-

In this paper, the phase field crystal method is used to study the dislocation motion and reaction of the square phase symmetric tilt low-angle grain boundaries, and the dislocation configurations with different misorientation angles are analyzed under the action of applied strain. The geometric phase approach is used to characterize the strain field around the dislocations. The results show that after the solidification relaxation, the interfacial dislocations on both sides of the grain are distributed in parallel but opposite direction. With the increase of misorientation angle between grains, the number of dislocations increases, the spacing between them decreases, and the free energy of the system increases. Imposed by the applied strain, the grain boundary dislocations undergo climbing, launching, and reactive annihilation, with the free energy fluctuating. When the misorientation increases, the dislocation motion mode changes from climbing to climbing-sliping, resulting in more dislocation group configurations, and more reactions between dislocations and dislocation groups. For the dislocation reactions of different configurations, positive shear strain drives dislocations to approach, and negative shear strain drives dislocations to annihilate.

-

Keywords:

- phase field crystal /

- square phase /

- dislocation reaction /

- grain boundary

[1] Elder K R, Katakowski M, Haataja M, Grant M 2002 Phys. Rev. Lett. 88 245701

Google Scholar

Google Scholar

[2] Elder K R, Grant M 2004 Phys. Rev. E 70 051605

Google Scholar

Google Scholar

[3] Elder K R, Provatas N, Berry J, Stefanovic P, Grant M 2007 Phys. Rev. B 75 064107

Google Scholar

Google Scholar

[4] 高英俊, 罗志荣, 黄创高, 卢强华, 林葵 2013 62 050507

Google Scholar

Google Scholar

Gao Y J, Luo Z R, Huang C G, Lu Q H, Lin K 2013 Acta Phys. Sin. 62 050507

Google Scholar

Google Scholar

[5] Yang T, Gao Y, Wang D, Shi R P, Chen Z, Nie J F, Li J, Wang Y 2017 Acta Mater. 127 481

Google Scholar

Google Scholar

[6] Greenwood M, Rottler J, Provatas N 2011 Phys. Rev. E 83 031601

Google Scholar

Google Scholar

[7] Gao Y J, Deng Q Q, Liu Z Y, Huang Z J, Li Y X, Luo Z R 2020 J. Mater. Sci. Technol. 49 236

Google Scholar

Google Scholar

[8] Gao Y J, Huang L L, Deng Q Q, Zhou W Q, Luo Z R, Lin K 2016 Acta Mater. 117 238

Google Scholar

Google Scholar

[9] 赵宇龙, 陈铮, 龙建, 杨涛 2013 62 118102

Google Scholar

Google Scholar

Zhao Y L, Chen Z, Long J, Yang T 2013 Acta Phys. Sin. 62 118102

Google Scholar

Google Scholar

[10] 赵宇龙, 陈铮, 龙建, 杨涛 2014 金属学报 27 81

Google Scholar

Google Scholar

Zhao Y L, Chen Z, Long J, Yang T 2014 Acta Metall. Sin. 27 81

Google Scholar

Google Scholar

[11] Gao Y J, Luo Z R, Huang L L, Mao H, Huang C G, Lin K 2016 Modell. Simul. Mater. Sci. 24 055010

Google Scholar

Google Scholar

[12] Hu S, Chen Z, Xi W, Peng Y Y 2017 J. Mater. Sci. 52 5641

Google Scholar

Google Scholar

[13] Seymour M, Sanches F, Elder K, Provatas N 2015 Phys. Rev. B 92 184109

Google Scholar

Google Scholar

[14] Faghihi N, Provatas N, Elder K R, Grant M, Karttunen M 2013 Phys. Rev. E 88 032407

Google Scholar

Google Scholar

[15] Berghoff M, Nestler B 2015 Comput. Condens. Matter 4 46

Google Scholar

Google Scholar

[16] Tang S, Wang Z J, Guo Y L, et al. 2012 Acta Mater. 60 5501

Google Scholar

Google Scholar

[17] 高英俊, 卢成健, 黄礼琳, 罗志荣, 黄创高 2014 金属学报 50 110

Google Scholar

Google Scholar

Gao Y J, Lu C J, Huang L L, Luo Z R, Huang C G 2014 Acta Metall. Sin. 50 110

Google Scholar

Google Scholar

[18] Hu S, Chen Z, Yu G G, Xi W, Peng Y Y 2016 Comput. Mater. Sci. 124 195

Google Scholar

Google Scholar

[19] Gutkin M Y, Ovid'ko I A 2001 Phys. Rev. B 63 064515

Google Scholar

Google Scholar

[20] Stefanovic P, Haataja M, Provatas N 2009 Phys. Rev. E 80 046107

Google Scholar

Google Scholar

[21] Bobylev S V, Gutkin M Y, Ovid'ko I A 2004 Phys. Solid State 46 2053

Google Scholar

Google Scholar

[22] Ohno T, Ii S, Shibata N, Matsunaga K, Ikuhara Y, Yamamoto T 2004 Mater. Trans. 45 2117

Google Scholar

Google Scholar

[23] Humphreys F J 2001 J. Mater. Sci. 36 3833

Google Scholar

Google Scholar

[24] Hirouchi T, Takaki T, Tomita Y 2009 Comput. Mater. Sci. 44 1192

Google Scholar

Google Scholar

[25] 龙建, 王诏玉, 赵宇龙, 龙清华, 杨涛, 陈铮 2013 62 218101

Google Scholar

Google Scholar

Long J, Wang Z Y, Zhao Y L, Long Q H, Yang T, Chen Z 2013 Acta Phys. Sin. 62 218101

Google Scholar

Google Scholar

[26] 鲁娜, 王永欣, 陈铮 2014 63 180508

Google Scholar

Google Scholar

Lu N, Wang Y X, Chen Z 2014 Acta Phys. Sin. 63 180508

Google Scholar

Google Scholar

[27] 杨涛, 陈铮, 董伟平 2011 金属学报 47 1301

Google Scholar

Google Scholar

Yang T, Chen Z, Dong W P 2011 Acta Metall. Sin. 47 1301

Google Scholar

Google Scholar

[28] Berkels B, Ratz A, Rumpf M, Voigt A 2008 J. Sci. Comput. 35 1

Google Scholar

Google Scholar

[29] Elsey M, Wirth B 2014 Multiscale Model. Sim. 12 1

Google Scholar

Google Scholar

[30] Singer H M, Singer I 2006 Phys. Rev. E 74 031103

Google Scholar

Google Scholar

[31] Wang Z J, Li J J, Guo Y L, Tang S, Wang J C 2013 Comput. Phys. Commun. 184 2489

Google Scholar

Google Scholar

[32] Hytch M J, Snoeck E, Kilaas R 1998 Ultramicroscopy 74 131

Google Scholar

Google Scholar

[33] Galindo P L, Kret S, Sanchez A M, et al. 2007 Ultramicroscopy 107 1186

Google Scholar

Google Scholar

[34] Hytch M J, Putaux J L, Penisson J M 2003 Nature 423 270

Google Scholar

Google Scholar

[35] Guo Y, Wang J, Wang Z, Li J, Tang S, Liu F, Zhou Y 2015 Philos. Mag. 95 973

Google Scholar

Google Scholar

[36] Wu K A, Adland A, Karma A 2010 Phys. Rev. E 81 061601

Google Scholar

Google Scholar

[37] Chen L Q, Shen J 1998 Comput. Phys. Commun. 108 147

Google Scholar

Google Scholar

-

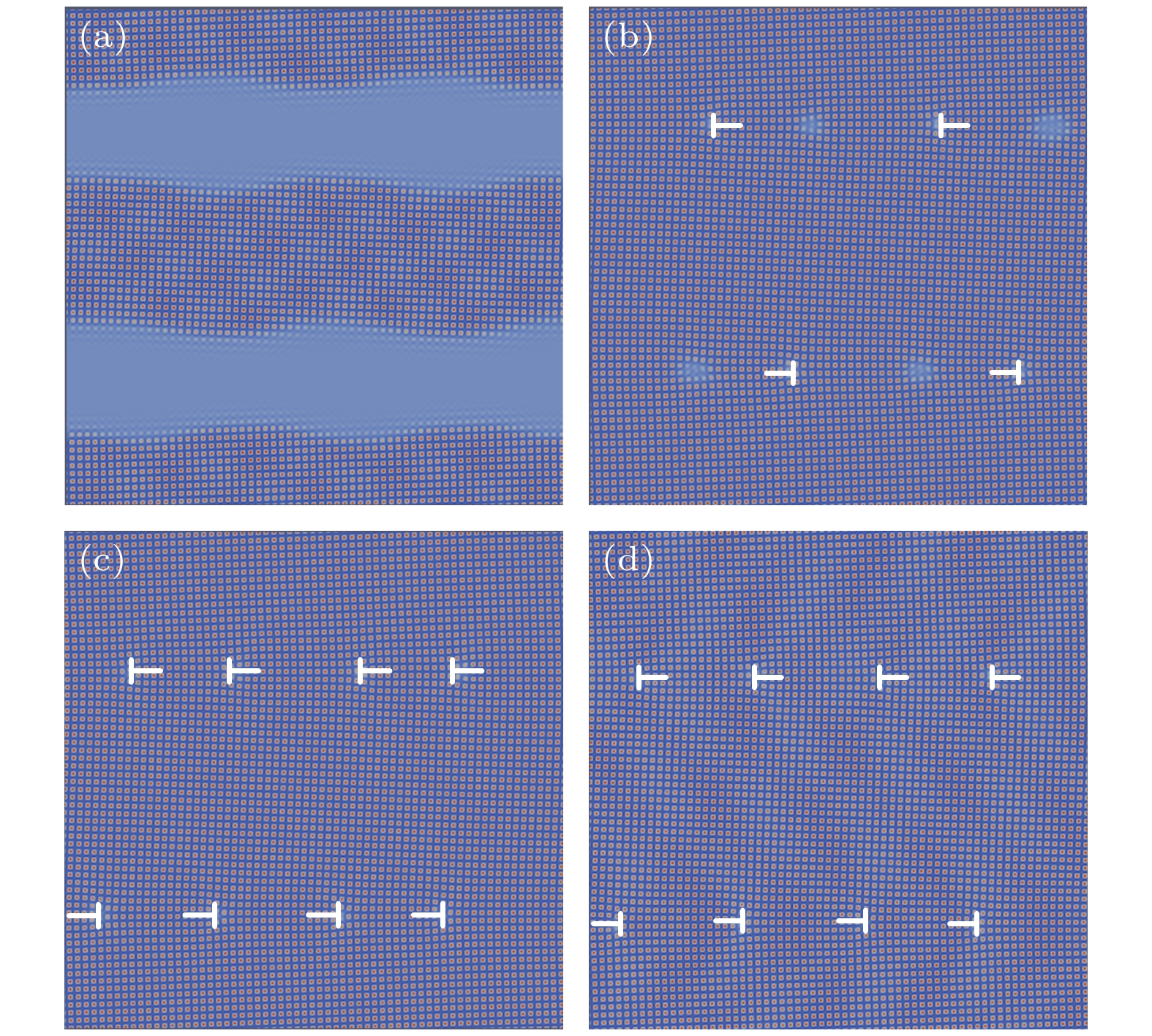

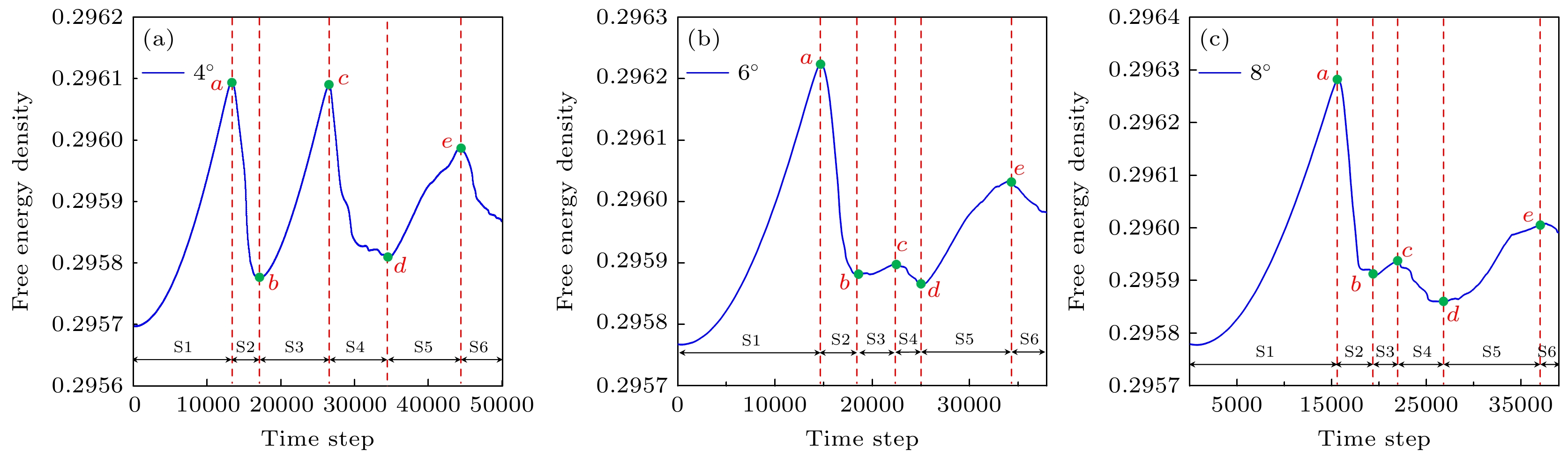

图 6 应变作用下

$ \theta ={4} $ °时晶界位错运动模拟图 (a) t = 50; (b) t = 14150; (c) t = 15250; (d) t = 17550; (e) t = 29100; (f) t = 48500. 图6(a)中插图(g)和(h)分别表示刃位错的类型和位错对应的伯氏矢量类型Figure 6. Simulation of grain boundary dislocation motion under strain with

$ \theta ={4} $ °: (a) t = 50; (b) t = 14150; (c) t = 15250; (d) t = 17550; (e) t = 29100; (f) t = 48500. Inset (g) and (h) represent the type of edge dislocation and the Burgers vector type respectively corresponding to the dislocation in Fig. 6(a).图 7 应变作用下

$ \theta ={6} $ °时晶界位错运动模拟图 (a) t = 50; (b) t = 15000; (c) t = 16350; (d) t = 19550; (e) t = 23500; (f) t = 26950Figure 7. Simulation of grain boundary dislocation motion under strain with

$ \theta ={6} $ °: (a) t = 50; (b) t = 15000; (c) t = 16350; (d) t = 19550; (e) t = 23500; (f) t = 26950.图 8 应变作用下

$ \theta ={8} $ °时晶界位错运动模拟图 (a) t = 100; (b) t = 16350; (c) t = 17500; (d) t = 20400; (e) t = 25000; (f) t = 34750Figure 8. Simulation of grain boundary dislocation motion under strain with

$ \theta ={8} $ °: (a) t = 100; (b) t = 16350; (c) t = 17500; (d) t = 20400; (e) t = 25000; (f) t = 34750.图 10 含位错组的晶体位错构型及对应的不同应变取向应变云图 (a) 晶体构型图; (b)

${\varepsilon }_{xx}$ ; (c)${\varepsilon }_{xy}$ ; (d)${\varepsilon }_{yy}$ Figure 10. Dislocation configuration of crystals containing dislocation groups and corresponding strain contours of different strain orientations: (a) Crystal configuration diagram; (b)

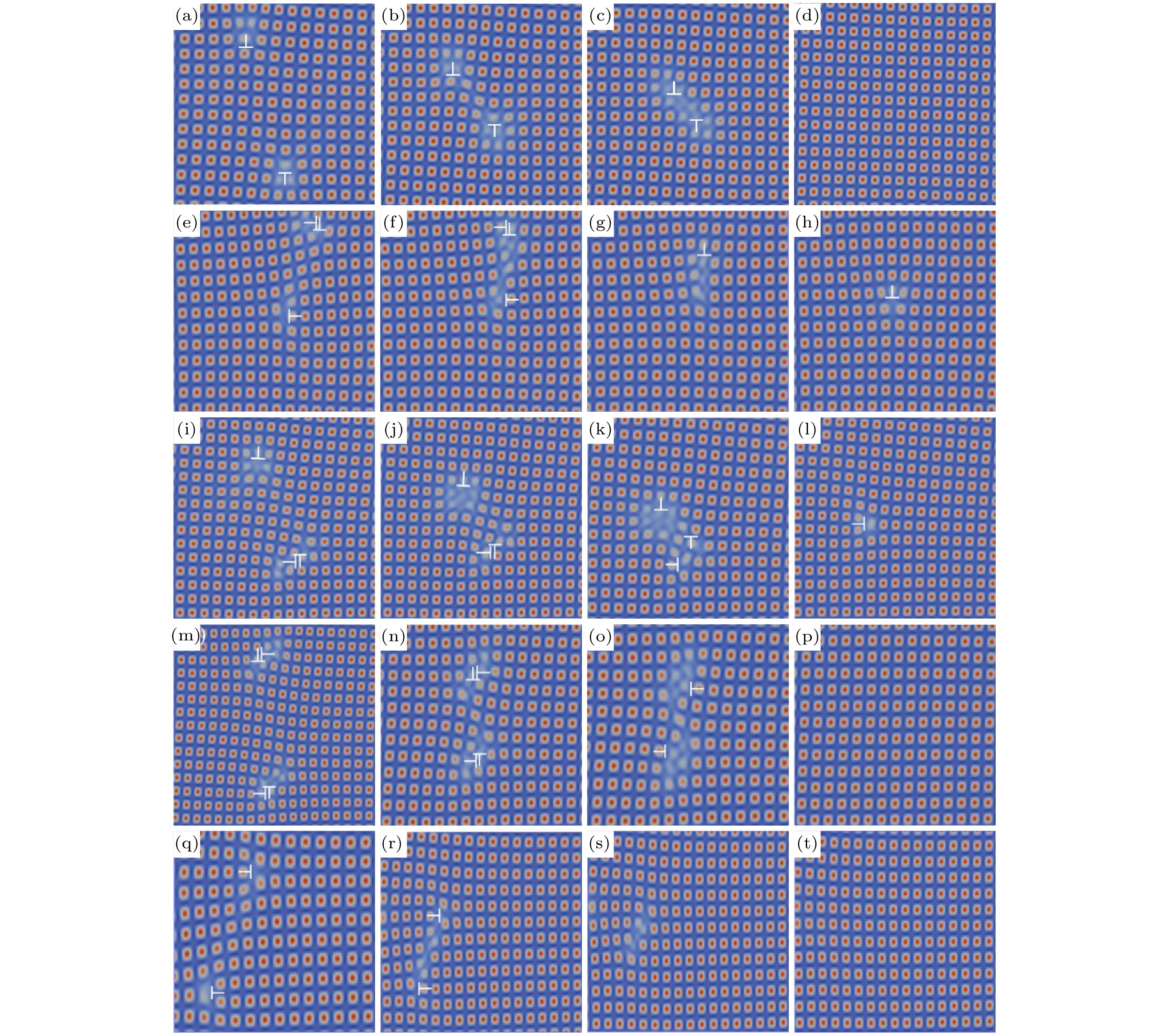

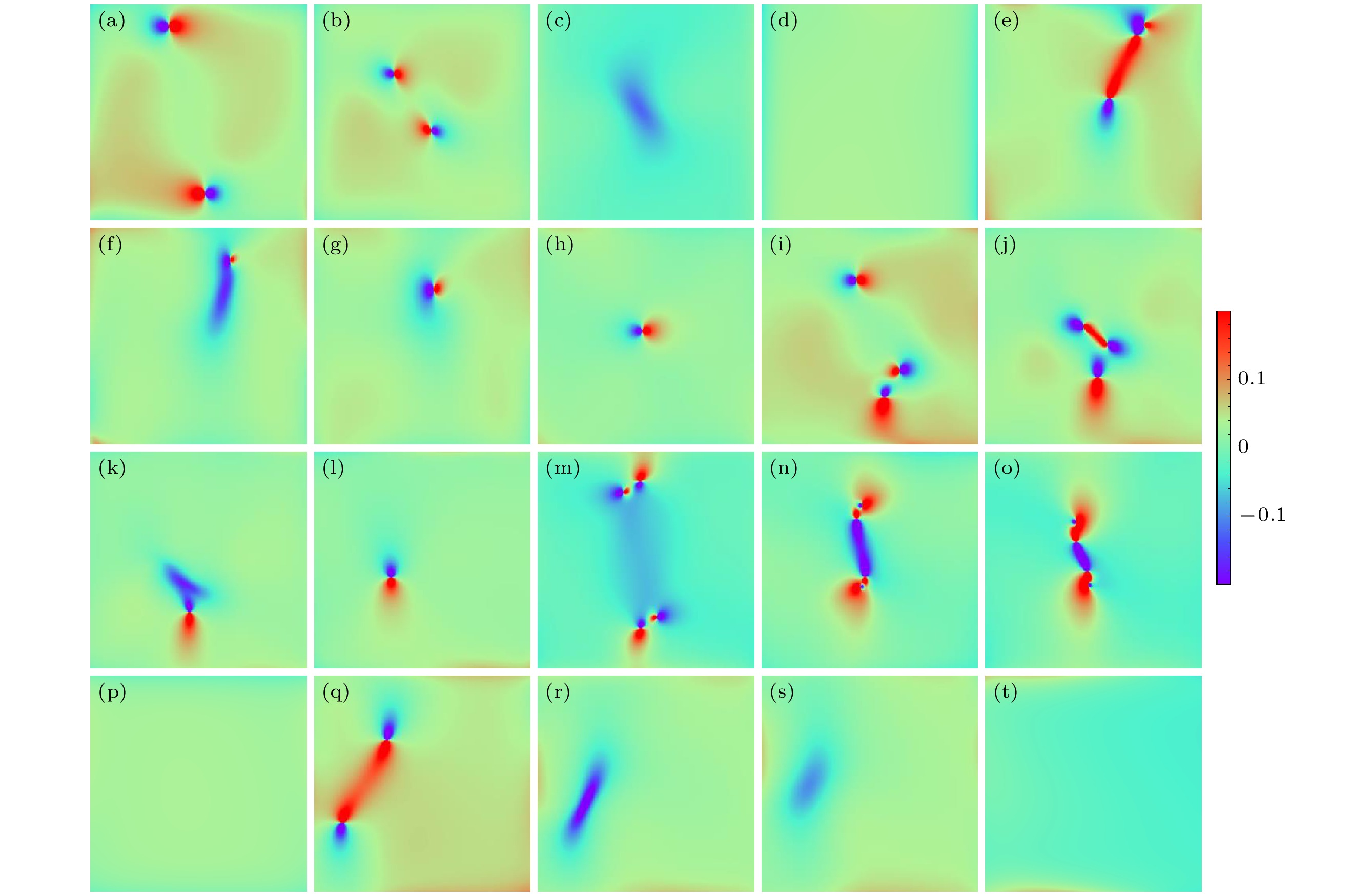

${\varepsilon }_{xx}$ ; (c)${\varepsilon }_{xy}$ ; (d)${\varepsilon }_{yy}$ .图 12 不同位错反应构型演化时应变(

${\varepsilon }_{xy}$ )云图 (a)—(d) R1构型; (e)—(h) R2构型; (i)—(l) R3构型; (m)—(p) R4构型; (q)—(t) R5构型Figure 12. Strain (

${\varepsilon }_{xy}$ ) contours during the evolution of different dislocation reaction configurations: (a)–(d) R1 configuration; (e)–(h) R2 configuration; (i)–(l) R3 configuration; (m)–(p) R4 configuration; (q)–(t) R5 configuration.表 1 模拟设定的参数

Table 1. Parameters in the simulation.

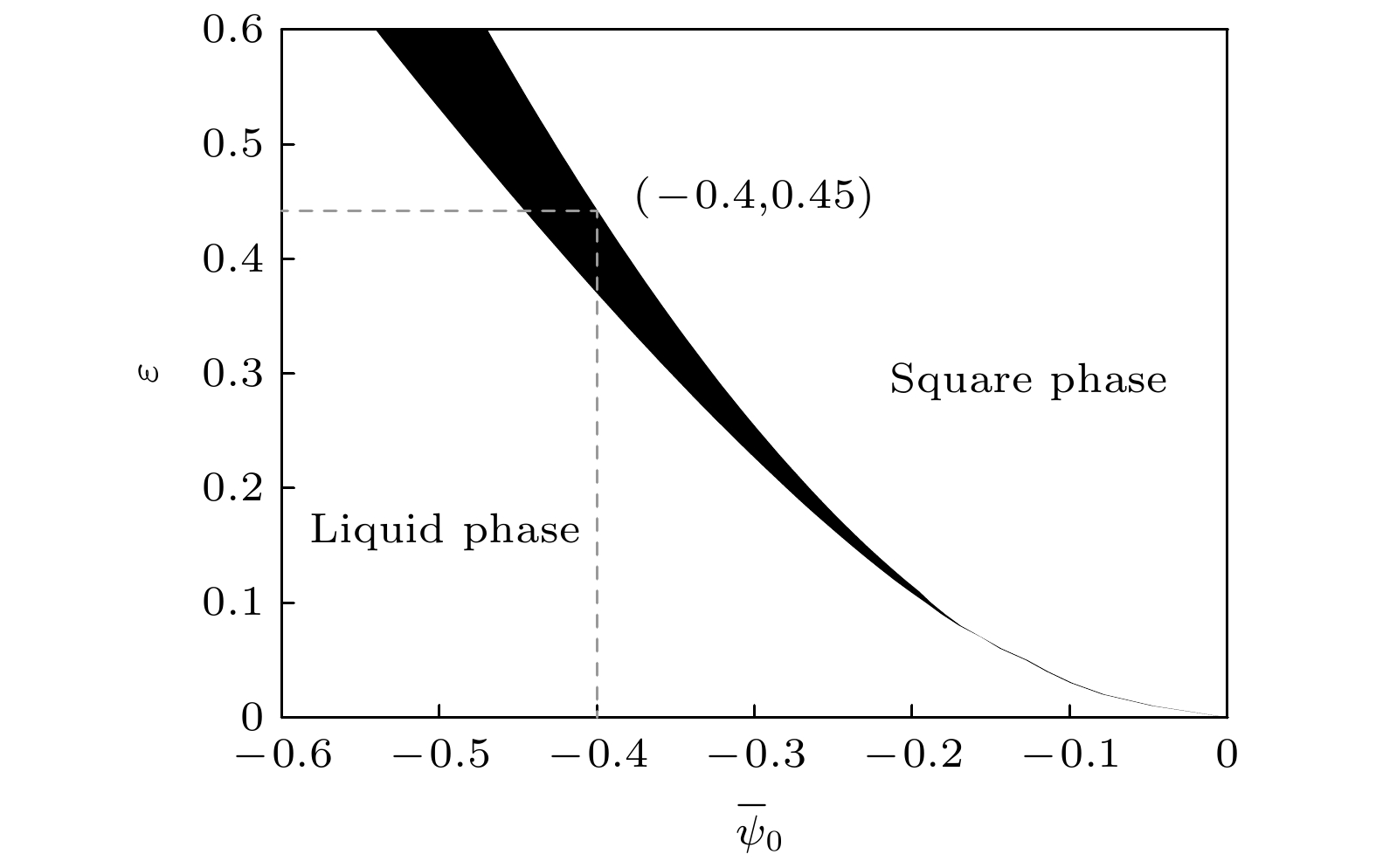

方案 初始原子密度$ {\overline \psi _0} $ 温度相关参量ε 取向差θ A $-0.40$ $ 0.45 $ $ {4} $° B $-0.40$ $ 0.45 $ $ {6} $° C $-0.40$ $ 0.45 $ $ {8} $° 表 2 不同构型的位错分解发射与位错反应

Table 2. Dislocation decomposition and dislocation reaction of different configuration.

编号 位错分解发射 编号 位错反应 L1 $n1\xrightarrow{\text{分解}}n1+n3+n4$ R1 $ n3+n4\xrightarrow{\text{反应}} 0 $ $ n2 \xrightarrow{\text{分解}} n2+n3+n4 $ R2 $n1+\overline{n2 n4}\xrightarrow{\text{反应} }n4,$

$n2+\overline{n2 n3}\xrightarrow{\text{反应}}n4$L2 $n1\xrightarrow{\text{分解}}\overline{n1 n3}+n4$ R3 $n3+\overline{n2 n4}\xrightarrow{\text{反应} }n2,$

$n4+\overline{n1 n3}\xrightarrow{\text{反应}}n1$$n2\xrightarrow{\text{分解}}\overline{n2 n3}+n4$ R4 $\overline{n1 n3}+\overline{n2 n4}\xrightarrow{\text{反应} }0,$

$\overline{n1 n4}+\overline{n2 n3}\xrightarrow{\text{反应}}0$L3 $n1\xrightarrow{\text{分解}}\overline{n1 n4}+n3$ R5 $ n1+n2\xrightarrow{\text{反应}}0 $ $n2\xrightarrow{\text{分解}}\overline{n2 n4}+n3$ -

[1] Elder K R, Katakowski M, Haataja M, Grant M 2002 Phys. Rev. Lett. 88 245701

Google Scholar

Google Scholar

[2] Elder K R, Grant M 2004 Phys. Rev. E 70 051605

Google Scholar

Google Scholar

[3] Elder K R, Provatas N, Berry J, Stefanovic P, Grant M 2007 Phys. Rev. B 75 064107

Google Scholar

Google Scholar

[4] 高英俊, 罗志荣, 黄创高, 卢强华, 林葵 2013 62 050507

Google Scholar

Google Scholar

Gao Y J, Luo Z R, Huang C G, Lu Q H, Lin K 2013 Acta Phys. Sin. 62 050507

Google Scholar

Google Scholar

[5] Yang T, Gao Y, Wang D, Shi R P, Chen Z, Nie J F, Li J, Wang Y 2017 Acta Mater. 127 481

Google Scholar

Google Scholar

[6] Greenwood M, Rottler J, Provatas N 2011 Phys. Rev. E 83 031601

Google Scholar

Google Scholar

[7] Gao Y J, Deng Q Q, Liu Z Y, Huang Z J, Li Y X, Luo Z R 2020 J. Mater. Sci. Technol. 49 236

Google Scholar

Google Scholar

[8] Gao Y J, Huang L L, Deng Q Q, Zhou W Q, Luo Z R, Lin K 2016 Acta Mater. 117 238

Google Scholar

Google Scholar

[9] 赵宇龙, 陈铮, 龙建, 杨涛 2013 62 118102

Google Scholar

Google Scholar

Zhao Y L, Chen Z, Long J, Yang T 2013 Acta Phys. Sin. 62 118102

Google Scholar

Google Scholar

[10] 赵宇龙, 陈铮, 龙建, 杨涛 2014 金属学报 27 81

Google Scholar

Google Scholar

Zhao Y L, Chen Z, Long J, Yang T 2014 Acta Metall. Sin. 27 81

Google Scholar

Google Scholar

[11] Gao Y J, Luo Z R, Huang L L, Mao H, Huang C G, Lin K 2016 Modell. Simul. Mater. Sci. 24 055010

Google Scholar

Google Scholar

[12] Hu S, Chen Z, Xi W, Peng Y Y 2017 J. Mater. Sci. 52 5641

Google Scholar

Google Scholar

[13] Seymour M, Sanches F, Elder K, Provatas N 2015 Phys. Rev. B 92 184109

Google Scholar

Google Scholar

[14] Faghihi N, Provatas N, Elder K R, Grant M, Karttunen M 2013 Phys. Rev. E 88 032407

Google Scholar

Google Scholar

[15] Berghoff M, Nestler B 2015 Comput. Condens. Matter 4 46

Google Scholar

Google Scholar

[16] Tang S, Wang Z J, Guo Y L, et al. 2012 Acta Mater. 60 5501

Google Scholar

Google Scholar

[17] 高英俊, 卢成健, 黄礼琳, 罗志荣, 黄创高 2014 金属学报 50 110

Google Scholar

Google Scholar

Gao Y J, Lu C J, Huang L L, Luo Z R, Huang C G 2014 Acta Metall. Sin. 50 110

Google Scholar

Google Scholar

[18] Hu S, Chen Z, Yu G G, Xi W, Peng Y Y 2016 Comput. Mater. Sci. 124 195

Google Scholar

Google Scholar

[19] Gutkin M Y, Ovid'ko I A 2001 Phys. Rev. B 63 064515

Google Scholar

Google Scholar

[20] Stefanovic P, Haataja M, Provatas N 2009 Phys. Rev. E 80 046107

Google Scholar

Google Scholar

[21] Bobylev S V, Gutkin M Y, Ovid'ko I A 2004 Phys. Solid State 46 2053

Google Scholar

Google Scholar

[22] Ohno T, Ii S, Shibata N, Matsunaga K, Ikuhara Y, Yamamoto T 2004 Mater. Trans. 45 2117

Google Scholar

Google Scholar

[23] Humphreys F J 2001 J. Mater. Sci. 36 3833

Google Scholar

Google Scholar

[24] Hirouchi T, Takaki T, Tomita Y 2009 Comput. Mater. Sci. 44 1192

Google Scholar

Google Scholar

[25] 龙建, 王诏玉, 赵宇龙, 龙清华, 杨涛, 陈铮 2013 62 218101

Google Scholar

Google Scholar

Long J, Wang Z Y, Zhao Y L, Long Q H, Yang T, Chen Z 2013 Acta Phys. Sin. 62 218101

Google Scholar

Google Scholar

[26] 鲁娜, 王永欣, 陈铮 2014 63 180508

Google Scholar

Google Scholar

Lu N, Wang Y X, Chen Z 2014 Acta Phys. Sin. 63 180508

Google Scholar

Google Scholar

[27] 杨涛, 陈铮, 董伟平 2011 金属学报 47 1301

Google Scholar

Google Scholar

Yang T, Chen Z, Dong W P 2011 Acta Metall. Sin. 47 1301

Google Scholar

Google Scholar

[28] Berkels B, Ratz A, Rumpf M, Voigt A 2008 J. Sci. Comput. 35 1

Google Scholar

Google Scholar

[29] Elsey M, Wirth B 2014 Multiscale Model. Sim. 12 1

Google Scholar

Google Scholar

[30] Singer H M, Singer I 2006 Phys. Rev. E 74 031103

Google Scholar

Google Scholar

[31] Wang Z J, Li J J, Guo Y L, Tang S, Wang J C 2013 Comput. Phys. Commun. 184 2489

Google Scholar

Google Scholar

[32] Hytch M J, Snoeck E, Kilaas R 1998 Ultramicroscopy 74 131

Google Scholar

Google Scholar

[33] Galindo P L, Kret S, Sanchez A M, et al. 2007 Ultramicroscopy 107 1186

Google Scholar

Google Scholar

[34] Hytch M J, Putaux J L, Penisson J M 2003 Nature 423 270

Google Scholar

Google Scholar

[35] Guo Y, Wang J, Wang Z, Li J, Tang S, Liu F, Zhou Y 2015 Philos. Mag. 95 973

Google Scholar

Google Scholar

[36] Wu K A, Adland A, Karma A 2010 Phys. Rev. E 81 061601

Google Scholar

Google Scholar

[37] Chen L Q, Shen J 1998 Comput. Phys. Commun. 108 147

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8038

- PDF Downloads: 90

- Cited By: 0

DownLoad:

DownLoad: