-

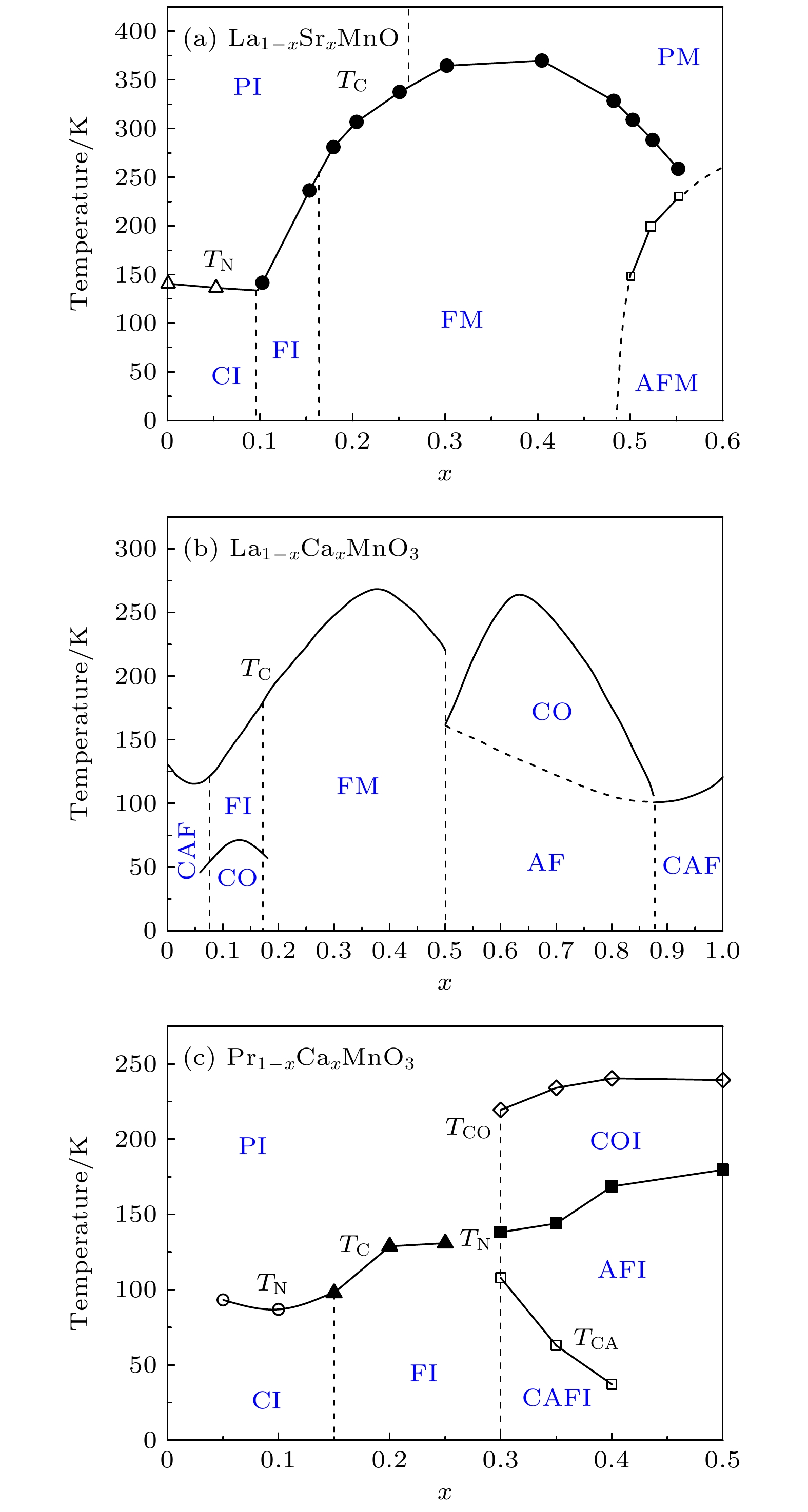

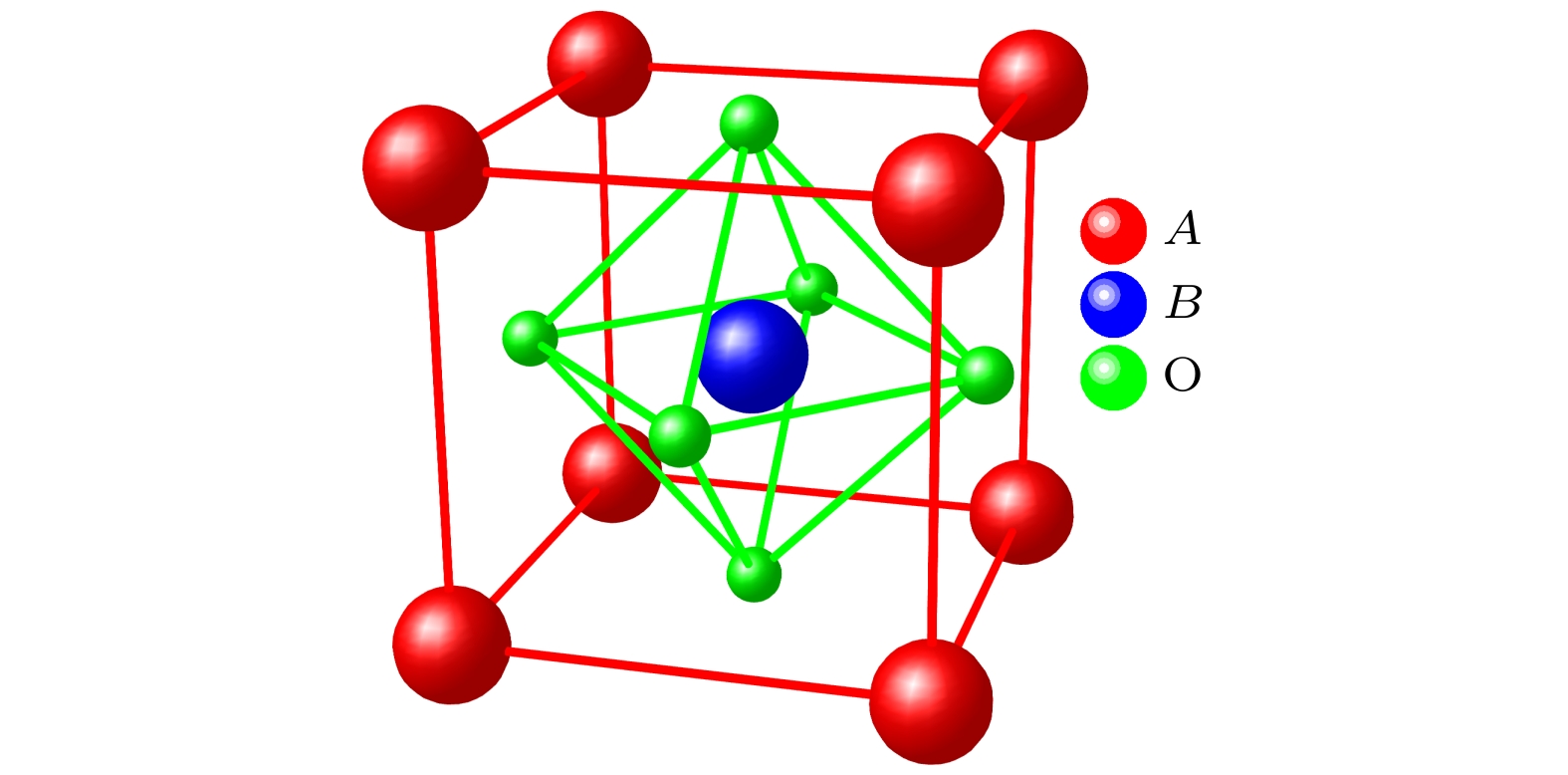

Hole-doped perovskite-type manganites have received intensive attention due to their intriguing physical phenomena such as giant magnetocaloric effect and magnetic-phase transitions. However, the mechanism of internal ferromagnetic interaction still needs to be further explored due to the complex natures of competing double-exchange (DE) and super-exchange (SE) interaction, Jahn-Teller (JT) polaron localization, charge ordering, and phase separation scenarios. Critical exponent analysis near magnetic phase transition is a powerful tool to investigate the details of the ferromagnetic interactions and has been used frequently in various magnetocaloric materials. In this article, the critical behavior analyses of perovskite manganites in recent years are comprehensively reviewed. A large number of studies have shown that even in single-phase materials with uniform structure and composition, the critical behavior can be affected by multiple factors such as grain boundary density and the degree of disorder, making them difficult to fully describe the intrinsic ferromagnetism. In this review, firstly, the critical behaviors of typical manganites with different bandwidths in single crystal and polycrystalline are discussed. In a double-exchange dominated system such as La-Sr-Mn-O, short-range 3D-Heisenberg model is basically in good accordance with optimally-doped single crystal sample. However, it would be replaced by long-range mean-field critical behavior in polycrystalline sample when the correlation length exceeds the crystallite size. In a typical intermediate bandwidth system such as La-Ca-Mn-O exhibiting a complex phase diagram described by competing SE/DE interactions, JT polaron localization/delocalization, and Griffith phase disorder, the critical exponent can vary from 3D-Heisenberg model to tricritical mean-field model, for the crossover from first to second order phase transition. Secondly, the studies of elements doping and different fabrication methods indicate that the critical behavior of manganites can be effectively modulated, and vary between different theoretical models including even nonuniversal exponent for highly disordered magnetic system. In the following part, the influence of magnetic field on the critical behavior and field induced crossover phenomena of La-Ca-Mn-O system near tricritical point is analyzed and discussed in detail. Furthermore, the magnetocaloric effects of materials near the tricritical point collected in many studies are listed and compared with each other. Excellent magnetocaloric properties with high magnetic entropy change and relative cooling power in plenty of researches indicate that ideal magnetocaloric material would be very likely to be found in the materials near the tricritical point, which lay at the borderline between first-order and second-order phase transition. Consequently, it is suggested that perovskite manganites are still quite promising in the potential magnetic refrigeration applications, and need to be further developed.

-

Keywords:

- perovskite manganites /

- critical behavior /

- magnetocaloric effect

[1] Pecharsky V K, Gschneidner Jr K A 1997 Phys. Rev. Lett. 78 4494

Google Scholar

Google Scholar

[2] Hu F X, Shen B G, Sun J R, Cheng Z H, Rao G H, Zhang X X 2001 Appl. Phys. Lett. 78 3675

Google Scholar

Google Scholar

[3] Tegus O, Bruck E, Buschow K H J, de Boer F R 2002 Nature 415 150

Google Scholar

Google Scholar

[4] Krenke T, Duman E, Acet M, Wassermann E F, Moya X, Mañosa L, Planes A 2005 Nat. Mater. 4 450

Google Scholar

Google Scholar

[5] Hu F X, Shen B G, Sun J R 2000 Appl. Phys. Lett. 76 3460

Google Scholar

Google Scholar

[6] Guo Z B, Du Y W, Zhu J S, Huang H, Ding W P, Feng D 1997 Phys. Rev. Lett. 78 1142

Google Scholar

Google Scholar

[7] Phan M H, Yu S C 2007 J. Magn. Magn. Mater. 308 325

Google Scholar

Google Scholar

[8] Law J Y, Franco V, Moreno-Ramírez L M, Conde A, Karpenkov D Y, Radulov I, Skokov K P, Gutfleisch O 2018 Nat. Commun. 9 2680

Google Scholar

Google Scholar

[9] Fujita A, Fujieda S, Hasegawa Y, Fukamichi K 2003 Phys. Rev. B 67 104416

Google Scholar

Google Scholar

[10] Sun Y, Arnold Z, Kamarad J, Wang G J, Shen B G, Cheng Z H 2006 Appl. Phys. Lett. 89 172513

Google Scholar

Google Scholar

[11] Liu J, Gottschall T, Skokov K P, Moore J D, Gutfleisch O 2012 Nat. Mater. 11 620

Google Scholar

Google Scholar

[12] Romero-Muñiz C, Tamura R, Tanaka S, Franco V 2016 Phys. Rev. B 94 134401

Google Scholar

Google Scholar

[13] Franco V, Law J Y, Conde A, Brabander V, Karpenkov D Y, Radulov I, Skokov K, Gutfleisch O 2017 J. Phys. D 50 414004

Google Scholar

Google Scholar

[14] Romero-Muñiz C, Franco V, Conde A 2017 Phys. Chem. Chem. Phys. 19 3582

Google Scholar

Google Scholar

[15] Dagotto E, Hotta T, Moreo A 2001 Phys. Rep. 344 1

Google Scholar

Google Scholar

[16] Alexandrov A S, Bratkovsky A M 1999 Phys. Rev. Lett. 82 141

Google Scholar

Google Scholar

[17] Yunoki S, Hu J, Malvezzi A L, Moreo A, Furukawa N, Dagotto E 1998 Phys. Rev. Lett. 80 845

Google Scholar

Google Scholar

[18] Banerjee B K 1964 Phys. Lett. 12 16

Google Scholar

Google Scholar

[19] Franco V, Blázquez J S, Conde A 2006 Appl. Phys. Lett. 89 222512

Google Scholar

Google Scholar

[20] Bonilla C M, Herrero-Albillos J, Bartolomé F, García L M, Parra-Borderías M, Franco V 2010 Phys. Rev. B 81 224424

Google Scholar

Google Scholar

[21] 张蕾 2018 67 137501

Google Scholar

Google Scholar

Zhang L 2018 Acta Phys. Sin. 67 137501

Google Scholar

Google Scholar

[22] Fan J, Pi L, Zhang L, Tong W, Ling L, Hong B, Shi Y, Zhang W, Lu D, Zhang Y 2011 Appl. Phys. Lett. 98 072508

Google Scholar

Google Scholar

[23] Huang K 1987 Statistical Mechanics (2nd Ed.) (New York: Wiley) pp398–432

[24] Kaul S N 1985 J. Magn. Magn. Mater. 53 5

Google Scholar

Google Scholar

[25] Fisher M E, Ma S K, Nickel B G 1972 Phys. Rev. Lett. 29 917

Google Scholar

Google Scholar

[26] Jiang W, Zhou X, Williams G, Mukovskii Y, Glazyrin K 2008 Phys. Rev. B 77 064424

Google Scholar

Google Scholar

[27] Linh D C, Thanh T D, Anh L H, Dao V D, Piao H G, Yu S C 2017 J. Alloys Compd. 725 484

Google Scholar

Google Scholar

[28] Moutis N, Panagiotopoulos I, Pissas M, Niarchos D 1999 Phys. Rev. B 59 1129

Google Scholar

Google Scholar

[29] Ghosh K, Lobb C J, Greene R L, Karabashev S G, Shulyatev D A, Arsenov A A, Mukovskii Y 1998 Phys. Rev. Lett. 81 4740

Google Scholar

Google Scholar

[30] Kim D, Zink B L, Hellman F, Coey J M D 2002 Phys. Rev. B 65 214424

Google Scholar

Google Scholar

[31] Mohan C V, Seeger M, Kronmüller H, Murugaraj P, Maier J 1998 J. Magn. Magn. Mater. 183 348

Google Scholar

Google Scholar

[32] Nair S, Banerjee A, Narlikar A V, Prabhakaran D, Boothroyd A T 2003 Phys. Rev. B 68 132404

Google Scholar

Google Scholar

[33] Kim D, Revaz B, Zink B L, Hellman F, Rhyne J J, Mitchell J F 2002 Phys. Rev. Lett. 89 227202

Google Scholar

Google Scholar

[34] Jiang W, Zhou X, Williams G, Mukovskii Y, Glazyrin K 2007 Phys. Rev. Lett. 99 177203

Google Scholar

Google Scholar

[35] Jiang W, Zhou X, Williams G, Privezentsev R, Mukovskii Y 2009 Phys. Rev. B 79 214433

Google Scholar

Google Scholar

[36] Oleaga A, Salazar A, Hatnean M C, Balakrishnan G 2015 Phys. Rev. B 92 024409

Google Scholar

Google Scholar

[37] Venkatesh R, Pattabiraman M, Sethupathi K, Rangarajan G, Angappane S, Park J G 2008 J. Appl. Phys. 103 07B319

Google Scholar

Google Scholar

[38] Phan T L, Ho T A, Thang P D, Tran Q T, Thanh T D, Phuc N X, Phan M H, Huy B T, Yu S C 2014 J. Alloys Compd. 615 937

Google Scholar

Google Scholar

[39] Rößler S, Nair H S, Rößler U K, Kumar C M N, Elizabeth S, Wirth S 2011 Phys. Rev. B 84 184422

Google Scholar

Google Scholar

[40] Elleuch F, Bekri M, Hussein M, Triki M, Dhahri E, Hlil E K, Bessais L 2015 Dalton Trans. 44 17712

Google Scholar

Google Scholar

[41] Jiang W, Zhou X, Williams G, Mukovskii Y, Glazyrin K 2008 Phys. Rev. B 78 144409

Google Scholar

Google Scholar

[42] Ho T A, Thanh T D, Yu Y, Tartakovsky D M, Ho T O, Thang P D, Le A T, Phan T L, Yu S C 2015 J. Appl. Phys. 117 17D122

Google Scholar

Google Scholar

[43] Ezaami A, Sellami-Jmal E, Cheikhrouhou-Koubaa W, Hlil E K, Cheikhrouhou A 2017 J. Mater. Sci. Mater. Electron. 28 6837

Google Scholar

Google Scholar

[44] Phan M H, Franco V, Bingham N S, Srikanth H, Hur N H, Yu S C 2010 J. Alloys Compd. 508 238

Google Scholar

Google Scholar

[45] Debbebi I S, Ezaami A, Cheikhrouhou-Koubaa W, Cheikhrouhou A, Hlil E K 2017 J. Mater. Sci. Mater. Electron. 28 14000

Google Scholar

Google Scholar

[46] Lam D S, Dung N T, Thanh T D, Linh D C, Nan W Z, Yu S C 2020 Mater. Res. Express 7 046101

Google Scholar

Google Scholar

[47] Elghoul A, Krichene A, Boudjada N C, Boujelben W 2018 Ceram. Int. 44 14510

Google Scholar

Google Scholar

[48] Fan J, Ling L, Hong B, Zhang L, Pi L, Zhang Y 2010 Phys. Rev. B 81 144426

Google Scholar

Google Scholar

[49] Mleiki A, Othmani S, Cheikhrouhou-Koubaa W, Koubaa M, Cheikhrouhou A, Hlil E K 2015 J. Alloys Compd. 648 1043

Google Scholar

Google Scholar

[50] Mnefgui S, Dhahri A, Dhahri N, Hlil E K, Dhahri J 2013 Solid State Sci. 21 19

Google Scholar

Google Scholar

[51] Oumezzine M, Peña O, Kallel S, Zemni S 2011 Solid State Sci. 13 1829

Google Scholar

Google Scholar

[52] Baazaoui M, Hcini S, Boudard M, Zemni S, Oumezzine M 2015 J. Supercond. Nov. Magn. 28 1887

Google Scholar

Google Scholar

[53] Ho T A, Phan M H, Phuc N X, Lam V D, Phan T L, Yu S C 2016 J. Electron. Mater. 45 2508

Google Scholar

Google Scholar

[54] Ghodhbane S, Dhahri A, Dhahri N, Hlil E K, Dhahri J, Alhabradi M, Zaidi M 2013 J. Alloys Compd. 580 558

Google Scholar

Google Scholar

[55] Wang G F, Zhao Z R, Li H L, Zhang X F 2016 Ceram. Int. 42 18196

Google Scholar

Google Scholar

[56] Khiem N V, Phong P T, Bau L V, Nam D N H, Hong L V, Phuc N X 2009 J. Magn. Magn. Mater. 321 2027

Google Scholar

Google Scholar

[57] Thanh T D, Linh D C, Manh T V, Ho T A, Phan T L, Yu S C 2015 J. Appl. Phys. 117 17C101

Google Scholar

Google Scholar

[58] Ginting D, Nanto D, Zhang Y D, Yu S C, Phan T L 2013 Physica B 412 17

Google Scholar

Google Scholar

[59] Phong P T, Ngan L T T, Bau, L V, Nam P H, Linh P H, Dang N V, Lee I J 2017 Ceram. Int. 43 16859

Google Scholar

Google Scholar

[60] Nisha P, Pillai S S, Varma M R, Suresh K G 2012 Solid State Sci. 14 40

Google Scholar

Google Scholar

[61] Rößler S, Rößler U K, Nenkov K, Eckert D, Yusuf S M, Dörr K, Müller K H 2004 Phys. Rev. B 70 104417

Google Scholar

Google Scholar

[62] Zhu X, Sun Y, Luo X, Lei H, Wang B, Song W, Yang Z, Dai J, Shi D, Dou S 2010 J. Magn. Magn. Mater. 322 242

Google Scholar

Google Scholar

[63] Phan T L, Tran Q T, Thanh P Q, Yen P D H, Thanh T D, Yu S C 2014 Solid State Commun. 184 40

Google Scholar

Google Scholar

[64] Phan T L, Thanh P Q, Sinh N H, Zhang Y D, Yu S C 2012 IEEE Trans. Magn. 48 1293

Google Scholar

Google Scholar

[65] Phan T L, Thanh P Q, Sinh N H, Lee K W, Yu S C 2011 Curr. Appl. Phys. 11 830

Google Scholar

Google Scholar

[66] Turki D, Ghouri Z K, Al-Meer S, Elsaid K, Ahmad M I, Easa A, Remenyi G, Mahmood S, Hlil E K, Ellouze M, Elhalouani F 2017 Magnetochemistry 3 28

Google Scholar

Google Scholar

[67] Arun B, Suneesh, Sudakshina B, Akshay V R. Chandrasekhar K D, Vasundhara M 2018 J. Phys. Chem. Solids 123 327

Google Scholar

Google Scholar

[68] Dhahr J, Belgacem C H, Dhahri A, Oumezzine M 2016 Appl. Phys. A 122 483

Google Scholar

Google Scholar

[69] Raoufi T, Ehsani M H, Khoshnoud D S 2017 Ceram. Int. 43 5204

Google Scholar

Google Scholar

[70] Mnefgui S, Zaidi N, Dhahri A, Hlil E K, Dhahri J 2014 J. Solid State Chem. 215 193

Google Scholar

Google Scholar

[71] Munazat D R, Kurniawan B, Razaq D S, Watanabe K, Tanaka H 2020 Physica B 592 412227

Google Scholar

Google Scholar

[72] Ezaami A, Sellami-Jmal E, Cheikhrouhou-Koubaa W, Cheikhrouhou A, Hlil E K 2017 J. Phys. Chem. Solids 109 109

Google Scholar

Google Scholar

[73] Thanh T D, Phan T L, Chien N V, Manh D H, Yu S C 2014 IEEE Trans. Magn. 50 2501504

Google Scholar

Google Scholar

[74] Ezaami A, Sfifir I, Cheikhrouhou-Koubaa W, Koubaa M, Cheikhrouhou A 2017 J. Alloys Compd. 693 658

Google Scholar

Google Scholar

[75] Ho T A, Thanh T D, Manh T V, Ho T O, Thang P D, Phan T L, Yu S C 2015 Mater. Trans. 56 1331

Google Scholar

Google Scholar

[76] Makni-Chakroun J, Cheikhrouhou-Koubaa W, Koubaa M, Cheikhrouhou A 2015 J. Alloys Compd. 650 421

Google Scholar

Google Scholar

[77] Phong P T, Ngan L T T, Dang N V, Nguyen L H, Nam P H, Thuy D M, Tuan N D, Bau L V, Lee I J 2018 J. Magn. Magn. Mater. 449 558

Google Scholar

Google Scholar

[78] Phong P T, Ngan L T T, Bau L V, Phuc N X, Nam P H, Phong L T H, Dang N V, Lee I J 2019 J. Magn. Magn. Mater. 475 374

Google Scholar

Google Scholar

[79] Messaoui I, Omrani H, Mansouri M, Cheikhrouhou-Koubaa W, Koubaa M, Cheikhrouhou A, Hlil E K 2016 Ceram. Int. 42 17032

Google Scholar

Google Scholar

[80] Mahjoub S, Baazaoui M, Hlil E K, Oumezzine M 2015 Ceram. Int. 41 12407

Google Scholar

Google Scholar

[81] Kharrat A B J, Hlil E K, Boujelben W 2018 J. Alloys Compd. 739 101

Google Scholar

Google Scholar

[82] Kharrat A B J, Boujelben W 2019 J. Low Temp. Phys. 197 357

Google Scholar

Google Scholar

[83] Zhang P, Lampen P, Phan T L, Yu S C, Thanh T D, Dan N H, Lam V D, Srikanth H, Phan M H 2013 J. Magn. Magn. Mater. 348 146

Google Scholar

Google Scholar

[84] Phan T L, Dang N T, Ho T A, Manh T V, Thanh T D, Jung C U, Lee B W, Le A T, Phan A D, Yu S C 2016 J. Alloys Compd. 657 818

Google Scholar

Google Scholar

[85] Phan T L, Tola P S, Dang N T, Rhyee J S, Shon W H, Ho T A 2017 J. Magn. Magn. Mater. 441 290

Google Scholar

Google Scholar

[86] Ghorai S, Skini R, Hedlund D, Ström P, Svedlindh P 2020 Sci. Rep. 10 19485

Google Scholar

Google Scholar

[87] Zaidi M A, Dhahri J, Zeydi I, Alharbi T, Belmabrouk H 2017 RSC Adv. 7 43590

Google Scholar

Google Scholar

[88] Assoudi N, Walha I, Nouri K, Dhahri E, Bessais L 2018 J. Alloys Compd. 753 282

Google Scholar

Google Scholar

[89] Jeddi M, Gharsallah H, Bejar M, Bekri M, Dhahri E, Hlil E K 2018 RSC Adv. 8 9430

Google Scholar

Google Scholar

[90] Phan T L, Zhang Y D, Zhang P, Thanh T D, Yu S C 2012 J. Appl. Phys. 112 093906

Google Scholar

Google Scholar

[91] Ho T A, Dang N T, Phan T L, Yang D S, Lee B W, Yu S C 2016 J. Alloys Compd. 676 305

Google Scholar

Google Scholar

[92] Laouyenne M R, Baazaoui M R, Farah K, Hlil E K, Oumezzine M 2019 J. Magn. Magn. Mater. 474 393

Google Scholar

Google Scholar

[93] Dhahri A, Dhahri E, Hlil E K 2017 J. Alloys Compd. 727 449

Google Scholar

Google Scholar

[94] Belkahla A, Cherif K, Dhahri J, Hlil E K 2017 J. Alloys Compd. 715 266

Google Scholar

Google Scholar

-

表 1 典型理论模型的临界参数

Table 1. Critical parameters of theoretical models.

表 2 典型锰氧化物材料在各种形态下的临界行为分析

Table 2. Critical behavior analysis of manganites in different morphologies (SC, single crystal; PC, polycrystalline).

Material Technique β γ δ Model Ref. La0.7Ba0.3MnO3SC MAP 0.35 1.41 5.5 3D-Heisenberg [26] La0.7Ba0.3MnO3PC MAP 0.493 1.059 3.15 Mean-field [27] La0.67Ba0.33MnO3PC MAP 0.464 1.29 3.78 Mean-field/3D-Heisenberg [28] La0.7Sr0.3MnO3SC MAP 0.37 1.22 4.25 close to 3D-Heisenberg [29] La0.75Sr0.25MnO3SC MAP 0.4 1.27 4.12 Mean-field/3D-Ising [30] La0.8Sr0.2MnO3PC MAP 0.5 1.08 3.13 Mean-field [31] La0.875Sr0.125MnO3SC MAP 0.37 1.38 4.72 3D-Heisenberg [32] La0.6Ca0.4MnO3PC MAP 0.25 1.03 5 Tricritical-Mean-field [33] La0.79Ca0.21MnO3SC MAP 0.09 1.71 20 nonuniversal [34] La0.8Ca0.2MnO3SC MAP 0.374 1.382 4.779 3D-Heisenberg [35] La0.82Ca0.18MnO3SC MAP 0.374 1.379 4.783 3D-Heisenberg [35] Nd0.6Sr0.4MnO3SC KF 0.308 1.172 4.75 3D-Ising [36] Nd0.6Sr0.4MnO3PC MAP 0.51 1.01 3.13 Mean-field [37] Nd0.67Sr0.33MnO3PC MAP 0.23 1.05 5.13 Tricritical-Mean-field [37] Nd0.7Sr0.3MnO3PC MAP 0.271 0.922 4.4 Tricritical-Mean-field [38] Pr0.6Sr0.4MnO3SC KF 0.312 1.106 4.545 3D-Ising [36] Pr0.6Sr0.4MnO3SC MAP 0.365 1.309 4.648 3D-Heisenberg [39] Pr0.6Sr0.4MnO3PC MAP 0.276 0.918 4.325 Tricritical-Mean-field [40] KF 0.273 1.001 4.325 Pr0.71Ca0.29MnO3SC MAP 0.37 1.38 4.62 3D-Heisenberg [41] Pr0.71Ca0.29MnO3PC MAP 0.521 0.912 2.71 Mean-field [42] Pr0.73Ca0.27MnO3SC MAP 0.36 1.36 4.81 3D-Heisenberg [41] Pr0.73Ca0.27MnO3PC MAP 0.362 1.132 4.09 3D-Heisenberg [42] 注: SC表示单晶; PC表示多晶. 表 3 A位掺杂不同元素或空位的锰氧化物临界行为分析

Table 3. Critical behavior analysis of manganites doped with different elements (vacancy) at A site (□, Ion vacancy).

Material Technique β γ δ Model Ref. La0.67(Ca0.5Ba0.5)0.33MnO3 MAP 0.402 1.110 3.761 Mean-field/3D-Heisenberg [28] La0.7Ca0.15Ba0.15MnO3 MAP 0.438 1.032 3.360 Mean-field [27] La0.7Ca0.2Ba0.1MnO3 MAP 0.284 0.909 4.200 Tricritical-Mean-field/3D-Ising [43] KF 0.297 0.925 4.110 La0.7Ca0.15Sr0.15MnO3 MAP 0.491 1.054 3.150 Mean-field [27] La0.7Ca0.1Sr0.2MnO3 KF 0.360 1.220 4.400 3D-Heisenberg [44] La0.7Ca0.2Sr0.1MnO3 KF 0.260 1.060 5.100 Tricritical-Mean-field [44] La0.69Dy0.01Ca0.3MnO3 MAP 0.230 0.920 5.000 Tricritical-Mean-field [45] KF 0.250 0.870 4.480 La0.7Ca0.28Sn0.02MnO3 KF 0.218 0.858 4.936 Tricritical-Mean-field [46] La0.7Ca0.26Sn0.04MnO3 KF 0.467 1.095 3.345 Mean-field [46] La0.75Dy0.05Sr0.2MnO3 MAP 0.266 0.920 4.460 Tricritical-Mean-field [47] KF 0.272 0.931 4.420 La0.1Nd0.6Sr0.3MnO3 MAP 0.248 1.066 5.170 Tricritical-Mean-field [48] KF 0.257 1.120 5.170 Pr0.4Sm0.15Sr0.45MnO3 KF 0.324 1.212 4.812 3D-Ising [49] Pr0.3Sm0.25Sr0.45MnO3 KF 0.255 0.957 5.105 Tricritical-Mean-field [49] La0.57Nd0.1Sr0.33MnO3 MAP 0.356 1.152 4.235 3D-Heisenberg [50] KF 0.368 1.191 4.236 La0.57Nd0.1Sr0.28□0.05MnO3 MAP 0.312 1.173 4.760 3D-Ising [50] KF 0.326 1.183 4.619 Pr0.6Sr0.4MnO3 MAP 0.276 0.918 4.325 Tricritical-Mean-field [40] KF 0.273 1.001 4.325 Pr0.6Sr0.3□0.1MnO3 MAP 0.253 0.987 4.890 Tricritical-Mean-field [40] KF 0.242 0.945 4.890 Pr0.5□0.1Sr0.4MnO3 MAP 0.323 1.113 4.446 3D-Ising [40] KF 0.325 1.092 4.446 注: □表示离子空位. 表 4 B位掺杂不同元素的锰氧化物临界行为分析

Table 4. Critical behavior analysis of manganites doped with different elements at B site.

Material Technique β γ δ Model Ref. La0.67Ba0.33Mn0.98Ti0.02O3 MAP 0.537 1.015 2.890 Mean-field [51] KF 0.551 1.020 2.851 La0.67Ba0.33Mn0.95Fe0.05O3 KF 0.504 1.013 3.040 Mean-field [52] La0.7Ba0.3Mn0.95Ti0.05O3 MAP 0.374 1.228 4.260 3D-Heisenberg [53] La0.7Ba0.3Mn0.9Ti0.1O3 MAP 0.339 1.307 4.780 3D-Ising [53] La0.8Ba0.2Mn0.8Fe0.2O3 MAP 0.365 1.227 4.362 3D-Heisenberg [54] KF 0.318 1.159 4.645 La0.67Sr0.33Mn0.9Fe0.1O3 MAP 0.450 1.240 3.740 Mean-field/3D-Heisenberg [55] KF 0.538 1.330 3.470 La0.7Sr0.3Mn0.95Al0.05O3 KF 0.458 1.001 3.185 Mean-field [56] La0.7Sr0.3Mn0.95Ti0.05O3 KF 0.344 1.149 4.340 Mean-field/3D-Heisenberg [56] La0.7Sr0.3Mn0.9Co0.1O3 KF 0.457 1.114 3.440 Mean-field/3D-Heisenberg [57] La0.7Sr0.3Mn0.99Ni0.01O3 MAP 0.394 1.092 3.990 Mean-field/3D-Heisenberg [58] La0.7Sr0.3Mn0.98Ni0.02O3 MAP 0.400 1.082 3.790 Mean-field/3D-Heisenberg [58] La0.7Sr0.3Mn0.97Ni0.03O3 MAP 0.468 1.010 2.670 Mean-field [58] La0.7Sr0.3Mn0.98Cu0.02O3 KF 0.464 1.162 3.546 close to Mean-field [59] La0.7Sr0.3Mn0.96Cu0.04O3 KF 0.449 1.202 3.681 close to Mean-field [59] La0.67Ca0.33Mn0.9Cr0.1O3 MAP 0.555 1.170 2.710 Mean-field [60] La0.67Ca0.33Mn0.75Cr0.25O3 MAP 0.680 1.090 2.936 close to Mean-field [60] La0.67Ca0.33Mn0.9Ga0.1O3 MAP 0.380 1.365 4.590 3D-Heisenberg [61] KF 0.387 1.362 4.520 La0.7Ca0.3Mn0.95Ti0.05O3 KF 0.601 1.171 2.950 Mean-field [62] La0.7Ca0.3Mn0.9Ti0.1O3 KF 0.389 1.403 4.400 3D-Heisenberg [62] La0.7Ca0.3Mn0.91Ni0.09O3 MAP 0.171 0.976 6.700 Tricritical-Mean-field [63] La0.7Ca0.3Mn0.88Ni0.12O3 MAP 0.262 0.978 4.700 Tricritical-Mean-field [63] La0.7Ca0.3Mn0.85Ni0.15O3 MAP 0.320 0.990 4.100 3D-Ising [63] La0.7Ca0.3Mn0.95Cu0.05O3 MAP 0.490 1.040 3.120 Mean-field [64] La0.7Ca0.3Mn0.9Zn0.1O3 MAP 0.474 1.152 3.430 Mean-field [65] La0.8Ca0.2Mn0.9Co0.1O3 MAP 0.204 1.969 11.983 nonuniversal [66] KF 0.123 1.351 11.983 La0.8Ca0.2Mn0.8Co0.2O3 MAP 0.401 1.332 4.321 3D-Heisenberg [66] KF 0.418 1.303 4.321 Nd0.67Sr0.33Mn0.9Cr0.1O3 MAP 0.337 0.784 3.326 nonuniversal [67] Nd0.67Sr0.33Mn0.9Fe0.1O3 MAP 0.436 0.94 3.156 Mean-field [67] Nd0.67Sr0.33Mn0.9Co0.1O3 MAP 0.431 0.929 3.155 Mean-field [67] Pr0.67Sr0.33Mn0.95Al0.05O3 MAP 0.381 1.323 4.635 3D-Heisenberg [68] KF 0.381 1.320 4.635 Pr0.67Sr0.33Mn0.9Al0.1O3 MAP 0.374 1.333 4.667 3D-Heisenberg [68] KF 0.377 1.331 4.667 表 5 不同制备方法锰氧化物的临界行为对比分析

Table 5. Critical behavior analysis of manganites from different preparation methods (SS, solid state reaction; SG, sol-gel; WM, wet mixing; BM, ball milling).

Material Technique β γ δ Model Ref. La0.6Sr0.4MnO3SG/800 ºC KF 0.560 1.140 3.035 close to Mean-field [69] La0.6Sr0.4MnO3SG/1100 ºC KF 0.480 1.052 3.190 Mean-field [69] La0.6Sr0.4MnO3SS KF 0.530 1.110 3.094 Mean-field [69] La0.67Sr0.33MnO3SS MAP 0.333 1.325 4.978 3D-Heisenberg [70] La0.67Sr0.33MnO3SG MAP 0.500 1.150 3.290 Mean-field [55] KF 0.479 1.260 3.630 La0.7Ba0.1Ca0.1Sr0.1MnO3WM MAP 0.448 1.148 3.563 Mean-field [71] KF 0.476 1.029 3.096 La0.7Ba0.1Ca0.1Sr0.1MnO3SG MAP 0.235 1.153 5.906 Tricritical-Mean-field [71] KF 0.262 1.165 5.447 La0.7Ca0.2Ba0.1MnO3BM MAP 0.265 0.867 4.271 Tricritical-Mean-field [72] KF 0.261 0.988 4.386 La0.7Ca0.2Ba0.1MnO3SS MAP 0.284 0.909 4.200 Tricritical-Mean-field/3D-Ising [43] KF 0.297 0.925 4.110 La0.7Ca0.2Sr0.1MnO3BM MAP 0.397 0.966 3.430 3D-Heisenberg [73] La0.7Ca0.2Sr0.1MnO3SS MAP 0.276 0.966 4.500 Tricritical-Mean-field [74] KF 0.315 0.954 4.028 La0.7Ca0.2Sr0.1MnO3SG MAP 0.484 1.037 3.143 Mean-field [74] KF 0.469 1.013 3.160 La0.7Ca0.3MnO3BM/40 nm MAP 0.485 1.051 3.100 Mean-field [75] La0.7Ca0.3MnO3BM/16 nm MAP 0.621 0.825 2.200 nonuniversal La0.7Ca0.3MnO3SG MAP 0.240 1.010 3.090 Tricritical-Mean-field [76] La0.75Ca0.25MnO3SG MAP 0.521 0.94 2.804 Mean-field [77] KF 0.529 0.939 2.775 La0.8Ca0.2MnO3SG MAP 0.505 1.004 3.060 Mean-field [78] KF 0.499 1.007 3.060 Nd0.7Ca0.15Sr0.15MnO3BM/4 h KF 0.243 0.907 4.540 Tricritical-Mean-field [79] Nd0.7Ca0.15Sr0.15MnO3BM/24 h KF 0.311 1.100 4.130 3D-Ising [79] Pr0.6Ca0.1Sr0.3Mn0.975Fe0.025O3SS MAP 0.644 1.075 2.763 Mean-field [80] KF 0.622 1.097 2.763 Pr0.6Ca0.1Sr0.3Mn0.975Fe0.025O3SG MAP 0.357 1.292 4.290 3D-Heisenberg [80] KF 0.370 1.220 4.290 Pr0.8Sr0.2MnO3SG MAP 0.260 0.978 4.760 Tricritical-Mean-field [81] KF 0.260 0.993 4.810 Pr0.8Sr0.2MnO3SS MAP 0.318 1.260 4.960 3D-Ising [82] KF 0.326 1.246 4.960 注: SS表示固相反应法; SG表示溶胶凝胶法(附烧结温度工艺条件); WM表示湿混法; BM表示球磨法(附平均粒径尺寸或球磨时间等工艺条件). 表 6 关于不同磁场强度范围所得磁相变临界参数的对比分析

Table 6. Comparative analysis of critical parameters in different magnetic field ranges.

Material Field range Technique β γ δ Model Ref. La0.6Ca0.4MnO3 1—2 T KF 0.249 1.008 5.043 Tricritical-Mean-field [83] 2—3 T KF 0.255 0.857 4.359 crossover 3—4 T KF 0.262 0.833 4.18 crossover 4—5 T KF 0.267 0.797 3.983 crossover 5—6 T KF 0.263 0.776 3.954 close to Tricritical-Mean-field La0.8Ca0.2MnO3 1—2 T KF 0.349 1.231 4.524 3D-Heisenberg/Ising [83] 2—3 T KF 0.316 1.081 4.421 crossover 3—4 T KF 0.281 0.992 4.534 crossover 4—5 T KF 0.272 0.91 4.341 crossover 5—6 T KF 0.259 0.918 4.552 Tricritical-Mean-field La0.7Ca0.275Ba0.025MnO3 2—3 T MAP 0.209 — — Tricritical-Mean-field [84] 3—4 T MAP 0.218 1.098 6.04 4—5 T MAP 0.227 1.06 5.67 La0.7Ca0.25Ba0.05MnO3 1—2 T MAP 0.221 — — Tricritical-Mean-field [84] 2—3 T MAP 0.225 1.052 5.68 3—4 T MAP 0.235 1.012 5.31 4—5 T MAP 0.249 1.022 5.1 La0.7Ca0.225Ba0.075MnO3 1—2 T MAP 0.216 0.973 5.5 Tricritical-Mean-field [84] 2—3 T MAP 0.224 0.982 5.38 3—4 T MAP 0.238 1.016 5.27 4—5 T MAP 0.253 0.992 4.92 La0.7Ca0.2Ba0.1MnO3 1—2 T MAP 0.301 1.382 5.59 Tricritical-Mean-field/3D-Ising [84] 2—3 T MAP 0.312 1.38 5.42 3D-Ising 3—4 T MAP 0.322 1.381 5.29 3D-Ising 4—5 T MAP 0.326 1.342 5.12 3D-Ising La0.7Ca0.3MnO3 10—14 T MAP 0.252 1.005 — Tricritical-Mean-field [85] 表 7 接近三重临界点的部分近室温钙钛矿锰氧化物的最大磁熵变和相对制冷能力

Table 7. Maximum magnetic entropy change and RCP values of perovskite manganites near tricritical point.

Material TC/K ΔH/ T –ΔSM/(J·kg–1·K–1) RCP/(J·kg–1) Ref. La0.7Ba0.2Ca0.1MnO3SG 350 2 2.35 70 [87] 5 5.80 167 La0.7Ba0.2Ca0.1Mn0.95Al0.05O3SG 321 2 2.12 85 [87] 5 5.30 180 La0.7Ba0.2Ca0.1Mn0.9Al0.1O3SG 300 2 1.86 96 [87] 5 4.60 193 La0.7Ca0.3MnO3SS 255 1 4.52 45.2 [46] La0.7Ca0.28Sn0.02MnO3SS 200 1 2.79 55.8 [46] La0.7Ca0.26Sn0.04MnO3SS 167 1 1.58 69.5 [46] La0.69Dy0.01Ca0.3MnO3SS 246 5 14.94 100.24 [45] La0.6Ca0.3Ag0.1MnO3SS 256 2 3.89 55.51 [88] 5 6.95 179.78 La0.6Ca0.3Ag0.1MnO3SG 270 2 5.55 84.46 [88] 5 8.67 230.35 La0.6Ca0.3Sr0.1MnO3SG 304 2 2.89 98.17 [89] 5 5.26 262.53 La0.7Ca0.2Sr0.1MnO3SS 284 3 4.30 150 [90] La0.7Ca0.2Sr0.1MnO3BM 297 1 1.47 54.4 [73] La0.7Ca0.19Sr0.11MnO3BM 301 1 1.42 52.5 [73] La0.7Ca0.18Sr0.12MnO3BM 309 1 1.38 44.2 [73] La0.7Ca0.27Na0.03MnO3SS 260 4 8.10 232 [91] La0.7Ca0.24Na0.06MnO3SS 263 4 7.00 234 [91] La0.7Ca0.21Na0.09MnO3SS 271 4 6.90 236 [91] La0.7Ba0.1Ca0.1Sr0.1MnO3WM 315 2 1.34 102.51 [71] 5 3.16 284.53 La0.7Ba0.1Ca0.1Sr0.1MnO3SG 330 2 2.58 74.92 [71] 5 4.89 229.29 La0.8Na0.2Mn0.97Bi0.03O3SS 320 5 4.77 218 [92] La0.8Na0.2Mn0.97Bi0.03O3SG 257 5 5.88 252 [92] La0.4Pr0.3Ca0.1Sr0.2MnO3SS 289 2 3.08 83.3 [86] La0.6Gd0.1Sr0.3Mn0.8Si0.2O3SG 271 5 5.35 180 [93] La0.7Bi0.05Sr0.15Ca0.1Mn0.95In0.05O3SG 310 5 6.00 258 [94] 注: 1) 表中符号含义如下: TC为居里温度; ΔH为磁场变化范围; –ΔSM为最大磁熵变值; RCP为相对制冷能力, 由磁熵变曲线的峰值与半峰宽数值相乘而得; 2) SS表示固相反应法; SG表示溶胶凝胶法; WM表示湿混法; BM表示球磨法. -

[1] Pecharsky V K, Gschneidner Jr K A 1997 Phys. Rev. Lett. 78 4494

Google Scholar

Google Scholar

[2] Hu F X, Shen B G, Sun J R, Cheng Z H, Rao G H, Zhang X X 2001 Appl. Phys. Lett. 78 3675

Google Scholar

Google Scholar

[3] Tegus O, Bruck E, Buschow K H J, de Boer F R 2002 Nature 415 150

Google Scholar

Google Scholar

[4] Krenke T, Duman E, Acet M, Wassermann E F, Moya X, Mañosa L, Planes A 2005 Nat. Mater. 4 450

Google Scholar

Google Scholar

[5] Hu F X, Shen B G, Sun J R 2000 Appl. Phys. Lett. 76 3460

Google Scholar

Google Scholar

[6] Guo Z B, Du Y W, Zhu J S, Huang H, Ding W P, Feng D 1997 Phys. Rev. Lett. 78 1142

Google Scholar

Google Scholar

[7] Phan M H, Yu S C 2007 J. Magn. Magn. Mater. 308 325

Google Scholar

Google Scholar

[8] Law J Y, Franco V, Moreno-Ramírez L M, Conde A, Karpenkov D Y, Radulov I, Skokov K P, Gutfleisch O 2018 Nat. Commun. 9 2680

Google Scholar

Google Scholar

[9] Fujita A, Fujieda S, Hasegawa Y, Fukamichi K 2003 Phys. Rev. B 67 104416

Google Scholar

Google Scholar

[10] Sun Y, Arnold Z, Kamarad J, Wang G J, Shen B G, Cheng Z H 2006 Appl. Phys. Lett. 89 172513

Google Scholar

Google Scholar

[11] Liu J, Gottschall T, Skokov K P, Moore J D, Gutfleisch O 2012 Nat. Mater. 11 620

Google Scholar

Google Scholar

[12] Romero-Muñiz C, Tamura R, Tanaka S, Franco V 2016 Phys. Rev. B 94 134401

Google Scholar

Google Scholar

[13] Franco V, Law J Y, Conde A, Brabander V, Karpenkov D Y, Radulov I, Skokov K, Gutfleisch O 2017 J. Phys. D 50 414004

Google Scholar

Google Scholar

[14] Romero-Muñiz C, Franco V, Conde A 2017 Phys. Chem. Chem. Phys. 19 3582

Google Scholar

Google Scholar

[15] Dagotto E, Hotta T, Moreo A 2001 Phys. Rep. 344 1

Google Scholar

Google Scholar

[16] Alexandrov A S, Bratkovsky A M 1999 Phys. Rev. Lett. 82 141

Google Scholar

Google Scholar

[17] Yunoki S, Hu J, Malvezzi A L, Moreo A, Furukawa N, Dagotto E 1998 Phys. Rev. Lett. 80 845

Google Scholar

Google Scholar

[18] Banerjee B K 1964 Phys. Lett. 12 16

Google Scholar

Google Scholar

[19] Franco V, Blázquez J S, Conde A 2006 Appl. Phys. Lett. 89 222512

Google Scholar

Google Scholar

[20] Bonilla C M, Herrero-Albillos J, Bartolomé F, García L M, Parra-Borderías M, Franco V 2010 Phys. Rev. B 81 224424

Google Scholar

Google Scholar

[21] 张蕾 2018 67 137501

Google Scholar

Google Scholar

Zhang L 2018 Acta Phys. Sin. 67 137501

Google Scholar

Google Scholar

[22] Fan J, Pi L, Zhang L, Tong W, Ling L, Hong B, Shi Y, Zhang W, Lu D, Zhang Y 2011 Appl. Phys. Lett. 98 072508

Google Scholar

Google Scholar

[23] Huang K 1987 Statistical Mechanics (2nd Ed.) (New York: Wiley) pp398–432

[24] Kaul S N 1985 J. Magn. Magn. Mater. 53 5

Google Scholar

Google Scholar

[25] Fisher M E, Ma S K, Nickel B G 1972 Phys. Rev. Lett. 29 917

Google Scholar

Google Scholar

[26] Jiang W, Zhou X, Williams G, Mukovskii Y, Glazyrin K 2008 Phys. Rev. B 77 064424

Google Scholar

Google Scholar

[27] Linh D C, Thanh T D, Anh L H, Dao V D, Piao H G, Yu S C 2017 J. Alloys Compd. 725 484

Google Scholar

Google Scholar

[28] Moutis N, Panagiotopoulos I, Pissas M, Niarchos D 1999 Phys. Rev. B 59 1129

Google Scholar

Google Scholar

[29] Ghosh K, Lobb C J, Greene R L, Karabashev S G, Shulyatev D A, Arsenov A A, Mukovskii Y 1998 Phys. Rev. Lett. 81 4740

Google Scholar

Google Scholar

[30] Kim D, Zink B L, Hellman F, Coey J M D 2002 Phys. Rev. B 65 214424

Google Scholar

Google Scholar

[31] Mohan C V, Seeger M, Kronmüller H, Murugaraj P, Maier J 1998 J. Magn. Magn. Mater. 183 348

Google Scholar

Google Scholar

[32] Nair S, Banerjee A, Narlikar A V, Prabhakaran D, Boothroyd A T 2003 Phys. Rev. B 68 132404

Google Scholar

Google Scholar

[33] Kim D, Revaz B, Zink B L, Hellman F, Rhyne J J, Mitchell J F 2002 Phys. Rev. Lett. 89 227202

Google Scholar

Google Scholar

[34] Jiang W, Zhou X, Williams G, Mukovskii Y, Glazyrin K 2007 Phys. Rev. Lett. 99 177203

Google Scholar

Google Scholar

[35] Jiang W, Zhou X, Williams G, Privezentsev R, Mukovskii Y 2009 Phys. Rev. B 79 214433

Google Scholar

Google Scholar

[36] Oleaga A, Salazar A, Hatnean M C, Balakrishnan G 2015 Phys. Rev. B 92 024409

Google Scholar

Google Scholar

[37] Venkatesh R, Pattabiraman M, Sethupathi K, Rangarajan G, Angappane S, Park J G 2008 J. Appl. Phys. 103 07B319

Google Scholar

Google Scholar

[38] Phan T L, Ho T A, Thang P D, Tran Q T, Thanh T D, Phuc N X, Phan M H, Huy B T, Yu S C 2014 J. Alloys Compd. 615 937

Google Scholar

Google Scholar

[39] Rößler S, Nair H S, Rößler U K, Kumar C M N, Elizabeth S, Wirth S 2011 Phys. Rev. B 84 184422

Google Scholar

Google Scholar

[40] Elleuch F, Bekri M, Hussein M, Triki M, Dhahri E, Hlil E K, Bessais L 2015 Dalton Trans. 44 17712

Google Scholar

Google Scholar

[41] Jiang W, Zhou X, Williams G, Mukovskii Y, Glazyrin K 2008 Phys. Rev. B 78 144409

Google Scholar

Google Scholar

[42] Ho T A, Thanh T D, Yu Y, Tartakovsky D M, Ho T O, Thang P D, Le A T, Phan T L, Yu S C 2015 J. Appl. Phys. 117 17D122

Google Scholar

Google Scholar

[43] Ezaami A, Sellami-Jmal E, Cheikhrouhou-Koubaa W, Hlil E K, Cheikhrouhou A 2017 J. Mater. Sci. Mater. Electron. 28 6837

Google Scholar

Google Scholar

[44] Phan M H, Franco V, Bingham N S, Srikanth H, Hur N H, Yu S C 2010 J. Alloys Compd. 508 238

Google Scholar

Google Scholar

[45] Debbebi I S, Ezaami A, Cheikhrouhou-Koubaa W, Cheikhrouhou A, Hlil E K 2017 J. Mater. Sci. Mater. Electron. 28 14000

Google Scholar

Google Scholar

[46] Lam D S, Dung N T, Thanh T D, Linh D C, Nan W Z, Yu S C 2020 Mater. Res. Express 7 046101

Google Scholar

Google Scholar

[47] Elghoul A, Krichene A, Boudjada N C, Boujelben W 2018 Ceram. Int. 44 14510

Google Scholar

Google Scholar

[48] Fan J, Ling L, Hong B, Zhang L, Pi L, Zhang Y 2010 Phys. Rev. B 81 144426

Google Scholar

Google Scholar

[49] Mleiki A, Othmani S, Cheikhrouhou-Koubaa W, Koubaa M, Cheikhrouhou A, Hlil E K 2015 J. Alloys Compd. 648 1043

Google Scholar

Google Scholar

[50] Mnefgui S, Dhahri A, Dhahri N, Hlil E K, Dhahri J 2013 Solid State Sci. 21 19

Google Scholar

Google Scholar

[51] Oumezzine M, Peña O, Kallel S, Zemni S 2011 Solid State Sci. 13 1829

Google Scholar

Google Scholar

[52] Baazaoui M, Hcini S, Boudard M, Zemni S, Oumezzine M 2015 J. Supercond. Nov. Magn. 28 1887

Google Scholar

Google Scholar

[53] Ho T A, Phan M H, Phuc N X, Lam V D, Phan T L, Yu S C 2016 J. Electron. Mater. 45 2508

Google Scholar

Google Scholar

[54] Ghodhbane S, Dhahri A, Dhahri N, Hlil E K, Dhahri J, Alhabradi M, Zaidi M 2013 J. Alloys Compd. 580 558

Google Scholar

Google Scholar

[55] Wang G F, Zhao Z R, Li H L, Zhang X F 2016 Ceram. Int. 42 18196

Google Scholar

Google Scholar

[56] Khiem N V, Phong P T, Bau L V, Nam D N H, Hong L V, Phuc N X 2009 J. Magn. Magn. Mater. 321 2027

Google Scholar

Google Scholar

[57] Thanh T D, Linh D C, Manh T V, Ho T A, Phan T L, Yu S C 2015 J. Appl. Phys. 117 17C101

Google Scholar

Google Scholar

[58] Ginting D, Nanto D, Zhang Y D, Yu S C, Phan T L 2013 Physica B 412 17

Google Scholar

Google Scholar

[59] Phong P T, Ngan L T T, Bau, L V, Nam P H, Linh P H, Dang N V, Lee I J 2017 Ceram. Int. 43 16859

Google Scholar

Google Scholar

[60] Nisha P, Pillai S S, Varma M R, Suresh K G 2012 Solid State Sci. 14 40

Google Scholar

Google Scholar

[61] Rößler S, Rößler U K, Nenkov K, Eckert D, Yusuf S M, Dörr K, Müller K H 2004 Phys. Rev. B 70 104417

Google Scholar

Google Scholar

[62] Zhu X, Sun Y, Luo X, Lei H, Wang B, Song W, Yang Z, Dai J, Shi D, Dou S 2010 J. Magn. Magn. Mater. 322 242

Google Scholar

Google Scholar

[63] Phan T L, Tran Q T, Thanh P Q, Yen P D H, Thanh T D, Yu S C 2014 Solid State Commun. 184 40

Google Scholar

Google Scholar

[64] Phan T L, Thanh P Q, Sinh N H, Zhang Y D, Yu S C 2012 IEEE Trans. Magn. 48 1293

Google Scholar

Google Scholar

[65] Phan T L, Thanh P Q, Sinh N H, Lee K W, Yu S C 2011 Curr. Appl. Phys. 11 830

Google Scholar

Google Scholar

[66] Turki D, Ghouri Z K, Al-Meer S, Elsaid K, Ahmad M I, Easa A, Remenyi G, Mahmood S, Hlil E K, Ellouze M, Elhalouani F 2017 Magnetochemistry 3 28

Google Scholar

Google Scholar

[67] Arun B, Suneesh, Sudakshina B, Akshay V R. Chandrasekhar K D, Vasundhara M 2018 J. Phys. Chem. Solids 123 327

Google Scholar

Google Scholar

[68] Dhahr J, Belgacem C H, Dhahri A, Oumezzine M 2016 Appl. Phys. A 122 483

Google Scholar

Google Scholar

[69] Raoufi T, Ehsani M H, Khoshnoud D S 2017 Ceram. Int. 43 5204

Google Scholar

Google Scholar

[70] Mnefgui S, Zaidi N, Dhahri A, Hlil E K, Dhahri J 2014 J. Solid State Chem. 215 193

Google Scholar

Google Scholar

[71] Munazat D R, Kurniawan B, Razaq D S, Watanabe K, Tanaka H 2020 Physica B 592 412227

Google Scholar

Google Scholar

[72] Ezaami A, Sellami-Jmal E, Cheikhrouhou-Koubaa W, Cheikhrouhou A, Hlil E K 2017 J. Phys. Chem. Solids 109 109

Google Scholar

Google Scholar

[73] Thanh T D, Phan T L, Chien N V, Manh D H, Yu S C 2014 IEEE Trans. Magn. 50 2501504

Google Scholar

Google Scholar

[74] Ezaami A, Sfifir I, Cheikhrouhou-Koubaa W, Koubaa M, Cheikhrouhou A 2017 J. Alloys Compd. 693 658

Google Scholar

Google Scholar

[75] Ho T A, Thanh T D, Manh T V, Ho T O, Thang P D, Phan T L, Yu S C 2015 Mater. Trans. 56 1331

Google Scholar

Google Scholar

[76] Makni-Chakroun J, Cheikhrouhou-Koubaa W, Koubaa M, Cheikhrouhou A 2015 J. Alloys Compd. 650 421

Google Scholar

Google Scholar

[77] Phong P T, Ngan L T T, Dang N V, Nguyen L H, Nam P H, Thuy D M, Tuan N D, Bau L V, Lee I J 2018 J. Magn. Magn. Mater. 449 558

Google Scholar

Google Scholar

[78] Phong P T, Ngan L T T, Bau L V, Phuc N X, Nam P H, Phong L T H, Dang N V, Lee I J 2019 J. Magn. Magn. Mater. 475 374

Google Scholar

Google Scholar

[79] Messaoui I, Omrani H, Mansouri M, Cheikhrouhou-Koubaa W, Koubaa M, Cheikhrouhou A, Hlil E K 2016 Ceram. Int. 42 17032

Google Scholar

Google Scholar

[80] Mahjoub S, Baazaoui M, Hlil E K, Oumezzine M 2015 Ceram. Int. 41 12407

Google Scholar

Google Scholar

[81] Kharrat A B J, Hlil E K, Boujelben W 2018 J. Alloys Compd. 739 101

Google Scholar

Google Scholar

[82] Kharrat A B J, Boujelben W 2019 J. Low Temp. Phys. 197 357

Google Scholar

Google Scholar

[83] Zhang P, Lampen P, Phan T L, Yu S C, Thanh T D, Dan N H, Lam V D, Srikanth H, Phan M H 2013 J. Magn. Magn. Mater. 348 146

Google Scholar

Google Scholar

[84] Phan T L, Dang N T, Ho T A, Manh T V, Thanh T D, Jung C U, Lee B W, Le A T, Phan A D, Yu S C 2016 J. Alloys Compd. 657 818

Google Scholar

Google Scholar

[85] Phan T L, Tola P S, Dang N T, Rhyee J S, Shon W H, Ho T A 2017 J. Magn. Magn. Mater. 441 290

Google Scholar

Google Scholar

[86] Ghorai S, Skini R, Hedlund D, Ström P, Svedlindh P 2020 Sci. Rep. 10 19485

Google Scholar

Google Scholar

[87] Zaidi M A, Dhahri J, Zeydi I, Alharbi T, Belmabrouk H 2017 RSC Adv. 7 43590

Google Scholar

Google Scholar

[88] Assoudi N, Walha I, Nouri K, Dhahri E, Bessais L 2018 J. Alloys Compd. 753 282

Google Scholar

Google Scholar

[89] Jeddi M, Gharsallah H, Bejar M, Bekri M, Dhahri E, Hlil E K 2018 RSC Adv. 8 9430

Google Scholar

Google Scholar

[90] Phan T L, Zhang Y D, Zhang P, Thanh T D, Yu S C 2012 J. Appl. Phys. 112 093906

Google Scholar

Google Scholar

[91] Ho T A, Dang N T, Phan T L, Yang D S, Lee B W, Yu S C 2016 J. Alloys Compd. 676 305

Google Scholar

Google Scholar

[92] Laouyenne M R, Baazaoui M R, Farah K, Hlil E K, Oumezzine M 2019 J. Magn. Magn. Mater. 474 393

Google Scholar

Google Scholar

[93] Dhahri A, Dhahri E, Hlil E K 2017 J. Alloys Compd. 727 449

Google Scholar

Google Scholar

[94] Belkahla A, Cherif K, Dhahri J, Hlil E K 2017 J. Alloys Compd. 715 266

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 12233

- PDF Downloads: 282

- Cited By: 0

DownLoad:

DownLoad: