-

The performance of magnetocaloric effect materials is one of the key factors restricting the development of magnetic refrigeration technology. Materials with anisotropic magnetocaloric effect can be used in the rotary magnetic refrigeration technology, which is beneficial to the simplification of refrigeration devices. In this work, the magnetic properties, magnetocaloric effects, and magnetic anisotropies of rapidly quenched HoCoSi compounds are investigated. At low temperatures below Tt = 5.7 K, the HoCoSi ferromagnetism and helical magnetism coexist. With the increase of temperature, the HoCoSi undergoes a second-order phase transition from ferromagnetic (FM) to paramagnetic (PM) phase at TC = 13.7 K. Both XRD and SEM show that the HoCoSi has a preferred orientation. In order to obtain a large magnetocaloric effect and to determine the effect of preferred orientation on magnetism and magnetocaloric effect, the isothermal magnetization curves of the 10 m/s–HoCoSi fast quenched belt in the directions of H parallel and perpendicular to texture around the Curie temperature are analyzed. The corresponding magnetic entropy change (–ΔSM) and magnetic refrigeration capacity (RC) are calculated. Under the magnetic field changing from 0 to 5 T, the value of –ΔSM is 22 J/(kg·K) in the direction of H parallel to the texture and 12 J/(kg·K) in the direction of H perpendicular to texture , and their corresponding values of RC(RCP)are 360 (393.8) J·kg–1 and 160 (254.4) J/kg. The value of –ΔSM reaches 12.5 J/(kg·K)even at μ0H = 0–2 T in the direction of H parallel to the texture. It is obvious that the 10-m/s-HoCoSi fast quenching belt shows a large low-field magnetocaloric effect and obvious magnetic anisotropy, which is expected to be used to realize the magnetic refrigeration technology of rotating samples.

[1] Shen B G, Sun J R, Hu F X, Zhang H W, Cheng Z H 2009 Adv. Mater. 21 4545

Google Scholar

Google Scholar

[2] Franco V, Blázquez J S, Ingale B, Conde A 2012 Annu. Rev. Mater. Sci. 42 305

Google Scholar

Google Scholar

[3] Zhang H, Shen B G, Xu Z Y, Shen J, Hu F X, Sun J R, Long Y 2013 Appl. Phys. Lett. 102 092401

Google Scholar

Google Scholar

[4] Gschneidner K A Jr, Pecharsky V K, Tsokol A O 2005 Rep. Prog. Phys. 68 1479

Google Scholar

Google Scholar

[5] Zhang H, Shen B G 2015 Chin. Phys. B 24 127504

Google Scholar

Google Scholar

[6] 郑新奇, 沈俊, 胡凤霞, 孙继荣, 沈保根 王军民 2016 65 217502

Google Scholar

Google Scholar

Zheng X Q, Shen J, Hu F X, Sun J R, Shen B G 2016 Acta Phys. Sin. 65 217502

Google Scholar

Google Scholar

[7] Li L W, Yan M 2022 JMST

[8] Zhang Y K 2019 J. Alloys Compd. 787 1173

Google Scholar

Google Scholar

[9] Li L W, Yan M 2020 J. Alloys Compd. 823 153810

Google Scholar

Google Scholar

[10] Nikitin S A, Skokov K P, Koshkid'ko Y S, Pastushenkov Y G, Ivanova T I 2010 Phys. Rev. Lett. 105 137205

Google Scholar

Google Scholar

[11] Balli M, Mansouri S, Dimitrov D Z, Fournier P, Jandl S, Juang J Y 2020 Phys. Rev. Mater. 4 114411

Google Scholar

Google Scholar

[12] Nikitin S A, Ivanova T I, Zvonov A I, Koshkid'ko Y S, Ćwik J, Rogacki K 2018 Acta Mater. 161 331

Google Scholar

Google Scholar

[13] Liu Y, Petrovic C 2018 Phys. Rev. B 97 174418

Google Scholar

Google Scholar

[14] Liu Y, Petrovic C 2019 Phys Rev. Mater. 3 014001

Google Scholar

Google Scholar

[15] Zhang H, Li Y V, Liu E K, Ke Y J 2015 Sci. Rep. 5 11929

Google Scholar

Google Scholar

[16] Zhang H, Xing C F, Zhou H, Zheng X Q, Miao X F, He L H, Chen J, Lu H L, Liu E K, Han W T, Zhang H G, Wang Y X, Long Y, Eijk L V, Brück E 2020 Acta Mater. 193 2020

[17] Barua R, Lejeune B T, Ke L, Hadjipanayis G, Levin E M, McCallum R W, Kramer M J, Lewis L H 2018 J. Alloys. Compd. 745 505

Google Scholar

Google Scholar

[18] Welter R, Venturini G, Ressouche E, Malaman B 1994 J. Alloys Compd. 210 279

Google Scholar

Google Scholar

[19] Gupta S, Suresh K G 2013 Mater. Lett. 113 195

Google Scholar

Google Scholar

[20] Leciejewicz J, Stusser N, Kolenda M, Szytuta A, Zygmunt A 1996 J. Alloys Compd. 240 164

Google Scholar

Google Scholar

[21] Yuan F, Du J, Shen B L 2012 Appl. Phys. Lett. 101 032405

Google Scholar

Google Scholar

[22] Szytula A, Balanda M, Hofmann M, Leciejewicz J, Kolenda M, Penc B, Zygmunt A 2009 J. Appl. Phys. 105 023901

Google Scholar

Google Scholar

[23] Wang J L, Marquina C, Ibarra M R, Wu G H 2006 Phys. Rev. B 73 094436

[24] Szytula A, Balanda M, Hofmann M, Leciejewicz J, Kolenda M, Penc B, Zygmunt A 1999 J. Magn. Magn. Mater. 191 122

Google Scholar

Google Scholar

[25] 许志一 2012 博士学位论文 (北京: 中国科学院物理研究所)

Xu Z Y 2012 Ph. D. Dissertation (Beijing: Institute of Physics, Chinese Academy of Sciences) (in Chinese)

[26] Guo D, Zhang Y K, Wu B B, Wang H F, Guan R G, Li X, Ren Z M 2020 J. Alloy. Compd. 830 154666

Google Scholar

Google Scholar

[27] Ma Y, Dong X, Qi Y, 2019 J. Magn. Magn. Mater. 471 25

Google Scholar

Google Scholar

[28] Zhang Y, Zhu J, Li S, Zhang Z Q, Wang J, Ren Z M 2022 Sci. China Mater. 65 1345

Google Scholar

Google Scholar

[29] Li L W, Xu P, Ye S K, Li Y, Liu G D, Huo D X, Yan M 2020 Acta Mater. 194 354

Google Scholar

Google Scholar

[30] Wu B B, Guo D, Wang Y M, Zhang Y K 2020 Ceram. Int. 46 11988

Google Scholar

Google Scholar

[31] Zhang Y K, Zhang B, Li S, Zhu J, Wu B B, Wang J, Ren Z M 2021 Ceram. Int. 47 18205

Google Scholar

Google Scholar

-

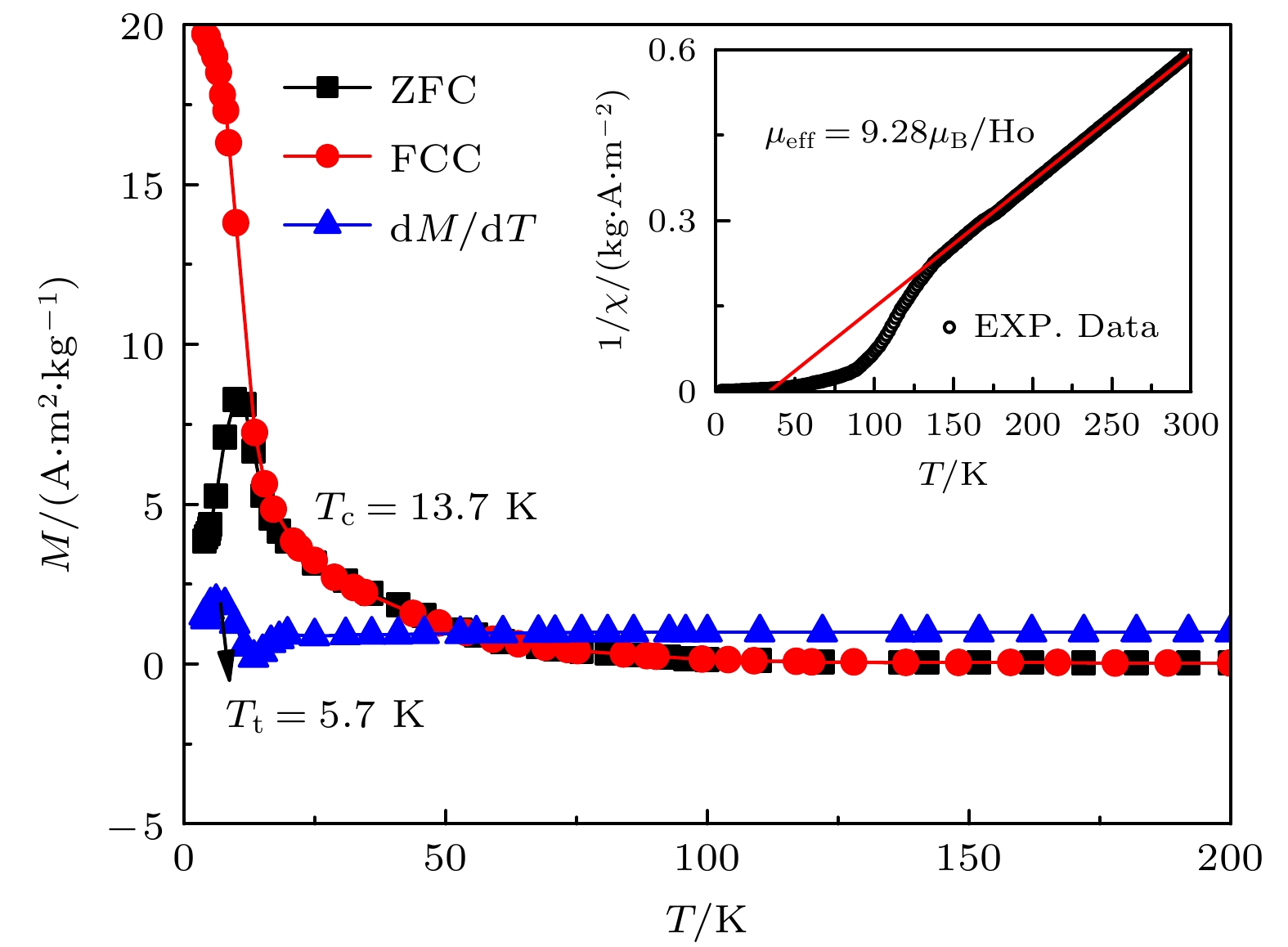

图 2 外场为0.1 T时, 10 m/s甩带速度下的HoCoSi在ZFC和FCC两种模式下的热磁曲线, ZFC的一阶导数曲线显示在下方; 内插图为ZFC模式的1/χ-T 曲线, 实线表示Curie-Weiss拟合

Figure 2. The temperature dependence of magnetization in ZFC and FC mode for HoCoSi of 10 m/s under the field of 0.01 T, and the corresponding ZFC first derivative curves are shown below. The 1/χ-T curve of ZFC was displayed in the insets. The solid line to inverse susceptibility shows the Curie-Weiss fit.

图 3 在5 m/s, 10 m/s, 15 m/s, 20 m/s甩带速度下HoCoSi快淬带的磁场//织构方向的等温磁化曲线 (a) T = 5 K, 插图为10 m/s的快淬带横截面的SEM图; (b) T = 17 K

Figure 3. The magnetization isotherms of 5 m/s, 10 m/s, 15 m/s, 20 m/s HoCoSi taken in the direction of H parallel to textures: (a) T = 5 K, the SEM image of the cross-section of 10 m/s HoCoSi was displayed in the inset; (b) T = 17 K.

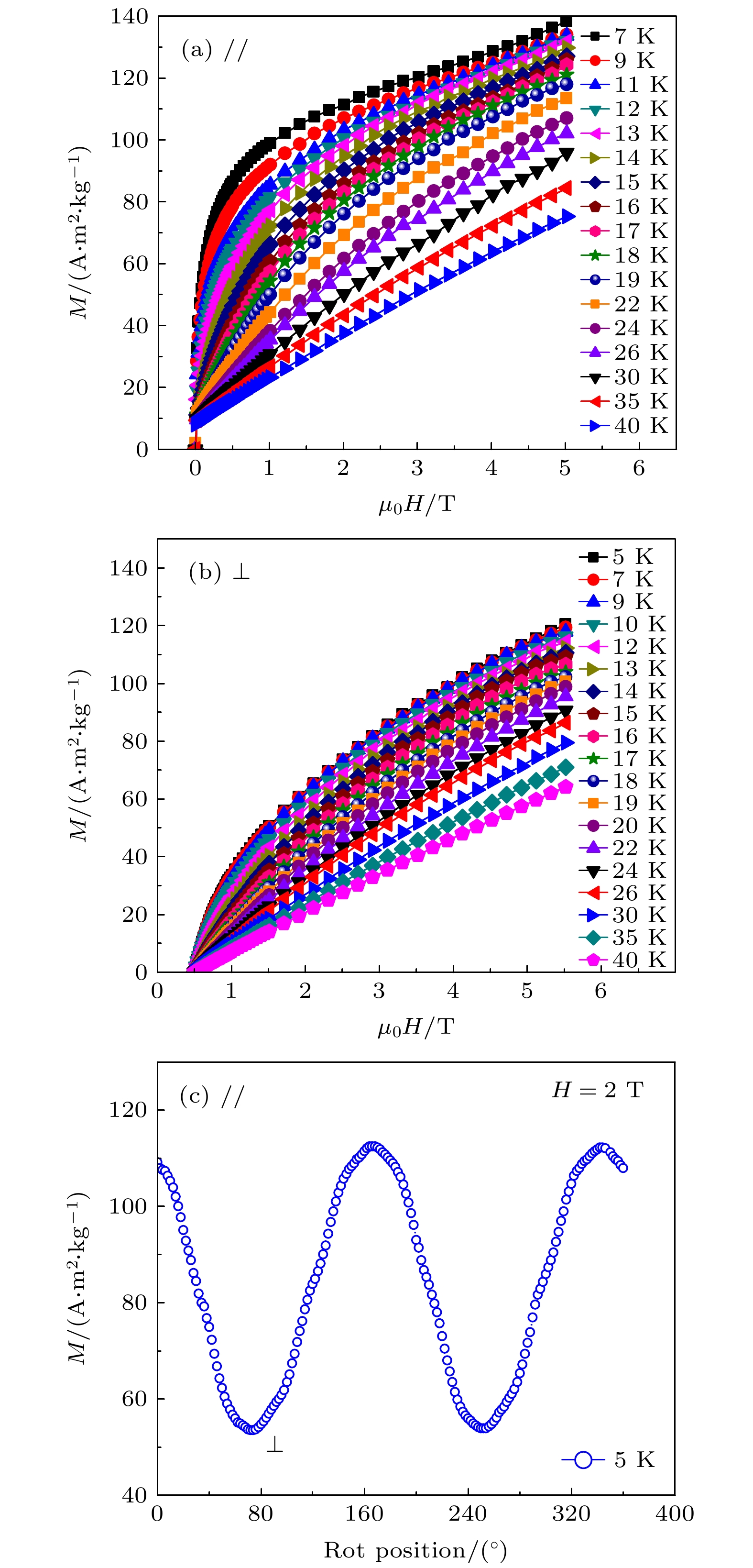

图 4 甩带速度10 m/s时HoCoSi快淬带在磁场平行 (a)和垂直(b)织构方向的等温磁化曲线; (c) T = 5 K, μ0H = 2 T下的转角磁化曲线

Figure 4. The magnetization isotherms of 10 m/s HoCoSi taken in the direction of H parallel to textures (a) and H perpendicular to textures (b); (c) the magnetization as a function of rotation angle at 5 K in the magnetic field of 2 T.

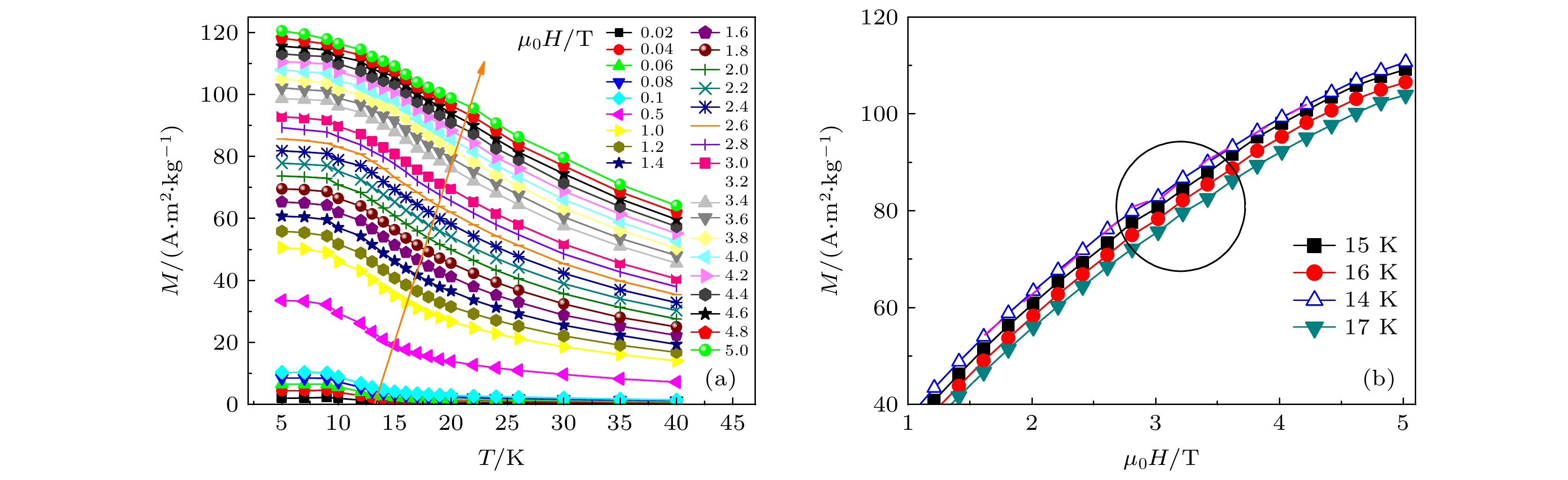

图 5 10 m/s的HoCoSi快淬带的

$\Delta {S}_{\mathrm{M}}\text-T$ 变化曲线 (a)磁场平行⊥织构方向; (b)磁场垂直织构方向; 内插图为制冷能力RC随外场变化关系Figure 5. The

$\Delta {S}_{\mathrm{M}}\text-T$ curves of 10 m/s HoCoSi: (a) In the direction of H parallel to textures; (b) in the direction of H perpendicular to textures. The corresponding magnetic refrigeration capacity RC were showed in the insets.表 1 10 m/s下HoCoSi化合物的磁热参数和一些最近报道的 Δμ0H = 5 T 的有前景的低温磁制冷材料

Table 1. Magnetocaloric parameters for the 10 m/s HoCoSi compounds and some recently reported promising cryogenic magnetic refrigerants for Δμ0H = 5 T.

Compound TM /K $ \left| {\Delta S_{\text{M}}^{{\max}}} \right| $/(J·(kg·K)–1) δTFWHM/K RCP/(J·kg–1) Refs. HoCoSi(parallel) 13.7 22 17.9 393.8 This study HoCoSi(perpendicular) 13.7 12 21.2 266.4 This study Er2Ni1.5Ga2.5 4.1 15.7 18.3 254.4 [26] PrFe2Si2 8.5 6.4 17 ~100.8 [27] NdFe2Si2 15.5 12.4 11 ~116.3 [27] GdFe2Si2 8.6 23.25 9 276.56 [28] Gd2ZnMnO6 6.4 15.2 14.9 226.2 [29] Ho2ZnMnO6 6.8 13.2 18.7 246.5 [29] Ho2CrMnO6 6.1 8.8 22.0 193.7 [30] Er2CrMnO6 5.2 10.3 14.2 146.0 [30] Er2CuMnO6 3.6 9.9 19.7 195.9 [31] -

[1] Shen B G, Sun J R, Hu F X, Zhang H W, Cheng Z H 2009 Adv. Mater. 21 4545

Google Scholar

Google Scholar

[2] Franco V, Blázquez J S, Ingale B, Conde A 2012 Annu. Rev. Mater. Sci. 42 305

Google Scholar

Google Scholar

[3] Zhang H, Shen B G, Xu Z Y, Shen J, Hu F X, Sun J R, Long Y 2013 Appl. Phys. Lett. 102 092401

Google Scholar

Google Scholar

[4] Gschneidner K A Jr, Pecharsky V K, Tsokol A O 2005 Rep. Prog. Phys. 68 1479

Google Scholar

Google Scholar

[5] Zhang H, Shen B G 2015 Chin. Phys. B 24 127504

Google Scholar

Google Scholar

[6] 郑新奇, 沈俊, 胡凤霞, 孙继荣, 沈保根 王军民 2016 65 217502

Google Scholar

Google Scholar

Zheng X Q, Shen J, Hu F X, Sun J R, Shen B G 2016 Acta Phys. Sin. 65 217502

Google Scholar

Google Scholar

[7] Li L W, Yan M 2022 JMST

[8] Zhang Y K 2019 J. Alloys Compd. 787 1173

Google Scholar

Google Scholar

[9] Li L W, Yan M 2020 J. Alloys Compd. 823 153810

Google Scholar

Google Scholar

[10] Nikitin S A, Skokov K P, Koshkid'ko Y S, Pastushenkov Y G, Ivanova T I 2010 Phys. Rev. Lett. 105 137205

Google Scholar

Google Scholar

[11] Balli M, Mansouri S, Dimitrov D Z, Fournier P, Jandl S, Juang J Y 2020 Phys. Rev. Mater. 4 114411

Google Scholar

Google Scholar

[12] Nikitin S A, Ivanova T I, Zvonov A I, Koshkid'ko Y S, Ćwik J, Rogacki K 2018 Acta Mater. 161 331

Google Scholar

Google Scholar

[13] Liu Y, Petrovic C 2018 Phys. Rev. B 97 174418

Google Scholar

Google Scholar

[14] Liu Y, Petrovic C 2019 Phys Rev. Mater. 3 014001

Google Scholar

Google Scholar

[15] Zhang H, Li Y V, Liu E K, Ke Y J 2015 Sci. Rep. 5 11929

Google Scholar

Google Scholar

[16] Zhang H, Xing C F, Zhou H, Zheng X Q, Miao X F, He L H, Chen J, Lu H L, Liu E K, Han W T, Zhang H G, Wang Y X, Long Y, Eijk L V, Brück E 2020 Acta Mater. 193 2020

[17] Barua R, Lejeune B T, Ke L, Hadjipanayis G, Levin E M, McCallum R W, Kramer M J, Lewis L H 2018 J. Alloys. Compd. 745 505

Google Scholar

Google Scholar

[18] Welter R, Venturini G, Ressouche E, Malaman B 1994 J. Alloys Compd. 210 279

Google Scholar

Google Scholar

[19] Gupta S, Suresh K G 2013 Mater. Lett. 113 195

Google Scholar

Google Scholar

[20] Leciejewicz J, Stusser N, Kolenda M, Szytuta A, Zygmunt A 1996 J. Alloys Compd. 240 164

Google Scholar

Google Scholar

[21] Yuan F, Du J, Shen B L 2012 Appl. Phys. Lett. 101 032405

Google Scholar

Google Scholar

[22] Szytula A, Balanda M, Hofmann M, Leciejewicz J, Kolenda M, Penc B, Zygmunt A 2009 J. Appl. Phys. 105 023901

Google Scholar

Google Scholar

[23] Wang J L, Marquina C, Ibarra M R, Wu G H 2006 Phys. Rev. B 73 094436

[24] Szytula A, Balanda M, Hofmann M, Leciejewicz J, Kolenda M, Penc B, Zygmunt A 1999 J. Magn. Magn. Mater. 191 122

Google Scholar

Google Scholar

[25] 许志一 2012 博士学位论文 (北京: 中国科学院物理研究所)

Xu Z Y 2012 Ph. D. Dissertation (Beijing: Institute of Physics, Chinese Academy of Sciences) (in Chinese)

[26] Guo D, Zhang Y K, Wu B B, Wang H F, Guan R G, Li X, Ren Z M 2020 J. Alloy. Compd. 830 154666

Google Scholar

Google Scholar

[27] Ma Y, Dong X, Qi Y, 2019 J. Magn. Magn. Mater. 471 25

Google Scholar

Google Scholar

[28] Zhang Y, Zhu J, Li S, Zhang Z Q, Wang J, Ren Z M 2022 Sci. China Mater. 65 1345

Google Scholar

Google Scholar

[29] Li L W, Xu P, Ye S K, Li Y, Liu G D, Huo D X, Yan M 2020 Acta Mater. 194 354

Google Scholar

Google Scholar

[30] Wu B B, Guo D, Wang Y M, Zhang Y K 2020 Ceram. Int. 46 11988

Google Scholar

Google Scholar

[31] Zhang Y K, Zhang B, Li S, Zhu J, Wu B B, Wang J, Ren Z M 2021 Ceram. Int. 47 18205

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5221

- PDF Downloads: 78

- Cited By: 0

DownLoad:

DownLoad: