-

The magnetic dipole theory has been widely and successfully used to qualitatively analyze the testing signals of metal magnetic memory (MMM) testing. However, the magnetic charge density of the existing models is always an assumed value distributed uniformly or linearly along the defect section or in a stress concentration area, as a result the existing models are unsuitable for quantitatively analyzing the metal magnetic memory signal. In this work, a new forward model of MMM testing is established by considering the influence of uneven stress on magnetic charge density distribution, discretizing the specimen into numbers of micro elements firstly, assuming that the magnetic characteristic parameters of each element are evenly distributed and the magnetic charge density changes with stress in each element which can be determined by combining the modified magneto-mechanical model and the classical theory of magnetic charges. Compared with the experimental results of hole defect and crack defect specimen, the theoretical results calculated by the proposed model prove to be in good agreement with the testing results both qualitatively and quantitatively. Consequently, the proposed model is a new theoretical and quantitative model for analyzing the experimental change rule of metal magnetic memory testing. Then, the effects of stress concentration and macroscopic defects on the distribution of magnetic field are analyzed, showing that when there is only a stress concentration in the specimen, the horizontal component is negative valley, and the normal component changes from negative to positive valley peak in the stress concentration area; when there is a crack defect in the specimen, the distribution of magnetic field is just opposite to that when there is only a stress concentration. The distribution characteristics of the magnetic field can be used to judge the damage type in the specimen. Moreover, taking crack defect for example, the horizontal and normal component of magnetic field and their characteristic parameters changing with the size parameters of crack defect, such as width, length, depth and buried depth of crack defect, are analyzed in detail. The results show that the

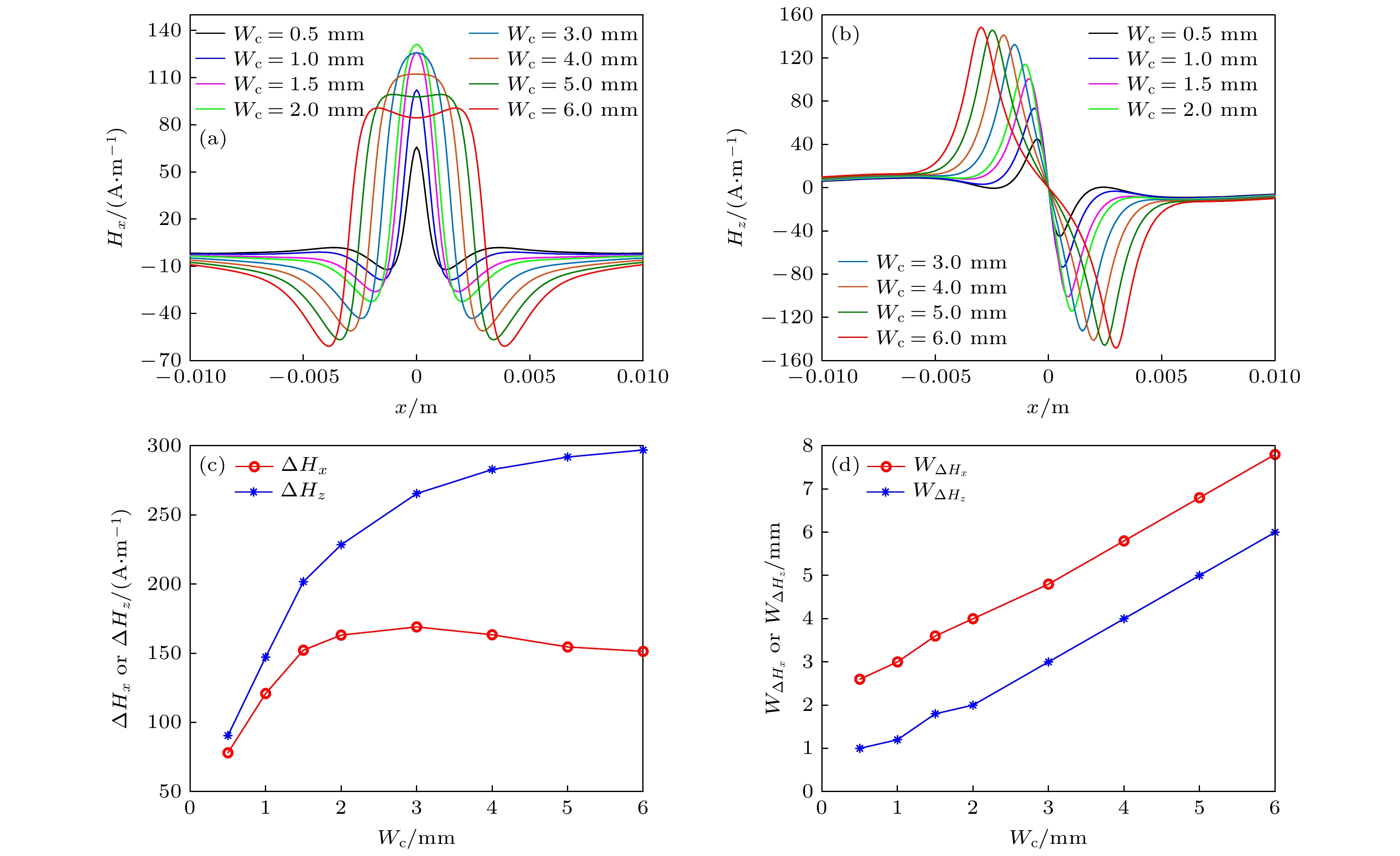

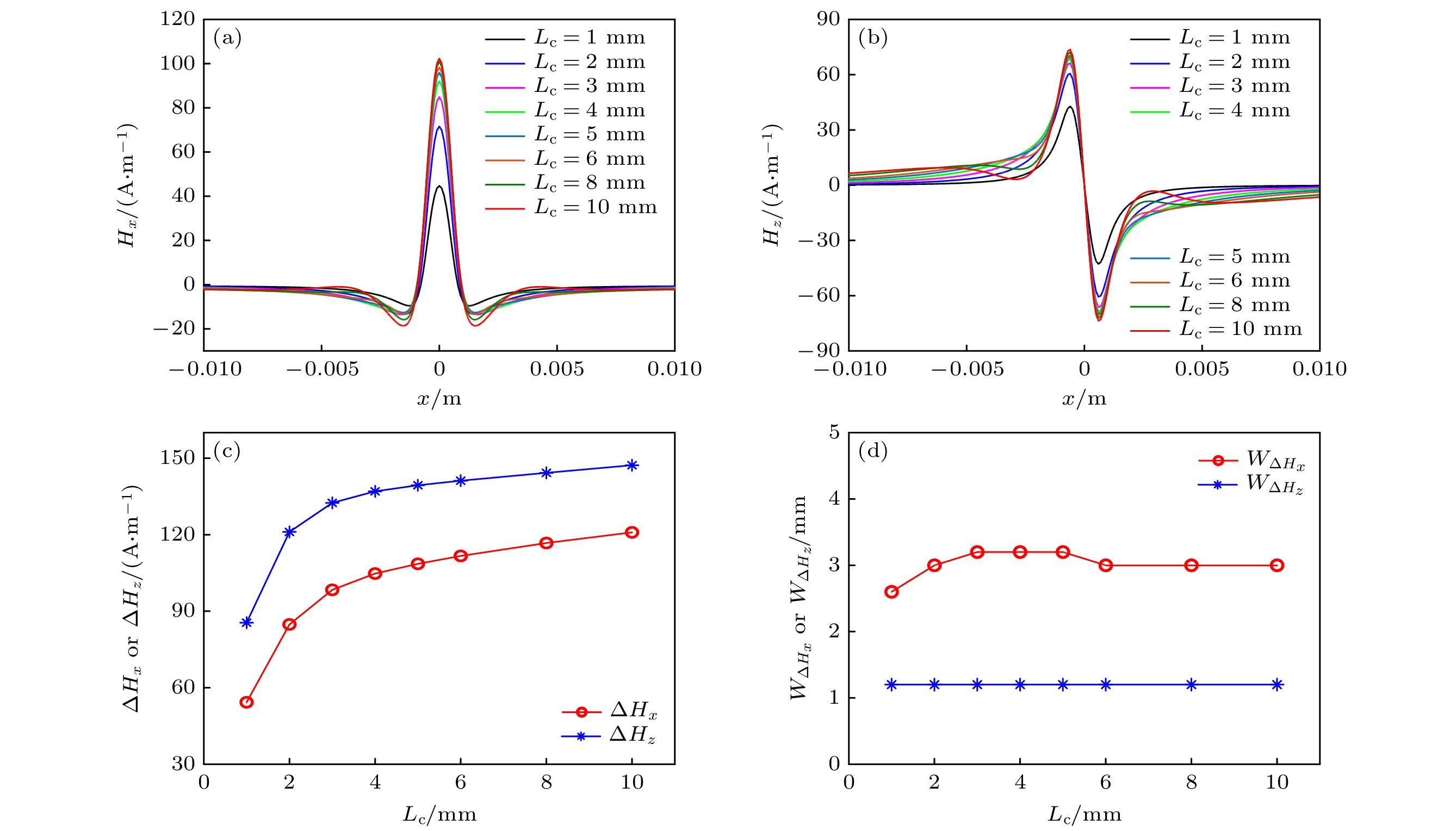

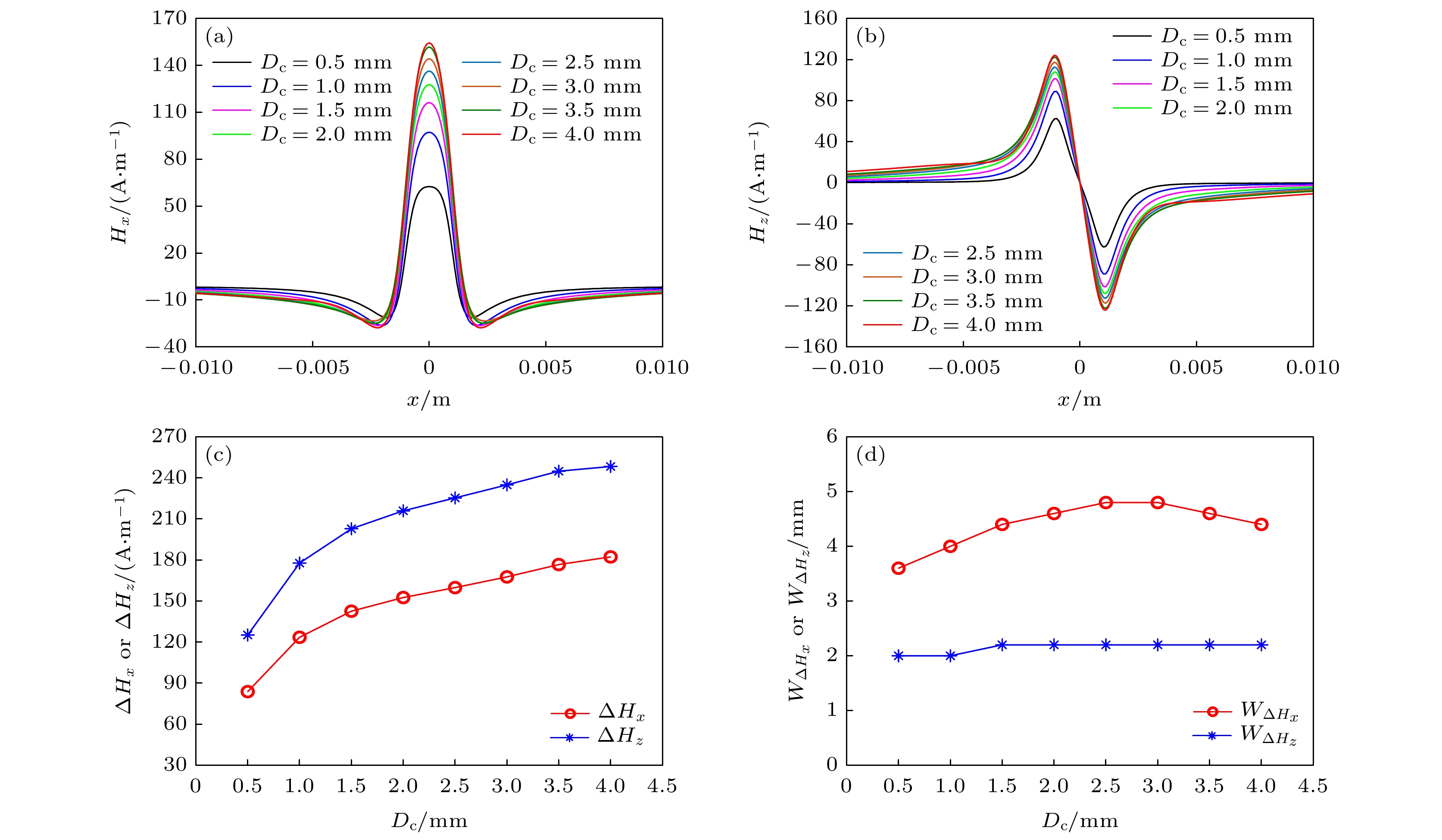

${W_{\Delta {H_x}}}$ and${W_{\Delta {H_z}}}$ increase lineally with the increase of the width of crack,$\Delta {H_x}$ and$\Delta {H_z}$ increase with the increase of the length and depth of crack, but gradually decrease with the increase of defect buried depth.-

Keywords:

- metal magnetic memory testing /

- magnetic charge theory /

- magneto-mechanical model /

- forward model

[1] Dubov A A 1997 Met. Sci. Heat Treat. 39 401

Google Scholar

Google Scholar

[2] Wang Z D, Yao K, Deng B, Ding K Q 2010 NDT and E Int. 43 354

Google Scholar

Google Scholar

[3] Wang Z D, Yao K, Deng B, Ding K Q 2010 NDT and E Int. 43 513

Google Scholar

Google Scholar

[4] 万强, 李思忠, 汤紫峰 2011 无损检测 33 12

Wang Q, Li S Z, Tang Z F 2011 Nondestr. Test. 33 12

[5] Leng J C, Xu M Q, Li J W 2010 Chin. J. Mech. Eng. 23 532

Google Scholar

Google Scholar

[6] Leng J C, Xing H Y, Zhou G Q, Gao Y T 2013 Insight 55 498

Google Scholar

Google Scholar

[7] 徐明秀, 尤天庆, 徐敏强, 樊久铭, 李立 2015 中南大学学报(自然科学版) 46 1215

Google Scholar

Google Scholar

Xu M X, You T Q, Xu M Q, Fan J M, Li L 2015 J. Cent. South Univ. 46 1215

Google Scholar

Google Scholar

[8] Shi P P, Zheng X J 2016 Nondestr. Test. Eval. 31 45

Google Scholar

Google Scholar

[9] 时朋朋, 郝帅 2021 70 034101

Google Scholar

Google Scholar

Shi P P, Hao S 2021 Acta Phys. Sin. 70 034101

Google Scholar

Google Scholar

[10] 孙乐 2007 博士学位论文 (兰州: 兰州大学)

Sun L 2007 Ph. D. Dissertation (Lanzhou: Lanzhou University) (in Chinese)

[11] 周浩淼 2007 博士学位论文 (兰州: 兰州大学)

Zhou H M 2007 Ph. D. Dissertation (Lanzhou: Lanzhou University) (in Chinese)

[12] Zhou H M, Zhou Y H, Zheng X J, Ye Q, Wei J 2009 J. Magn. Magn. Mater. 321 281

Google Scholar

Google Scholar

[13] 时朋朋 2017 博士学位论文 (西安: 西安电子科技大学)

Shi P P 2017 Ph. D. Dissertation (Xi’an: Xidian University) (in Chinese)

[14] Shi P P 2020 J. Magn. Magn. Mater. 512 166980

Google Scholar

Google Scholar

[15] Shi P P, Jin K, Zheng X J 2016 J. Appl. Phys. 119 145103

Google Scholar

Google Scholar

[16] 罗旭, 朱海燕, 丁雅萍 2019 68 187501

Google Scholar

Google Scholar

Luo X, Zhu H Y, Ding Y P 2019 Acta Phys. Sin. 68 187501

Google Scholar

Google Scholar

[17] 刘清友, 罗旭, 朱海燕, 韩一维, 刘建勋 2017 66 107501

Google Scholar

Google Scholar

Liu Q Y, Luo X, Zhu H Y, Liu J X, Han Y W 2017 Acta Phys. Sin. 66 107501

Google Scholar

Google Scholar

[18] 周国华, 肖昌汉, 刘胜道, 高俊吉 2009 电工技术学报 24 1

Google Scholar

Google Scholar

Zhou G H, Xiao C H, Liu S D, Gao J J 2009 Trans. Chin. Elect. Soc. 24 1

Google Scholar

Google Scholar

[19] 孙阳 2018 硕士学位论文 (西安: 长安大学)

Sun Y 2018 M. S. Thesis (Xi’an: Chang’ an University) (in Chinese)

[20] 周耀忠, 张国友 2004 舰船磁场分析计算 (北京: 国防工业出版社) 第187—195页

Zhou Y Z, Zhang G Y 2004 Analysis and Calculation of Ship Magnetic Field (Beijing: National Defense Industry Press) pp187–195 (in Chinese)

[21] Maciej R, Gawrilenko P 2008 NDT and E Int. 41 507

Google Scholar

Google Scholar

[22] Maciej R, Andrzej R, Michal B 2013 Meccanica 48 45

Google Scholar

Google Scholar

-

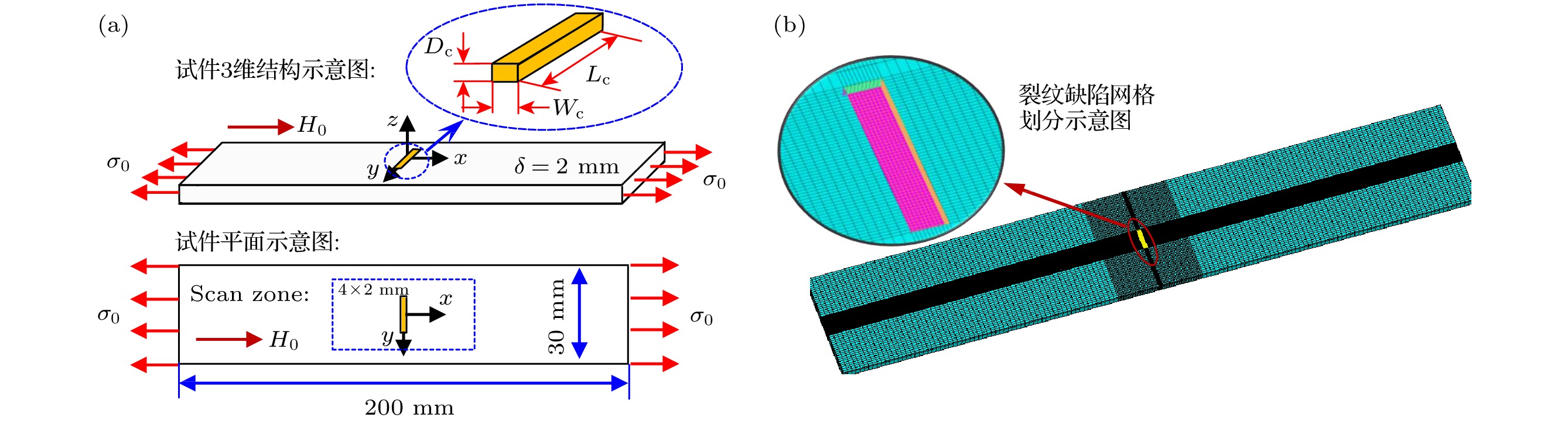

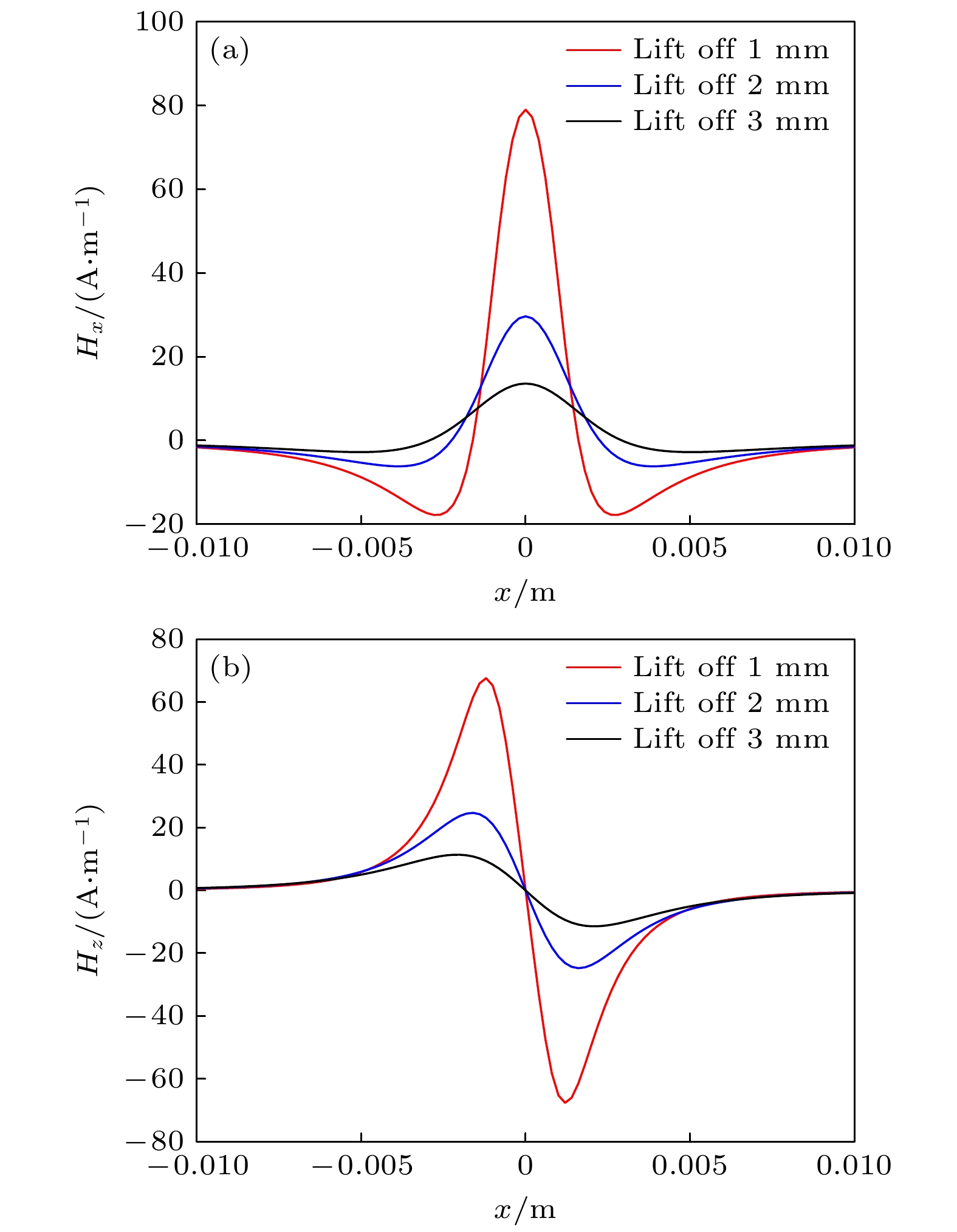

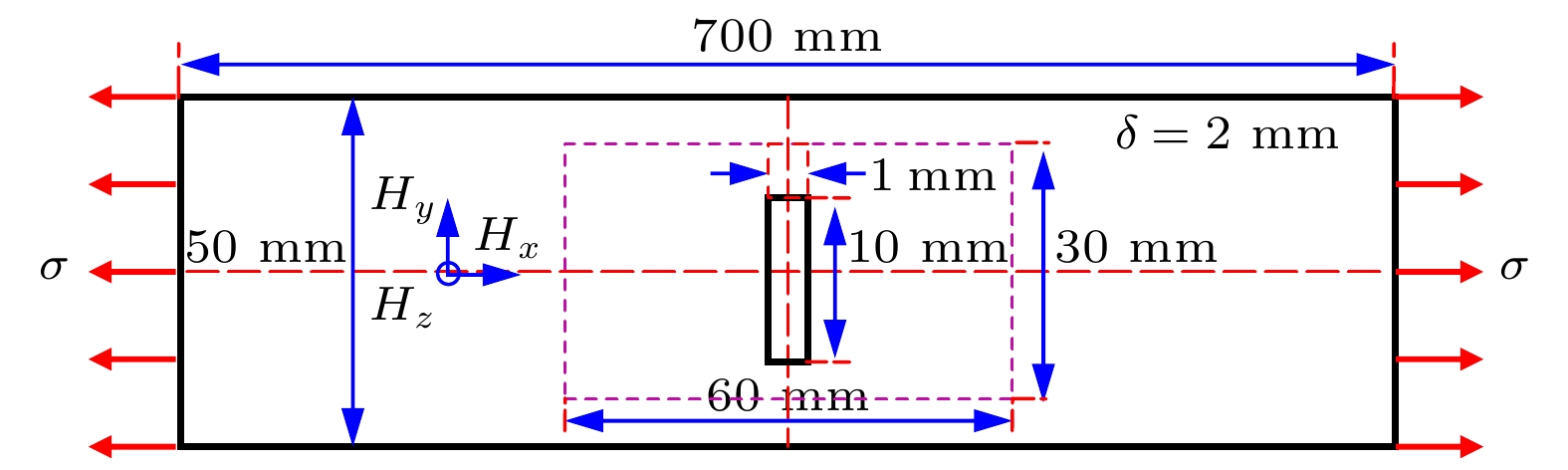

图 7 含圆孔缺陷拉伸试样表面磁场分布理论计算结果与实验结果对比 (a)实验测试的

${H_x}$ 分布情况; (b) 实验测试的${H_y}$ 分布情况; (c) 实验测试的${H_z}$ 分布情况; (d) 理论计算的${H_x}$ 分布情况; (e) 理论计算的${H_y}$ 分布情况; (f) 理论计算的${H_z}$ 分布情况Figure 7. Comparison between theoretical results and experimental results of magnetic field distribution of the specimen with hole defect: (a)

${H_x}$ of experimental results; (b)${H_y}$ of experimental results; (c)${H_z}$ of experimental results; (d)${H_x}$ of theoretical results; (e)${H_y}$ of theoretical results; (f)${H_z}$ of theoretical results.图 9 含裂纹缺陷拉伸试样表面磁场分布理论计算结果与实验结果对比 (a) 实验测试的

${H_x}$ 分布情况; (b) 实验测试的${H_y}$ 分布情况; (c) 实验测试的${H_z}$ 分布情况; (d) 理论计算的${H_x}$ 分布情况; (e) 理论计算的${H_y}$ 分布情况; (f) 理论计算的${H_z}$ 分布情况Figure 9. Comparison between theoretical results and experimental results of magnetic field distribution of the specimen with crack defect: (a)

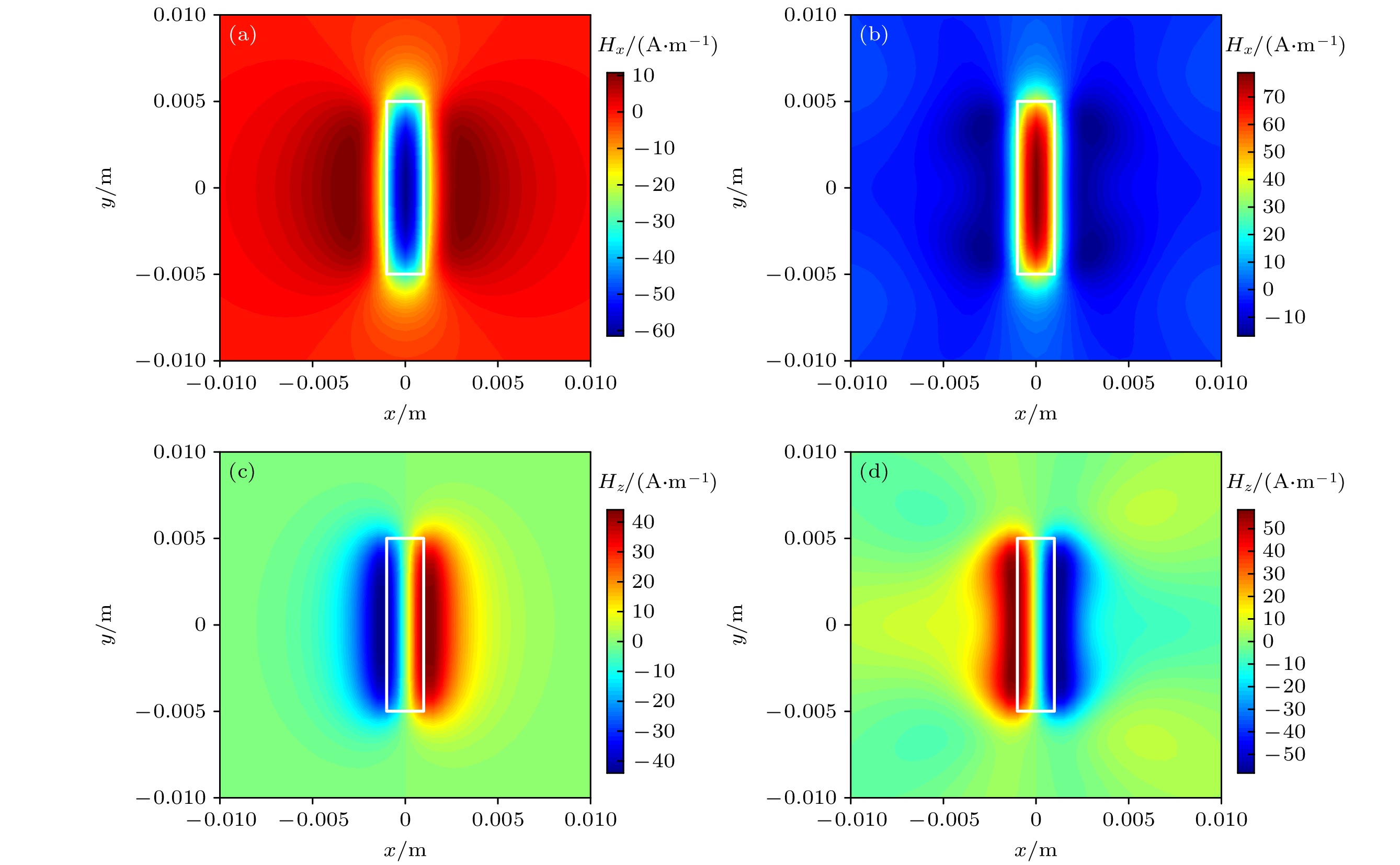

${H_x}$ of experimental results; (b)${H_y}$ of experimental results; (c)${H_z}$ of experimental results; (d)${H_x}$ of theoretical results; (e)${H_y}$ of theoretical results; (f)${H_z}$ of theoretical results.图 10 应力集中与宏观裂纹缺陷对试件表面磁场分布的影响对比 (a) 应力集中区域

${H_x}$ 分布情况; (b) 宏观裂纹缺陷${H_x}$ 分布情况; (c) 应力集中区域${H_z}$ 分布情况; (d) 宏观裂纹缺陷${H_z}$ 分布情况Figure 10. Comparison of effects of stress concentration and macroscopic crack defect on the distribution of magnetic field distribution: (a)

${H_x}$ of stress concentration; (b)${H_x}$ of macroscopic crack defects; (c)${H_z}$ of stress concentration; (d)${H_z}$ of macroscopic crack defects.图 13 槽形缺陷宽度

${W_{\text{c}}}$ 对磁场分布的影响 (a)${H_x}$ 随缺陷宽度${W_{\text{c}}}$ 变化情况; (b)${H_z}$ 随缺陷宽度${W_{\text{c}}}$ 变化情况; (c)$\Delta {H_x}$ 和$\Delta {H_z}$ 随缺陷宽度${W_{\text{c}}}$ 变化情况; (d)${W_{\Delta {H_x}}}$ 和${W_{\Delta {H_z}}}$ 随缺陷宽度${W_{\text{c}}}$ 变化情况Figure 13. Influence of crack defect width

${W_{\text{c}}}$ on magnetic field distribution: (a) Variation of${H_x}$ with${W_{\text{c}}}$ ; (b) variation of${H_z}$ with${W_{\text{c}}}$ ; (c) variation of$\Delta {H_x}$ and$\Delta {H_z}$ with${W_{\text{c}}}$ ; (d) variation of${W_{\Delta {H_x}}}$ and${W_{\Delta {H_z}}}$ with${W_{\text{c}}}$ .图 14 槽形缺陷长度

${L_{\text{c}}}$ 对磁场分布的影响 (a)${H_x}$ 随缺陷长度${L_{\text{c}}}$ 变化情况; (b)${H_z}$ 随缺陷长度${L_{\text{c}}}$ 变化情况; (c)$\Delta {H_x}$ 和$\Delta {H_z}$ 随缺陷长度${L_{\text{c}}}$ 变化情况; (d)${W_{\Delta {H_x}}}$ 和${W_{\Delta {H_z}}}$ 随缺陷长度${L_{\text{c}}}$ 变化情况Figure 14. Influence of crack defect lengthen

${L_{\text{c}}}$ on magnetic field distribution: (a) Variation of${H_x}$ with${L_{\text{c}}}$ ; (b) variation of${H_z}$ with${L_{\text{c}}}$ ; (c) variation of$\Delta {H_x}$ and$\Delta {H_z}$ with${L_{\text{c}}}$ ; (d) variation of${W_{\Delta {H_x}}}$ and${W_{\Delta {H_z}}}$ with Lc.图 15 槽形缺陷深度

${D_{\text{c}}}$ 对磁场分布的影响 (a)${H_x}$ 随缺陷深度${D_{\text{c}}}$ 变化情况; (b)${H_z}$ 随缺陷深度${D_{\text{c}}}$ 变化情况; (c)$\Delta {H_x}$ 和$\Delta {H_z}$ 随缺陷深度${D_{\text{c}}}$ 变化情况; (d)${W_{\Delta {H_x}}}$ 和${W_{\Delta {H_z}}}$ 随缺陷深度${D_{\text{c}}}$ 变化情况Figure 15. Influence of crack defect depth

${D_{\text{c}}}$ on magnetic field distribution: (a) Variation of${H_x}$ with${D_{\text{c}}}$ ; (b) variation of${H_z}$ with${D_{\text{c}}}$ ; (c) variation of$\Delta {H_x}$ and$\Delta {H_z}$ with${D_{\text{c}}}$ ; (d) variations of${W_{\Delta {H_x}}}$ and${W_{\Delta {H_z}}}$ with${D_{\text{c}}}$ .图 16 槽形缺陷埋深

${B_{\text{c}}}$ 对磁场分布的影响 (a)${H_x}$ 随缺陷埋深${B_{\text{c}}}$ 变化情况; (b)${H_z}$ 随缺陷埋深${B_{\text{c}}}$ 变化情况; (c)$\Delta {H_x}$ 和$\Delta {H_z}$ 随缺陷埋深${B_{\text{c}}}$ 变化情况; (d)${W_{\Delta {H_x}}}$ 和${W_{\Delta {H_z}}}$ 随缺陷埋深${B_{\text{c}}}$ 变化情况Figure 16. Influence of crack defect buried depth

${B_{\text{c}}}$ on magnetic field distribution: (a) Variation of${H_x}$ with${B_{\text{c}}}$ ; (b) variation of${H_z}$ with${B_{\text{c}}}$ ; (c) variation of$\Delta {H_x}$ and$\Delta {H_z}$ with${B_{\text{c}}}$ ; (d) variation of${W_{\Delta {H_x}}}$ and${W_{\Delta {H_z}}}$ with${B_{\text{c}}}$ .表 1 不同正演模型计算结果与实验测试结果对比

Table 1. Comparison of magnetic field distribution of specimen with hole defect calculated by different models.

表 2 不同正演模型计算含裂纹缺陷试件结果与实验测试结果对比

Table 2. Comparison of magnetic field distribution of specimen with crack defect calculated by different models

-

[1] Dubov A A 1997 Met. Sci. Heat Treat. 39 401

Google Scholar

Google Scholar

[2] Wang Z D, Yao K, Deng B, Ding K Q 2010 NDT and E Int. 43 354

Google Scholar

Google Scholar

[3] Wang Z D, Yao K, Deng B, Ding K Q 2010 NDT and E Int. 43 513

Google Scholar

Google Scholar

[4] 万强, 李思忠, 汤紫峰 2011 无损检测 33 12

Wang Q, Li S Z, Tang Z F 2011 Nondestr. Test. 33 12

[5] Leng J C, Xu M Q, Li J W 2010 Chin. J. Mech. Eng. 23 532

Google Scholar

Google Scholar

[6] Leng J C, Xing H Y, Zhou G Q, Gao Y T 2013 Insight 55 498

Google Scholar

Google Scholar

[7] 徐明秀, 尤天庆, 徐敏强, 樊久铭, 李立 2015 中南大学学报(自然科学版) 46 1215

Google Scholar

Google Scholar

Xu M X, You T Q, Xu M Q, Fan J M, Li L 2015 J. Cent. South Univ. 46 1215

Google Scholar

Google Scholar

[8] Shi P P, Zheng X J 2016 Nondestr. Test. Eval. 31 45

Google Scholar

Google Scholar

[9] 时朋朋, 郝帅 2021 70 034101

Google Scholar

Google Scholar

Shi P P, Hao S 2021 Acta Phys. Sin. 70 034101

Google Scholar

Google Scholar

[10] 孙乐 2007 博士学位论文 (兰州: 兰州大学)

Sun L 2007 Ph. D. Dissertation (Lanzhou: Lanzhou University) (in Chinese)

[11] 周浩淼 2007 博士学位论文 (兰州: 兰州大学)

Zhou H M 2007 Ph. D. Dissertation (Lanzhou: Lanzhou University) (in Chinese)

[12] Zhou H M, Zhou Y H, Zheng X J, Ye Q, Wei J 2009 J. Magn. Magn. Mater. 321 281

Google Scholar

Google Scholar

[13] 时朋朋 2017 博士学位论文 (西安: 西安电子科技大学)

Shi P P 2017 Ph. D. Dissertation (Xi’an: Xidian University) (in Chinese)

[14] Shi P P 2020 J. Magn. Magn. Mater. 512 166980

Google Scholar

Google Scholar

[15] Shi P P, Jin K, Zheng X J 2016 J. Appl. Phys. 119 145103

Google Scholar

Google Scholar

[16] 罗旭, 朱海燕, 丁雅萍 2019 68 187501

Google Scholar

Google Scholar

Luo X, Zhu H Y, Ding Y P 2019 Acta Phys. Sin. 68 187501

Google Scholar

Google Scholar

[17] 刘清友, 罗旭, 朱海燕, 韩一维, 刘建勋 2017 66 107501

Google Scholar

Google Scholar

Liu Q Y, Luo X, Zhu H Y, Liu J X, Han Y W 2017 Acta Phys. Sin. 66 107501

Google Scholar

Google Scholar

[18] 周国华, 肖昌汉, 刘胜道, 高俊吉 2009 电工技术学报 24 1

Google Scholar

Google Scholar

Zhou G H, Xiao C H, Liu S D, Gao J J 2009 Trans. Chin. Elect. Soc. 24 1

Google Scholar

Google Scholar

[19] 孙阳 2018 硕士学位论文 (西安: 长安大学)

Sun Y 2018 M. S. Thesis (Xi’an: Chang’ an University) (in Chinese)

[20] 周耀忠, 张国友 2004 舰船磁场分析计算 (北京: 国防工业出版社) 第187—195页

Zhou Y Z, Zhang G Y 2004 Analysis and Calculation of Ship Magnetic Field (Beijing: National Defense Industry Press) pp187–195 (in Chinese)

[21] Maciej R, Gawrilenko P 2008 NDT and E Int. 41 507

Google Scholar

Google Scholar

[22] Maciej R, Andrzej R, Michal B 2013 Meccanica 48 45

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6089

- PDF Downloads: 74

- Cited By: 0

DownLoad:

DownLoad: