-

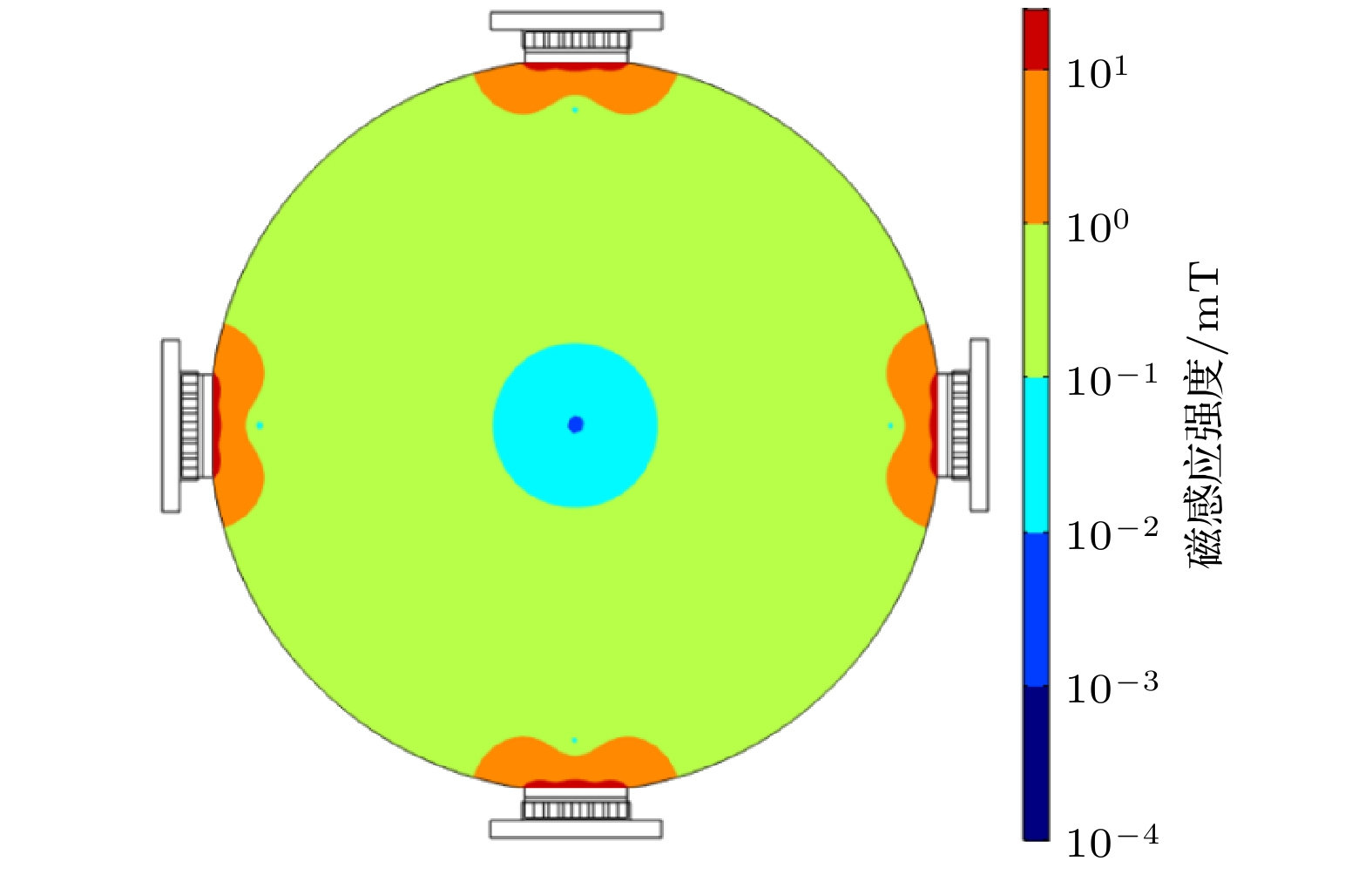

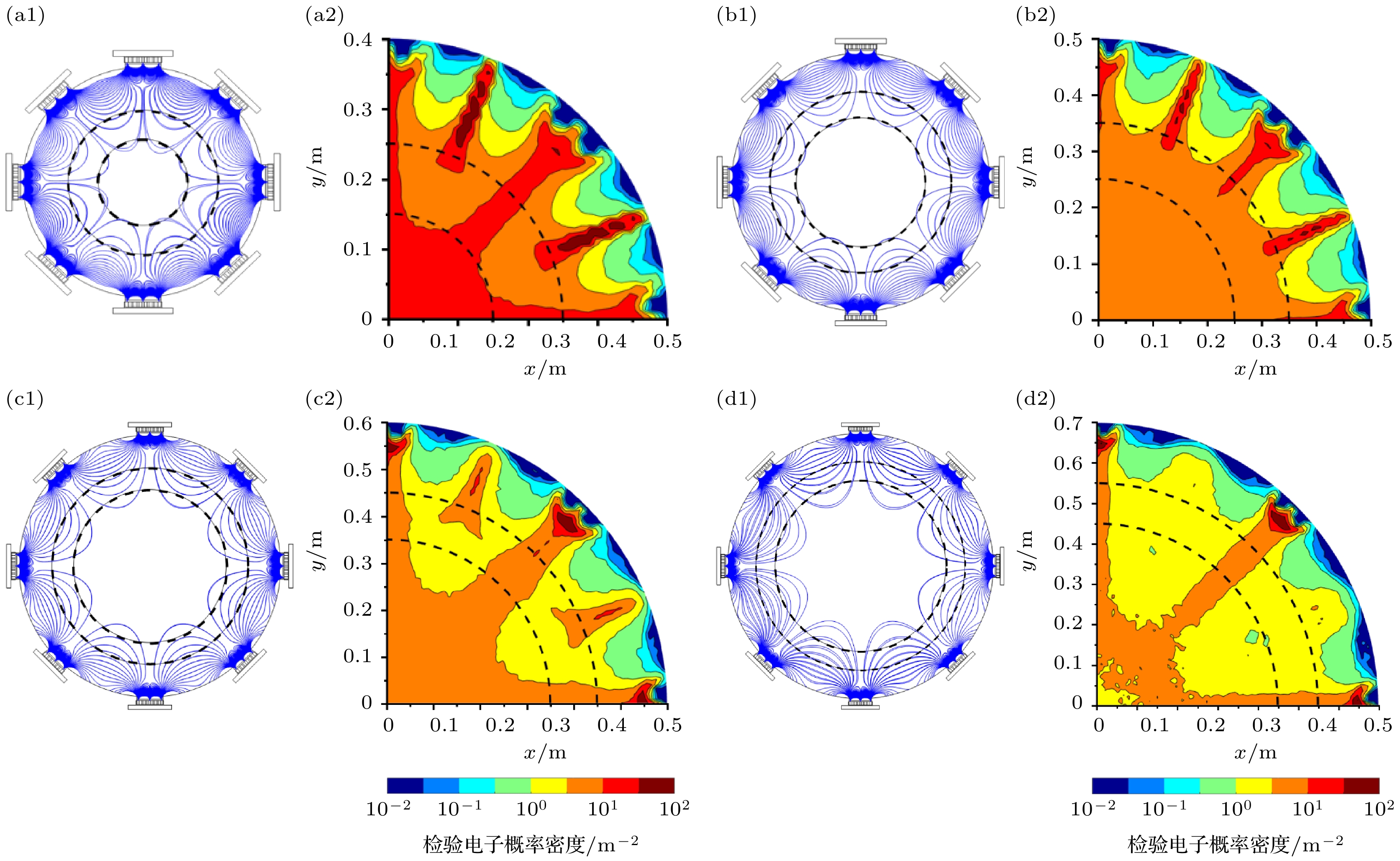

Closed magnetic field constructed by unbalanced magnetron sputtering (MS) cathodes has been a general means of developing the MS coating system. However, owing to the difficulties in characterizing the complex plasma behaviors, there are still no quantitative criteria or design bases for some critical points, such as the effective object, the working mechanism, the closure condition, the layout logic and the effectivity of the closed magnetic field. Here in this work, out of the movements of charged particles in magnetic field, the motion behaviors of electrons and ions in the vacuum chamber are studied and it is also revealed that the closed magnetic field can affect mainly the electrons and further control the distributions of ions. A Monte-Carlo collision (MCC) model of the closed magnetic field MS coating system is established by test-electron to characterize the plasma transport characteristics, and the electron constraint and coating deposition efficiency are studied by different layouts of the magnetron cathodes and the ion sources. The simulation results show that the cathode numbers and vacuum chamber size determine the constraint effect on electrons in closed magnetic field. By 8 MS cathodes and the chamber radius of 0.5 m, the proportion of the overflow electrons can decrease to 1.77%. To increase the proportion of the electrons in the coating region, four coupled magnetic fields are introduced in the center of vacuum chamber. The studies of cathode type, rotation angle and magnetic field direction reveal that the proportion of the overflow electrons is less than 3%. A local dense plasma distribution and a continuous uniform plasma distribution can be observed in the vacuum chamber, corresponding to the same and opposite layout in magnetic poles of the MS cathodes and the ion sources, and the proportion of the electrons in the coating region significantly increases to 53.41% and 42.25%, respectively.

-

Keywords:

- closed magnetic field /

- electron motion /

- vacuum layout /

- deposition efficiency

[1] Window B, Savvides N 1986 J. Vac. Sci. Technol. A-Vac. Surf. Films 4 196

Google Scholar

Google Scholar

[2] Window B 1986 J. Vac. Sci. Technol. A-Vac. Surf. Films 4 453

Google Scholar

Google Scholar

[3] Savvides N, Window B 1986 J. Vac. Sci. Technol. A 4 504

Google Scholar

Google Scholar

[4] Kelly P J, Arnell R D, Ahmed W, Afzal A 1996 Mater. Des. 17 215

Google Scholar

Google Scholar

[5] Monaghan D P, Teer D G, Laing K C, Efeoglu I, Arnell R D 1993 Surf. Coat. Technol. 59 21

Google Scholar

Google Scholar

[6] Arnell R D, Kelly P J 1999 Surf. Coat. Technol. 112 170

Google Scholar

Google Scholar

[7] Zhou J, Wu Z, Liu Z H 2008 J. Univ. Sci. Technol. Beijing Miner. Metallurgy Mater. 15 775

[8] Kelly P J, Aenell R D 1998 Surf. Coat. Technol. 108 317

[9] Kelly P J, Arnell R D 1998 J. Vac. Sci. Technol. A-Vac. Surf. Films 16 2858

Google Scholar

Google Scholar

[10] Rohde S L, Petrov I, Sproul W D, Barnett S A, Rudnik P J, Graham M E 1990 Thin Solid Films 193 117

[11] Sproul W D, Rudnik P J, Graham M E, Rohde S L 1990 Surf. Coat. Technol. 43 270

[12] 蒋百灵, 曹政, 鲁媛媛, 栾亚 2011 材料热处理学报 32 92

Jiang B L, Cao Z, Lu Y Y, Luan Y 2011 Transact. mater. heat treatment 32 92

[13] Kelly P J, Arnell R D 1996 Surf. Coat. Technol. 86–87 425

[14] Kelly P J, Arnell R D 1998 Vacuum 49 43

Google Scholar

Google Scholar

[15] 迈克尔·A. 力伯曼, 阿伦·J. 里登伯格著(浦以康 译) 2007 等离子体放电原理与材料处理 (北京: 科学出版社) 第18—30页

Lieberman M A, Lichtenberg A J (translated by Pu Y K) 2007 Principles of Plasma Discharges and Materials Processing (Beijing: Science Press) pp5–7 (in Chinese)

[16] 曹政, 蒋百灵, 鲁媛媛, 王陶 2011 材料研究学报 25 313

Cao Z, Jiang B L, Lu Y Y, Wang T 2011 Chin. J. Mater. Res. 25 313

[17] 陈明, 周细应, 毛秀娟, 邵佳佳, 杨国良 2014 63 098103

Google Scholar

Google Scholar

Chen M, Zhou X Y, Mao X J, Shao J J, Yang G L 2014 Acta Phys. Sin. 63 098103

Google Scholar

Google Scholar

[18] Yusupov M, Bultinck E, Depla D, Bogaerts 2011 New J. Phys. 13 033018

Google Scholar

Google Scholar

[19] Bultinck E, Bogaerts A 2009 New J. Phys. 11 103010

Google Scholar

Google Scholar

[20] 汪天龙, 邱清泉, 靖立伟, 张小波 2018 67 070703

Google Scholar

Google Scholar

Wang T L, Qiu Q Q, Jing L W, Zhang X B 2018 Acta Phys. Sin. 67 070703

Google Scholar

Google Scholar

[21] Shidoji E, Ohtake H, Nakano N, Makabe T 1999 Jpn. J. Appl. Phys. Part 1 38 2131

[22] Kim J S, Liu C, Edgell D H, Pardo R 2006 Rev. Sci. Instrum. 77 03B106

Google Scholar

Google Scholar

[23] 崔岁寒, 吴忠振, 肖舒, 陈磊, 李体军, 刘亮亮, 傅劲裕, 田修波, 朱剑豪, 谭文长 2019 68 195204

Cui S H, Wu Z Z, Xiao S, Chen L, Li T J, Liu L L, Fu J Y, Tian X B, Zhu J H, Tan W C 2019 Acta Phys. Sin 68 195204

[24] Rossnagel S M, Kaufman H R 1987 J. Vac. Sci. Technol. A-Vac. Surf. Films 5 2276

Google Scholar

Google Scholar

[25] Rossnagel S M, Kaufman H R 1988 J. Vac. Sci. Technol. A-Vac. Surf. Films 6 223

Google Scholar

Google Scholar

[26] 弗朗西斯F. 陈(林光海 译) 1980 等离子体物理学导论 (北京: 科学出版社) 第5—7页

Chen F F (translated by Lin G H) 1980 Introduction to Plasma Physics (Beijing: Science Press) pp5–7 (in Chinese)

[27] Sirghi L, Aoki T, Hatanaka Y 2004 Surf. Coat. Technol. 187 358

Google Scholar

Google Scholar

[28] Chen L, Cui S H, Tang W, Zhou L, Li T J, Liu L L, An X K, Wu Z C, Ma Z Y, Lin H, Tian X B, Fu J Y, Chu P K, Wu Z Z 2020 Plasma Sources Sci. Technol. 29 025016

Google Scholar

Google Scholar

[29] Birdsall C K 1991 IEEE Trans. Plasma Sci. 19 65

Google Scholar

Google Scholar

[30] Samuelsson M, Lundin D, Jensen J, Raadu M A, Gudmundsson J T, Helmersson U 2010 Surf. Coat. Tech. 205 591

Google Scholar

Google Scholar

-

表 1 电子参与的Ar放电主要反应表

Table 1. Reactions of Ar discharge involving electrons.

序号 反应方程式 反应类型 反应能量阈值/eV 1 e + Ar → Ar+ + 2e 电离碰撞 15.7 2 e + Ar → Arm + e 激发碰撞 11.5 3 e + Ar → Ar + e 弹性碰撞 — 表 2 不同数量阴极构成的闭合磁场中30 μs电子运动情况统计

Table 2. Statistics of electron motion in closed magnetic field composed of 4, 6, 8 and 10 cathodes at 30 μs.

阴极数量 电子溢出比例/% 镀膜区域电子占比/% 4 7.57 22.77 6 4.45 25.78 8 1.77 27.53 10 0.10 26.87 表 3 不同真空室尺寸构成的闭合磁场中30 μs电子运动情况统计

Table 3. Statistics of electron motion in closed magnetic field with different sizes at 30 μs.

真空室尺寸/mm 电子溢出比例/% 镀膜区域电子占比/% 400 0.82 29.93 500 1.77 27.53 600 3.95 21.59 700 5.49 19.13 -

[1] Window B, Savvides N 1986 J. Vac. Sci. Technol. A-Vac. Surf. Films 4 196

Google Scholar

Google Scholar

[2] Window B 1986 J. Vac. Sci. Technol. A-Vac. Surf. Films 4 453

Google Scholar

Google Scholar

[3] Savvides N, Window B 1986 J. Vac. Sci. Technol. A 4 504

Google Scholar

Google Scholar

[4] Kelly P J, Arnell R D, Ahmed W, Afzal A 1996 Mater. Des. 17 215

Google Scholar

Google Scholar

[5] Monaghan D P, Teer D G, Laing K C, Efeoglu I, Arnell R D 1993 Surf. Coat. Technol. 59 21

Google Scholar

Google Scholar

[6] Arnell R D, Kelly P J 1999 Surf. Coat. Technol. 112 170

Google Scholar

Google Scholar

[7] Zhou J, Wu Z, Liu Z H 2008 J. Univ. Sci. Technol. Beijing Miner. Metallurgy Mater. 15 775

[8] Kelly P J, Aenell R D 1998 Surf. Coat. Technol. 108 317

[9] Kelly P J, Arnell R D 1998 J. Vac. Sci. Technol. A-Vac. Surf. Films 16 2858

Google Scholar

Google Scholar

[10] Rohde S L, Petrov I, Sproul W D, Barnett S A, Rudnik P J, Graham M E 1990 Thin Solid Films 193 117

[11] Sproul W D, Rudnik P J, Graham M E, Rohde S L 1990 Surf. Coat. Technol. 43 270

[12] 蒋百灵, 曹政, 鲁媛媛, 栾亚 2011 材料热处理学报 32 92

Jiang B L, Cao Z, Lu Y Y, Luan Y 2011 Transact. mater. heat treatment 32 92

[13] Kelly P J, Arnell R D 1996 Surf. Coat. Technol. 86–87 425

[14] Kelly P J, Arnell R D 1998 Vacuum 49 43

Google Scholar

Google Scholar

[15] 迈克尔·A. 力伯曼, 阿伦·J. 里登伯格著(浦以康 译) 2007 等离子体放电原理与材料处理 (北京: 科学出版社) 第18—30页

Lieberman M A, Lichtenberg A J (translated by Pu Y K) 2007 Principles of Plasma Discharges and Materials Processing (Beijing: Science Press) pp5–7 (in Chinese)

[16] 曹政, 蒋百灵, 鲁媛媛, 王陶 2011 材料研究学报 25 313

Cao Z, Jiang B L, Lu Y Y, Wang T 2011 Chin. J. Mater. Res. 25 313

[17] 陈明, 周细应, 毛秀娟, 邵佳佳, 杨国良 2014 63 098103

Google Scholar

Google Scholar

Chen M, Zhou X Y, Mao X J, Shao J J, Yang G L 2014 Acta Phys. Sin. 63 098103

Google Scholar

Google Scholar

[18] Yusupov M, Bultinck E, Depla D, Bogaerts 2011 New J. Phys. 13 033018

Google Scholar

Google Scholar

[19] Bultinck E, Bogaerts A 2009 New J. Phys. 11 103010

Google Scholar

Google Scholar

[20] 汪天龙, 邱清泉, 靖立伟, 张小波 2018 67 070703

Google Scholar

Google Scholar

Wang T L, Qiu Q Q, Jing L W, Zhang X B 2018 Acta Phys. Sin. 67 070703

Google Scholar

Google Scholar

[21] Shidoji E, Ohtake H, Nakano N, Makabe T 1999 Jpn. J. Appl. Phys. Part 1 38 2131

[22] Kim J S, Liu C, Edgell D H, Pardo R 2006 Rev. Sci. Instrum. 77 03B106

Google Scholar

Google Scholar

[23] 崔岁寒, 吴忠振, 肖舒, 陈磊, 李体军, 刘亮亮, 傅劲裕, 田修波, 朱剑豪, 谭文长 2019 68 195204

Cui S H, Wu Z Z, Xiao S, Chen L, Li T J, Liu L L, Fu J Y, Tian X B, Zhu J H, Tan W C 2019 Acta Phys. Sin 68 195204

[24] Rossnagel S M, Kaufman H R 1987 J. Vac. Sci. Technol. A-Vac. Surf. Films 5 2276

Google Scholar

Google Scholar

[25] Rossnagel S M, Kaufman H R 1988 J. Vac. Sci. Technol. A-Vac. Surf. Films 6 223

Google Scholar

Google Scholar

[26] 弗朗西斯F. 陈(林光海 译) 1980 等离子体物理学导论 (北京: 科学出版社) 第5—7页

Chen F F (translated by Lin G H) 1980 Introduction to Plasma Physics (Beijing: Science Press) pp5–7 (in Chinese)

[27] Sirghi L, Aoki T, Hatanaka Y 2004 Surf. Coat. Technol. 187 358

Google Scholar

Google Scholar

[28] Chen L, Cui S H, Tang W, Zhou L, Li T J, Liu L L, An X K, Wu Z C, Ma Z Y, Lin H, Tian X B, Fu J Y, Chu P K, Wu Z Z 2020 Plasma Sources Sci. Technol. 29 025016

Google Scholar

Google Scholar

[29] Birdsall C K 1991 IEEE Trans. Plasma Sci. 19 65

Google Scholar

Google Scholar

[30] Samuelsson M, Lundin D, Jensen J, Raadu M A, Gudmundsson J T, Helmersson U 2010 Surf. Coat. Tech. 205 591

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8828

- PDF Downloads: 136

- Cited By: 0

DownLoad:

DownLoad: