-

Nowadays, metal soft magnetic materials are mainly used in electronic components such as high-frequency inductors. Since all the elements in the soft magnetic alloys are transition metals, dense oxide layer is easily formed on their surfaces, which can affect the regulation of soft magnetic properties. In order to solve the problems, in this work, an innovative high-temperature pretreatment process in H2/Ar mixture is adopted to pretreat FeNiMo raw powders. We confirm that the high temperature treatment in reducing atmosphere can effectively remove metal oxides from the FeNiMo material surface and increase the content of elemental states, thereby further significantly improving the effective permeability of FeNiMo raw powders. The pretreated FeNiMo powder is evenly coated with SiO2 layers, forming the FeNiMo/SiO2 soft magnetic composites. Compared with the untreated FeNiMo powder coated with SiO2, the FeNiMo/SiO2 pretreated with H2/Ar mixture gas at high temperatures has high effective permeability and low loss. Our FeNiMo/SiO2 cores prepared by the synergistic effect of high-temperature pretreatment process in H2/Ar mixture and insulation coating process have more excellent soft magnetic properties than other iron-based soft magnetic composites. Therefore, the insulation coating after being pretreated at high temperature in reducing atmosphere can greatly improve the permeability and reduce the core loss of soft magnetic composites. This will provide a new strategy for enhancing the soft magnetic properties of the composite cores.

-

Keywords:

- FeNiMo /

- SiO2 coating /

- heat treatment /

- magnetic properties

[1] Xie D Z, Lin K H, Lin S T 2014 J. Magn. Magn. Mater. 353 34

Google Scholar

Google Scholar

[2] Ustinovshikov Y, Shabanova I 2013 J. Alloys Compd. 578 292

Google Scholar

Google Scholar

[3] Füzer J, Kollár P, Olekšáková D, Roth S 2009 J. Alloys Compd. 483 557

Google Scholar

Google Scholar

[4] 丁燕红, 李明吉, 杨保和, 马叙 2011 60 097502

Google Scholar

Google Scholar

Ding Y H, Li M J, Yang B H, Ma X 2011 Acta Phys. Sin. 60 097502

Google Scholar

Google Scholar

[5] Streckova M, Bures R, Faberova M, Medvecky L, Fuzer J, Kollar P 2015 Chin. J. Chem. Eng. 23 736

Google Scholar

Google Scholar

[6] Yi Y, Peng Y D, Xia C, Wu L Y, Ke X, Nie J W 2019 J. Magn. Magn. Mater. 476 100

Google Scholar

Google Scholar

[7] Sunday K J, Darling K A, Hanejko F G, Anasori B, Liu Y C, Taheri M L 2015 J. Alloys Compd. 653 61

Google Scholar

Google Scholar

[8] Peng Y D, Nie J W, Zhang W J, Ma J, Bao C X, Cao Y 2016 J. Magn. Magn. Mater. 399 88

Google Scholar

Google Scholar

[9] Zhong X X, Chen J C, Wang L, Li B J, Li L Z 2018 J. Alloys Compd. 735 1603

Google Scholar

Google Scholar

[10] Fan X A, Wang J, Wu Z Y, Li G Q 2015 Mater. Sci. Eng., B 201 79

Google Scholar

Google Scholar

[11] Yao Z X, Peng Y D, Xia C, Yi X W, Mao S H, Zhang M T 2020 J. Alloys Compd. 827 154345

Google Scholar

Google Scholar

[12] Neamtu B V, Geoffroy O, Chicinaş I, Isnard O 2012 Mater. Sci. Eng., B 177 661

Google Scholar

Google Scholar

[13] Peng Y D, Yi Y, Li L Y, Ai H Y, Wang X X, Chen L L 2017 J. Magn. Magn. Mater. 428 148

Google Scholar

Google Scholar

[14] 张凯, 王征, 张义, 魏荣飞, 兰中文, 余忠, 傅膑 2018 磁性材料及器件 49 52

Google Scholar

Google Scholar

Zhang K, Wang Z, Zhang Y, Wei R F, Lan Z W, Yu Z 2018 J. Magn. Mater. Devices 49 52

Google Scholar

Google Scholar

[15] Lei J, Zheng J W, Zheng H D, Qiao L, Ying Y, Cai W, Li W C, Yu J, Lin M, Che S L 2019 J. Magn. Magn. Mater. 472 7

Google Scholar

Google Scholar

[16] Zhang Z Q, Cong L C, Yu Z C, Qu L N, Qian M M, Huang W M 2020 Mater. Adv. 1 54

Google Scholar

Google Scholar

[17] Tu X, Gallon H J, Whitehead J C 2013 Catal. Today 211 120

Google Scholar

Google Scholar

[18] 冯波, 武鹏, 李永龙 2021 天然气化工 46 66

Feng B, Wu P, Li Y L 2021 Nat. Gas Chem. Ind. 46 66

[19] Cong L C, Yu Z C, Liu F B, Huang W M 2019 Catal. Sci. Technol. 9 1208

Google Scholar

Google Scholar

[20] 张亚菊, 谢忠帅, 郑海务, 袁国亮 2020 69 127709

Google Scholar

Google Scholar

Zhang Y J, Xie Z S, Zheng H W, Yuan G L 2020 Acta Phys. Sin. 69 127709

Google Scholar

Google Scholar

[21] Ray S K, Dhakal D, Lee S W 2018 Chem. Eng. J. 347 836

Google Scholar

Google Scholar

[22] Xiang M L, Li D B, Zou J, Li W H, Sun Y H, She X C 2010 J. Nat. Gas Chem. 19 151

Google Scholar

Google Scholar

[23] Wu K Z, Zhao J J, Zhang X Y, Zhou H W, Wu M X 2019 J. Taiwan Inst. Chem. Eng. 102 212

Google Scholar

Google Scholar

[24] Liu Y L, Zhang H, Ouyang P, Li Z C 2013 Electrochim. Acta 102 429

Google Scholar

Google Scholar

[25] Chen X Y, Zhang Z J, Li X X, Shi C W, Li X L 2006 Chem. Phys. Lett. 418 105

Google Scholar

Google Scholar

[26] 严密, 彭晓领 2006 磁学基础与磁性材料(杭州: 浙江大学出版社) 第120页

Yan M, Peng X L 2006 Fundamentals of Magnetism and Magnetic Materials (Hangzhou: Zhejiang University Press) p120 (in Chinese)

[27] Takahashi S, Harada S, Tamaki S 1989 J. Phys. Soc. Jpn. 58 2075

Google Scholar

Google Scholar

[28] Zhang L M, Huang X H, Song X L 2008 Fundamentals of Materials Science (2nd Ed.) (Wuhan: Wuhan University of Technology Press) p454 (in Chinese) [张联盟, 黄学辉, 宋晓岚 2008 材料科学基础(第二版) (武汉: 武汉理工大学出版社) 第454页]

[29] Wang Z, Liu X S, Kan X C, Zhu R W, Yang W, Wu Q Y, Zhou S Q 2019 Curr. Appl. Phys. 19 924

Google Scholar

Google Scholar

[30] Steinmetz C P 1984 Proc. IEEE 72 197

Google Scholar

Google Scholar

[31] Reinert J, Brockmeyer A, De Doncker R W A A 2001 IEEE Trans. Ind. Appl. 37 1055

Google Scholar

Google Scholar

[32] Zheng J W, Zheng H D, Lei J, Ying Y, Qiao L, Cai W, Li W C, Yu J, Tang Y P, Che S L 2020 J. Magn. Magn. Mater. 499 166255

Google Scholar

Google Scholar

[33] Luo F, Fan X A, Luo Z G, Hu W T, Wang J, Wu Z Y, Li G Q, Li Y W, Liu X 2020 J. Magn. Magn. Mater. 498 166084

Google Scholar

Google Scholar

[34] Li L Y, Chen Q L, Gao Z, Ge Y C, Yi J H 2019 J. Alloys Compd. 805 609

Google Scholar

Google Scholar

[35] 任劲松, 李勃, 王进, 庞新峰, 郭海 2018 电子元件与材料 37 51

Google Scholar

Google Scholar

Ren J S, Li B, Wang J, Pang X F, Guo H 2018 Electron. Compon. Mater. 37 51

Google Scholar

Google Scholar

[36] Guo R D, Wang S M, Yu Z, Sun K, Jiang X N, Wu G H, Wu C J, Lan Z W 2020 J. Alloys Compd. 830 154736

Google Scholar

Google Scholar

-

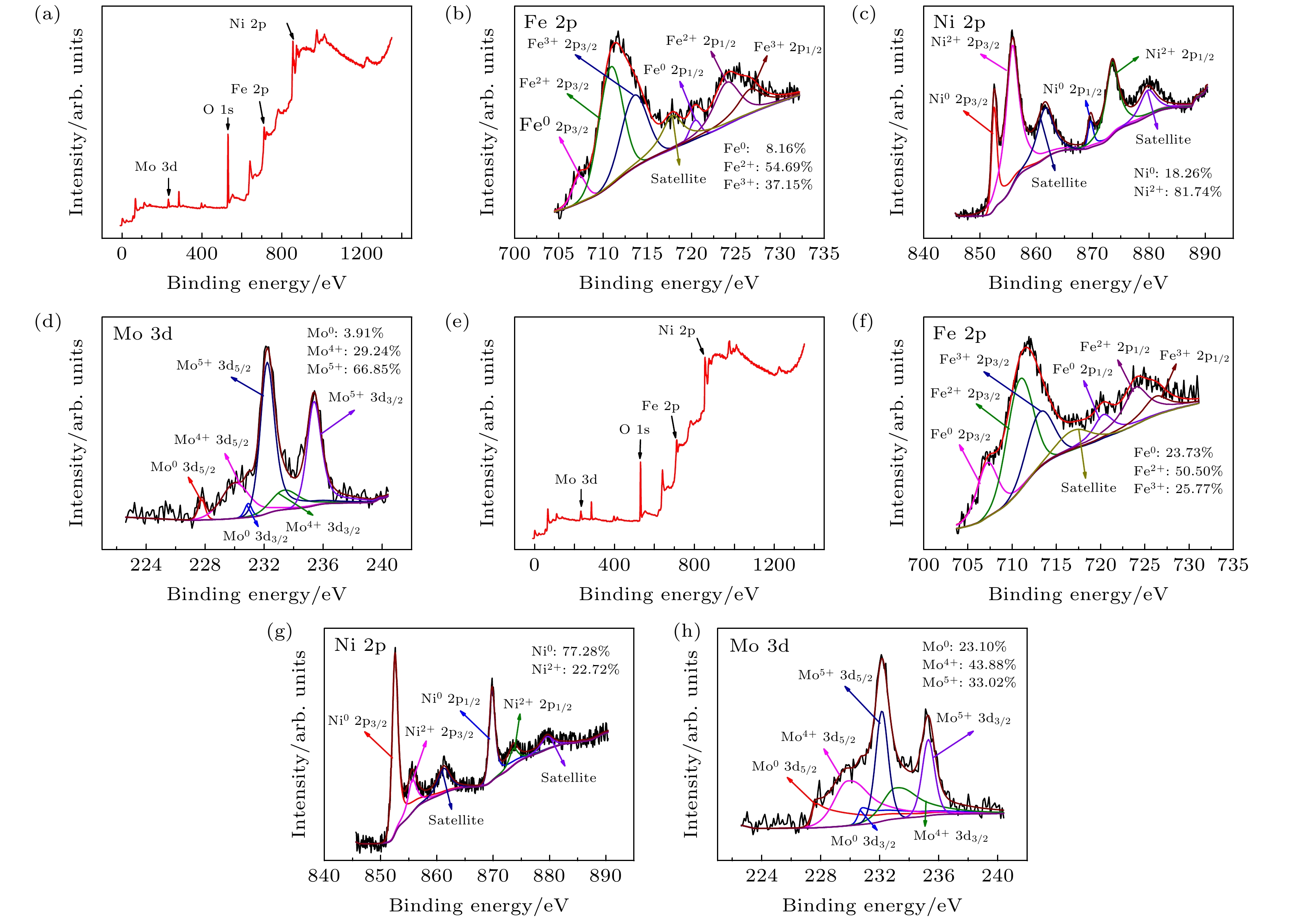

图 3 样品F0和F600的XPS图 (a)—(d)样品F0的XPS全谱, Fe 2p, Ni 2p和Mo 3d谱; (e)—(h)样品F600的XPS全谱, Fe 2p, Ni 2p和Mo 3d谱

Figure 3. XPS image of sample F0 and F600: (a)–(d) XPS survey spectrum, Fe 2p spectrum, Ni 2p spectrum and Mo 3d spectrum of sample F0; (e)–(h) XPS survey spectrum, Fe 2p spectrum, Ni 2p spectrum and Mo 3d spectrum of sample F600.

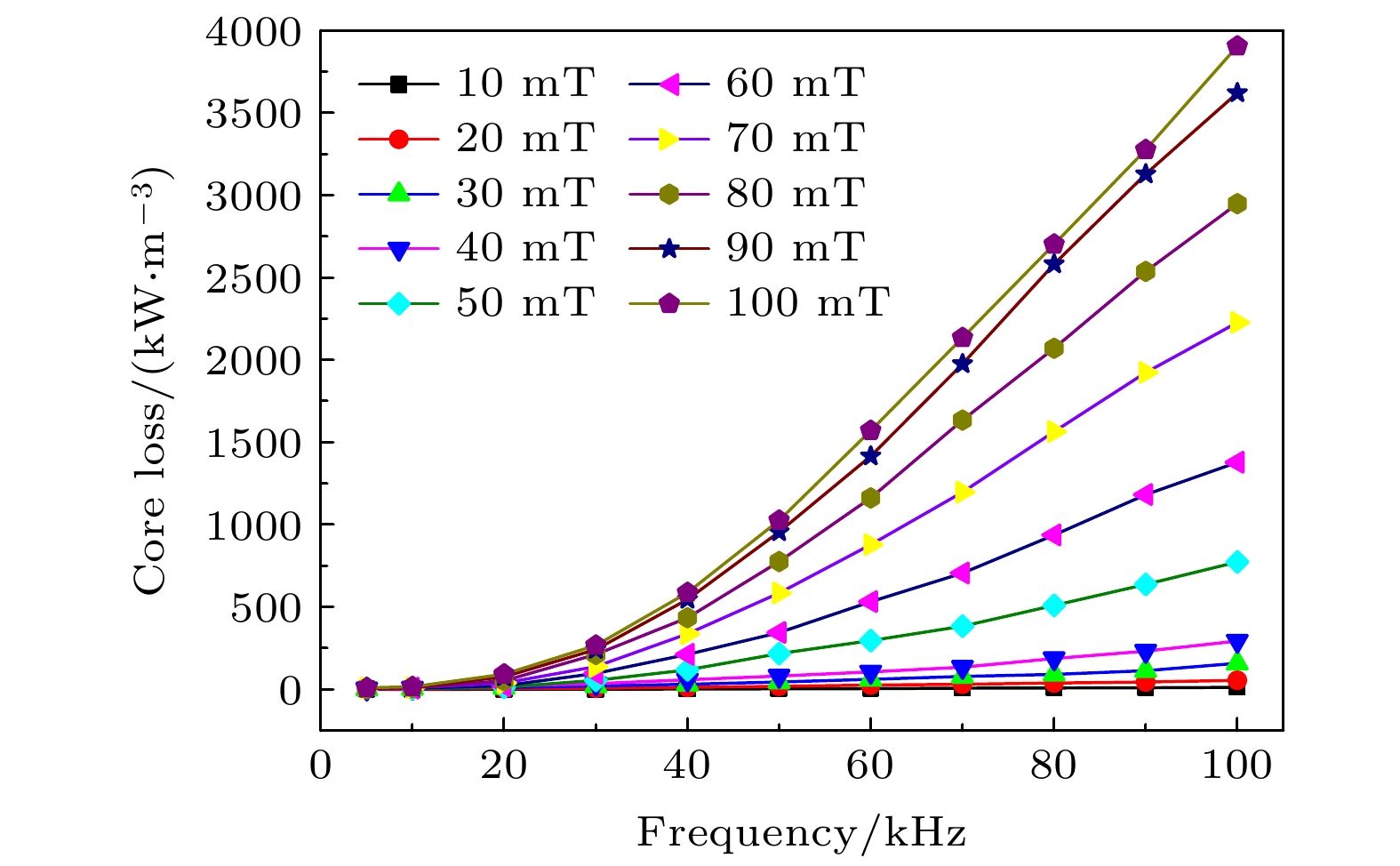

图 5 在B = 100 mT条件下, 测得的样品FS0和FS600在不同温度下退火后的磁性能 (a) 样品FS0的有效磁导率; (b) 样品FS0的损耗; (c) 样品FS600的有效磁导率; (d) 样品FS600的损耗. 图(c)中的插图为800 ℃烧结后复合粉芯截面的SEM图

Figure 5. Magnetic properties measured at B = 100 mT of samples FS0 and FS600 annealed at different temperatures: (a) Effective permeability of sample FS0; (b) core loss of sample FS0; (c) effective permeability of sample FS600; (d) core loss of sample FS600. The inset in panel (c) is the cross-section SEM image of the sample FS600 sintered at 800 ℃.

表 1 不同SMCs软磁性能的对比

Table 1. Comparison of the magnetic properties of different SMCs.

表 A1 根据测试结果拟合所得的数值

Table A1. Values fitted according to the test results.

Fixed condition Constant Cm α β B = 20 mT 0.02702 1.56019 2.44999 B = 50 mT 0.01310 1.96241 2.26657 B = 100 mT 0.02483 1.91492 2.18883 f = 20 kHz 0.03042 1.34380 2.36837 f = 50 kHz 0.10170 1.63830 2.36837 f = 100 kHz 0.03017 1.30323 2.83566 -

[1] Xie D Z, Lin K H, Lin S T 2014 J. Magn. Magn. Mater. 353 34

Google Scholar

Google Scholar

[2] Ustinovshikov Y, Shabanova I 2013 J. Alloys Compd. 578 292

Google Scholar

Google Scholar

[3] Füzer J, Kollár P, Olekšáková D, Roth S 2009 J. Alloys Compd. 483 557

Google Scholar

Google Scholar

[4] 丁燕红, 李明吉, 杨保和, 马叙 2011 60 097502

Google Scholar

Google Scholar

Ding Y H, Li M J, Yang B H, Ma X 2011 Acta Phys. Sin. 60 097502

Google Scholar

Google Scholar

[5] Streckova M, Bures R, Faberova M, Medvecky L, Fuzer J, Kollar P 2015 Chin. J. Chem. Eng. 23 736

Google Scholar

Google Scholar

[6] Yi Y, Peng Y D, Xia C, Wu L Y, Ke X, Nie J W 2019 J. Magn. Magn. Mater. 476 100

Google Scholar

Google Scholar

[7] Sunday K J, Darling K A, Hanejko F G, Anasori B, Liu Y C, Taheri M L 2015 J. Alloys Compd. 653 61

Google Scholar

Google Scholar

[8] Peng Y D, Nie J W, Zhang W J, Ma J, Bao C X, Cao Y 2016 J. Magn. Magn. Mater. 399 88

Google Scholar

Google Scholar

[9] Zhong X X, Chen J C, Wang L, Li B J, Li L Z 2018 J. Alloys Compd. 735 1603

Google Scholar

Google Scholar

[10] Fan X A, Wang J, Wu Z Y, Li G Q 2015 Mater. Sci. Eng., B 201 79

Google Scholar

Google Scholar

[11] Yao Z X, Peng Y D, Xia C, Yi X W, Mao S H, Zhang M T 2020 J. Alloys Compd. 827 154345

Google Scholar

Google Scholar

[12] Neamtu B V, Geoffroy O, Chicinaş I, Isnard O 2012 Mater. Sci. Eng., B 177 661

Google Scholar

Google Scholar

[13] Peng Y D, Yi Y, Li L Y, Ai H Y, Wang X X, Chen L L 2017 J. Magn. Magn. Mater. 428 148

Google Scholar

Google Scholar

[14] 张凯, 王征, 张义, 魏荣飞, 兰中文, 余忠, 傅膑 2018 磁性材料及器件 49 52

Google Scholar

Google Scholar

Zhang K, Wang Z, Zhang Y, Wei R F, Lan Z W, Yu Z 2018 J. Magn. Mater. Devices 49 52

Google Scholar

Google Scholar

[15] Lei J, Zheng J W, Zheng H D, Qiao L, Ying Y, Cai W, Li W C, Yu J, Lin M, Che S L 2019 J. Magn. Magn. Mater. 472 7

Google Scholar

Google Scholar

[16] Zhang Z Q, Cong L C, Yu Z C, Qu L N, Qian M M, Huang W M 2020 Mater. Adv. 1 54

Google Scholar

Google Scholar

[17] Tu X, Gallon H J, Whitehead J C 2013 Catal. Today 211 120

Google Scholar

Google Scholar

[18] 冯波, 武鹏, 李永龙 2021 天然气化工 46 66

Feng B, Wu P, Li Y L 2021 Nat. Gas Chem. Ind. 46 66

[19] Cong L C, Yu Z C, Liu F B, Huang W M 2019 Catal. Sci. Technol. 9 1208

Google Scholar

Google Scholar

[20] 张亚菊, 谢忠帅, 郑海务, 袁国亮 2020 69 127709

Google Scholar

Google Scholar

Zhang Y J, Xie Z S, Zheng H W, Yuan G L 2020 Acta Phys. Sin. 69 127709

Google Scholar

Google Scholar

[21] Ray S K, Dhakal D, Lee S W 2018 Chem. Eng. J. 347 836

Google Scholar

Google Scholar

[22] Xiang M L, Li D B, Zou J, Li W H, Sun Y H, She X C 2010 J. Nat. Gas Chem. 19 151

Google Scholar

Google Scholar

[23] Wu K Z, Zhao J J, Zhang X Y, Zhou H W, Wu M X 2019 J. Taiwan Inst. Chem. Eng. 102 212

Google Scholar

Google Scholar

[24] Liu Y L, Zhang H, Ouyang P, Li Z C 2013 Electrochim. Acta 102 429

Google Scholar

Google Scholar

[25] Chen X Y, Zhang Z J, Li X X, Shi C W, Li X L 2006 Chem. Phys. Lett. 418 105

Google Scholar

Google Scholar

[26] 严密, 彭晓领 2006 磁学基础与磁性材料(杭州: 浙江大学出版社) 第120页

Yan M, Peng X L 2006 Fundamentals of Magnetism and Magnetic Materials (Hangzhou: Zhejiang University Press) p120 (in Chinese)

[27] Takahashi S, Harada S, Tamaki S 1989 J. Phys. Soc. Jpn. 58 2075

Google Scholar

Google Scholar

[28] Zhang L M, Huang X H, Song X L 2008 Fundamentals of Materials Science (2nd Ed.) (Wuhan: Wuhan University of Technology Press) p454 (in Chinese) [张联盟, 黄学辉, 宋晓岚 2008 材料科学基础(第二版) (武汉: 武汉理工大学出版社) 第454页]

[29] Wang Z, Liu X S, Kan X C, Zhu R W, Yang W, Wu Q Y, Zhou S Q 2019 Curr. Appl. Phys. 19 924

Google Scholar

Google Scholar

[30] Steinmetz C P 1984 Proc. IEEE 72 197

Google Scholar

Google Scholar

[31] Reinert J, Brockmeyer A, De Doncker R W A A 2001 IEEE Trans. Ind. Appl. 37 1055

Google Scholar

Google Scholar

[32] Zheng J W, Zheng H D, Lei J, Ying Y, Qiao L, Cai W, Li W C, Yu J, Tang Y P, Che S L 2020 J. Magn. Magn. Mater. 499 166255

Google Scholar

Google Scholar

[33] Luo F, Fan X A, Luo Z G, Hu W T, Wang J, Wu Z Y, Li G Q, Li Y W, Liu X 2020 J. Magn. Magn. Mater. 498 166084

Google Scholar

Google Scholar

[34] Li L Y, Chen Q L, Gao Z, Ge Y C, Yi J H 2019 J. Alloys Compd. 805 609

Google Scholar

Google Scholar

[35] 任劲松, 李勃, 王进, 庞新峰, 郭海 2018 电子元件与材料 37 51

Google Scholar

Google Scholar

Ren J S, Li B, Wang J, Pang X F, Guo H 2018 Electron. Compon. Mater. 37 51

Google Scholar

Google Scholar

[36] Guo R D, Wang S M, Yu Z, Sun K, Jiang X N, Wu G H, Wu C J, Lan Z W 2020 J. Alloys Compd. 830 154736

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7766

- PDF Downloads: 133

- Cited By: 0

DownLoad:

DownLoad: