-

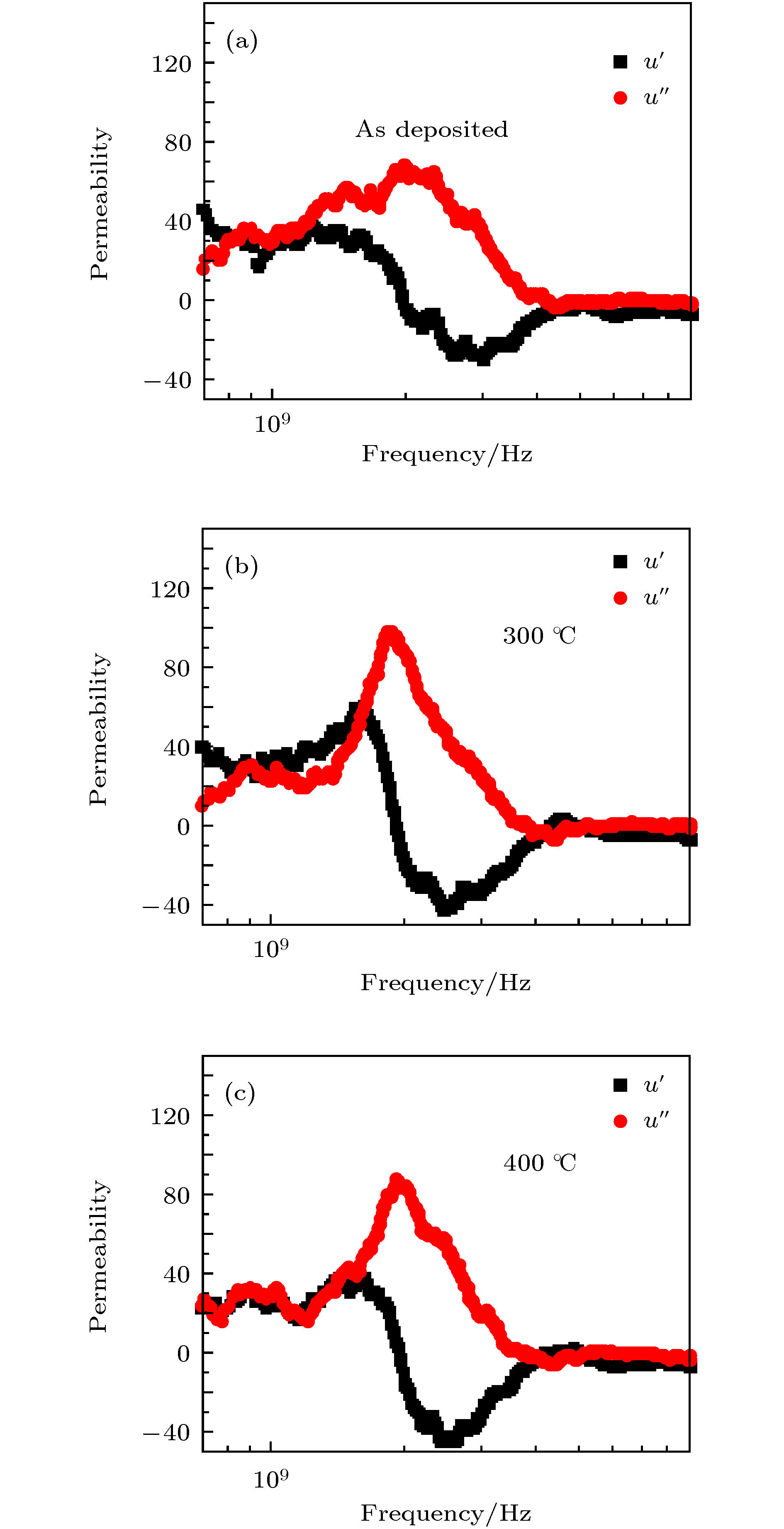

利用射频磁控共溅射方法, 在Si衬底上制备了Ni88Cu12薄膜, 并且研究了膜厚以及真空磁场热处理温度对畴结构和磁性的影响. X射线衍射结果表明热处理后的薄膜晶粒长大, 扫描电子显微镜结果发现不同热处理温度下薄膜表现出不同的形貌特征. 热处理前后的薄膜面内归一化磁滞回线结果显示, 经过热处理的Ni88Cu12薄膜条纹畴形成的临界厚度降低, 未热处理的Ni88Cu12薄膜在膜厚为210 nm时出现条纹畴结构, 而经过 300 ℃热处理的Ni88Cu12薄膜在膜厚为105 nm就出现了条纹畴结构. 高频磁谱的结果表明, 随着热处理温度的增加, Ni88Cu12薄膜的共振峰会有小范围的移动.In this paper, Ni88Cu12 thin films are prepared on Si substrates by radio-frequency magnetron co-sputtering. The effects of film thickness and heat treatment on domain structure and magnetic properties are studied. The Ni88Cu12 films with thickness less than 210 nm show weak in-plane anisotropy. After the vacuum magnetic field heat treatment, the crystal grains of all films grow, and the in-plane anisotropy extents of Ni88Cu12 films with thickness less than 210 nm become weaker. The films have different morphological characteristics at different heat treatment temperatures. The surface of the film is very dense before heat treatment. After heat treatment at 300 °C, it forms island shape due to the solid solution between the grains. Compared with the grains on the surface of the heat-treated film at 300 °C, the grains grow further after being heat-treated at 400 °C. Grown grains cover the gaps between the grains, which makes the film surface flat. The results of in-plane normalized hysteresis loop of the films show that the critical thickness of the stripe domains decreases after heat treatment. The stripe domain structure appears in the 210-nm-thick films without being heat-treated. For the film with the heat treatment, its remanence ratio Mr/Ms decreases, and the saturation field Hs increases, and thus leading the perpendicular anisotropy constant Kp to increase. Therefore, the thickness of the stripe domain in the film after being heat-treated decreases. Compared with the films after being heat-treated, the 105-nm-thick as-prepared Ni88Cu12 film has a maximum natural resonance frequency of 2.1 GHz, which is attributed to the uniaxial anisotropy of the as-prepared Ni88Cu12 film. The saturation magnetization of the 300 °C-treated 105-nm-thick film decreases to 3.01 × 105 A/m. However, the saturation magnetization decreases to 5.9 × 105 A/m after heat treatment at 400 °C. Moreover, the ferromagnetic resonance peak of the film narrows after being treated at 300 °C, and the resonance frequency decreases to 1.95 GHz.

-

Keywords:

- stripe domain /

- Ni88Cu12 /

- heat treatment

[1] Lekas M, Davies R, Sturcken N 2018 IEEE Magn. Lett. 10 1

Google Scholar

Google Scholar

[2] Greaves S, Kanai Y 2018 IEEE Trans. Magn. 55 1

Google Scholar

Google Scholar

[3] Feng H, Zhu Z, Liu W, Li X, Xie H, Liu Q, Wang J 2019 J. Mater. Sci. 54 14189

Google Scholar

Google Scholar

[4] Kittel C 1948 Phys. Rev. 73 155

Google Scholar

Google Scholar

[5] Phuoc N N, Ong C K 2013 J. Phys. D: Appl. Phys. 46 485002

Google Scholar

Google Scholar

[6] 李金财, 詹清峰, 潘民杰, 刘鲁萍, 杨华礼, 谢亚丽, 谢淑红, 李润伟 2016 65 217501

Google Scholar

Google Scholar

Li J C, Zhan Q F, Pan M J, Liu L P, Yang H L, Xie Y L, Xie S H, Li R W 2016 Acta Phys. Sin. 65 217501

Google Scholar

Google Scholar

[7] Ziberi B, Frost F, Höche T, Rauschenbach B 2005 Phys. Rev. B 72 235310

Google Scholar

Google Scholar

[8] Zhou C, You M, Ding L, Feng C, Xu M, Wang S 2019 Appl. Phys. A 125 174

Google Scholar

Google Scholar

[9] Spain R 1965 Appl. Phys. Lett. 6 8

Google Scholar

Google Scholar

[10] Cao D, Wang Z, Feng E, Wei J, Wang J, Liu Q 2013 J. Alloys Compd. 581 66

Google Scholar

Google Scholar

[11] Wei J, Zhu Z, Feng H, Du J, Liu Q, Wang J 2015 J. Phys. D: Appl. Phys. 48 465001

Google Scholar

Google Scholar

[12] Prosen R J, Holmen J O, Gran B E 1961 J. Appl. Phys. 32 S91

Google Scholar

Google Scholar

[13] Iwata T, Prosen R J, Gran B E 1966 J. Appl. Phys. 37 1285

Google Scholar

Google Scholar

[14] Amos N, Fernandez R, Ikkawi R, Lee E, Lavrenov A, Litvinov l K D, Khizroev S 2008 J. Appl. Phys. 103 07E732

Google Scholar

Google Scholar

[15] Ben Youssef J, Vukadinovic N, Billet D, Labrune M 2004 Phys. Rev. B 69 174402

Google Scholar

Google Scholar

[16] Brandenburg J, Hühne R, Schultz L, Neu V 2009 Phys. Rev. B 79 054429

Google Scholar

Google Scholar

[17] Vladyslav A, Vas’ko, Rantschler J O, Kief M T 2004 IEEE Trans. Magn. 40 2335

Google Scholar

Google Scholar

[18] Zou P, Yu W, Bain J A 2002 J. Appl. Phys. 91 7830

Google Scholar

Google Scholar

[19] Phuoc N N, Ong C K 2013 J. Appl. Phys. 114 023901

Google Scholar

Google Scholar

[20] 王锐, 郑富, 罗飞龙, 娄元付, 王颖, 曹江伟, 白建民, 魏福林, 阿谢卡姆津 2013 62 217503

Google Scholar

Google Scholar

Wang R, Zheng F, Luo F L, Lou Y F, Wang Y, Cao J W, Bai J M, Wei F L, Kamzin A S 2013 Acta Phys. Sin. 62 217503

Google Scholar

Google Scholar

[21] Cao D, Pan L, Cheng X, Wang Z, Feng H, Zhu Z, Xu J, Li Q, Li S, Wang J, Liu Q 2018 J. Phys. D: Appl. Phys. 51 025001

Google Scholar

Google Scholar

[22] Leva E S, Valente R C, Tabares F M, Mansilla M V 2010 Phys. Rev. B 82 144410

Google Scholar

Google Scholar

[23] Tu Y O 1981 J. Appl. Phys. 52 3130

Google Scholar

Google Scholar

[24] Debonte W J 1975 IEEE Trans. Magn. 11 3

Google Scholar

Google Scholar

[25] 郑富, 陈治鹏, 马亚楠, 周俊 2017 磁性材料及器件 48 19701

Google Scholar

Google Scholar

Zheng F, Chen Z P, Ma YN, Zhou J 2017 J. Magn. Mater. Devices 48 19701

Google Scholar

Google Scholar

[26] Patterson A L 1939 Phys. Rev. 56 978

Google Scholar

Google Scholar

[27] Soh W T, Phuoc N N, Tan C Y, Ong C K 2013 J. Appl. Phys. 114 053908

Google Scholar

Google Scholar

[28] Sultan M, Singh R 2010 JPCS 200 072090

Google Scholar

Google Scholar

[29] Shah L R, Fan X, Kou X, Wang W G, Zhang Y P, Lou J, Sun N X, Xiao J Q 2010 J. Appl. Phys. 107 09D909

Google Scholar

Google Scholar

[30] Bhoi B, Venkataramani N, Aiyar R, Prasad S, Kostylev M 2018 IEEE Trans. Magn. 54 2801205

Google Scholar

Google Scholar

-

图 2 未进行热处理的膜厚为(a) 105 nm, (b) 210 nm和(c) 262 nm的Ni88Cu12薄膜的MFM图像; (d)不同厚度Ni88Cu12薄膜的面内归一化磁滞回线; (e)薄膜的Mr/Ms随薄膜厚度的变化

Fig. 2. The MFM images of (a) 105 nm, (b) 210 nm and (c) 262 nm-thick Ni88Cu12 films before heat treatment; (d) in-plane normalized hysteresis loop of Ni88Cu12; (e) remanence ratio vs. film thickness.

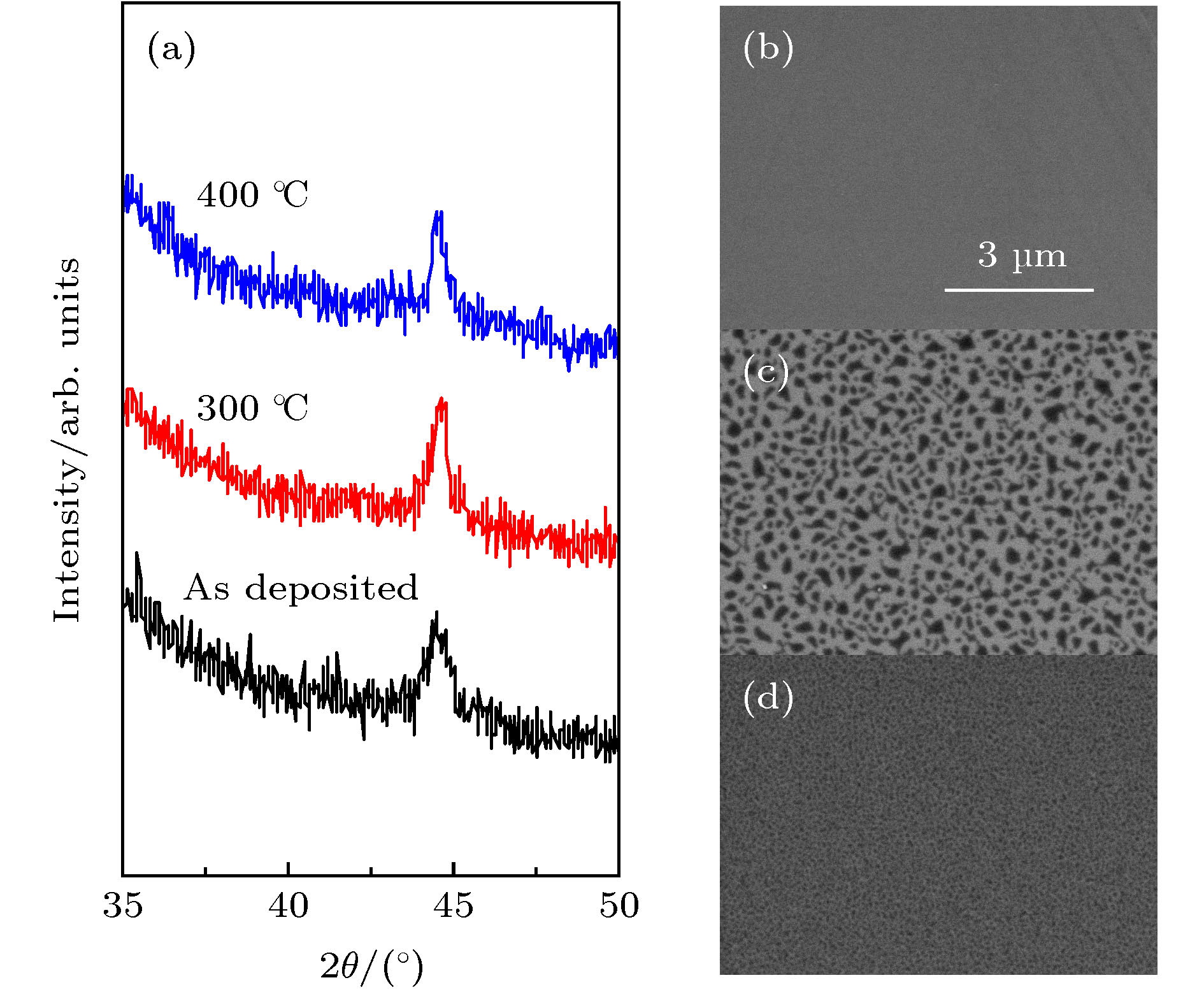

图 3 (a)厚度为105 nm的Ni88Cu12薄膜热处理前后的XRD图谱; 厚度为105 nm的Ni88Cu12薄膜在(b)热处理前、(c) 300 ºC热处理后和(d) 400 ºC热处理后的SEM形貌图

Fig. 3. (a) XRD pattern of 105 nm-thick Ni88Cu12 film before and after heat treatment; the SEM surface morphology of 105 nm-thick Ni88Cu12 films (b) before heat treatment, (c) after 300 ºC heat treatment, and (d) after 400 ºC heat treatment.

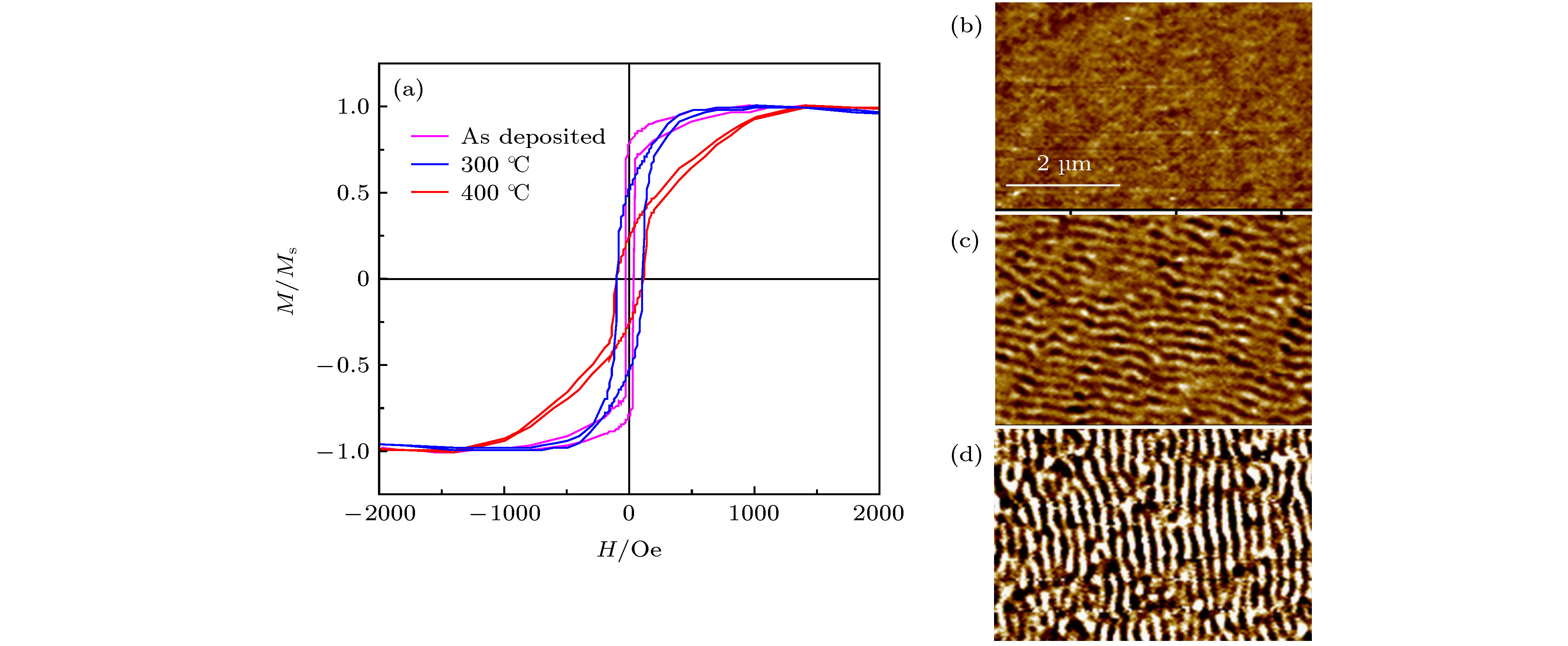

图 4 (a)厚度为105 nm的Ni88Cu12薄膜在热处理前后的归一化磁滞回线; (b)厚度为105 nm的Ni88Cu12薄膜在热处理前、(c) 300 ℃热处理后和(d) 400 ℃热处理后的MFM图像

Fig. 4. (a) In-plane normalized hysteresis loop of 105 nm-thick Ni88Cu12 film before and after heat treatment; The MFM images of 105 nm-thick Ni88Cu12 films (b) before heat treatment, (c) after 300 ºC heat treatment, and (d) after 400 ºC heat treatment.

-

[1] Lekas M, Davies R, Sturcken N 2018 IEEE Magn. Lett. 10 1

Google Scholar

Google Scholar

[2] Greaves S, Kanai Y 2018 IEEE Trans. Magn. 55 1

Google Scholar

Google Scholar

[3] Feng H, Zhu Z, Liu W, Li X, Xie H, Liu Q, Wang J 2019 J. Mater. Sci. 54 14189

Google Scholar

Google Scholar

[4] Kittel C 1948 Phys. Rev. 73 155

Google Scholar

Google Scholar

[5] Phuoc N N, Ong C K 2013 J. Phys. D: Appl. Phys. 46 485002

Google Scholar

Google Scholar

[6] 李金财, 詹清峰, 潘民杰, 刘鲁萍, 杨华礼, 谢亚丽, 谢淑红, 李润伟 2016 65 217501

Google Scholar

Google Scholar

Li J C, Zhan Q F, Pan M J, Liu L P, Yang H L, Xie Y L, Xie S H, Li R W 2016 Acta Phys. Sin. 65 217501

Google Scholar

Google Scholar

[7] Ziberi B, Frost F, Höche T, Rauschenbach B 2005 Phys. Rev. B 72 235310

Google Scholar

Google Scholar

[8] Zhou C, You M, Ding L, Feng C, Xu M, Wang S 2019 Appl. Phys. A 125 174

Google Scholar

Google Scholar

[9] Spain R 1965 Appl. Phys. Lett. 6 8

Google Scholar

Google Scholar

[10] Cao D, Wang Z, Feng E, Wei J, Wang J, Liu Q 2013 J. Alloys Compd. 581 66

Google Scholar

Google Scholar

[11] Wei J, Zhu Z, Feng H, Du J, Liu Q, Wang J 2015 J. Phys. D: Appl. Phys. 48 465001

Google Scholar

Google Scholar

[12] Prosen R J, Holmen J O, Gran B E 1961 J. Appl. Phys. 32 S91

Google Scholar

Google Scholar

[13] Iwata T, Prosen R J, Gran B E 1966 J. Appl. Phys. 37 1285

Google Scholar

Google Scholar

[14] Amos N, Fernandez R, Ikkawi R, Lee E, Lavrenov A, Litvinov l K D, Khizroev S 2008 J. Appl. Phys. 103 07E732

Google Scholar

Google Scholar

[15] Ben Youssef J, Vukadinovic N, Billet D, Labrune M 2004 Phys. Rev. B 69 174402

Google Scholar

Google Scholar

[16] Brandenburg J, Hühne R, Schultz L, Neu V 2009 Phys. Rev. B 79 054429

Google Scholar

Google Scholar

[17] Vladyslav A, Vas’ko, Rantschler J O, Kief M T 2004 IEEE Trans. Magn. 40 2335

Google Scholar

Google Scholar

[18] Zou P, Yu W, Bain J A 2002 J. Appl. Phys. 91 7830

Google Scholar

Google Scholar

[19] Phuoc N N, Ong C K 2013 J. Appl. Phys. 114 023901

Google Scholar

Google Scholar

[20] 王锐, 郑富, 罗飞龙, 娄元付, 王颖, 曹江伟, 白建民, 魏福林, 阿谢卡姆津 2013 62 217503

Google Scholar

Google Scholar

Wang R, Zheng F, Luo F L, Lou Y F, Wang Y, Cao J W, Bai J M, Wei F L, Kamzin A S 2013 Acta Phys. Sin. 62 217503

Google Scholar

Google Scholar

[21] Cao D, Pan L, Cheng X, Wang Z, Feng H, Zhu Z, Xu J, Li Q, Li S, Wang J, Liu Q 2018 J. Phys. D: Appl. Phys. 51 025001

Google Scholar

Google Scholar

[22] Leva E S, Valente R C, Tabares F M, Mansilla M V 2010 Phys. Rev. B 82 144410

Google Scholar

Google Scholar

[23] Tu Y O 1981 J. Appl. Phys. 52 3130

Google Scholar

Google Scholar

[24] Debonte W J 1975 IEEE Trans. Magn. 11 3

Google Scholar

Google Scholar

[25] 郑富, 陈治鹏, 马亚楠, 周俊 2017 磁性材料及器件 48 19701

Google Scholar

Google Scholar

Zheng F, Chen Z P, Ma YN, Zhou J 2017 J. Magn. Mater. Devices 48 19701

Google Scholar

Google Scholar

[26] Patterson A L 1939 Phys. Rev. 56 978

Google Scholar

Google Scholar

[27] Soh W T, Phuoc N N, Tan C Y, Ong C K 2013 J. Appl. Phys. 114 053908

Google Scholar

Google Scholar

[28] Sultan M, Singh R 2010 JPCS 200 072090

Google Scholar

Google Scholar

[29] Shah L R, Fan X, Kou X, Wang W G, Zhang Y P, Lou J, Sun N X, Xiao J Q 2010 J. Appl. Phys. 107 09D909

Google Scholar

Google Scholar

[30] Bhoi B, Venkataramani N, Aiyar R, Prasad S, Kostylev M 2018 IEEE Trans. Magn. 54 2801205

Google Scholar

Google Scholar

计量

- 文章访问数: 11534

- PDF下载量: 88

- 被引次数: 0

下载:

下载: