-

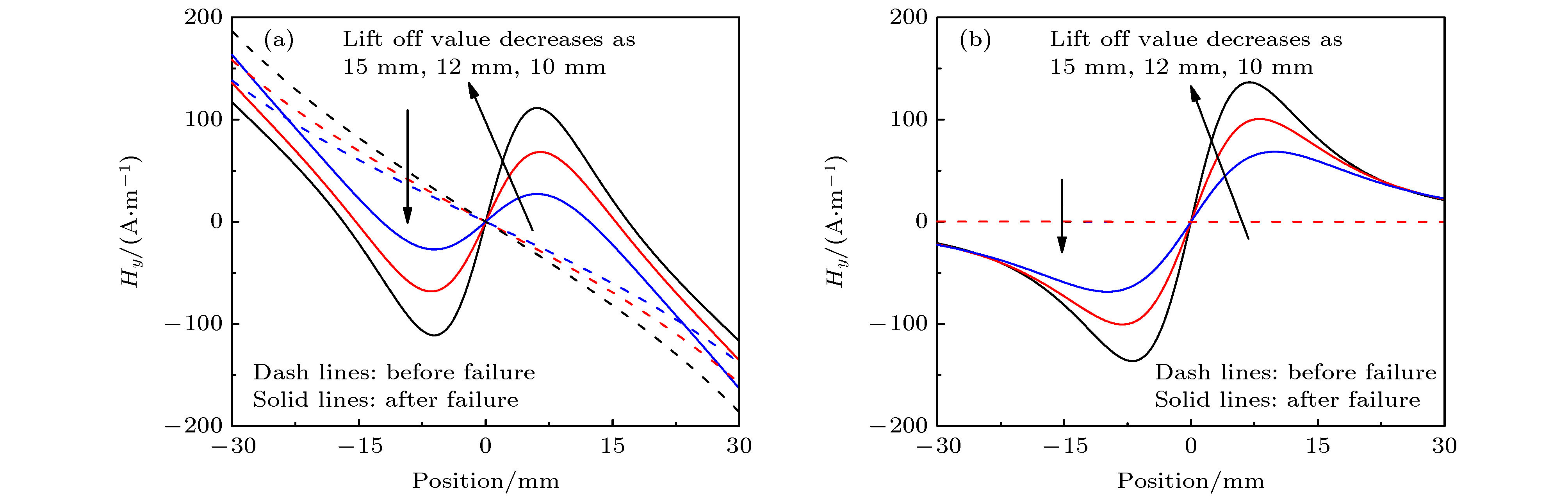

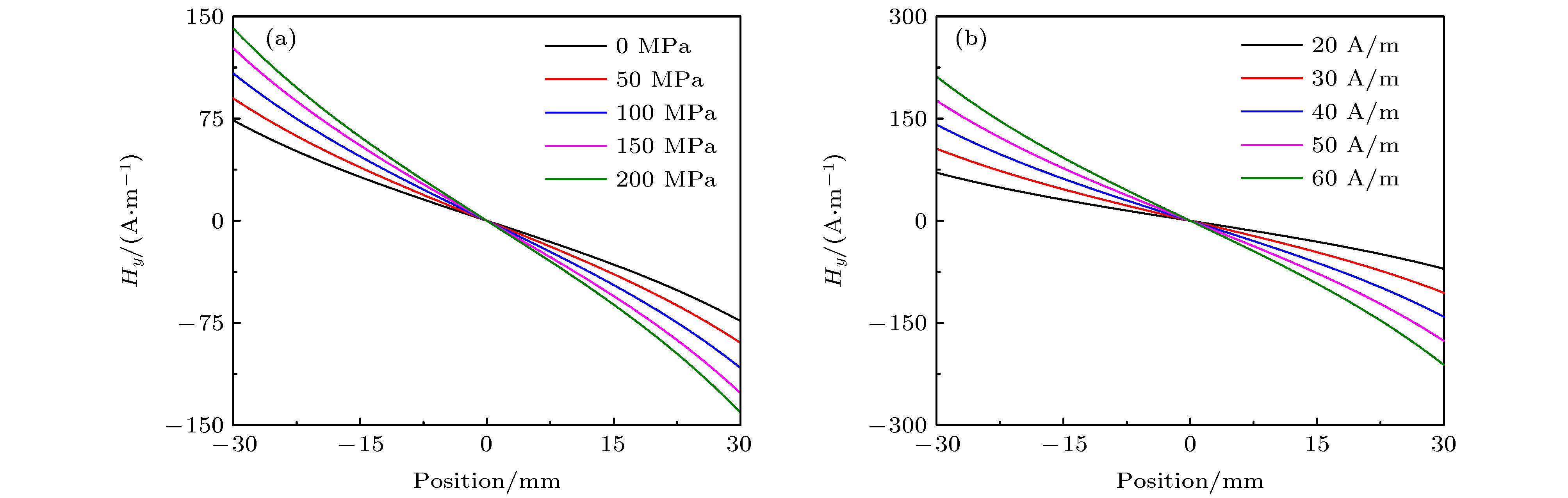

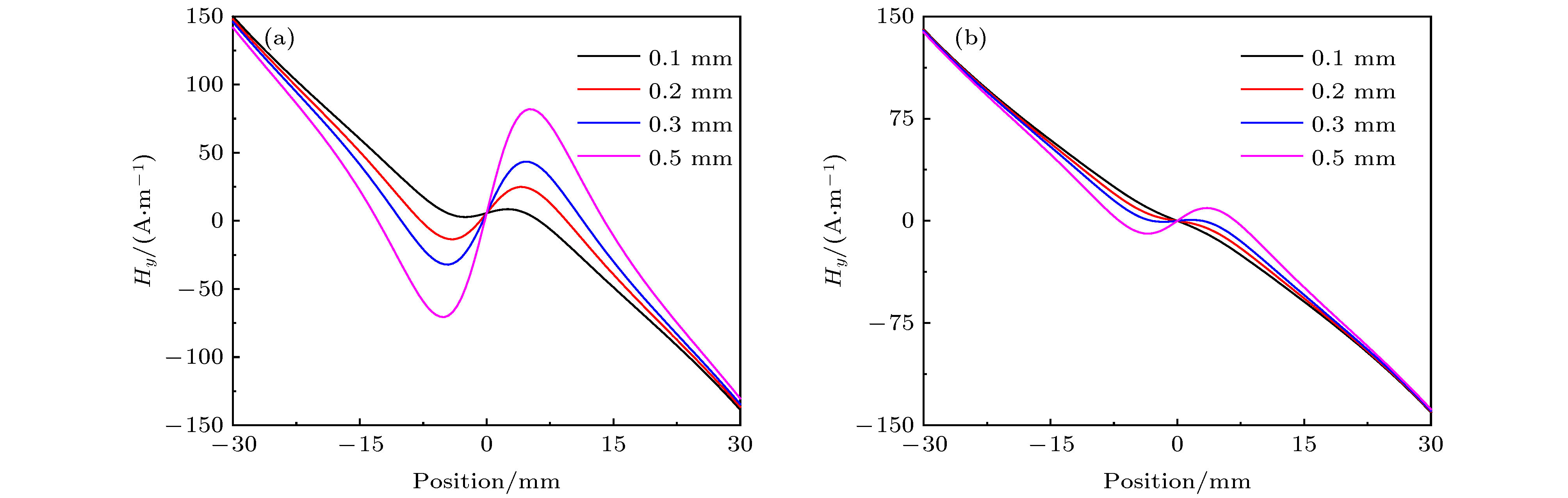

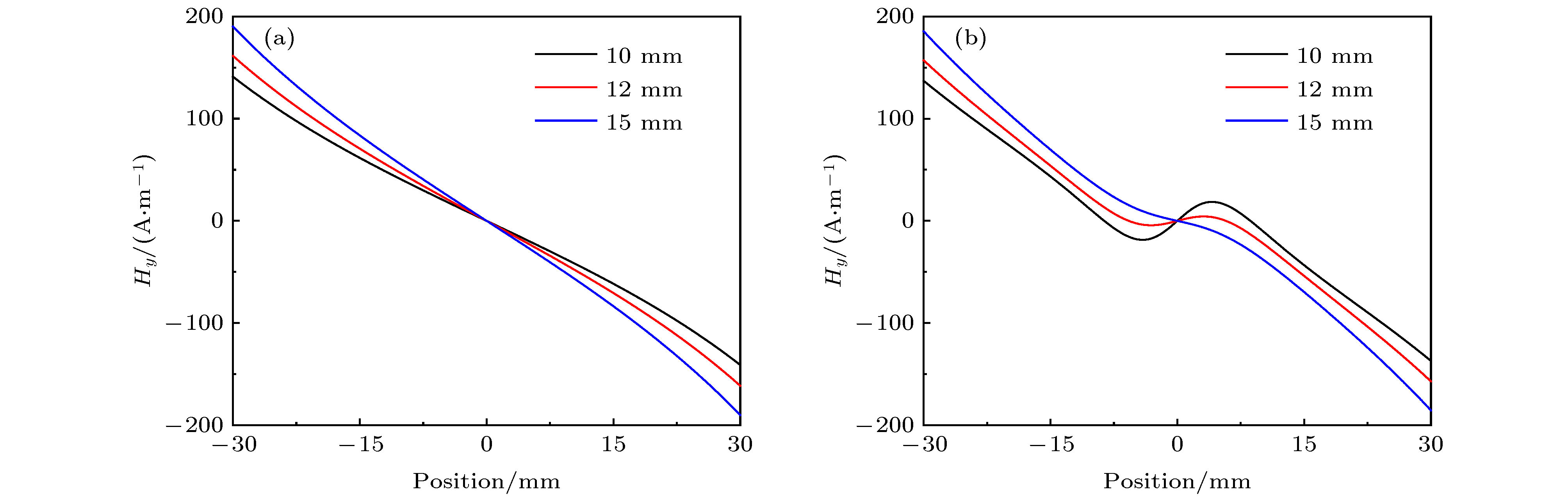

磁偶极子理论在缺陷漏磁场解释中被成功广泛使用. 由于磁荷密度等参数不易定量, 磁偶极子理论在应用中常常进行归一化处理, 被认为不适用于对应力相关的磁记忆信号做量化分析. 本文通过建立力磁耦合型磁偶极子理论模型, 以适用于分析磁记忆检测中应力对磁信号的影响. 基于铁磁学理论确定应力和磁场联合作用下的等效场强度, 基于弱磁化状态的一阶近似, 获得了各向同性铁磁材料微弱环境磁场下的应力磁化解析解. 结合磁信号二维问题中矩形和V形磁荷分布假定, 建立了光滑与破坏试件表面磁信号、矩形和V形表面缺陷所诱导磁信号的力磁耦合型磁偶极子理论分析模型, 并获得其解析解. 基于力磁耦合型磁偶极子理论的解析解, 对拉伸实验中试件破坏前后的信号差异、矩形和V形表面缺陷诱导磁信号, 以及磁信号的影响因素和规律等进行了详细分析. 理论研究表明, 基于本文理论模型的解析解可实现对磁记忆检测中的一些基本实验现象和规律的解释.Magnetic dipole theory has been widely and successfully used to explain the leakage magnetic field signals. Because the model parameter such as magnetic dipole density is not easy to quantify, magnetic dipole theory often needs normalizing in application, which is considered to be unsuitable for quantitatively analyzing the magnetic memory signals with the stress effect. In this paper, the theoretical model of magneto-mechanical coupling magnetic dipole is established, which is suitable for analyzing the stress effect on magnetic signals in magnetic memory testing method. Based on the ferromagnetic theory, the equivalent field under the combined action of the applied load and the magnetic field is determined. And then, the magneto-mechanical analytical model is obtained for the isotropic ferromagnetic material under the weak magnetic field based on the first-order magnetization approximation in the weak magnetization state. Under the assumptions of rectangular and V-shaped magnetic charge distribution for the two-dimensional magnetic signal problem, the theoretical analytical models of the magnetic memory signals from the smooth and cracked specimens, and the analytical models of the magnetic memory signal induced by the rectangular and V-shaped surface defect are established. Based on the analytical solution of the proposed magneto-mechanical magnetic dipole theory, the difference in signal between before and after the failure of the specimen, the signal from the rectangular and V-shaped defect, and other influencing factors and laws of the magnetic signal are analyzed in detail. In particular, the influence of stress, environmental magnetic field, defect morphology and size, lift-off effect, specimen size and other factors on magnetic memory signals can be described based on the analytical solution of magneto-mechanical magnetic dipole models proposed in this paper. The proposed analytical model of magneto-mechanical magnetic dipole in this paper is simple and easy to use, and the present research shows that the proposed analytical solution in this paper can explain some basic experimental phenomena and laws in magnetic memory testing experiments. In addition, the precise magneto-mechanical coupling quantitative model combined with the finite element analysis method is still needed for accurately analyzing the magnetic memory signals in experiment.

-

Keywords:

- metal magnetic memory /

- magneto-mechanical coupling /

- magnetic dipole /

- analytical solution

[1] Dubov A A 1997 Met. Sci. Heat Treat. 39 401

Google Scholar

Google Scholar

[2] Leng J C, Xu M Q, Li J W, et al. 2010 Chin. J. Mech. Eng. 23 532

Google Scholar

Google Scholar

[3] Huang H H, Jiang S L, Yang C, et al. 2014 Nondestr. Test. Eval. 29 377

Google Scholar

Google Scholar

[4] Minkov D, Lee J, Shoji T 2000 J. Magn. Magn. Mater. 217

Google Scholar

Google Scholar

[5] 时朋朋 2015 无损检测 37 1

Shi P P 2015 Nondestr. Test. 37 1

[6] Wang Z D, Deng B, Yao K 2011 J. Appl. Phys. 109 083928

Google Scholar

Google Scholar

[7] Li J W, Xu M Q 2011 J. Appl. Phys. 110 063918

Google Scholar

Google Scholar

[8] Shi P P 2020 J. Magn. Magn. Mater. 512 166980

Google Scholar

Google Scholar

[9] Avakian A, Ricoeur A 2017 J. Appl. Phys. 121 053901

Google Scholar

Google Scholar

[10] Shi P P, Bai P G, Chen H E, et al. 2020 J. Magn. Magn. Mater. 504 166669

Google Scholar

Google Scholar

[11] Zhong L Q, Li L M, Chen X 2013 IEEE Trans. Magn. 49 1128

Google Scholar

Google Scholar

[12] Shi P P, Jin K, Zheng X J 2016 J. Appl. Phys. 119 145103

Google Scholar

Google Scholar

[13] Shi P P, Jin K, Zhang P C, et al. 2018 IEEE Trans. Magn. 54 6202011

Google Scholar

Google Scholar

[14] Zhang P C, Shi P P, Jin K, et al. 2019 J. Appl. Phys. 125 233901

Google Scholar

Google Scholar

[15] Shi P P, Zhang P C, Jin K, et al. 2018 J. Appl. Phys. 123 145102

Google Scholar

Google Scholar

[16] Shi P P, Zheng X J 2016 Nondestr. Test. Eval. 31 45

Google Scholar

Google Scholar

[17] Shi P P, Su S Q, Chen Z M 2020 J. Nondestr. Eval. 39

Google Scholar

Google Scholar

[18] Zhong L Q, Li L L, Chen X 2010 Nondestr. Test. Eval 25 161

Google Scholar

Google Scholar

[19] Shi P P 2020 J. Appl. Phys. 128 115102

Google Scholar

Google Scholar

[20] Shi P P, Jin K, Zheng X J 2017 Int. J. Mech. Sci. 124–125 229

Google Scholar

Google Scholar

-

-

[1] Dubov A A 1997 Met. Sci. Heat Treat. 39 401

Google Scholar

Google Scholar

[2] Leng J C, Xu M Q, Li J W, et al. 2010 Chin. J. Mech. Eng. 23 532

Google Scholar

Google Scholar

[3] Huang H H, Jiang S L, Yang C, et al. 2014 Nondestr. Test. Eval. 29 377

Google Scholar

Google Scholar

[4] Minkov D, Lee J, Shoji T 2000 J. Magn. Magn. Mater. 217

Google Scholar

Google Scholar

[5] 时朋朋 2015 无损检测 37 1

Shi P P 2015 Nondestr. Test. 37 1

[6] Wang Z D, Deng B, Yao K 2011 J. Appl. Phys. 109 083928

Google Scholar

Google Scholar

[7] Li J W, Xu M Q 2011 J. Appl. Phys. 110 063918

Google Scholar

Google Scholar

[8] Shi P P 2020 J. Magn. Magn. Mater. 512 166980

Google Scholar

Google Scholar

[9] Avakian A, Ricoeur A 2017 J. Appl. Phys. 121 053901

Google Scholar

Google Scholar

[10] Shi P P, Bai P G, Chen H E, et al. 2020 J. Magn. Magn. Mater. 504 166669

Google Scholar

Google Scholar

[11] Zhong L Q, Li L M, Chen X 2013 IEEE Trans. Magn. 49 1128

Google Scholar

Google Scholar

[12] Shi P P, Jin K, Zheng X J 2016 J. Appl. Phys. 119 145103

Google Scholar

Google Scholar

[13] Shi P P, Jin K, Zhang P C, et al. 2018 IEEE Trans. Magn. 54 6202011

Google Scholar

Google Scholar

[14] Zhang P C, Shi P P, Jin K, et al. 2019 J. Appl. Phys. 125 233901

Google Scholar

Google Scholar

[15] Shi P P, Zhang P C, Jin K, et al. 2018 J. Appl. Phys. 123 145102

Google Scholar

Google Scholar

[16] Shi P P, Zheng X J 2016 Nondestr. Test. Eval. 31 45

Google Scholar

Google Scholar

[17] Shi P P, Su S Q, Chen Z M 2020 J. Nondestr. Eval. 39

Google Scholar

Google Scholar

[18] Zhong L Q, Li L L, Chen X 2010 Nondestr. Test. Eval 25 161

Google Scholar

Google Scholar

[19] Shi P P 2020 J. Appl. Phys. 128 115102

Google Scholar

Google Scholar

[20] Shi P P, Jin K, Zheng X J 2017 Int. J. Mech. Sci. 124–125 229

Google Scholar

Google Scholar

计量

- 文章访问数: 10788

- PDF下载量: 191

- 被引次数: 0

下载:

下载: