NiSb1.15 Ti0.80Sc0.05NiSb Ti0.80Sc0.06NiSb1.04 表 2 室温下Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05) 样品的横波

${{v}}_{\text{l}}$ 和纵波声速${{v}}_{\text{t}}$ , 以及利用公式①计算得到的平均声速${{v}}_{\text{s}}$ Table 2. Measured longitudinal

${{v}}_{\text{l}}\text{}$ and transverse${{v}}_{\text{t}}$ sound velocities for Ti1–x–yScyNiSb (x = 0.10, 0.15; y = 0.03, 0.05) samples at room temperature. The average sound velocity${{v}}_{\text{s}}$ is calculated by the formula①样品 ${ {v} }_{{\rm{l}} }$/(m·s–1) ${v} _{{\rm{t}}}$/(m·s–1) ${v}_{{\rm{s}}}$/(m·s–1) Ti0.9NiSb 3085 5887 3451 Ti0.87Sc0.03NiSb 3094 5841 3458 Ti0.85Sc0.05NiSb 3100 5844 3464 Ti0.80Sc0.05NiSb 3121 5977 3491 注: ① ${ {v} }_{\text{s} }=\left[\dfrac{\text{1} }{\text{3} }\text{}\left(\dfrac{\text{1} }{ { {v} }_{\text{l} }^{\text{3} } }+\dfrac{\text{2} }{ { {v} }_{\text{t} }^{\text{3} } }\right)\right] ^{ {-1/3} }.$ -

[1] Bell L E 2008 Science 321 1457

Google Scholar

Google Scholar

[2] Jia N, Cao J, Tan X Y, Dong J F, Liu H F, Tan C K I, Xu J W, Yan Q Y, Loh X J, Suwardi A 2021 Energy Environ. Sci. 21 100519

Google Scholar

Google Scholar

[3] Min R A, Wang Y X, Jiang X, Chen R C, Kang H J, Guo E Y, Chen Z N, Yang X, Wang T M 2022 Chem. Eng. J. 449 137898

Google Scholar

Google Scholar

[4] Joshi G, Dahal T, Chen S, Wang H Z, Shiomi J, Chen G, Ren Z F 2013 Nano Energy 2 82

Google Scholar

Google Scholar

[5] Yu C, Zhu T J, Shi R Z, Zhang Y, Zhao X B, He J 2009 Acta Mater. 57 2757

Google Scholar

Google Scholar

[6] Fu C G, Zhu T J, Liu Y T, Xie H H, Zhao X B 2015 Energy Environ. Sci. 8 216

Google Scholar

Google Scholar

[7] Pei Y Z, Shi X Y, LaLonde A, Wang H, Chen L D, Snyder G J 2011 Nature 473 66

Google Scholar

Google Scholar

[8] Fu C G, Zhu T J, Pei Y Z, Xie H H, Wang H, Snyder G J, Liu Y, Liu Y T, Zhao X B 2014 Adv. Energy Mater. 4 1400600

Google Scholar

Google Scholar

[9] Tan C, Wang H X, Yao J, Chen T T, Wang L, Sun Y Q, Khan M, Wang H C, Wang C L 2022 J. Eur. Ceram. Soc. 42 7010

Google Scholar

Google Scholar

[10] Biswas K, He J Q, Blum I D, Wu C I, Hogan T P, Seidman D N, Dravid V P, Kanatzidis M G 2012 Nature 489 414

Google Scholar

Google Scholar

[11] Sun Y J, Shuai Z G, Wang D 2019 J. Phys. Chem. C 123 12001

Google Scholar

Google Scholar

[12] He R, Gahlawat S, Guo C F, Chen S, Dahal T, Zhang H, Liu W S, Zhang Q, Chere E, White K, Ren Z F 2015 Phys. Status. Solidi. A 212 2191

Google Scholar

Google Scholar

[13] Graf T, Felser C, Parkin S S P 2011 Prog. Solid. State Ch. 39 1

Google Scholar

Google Scholar

[14] Sakurada S, Shutoh N 2005 Appl. Phys. Lett. 86 082105

Google Scholar

Google Scholar

[15] Uher C, Yang J, Hu S, Morelli D T, Meisner G P 1999 Phys. Rev. B 59 8615

Google Scholar

Google Scholar

[16] 王鹏将, 康慧君, 杨雄, 刘颖, 程成, 王同敏 2022 无机材料学报 37 717

Google Scholar

Google Scholar

Wang P J, Kang H J, Yang X, Liu Y, Cheng C, Wang T M 2022 J. Inorg. Mater. 37 717

Google Scholar

Google Scholar

[17] Sekimoto T, Kurosaki K, Muta H, Yamanaka S 2006 Mater. Trans. 47 1445

Google Scholar

Google Scholar

[18] Sekimoto T, Kurosaki K, Muta H, Yamanaka S 2005 Mater. Trans. 46 1481

Google Scholar

Google Scholar

[19] Sekimoto T, Kurosaki K, Muta H, Yamanaka S 2007 Jpn. J. Appl. Phys. 46 L673

Google Scholar

Google Scholar

[20] Huang Y, Hayashi K, Miyazaki Y 2020 Chem. Mater. 32 5173

Google Scholar

Google Scholar

[21] Joshi G, He R, Engber M, Samsonidze G, Pantha T, Dahal E, Dahal K, Yang J, Lan Y C, Kozinsky B, Ren Z F 2014 Energy Environ. Sci. 7 4070

Google Scholar

Google Scholar

[22] Zhu H T, Mao J, Li Y W, et al. 2019 Nat. Commun. 10 270

Google Scholar

Google Scholar

[23] Xia K, Liu Y, Anand S, Snyder G J, Xin J, Yu J, Zhao X, Zhu T 2018 Adv. Funct. Mater. 28 1705845

Google Scholar

Google Scholar

[24] Li S, Bai F X, Wang R F, Chen C, Li X F, Cao F, Yu B, Sui J H, Liu X J, Ren Z F, Zhang Q 2020 Ann. Phys. 532 1900440

Google Scholar

Google Scholar

[25] Miranda J, Gruhn T 2022 J. Electron. Mater. 51 2043

Google Scholar

Google Scholar

[26] Huang L H, Wang J C, Mo X B, Lei X B, Ma S D, Wang C, Zhang Q Y 2019 Materials 12 1637

Google Scholar

Google Scholar

[27] Kainuma R, Umino R, Xu X, Han K, Omori T 2020 J. Phase. Equilibria. Diffus. 41 116

Google Scholar

Google Scholar

[28] Romaka V V, Rogl P, Romaka L, Stadnyk Y, Melnychenko N, Grytsiv A, Falmbigl M, Skryabina N 2013 J. Solid State Chem. 197 103

Google Scholar

Google Scholar

[29] Anand S, Xia K Y, Zhu T J, Wolverton C, Snyder G J 2018 Adv. Energy Mater. 8 1801409

Google Scholar

Google Scholar

[30] Luo F, Wang J, Zhu C, He X, Zhang S, Wang J F, Liu H X, Sun Z G 2022 J. Mater. Chem. A 10 9655

Google Scholar

Google Scholar

[31] Anand S, Xia K Y, Hegde V I, Aydemir U, Kocevski V, Zhu T J, Wolverton C, Snyder G J 2018 Energy Environ. Sci. 11 1480

Google Scholar

Google Scholar

[32] Romaka V V, Rogl G, Grytsiv A, Rogl P 2020 Comput. Mater. Sci. 172 109307

Google Scholar

Google Scholar

[33] Zhou M, Chen L D, Feng C D, Wang D L, Li J F 2007 J. Appl. Phys. 101 113714

Google Scholar

Google Scholar

[34] Zhao D G, Wang L, Bo L, Wu D 2018 Metals 8 61

Google Scholar

Google Scholar

[35] Tavassoli A, Failamani F, Grytsiv A, Rogl G, Heinrich P, Müller H, Bauer E, Zehetbauer M, Rogl P 2017 Acta Mater. 135 263

Google Scholar

Google Scholar

[36] Kim H S, Gibbs Z M, Tang Y L, Wang H, Snyder G J 2015 APL Mater. 3 041506

Google Scholar

Google Scholar

[37] 沈家骏, 方腾, 傅铁铮, 忻佳展, 赵新兵, 朱铁军 2019 无机材料学报 34 260

Google Scholar

Google Scholar

Shen J J, Fang T, Fu T Z, Xin J Z, Zhao X B, Zhu T J 2019 J. Inorg. Mater. 34 260

Google Scholar

Google Scholar

[38] Zhu T J, Yu G T, Xu J, Wu H J, Fu C G, Liu X H, He J Q, Zhao X B 2016 Adv. Electron. Mater. 2 1600171

Google Scholar

Google Scholar

[39] Karati A, Hariharan V S, Ghosh S, Prasad A, Nagini M, Guruvidyathri K, Mallik R C, Shabadi R, Bichler L, Murty B S, Varadaraju U V 2020 Scr. Mater. 186 375

Google Scholar

Google Scholar

[40] Hasan R, Park T, Kim S I, Kim H S, Jo S, Lee K H 2022 Adv. Energy Sustainability Res. 3 2100206

Google Scholar

Google Scholar

[41] Zhang X Y, Bu Z L, Shi X M, Chen Z W, Lin S Q, Shan B, Wood M, Snyder A H, Chen L D, Snyder G J, Pei Y Z 2020 Sci. Adv. 6 eabc0726

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5051

- PDF Downloads: 81

- Cited By: 0

DownLoad:

DownLoad: