-

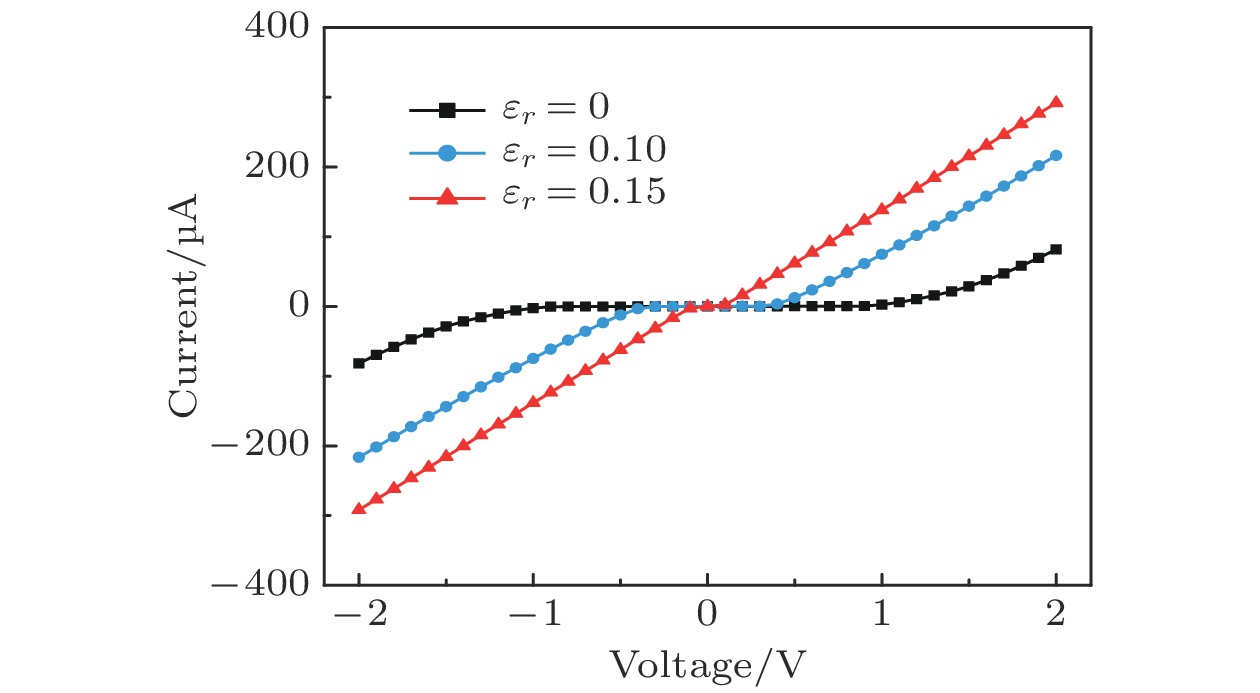

In this paper, molecular dynamics simulation method is used to investigate the contacting configuration of carbon nanotubes with open ends and metal, thereby obtaining the law of radial compression deformation of carbon nanotubes. The obtained results show that after horizontally contacting the metal surface, the radial compression deformation is affected by the contact length, the diameter of the tube, the type of metal and the number of layers. Based on the first principles combining tight-binding density functional theory and non-equilibrium Green's function, the electron transport properties of carbon nanotubes with different diameters, chiralities, lamellar deformations and radial deformations are systematically studied. The obtained results show that the current of metallic single-walled carbon nanotubes presents linear change in a bias voltage range between –2 V and 2 V, and the current-voltage curve is symmetrical about the origin. The magnitude of the current is only related to the bias voltage, but not to the diameter; when the carbon nanotubes are deformed by radial compression, the current growth trend is downward and even plateau effect may appear under a larger bias voltage. The current flowing in the semiconducting single-walled carbon nanotubes decreases with the increase of radial compression deformation, and the current-voltage curve gradually transforms from semiconductor characteristics into metallic characteristics. The trend of the current-voltage curve of double-walled carbon nanotubes is consistent with that of metallic single-walled carbon nanotubes. However, the non-linear variation amplitude of the current-voltage curve of double-walled carbon nanotubes is less affected by the radial compression deformation. Owing to the increase of walls of nanotubes, the current of double-walled carbon nanotubes is twice as high as that of single-walled carbon nanotubes under the same bias voltage. The electrons can produce transitions through rapid vibration between adjacent tubes, in view of the fact that interlayer coupling characteristics of three-walled carbon nanotubes reduce the degeneracy of the energy level and larger system increases the density of states near the Fermi level, resulting in large oscillations and asymmetry about the origin of the current-voltage curve.

[1] 王亚洲, 马立, 杨权, 耿松超, 林旖旎, 陈涛, 孙立宁 2020 69 068801

Google Scholar

Google Scholar

Wang Y Z, Ma L, Yang Q, Geng S C, Lin Y N, Chen T, Sun L N 2020 Acta Phys. Sin. 69 068801

Google Scholar

Google Scholar

[2] 杨权, 马立, 杨斌, 丁汇洋, 陈涛, 杨湛, 孙立宁, 福田敏男 2018 67 136801

Google Scholar

Google Scholar

Yang Q, Ma L, Yang B, Ding H Y, Chen T, Yang Z, Sun L N, Toshio F 2018 Acta Phys. Sin. 67 136801

Google Scholar

Google Scholar

[3] Ding H Y, Shi C Y, Li M, Zhan Y, Wang M Y, Wang Y Q, Tao C, Sun L N, Fukuda T 2018 Sensors 18 1137

Google Scholar

Google Scholar

[4] 杨权, 马立, 耿松超, 林旖旎, 陈涛, 孙立宁 2021 70 106101

Yang Q, Ma L, Geng S C, Lin Y N, Chen T, Sun L N 2021 Acta Phys. Sin. 70 106101

[5] Mishra K B, Ashok B 2018 Mater. Res. Express 5 075023

Google Scholar

Google Scholar

[6] Iijima S 1991 Nature 354 56

Google Scholar

Google Scholar

[7] Jia J, Shi D, Feng X, Chen G 2014 Carbon 76 54

Google Scholar

Google Scholar

[8] Deng W, Li Y, Chen Y, Zhou W 2014 Micro Nano Lett. 9 626

Google Scholar

Google Scholar

[9] Xia C J, Zhang B Q, Yang M, Wang C L, Yang A Y 2016 Chin. Phys. Lett. 33 047101

Google Scholar

Google Scholar

[10] Fu W Y, Xu Z, Bai X D, Gu C Z, Wang E 2009 Nano Lett. 9 921

Google Scholar

Google Scholar

[11] Brady G J, Way A J, Safron N S, Evensen H T, Gopalan P, Arnold M S 2016 Sci. Adv. 2 9

[12] Chen B Y, Zhang P P, Ding L, Han J, Qiu S, Li Q W, Zhang Z Y, Peng L M 2016 Nano Lett. 16 5120

Google Scholar

Google Scholar

[13] Ma K L, Yan X H, Guo Y D, Xiao Y 2011 Eur. Phys. J. B 83 487

Google Scholar

Google Scholar

[14] An Y P, Sun Y Q, Jiao J T, Zhang M J, Wang K, Chen X C, Wu D P, Wang T X, Fu Z M, Jiao Z Y 2017 Org. Electron. 50 43

Google Scholar

Google Scholar

[15] Berdiyorov G R, Hamoudi H 2020 ACS Omega 5 189

Google Scholar

Google Scholar

[16] Yang Q, Ma L, Xiao S G, Zhang D X, Djoulde A, Ye M S, Lin Y N, Geng S C, Li X, Chen T, Sun L N 2021 Nanomater. 11 1290

Google Scholar

Google Scholar

[17] Wen B, Cao M S, Hou Z L, Song W L, Zhang L, Lu M M, Jin H B, Fang X Y, Wang W Z, Yuan J 2013 Carbon 65 124

Google Scholar

Google Scholar

[18] Berdiyorov G R, Eshonqulov G, Hamoudi H 2020 Comput. Mater. Sci. 183 109809

Google Scholar

Google Scholar

[19] Algharagholy L A 2019 J. Electron. Mater. 48 2301

Google Scholar

Google Scholar

[20] Teichert F, Wagner C, Croy A, Schuster J 2018 J. Phys. Commun. 2 115023

Google Scholar

Google Scholar

[21] Ohnishi M, Suzuki K, Miura H 2016 Nano Res. 9 1267

Google Scholar

Google Scholar

[22] Srivastava S, Mishra B K 2018 J. Nanopart. Res. 20 295

Google Scholar

Google Scholar

[23] Espinosa-Torres N D, Guillén-López A, Martínez-Juárez J, Hernández de la Luz J Á D, Rodríguez-Victoria Á P, Muñiz J 2019 Int. J. Quantum Chem. 119 2

[24] Buonocore F 2010 Mol. Simul. 36 729

Google Scholar

Google Scholar

[25] 刘红, 印海建, 夏树宁 2009 58 8489

Google Scholar

Google Scholar

Liu H, Yin H J, Xia S N 2009 Acta Phys. Sin. 58 8489

Google Scholar

Google Scholar

[26] Yang L, Han J 2000 Phys. Rev. Lett. 85 154

Google Scholar

Google Scholar

[27] 赵起迪, 张振华 2010 59 8098

Google Scholar

Google Scholar

Zhao Q D, Zhang Z H 2010 Acta Phys. Sin. 59 8098

Google Scholar

Google Scholar

[28] Patel A M, Joshi A Y 2016 Procedia Technol. 23 122

Google Scholar

Google Scholar

[29] Di Carlo A, Gheorghe M, Lugli P, Sternberg M, Seifert G, Frauenheim T 2002 Phys. B 314 86

Google Scholar

Google Scholar

[30] Pecchia A, Di Carlo 2004 Rep. Prog. Phys. 67 1497

Google Scholar

Google Scholar

[31] Büttiker M, Imry Y, Landauer R, Pinhas S 1985 Phys. Rev. B 31 6207

Google Scholar

Google Scholar

-

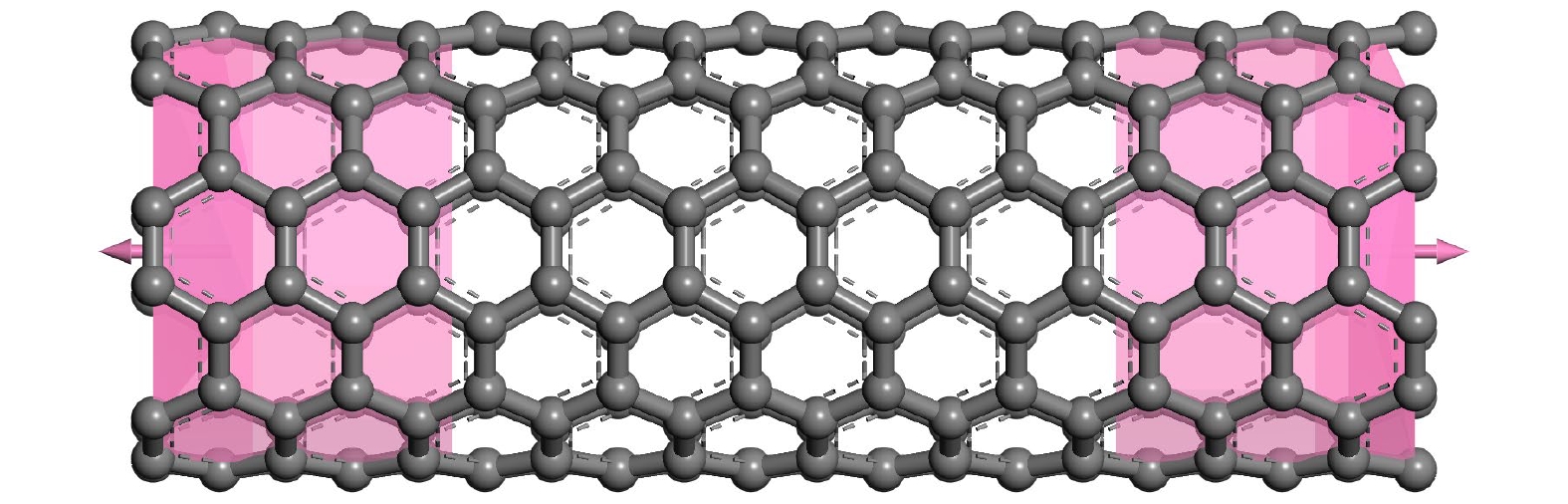

图 2 多壁碳纳米管及其分子动力学模型 碳纳米管和AFM (a)接触前和 (b)接触后的SEM图像; 原子模型的(c)侧视图和(d)主视图; 径向压缩形变后原子模型的(e)侧视图和(f)主视图

Figure 2. Picked CNT and its molecular dynamic model: SEM images of CNT and AFM (a) before contact, (b) after contact; (c) side view and (d) front view of model; after collapse (e) side view and (f) front view of model.

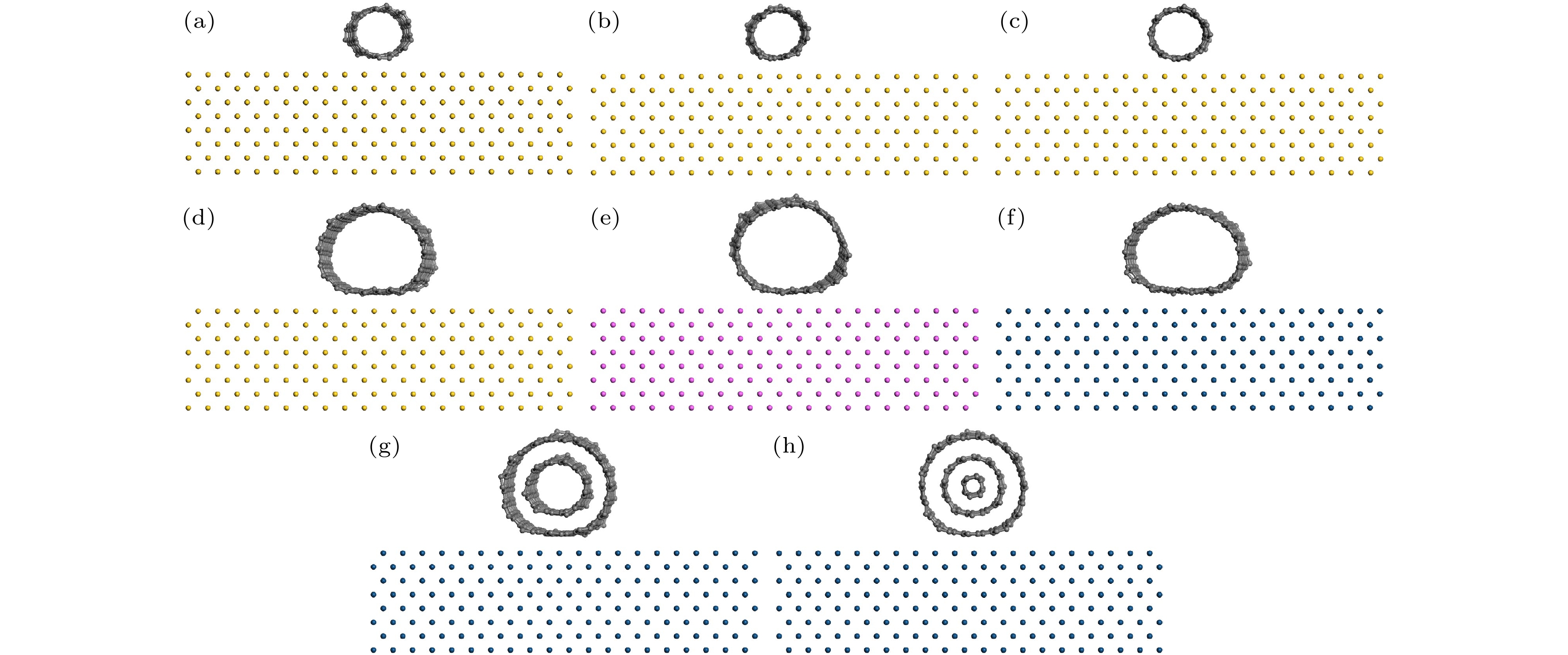

图 3 碳纳米管与金属表面接触模型. 接触长度为 (a) 11.095 Å, (b) 23.422 Å, (c) 48.078 Å的扶手椅型碳纳米管(6, 6)与金; 扶手椅型碳纳米管(11, 11)与(d)金、(e)铝、(f)铂; (g)双壁碳纳米管与铂; (h)三壁碳纳米管与铂

Figure 3. Contact behavior of CNT on metal. Armchir CNT(6, 6) on gold with contact length of (a) 11.095 Å, (b) 23.422 Å, (c) 48.078 Å. Armchir CNT(11, 11) contact behavior on (d) gold, (e) aluminium, (f) platinum. (g) DWCNT contact behavior on platinum. (h) MWCNT contact behavior on platinum.

图 4 碳纳米管径向压缩形变后原子模型主视图接触长度为(a) 11.095 Å, (b) 23.422 Å, (c) 48.078 Å的扶手椅型碳纳米管(6, 6)与金; 扶手椅型碳纳米管(11, 11)与(d)金、(e)铝、(f)铂; (g)双壁碳纳米管与铂; (h)三壁碳纳米管与铂

Figure 4. Front view after collapse of CNT. Armchir CNT(6, 6) on gold with contact length of (a) 11.095 Å, (b) 23.422 Å, (c) 48.078 Å. Armchir CNT (11, 11) contact behavior on (d) gold, (e) aluminium, (f) platinum. (g) DWCNT contact behavior on platinum. (h) MWCNT contact behavior on platinum.

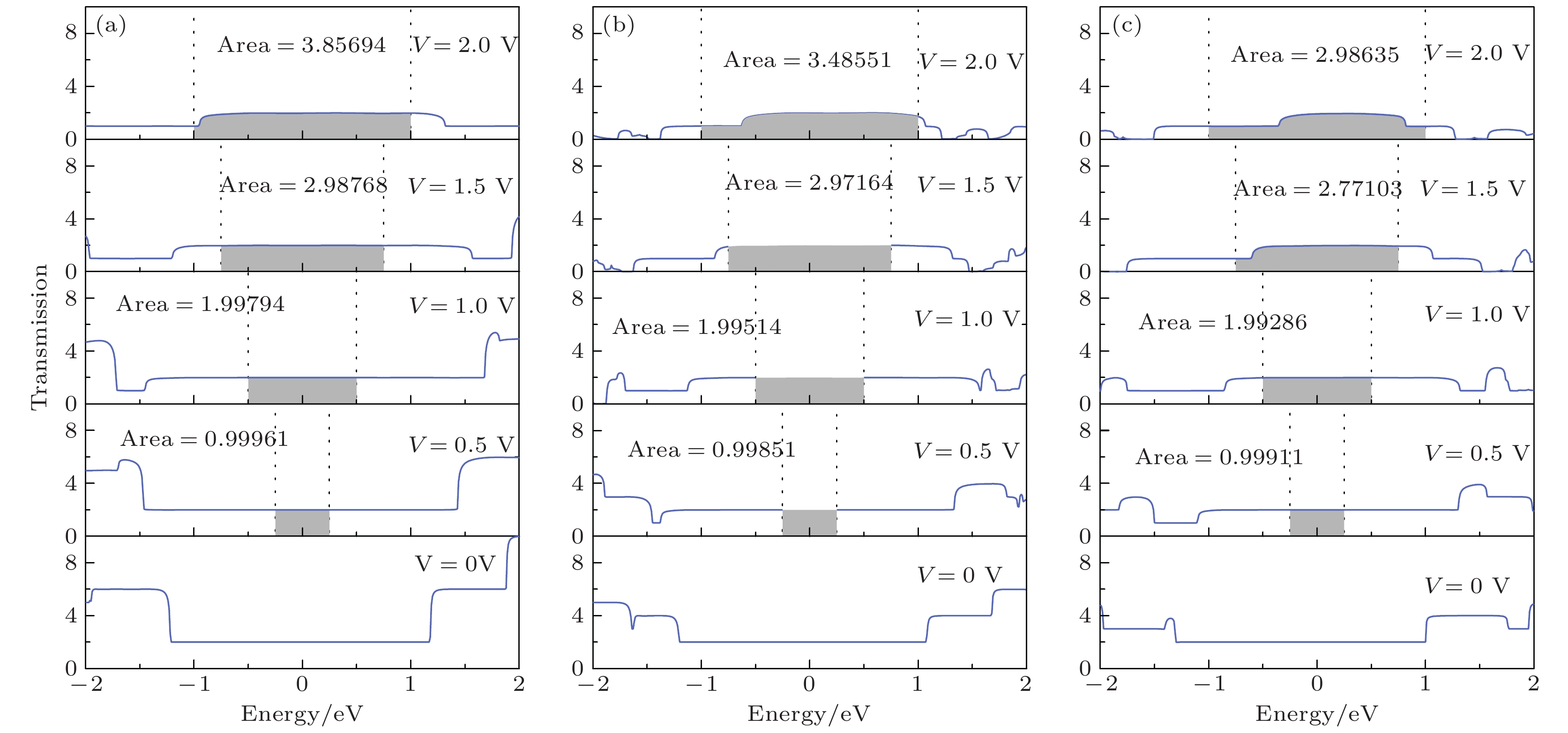

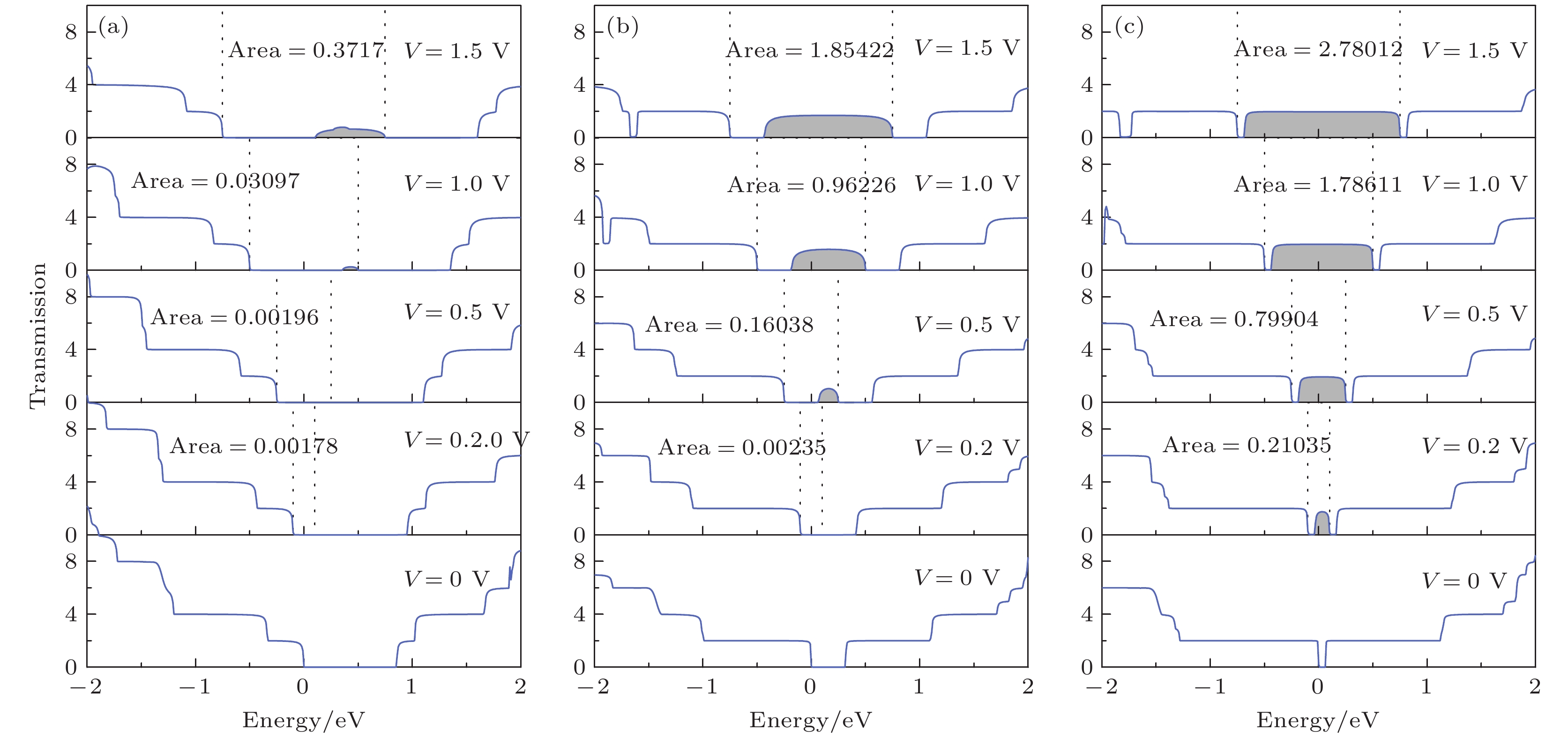

图 6 扶手椅型碳纳米管(6, 6)在0, 0.5, 1.0, 1.5及2.0 V偏压下的透射谱 (a)

${\varepsilon _r}=0 $ ; (b)${\varepsilon _r}=0.10 $ ; (c)${\varepsilon _r}=0.15 $ Figure 6. Transmission spectrum of Armchair CNT (6, 6) under the bias voltage of 0, 0.5, 1.0, 1.5 and 2.0 V with different radial deformation: (a)

${\varepsilon _r}=0 $ ; (b)${\varepsilon _r}=0.10 $ ; (c)${\varepsilon _r}=0.15 $ .图 9 锯齿型碳纳米管(11, 0)在0, 0.2, 0.5, 1及1.5 V偏压下的透射谱 (a)

${\varepsilon _r}=0 $ ; (b)${\varepsilon _r}= 0.1$ ; (c)${\varepsilon _r}=0.15 $ Figure 9. Transmission spectrum of Zigzag CNT (11, 0) under the bias voltage of 0, 0.2, 0.5, 1 and 1.5 V with different radial deformation: (a)

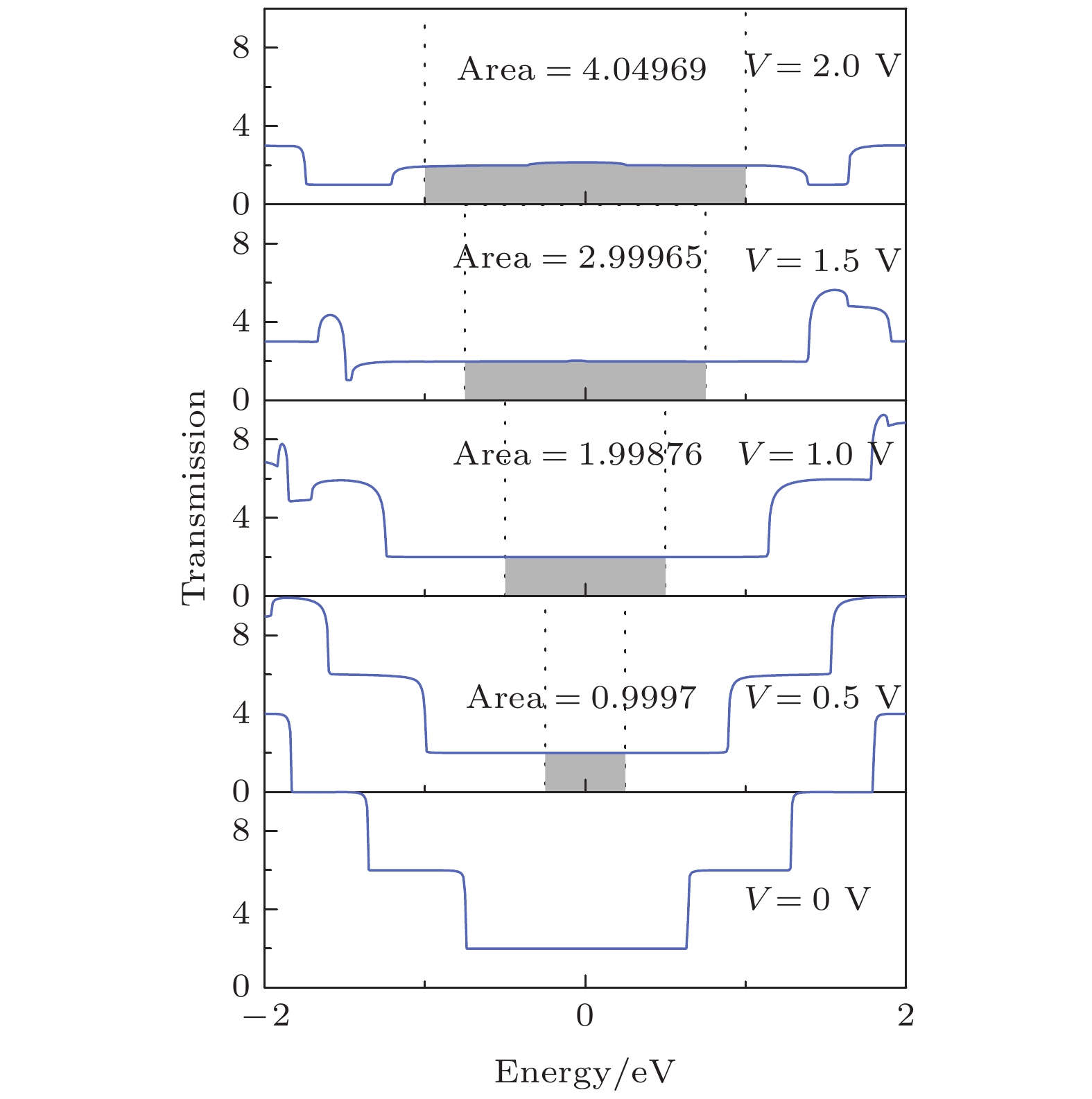

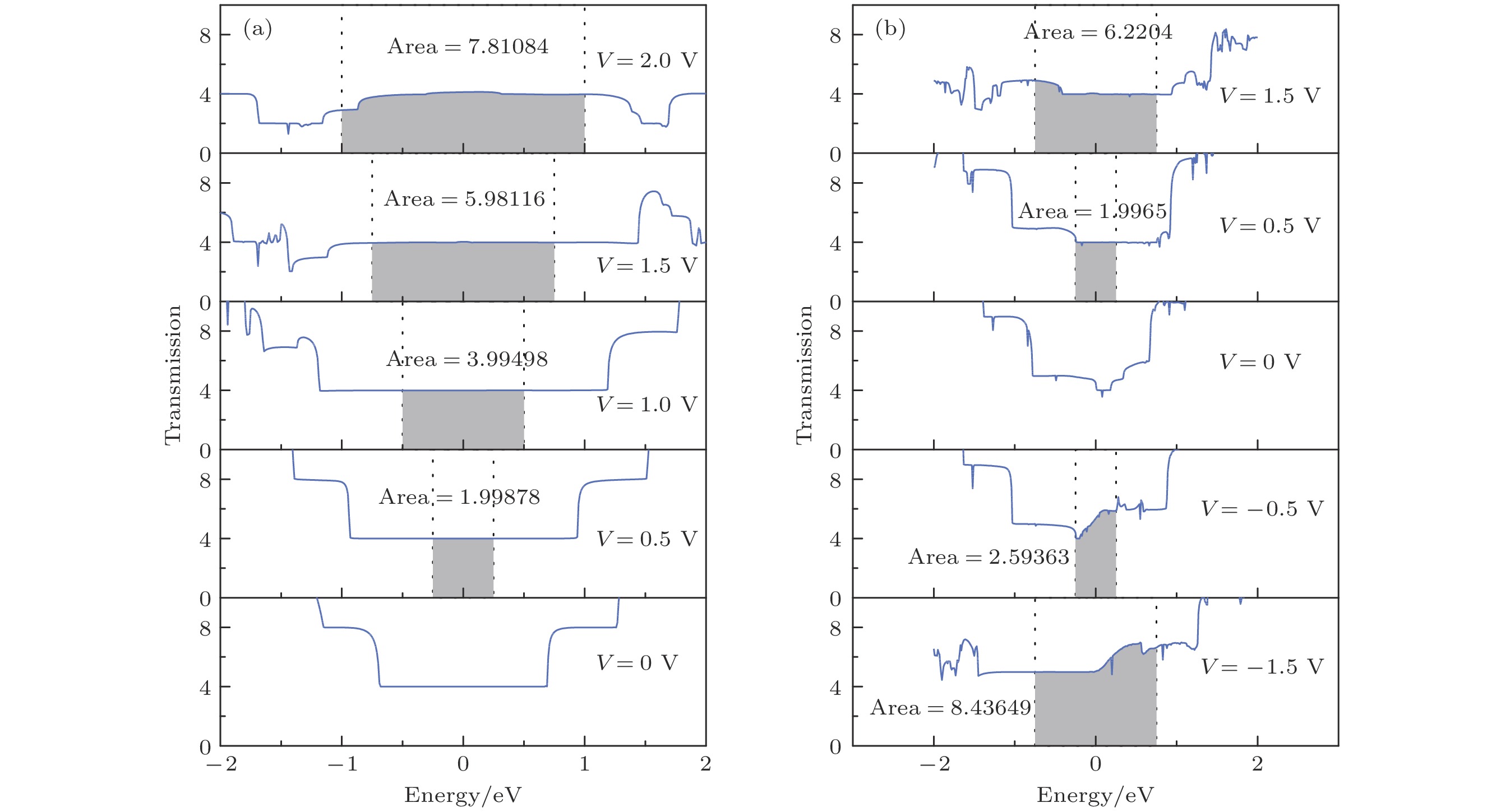

${\varepsilon _r}=0 $ ; (b)${\varepsilon _r}= 0.1$ ; (c)${\varepsilon _r}=0.15 $ .图 11

${\varepsilon _r}=0 $ 时碳纳米管的透射谱 (a)双壁碳纳米管在0, 0.5, 1.0, 1.5及2.0 V偏压下的透射谱; (b)三壁碳纳米管在–1.5, –0.5, 0, 0.5及1.5 V偏压下的透射谱Figure 11. Transmission spectrum of CNT with the radial deformation of

${\varepsilon _r}=0 $ : (a) DWCNT under the bias voltage of 0, 0.5, 1.0, 1.5 and 2.0 V; (b) MWCNT under the bias voltage of –1.5, –0.5, 0, 0.5 and 1.5 V.表 1 DFTB的计算方法及参数设置

Table 1. Scheme and parameter setting up in calculations with DFTB.

电子态描述及

求解方法计算方法 参数设置 结构优化 算法 Smart精确计算法 精度控制 能量0.02 kcal/mol 力0.1 kcal/(mol·Å) 应力0.05 GPa 位移0.001 Å 最大步数500 Slater-Koster参数 CHNO 哈密顿量

对角化Divide and conquer

本征求解法自洽场计算 自洽电荷(SCC) 收敛阈值1 × 10–8 eV 最大循环次数500 Broyden电荷混合 最大混合幅度0.05 布里渊区

K点取样

(电子输运)均匀分布 0.02/Å 泊松求解 边界区域缓冲长度 7.5 Å 泊松网格最大

网格间距0.5 Å 电极区域边界条件 Dirichlet 非电极区域边界条件 Neumann 电极区域缓冲长度 0.3 Å 表 2 碳纳米管与金属界面接触的分子动力学模拟

Table 2. Molecular dynamic of different CNT on different metal.

碳纳米管类型 管长/Å 金属

类型初始

直径/Å最终

直径/Å径向压缩

形变量范德瓦耳斯能

差/(kcal·mol–1)结合能

/(kcal·mol–1)(6, 6) 11.095 金 8.14 7.147 0.1220 121.3 –418.13 23.422 7.266 0.1074 261.97 –743.75 48.078 7.336 0.0988 490.28 –1453.96 (11, 11) 23.410 金 14.92 11.960 0.1984 347.65 –1172.86 铝 12.558 0.1583 250.96 –1094.97 铂 11.199 0.2494 495.91 –1307.86 (6, 6) @ (11, 11) 23.400 铂 14.92 13.477 0.0967 427.66 –1769.67 (2, 2) @ (6, 6) @ (11, 11) 23.456 铂 14.92 13.850 0.0717 428.89 –1867.47 -

[1] 王亚洲, 马立, 杨权, 耿松超, 林旖旎, 陈涛, 孙立宁 2020 69 068801

Google Scholar

Google Scholar

Wang Y Z, Ma L, Yang Q, Geng S C, Lin Y N, Chen T, Sun L N 2020 Acta Phys. Sin. 69 068801

Google Scholar

Google Scholar

[2] 杨权, 马立, 杨斌, 丁汇洋, 陈涛, 杨湛, 孙立宁, 福田敏男 2018 67 136801

Google Scholar

Google Scholar

Yang Q, Ma L, Yang B, Ding H Y, Chen T, Yang Z, Sun L N, Toshio F 2018 Acta Phys. Sin. 67 136801

Google Scholar

Google Scholar

[3] Ding H Y, Shi C Y, Li M, Zhan Y, Wang M Y, Wang Y Q, Tao C, Sun L N, Fukuda T 2018 Sensors 18 1137

Google Scholar

Google Scholar

[4] 杨权, 马立, 耿松超, 林旖旎, 陈涛, 孙立宁 2021 70 106101

Yang Q, Ma L, Geng S C, Lin Y N, Chen T, Sun L N 2021 Acta Phys. Sin. 70 106101

[5] Mishra K B, Ashok B 2018 Mater. Res. Express 5 075023

Google Scholar

Google Scholar

[6] Iijima S 1991 Nature 354 56

Google Scholar

Google Scholar

[7] Jia J, Shi D, Feng X, Chen G 2014 Carbon 76 54

Google Scholar

Google Scholar

[8] Deng W, Li Y, Chen Y, Zhou W 2014 Micro Nano Lett. 9 626

Google Scholar

Google Scholar

[9] Xia C J, Zhang B Q, Yang M, Wang C L, Yang A Y 2016 Chin. Phys. Lett. 33 047101

Google Scholar

Google Scholar

[10] Fu W Y, Xu Z, Bai X D, Gu C Z, Wang E 2009 Nano Lett. 9 921

Google Scholar

Google Scholar

[11] Brady G J, Way A J, Safron N S, Evensen H T, Gopalan P, Arnold M S 2016 Sci. Adv. 2 9

[12] Chen B Y, Zhang P P, Ding L, Han J, Qiu S, Li Q W, Zhang Z Y, Peng L M 2016 Nano Lett. 16 5120

Google Scholar

Google Scholar

[13] Ma K L, Yan X H, Guo Y D, Xiao Y 2011 Eur. Phys. J. B 83 487

Google Scholar

Google Scholar

[14] An Y P, Sun Y Q, Jiao J T, Zhang M J, Wang K, Chen X C, Wu D P, Wang T X, Fu Z M, Jiao Z Y 2017 Org. Electron. 50 43

Google Scholar

Google Scholar

[15] Berdiyorov G R, Hamoudi H 2020 ACS Omega 5 189

Google Scholar

Google Scholar

[16] Yang Q, Ma L, Xiao S G, Zhang D X, Djoulde A, Ye M S, Lin Y N, Geng S C, Li X, Chen T, Sun L N 2021 Nanomater. 11 1290

Google Scholar

Google Scholar

[17] Wen B, Cao M S, Hou Z L, Song W L, Zhang L, Lu M M, Jin H B, Fang X Y, Wang W Z, Yuan J 2013 Carbon 65 124

Google Scholar

Google Scholar

[18] Berdiyorov G R, Eshonqulov G, Hamoudi H 2020 Comput. Mater. Sci. 183 109809

Google Scholar

Google Scholar

[19] Algharagholy L A 2019 J. Electron. Mater. 48 2301

Google Scholar

Google Scholar

[20] Teichert F, Wagner C, Croy A, Schuster J 2018 J. Phys. Commun. 2 115023

Google Scholar

Google Scholar

[21] Ohnishi M, Suzuki K, Miura H 2016 Nano Res. 9 1267

Google Scholar

Google Scholar

[22] Srivastava S, Mishra B K 2018 J. Nanopart. Res. 20 295

Google Scholar

Google Scholar

[23] Espinosa-Torres N D, Guillén-López A, Martínez-Juárez J, Hernández de la Luz J Á D, Rodríguez-Victoria Á P, Muñiz J 2019 Int. J. Quantum Chem. 119 2

[24] Buonocore F 2010 Mol. Simul. 36 729

Google Scholar

Google Scholar

[25] 刘红, 印海建, 夏树宁 2009 58 8489

Google Scholar

Google Scholar

Liu H, Yin H J, Xia S N 2009 Acta Phys. Sin. 58 8489

Google Scholar

Google Scholar

[26] Yang L, Han J 2000 Phys. Rev. Lett. 85 154

Google Scholar

Google Scholar

[27] 赵起迪, 张振华 2010 59 8098

Google Scholar

Google Scholar

Zhao Q D, Zhang Z H 2010 Acta Phys. Sin. 59 8098

Google Scholar

Google Scholar

[28] Patel A M, Joshi A Y 2016 Procedia Technol. 23 122

Google Scholar

Google Scholar

[29] Di Carlo A, Gheorghe M, Lugli P, Sternberg M, Seifert G, Frauenheim T 2002 Phys. B 314 86

Google Scholar

Google Scholar

[30] Pecchia A, Di Carlo 2004 Rep. Prog. Phys. 67 1497

Google Scholar

Google Scholar

[31] Büttiker M, Imry Y, Landauer R, Pinhas S 1985 Phys. Rev. B 31 6207

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8380

- PDF Downloads: 170

- Cited By: 0

DownLoad:

DownLoad: