-

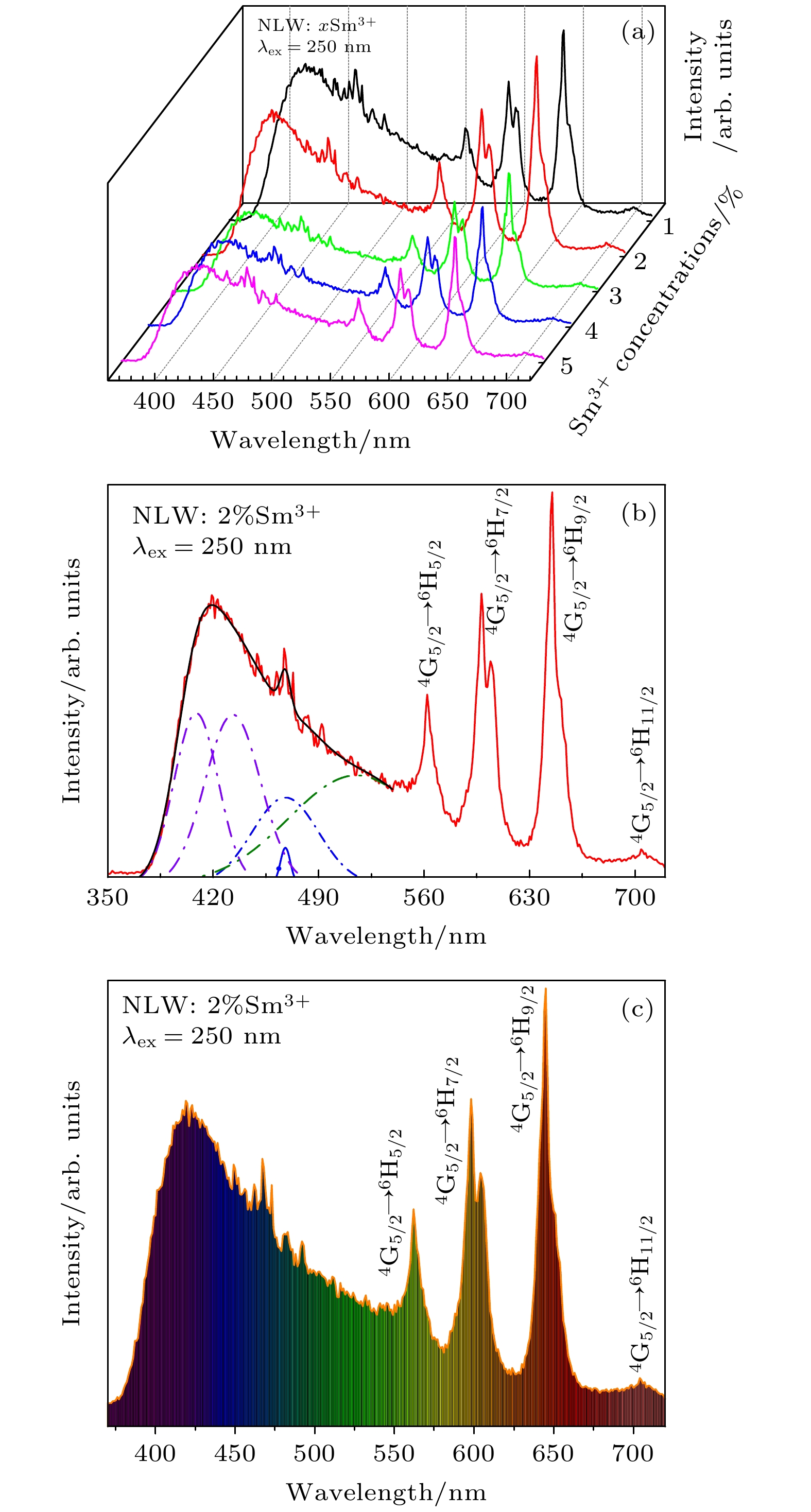

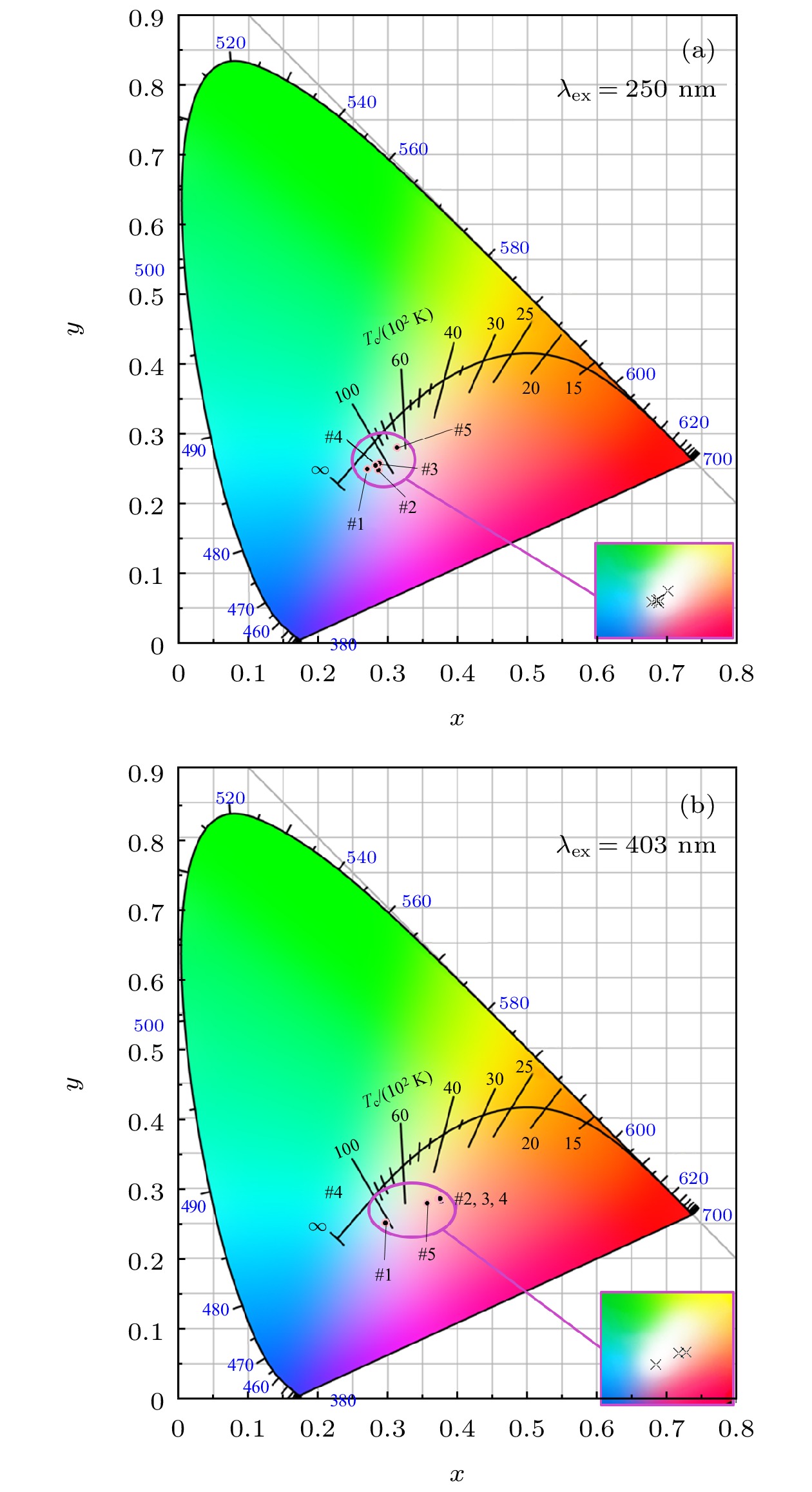

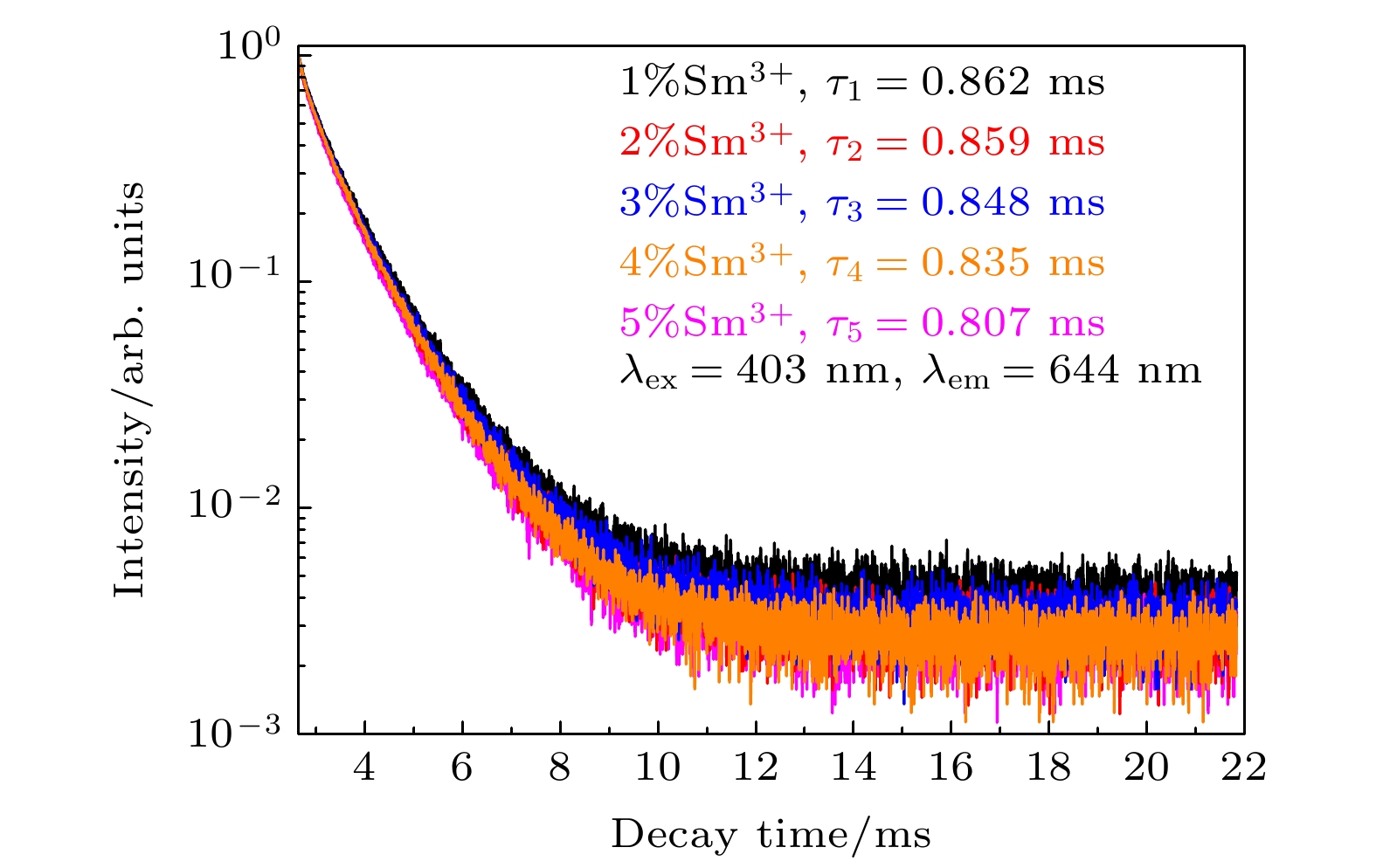

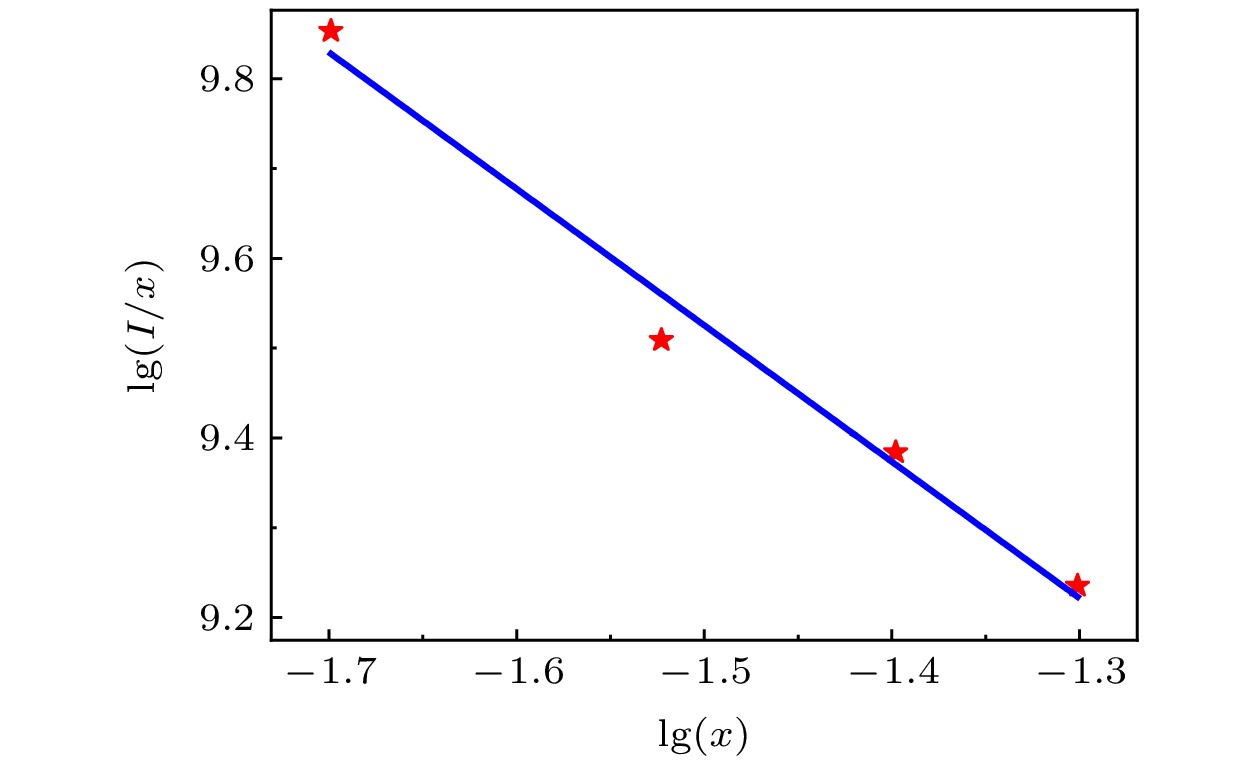

Single ion doped single phase white emitting phosphors have some special advantages and great potential applications in the field of high quality LED lighting. This type of phosphors can effectively solve the problem of uneven particle dispersion and sedimentation in the white light scheme obtained by UV chip plus trichromatic phosphor, and solve the problems of the luminescence and reabsorption between phosphors and the regulation of trichromatic ratio. A comparison of the single-ion doping luminescent material with the multi-ion doping system shows that the single-ion doping luminescent material is simpler in both preparation process and luminescence color adjustment, which can achieve higher color rendering index, more easily controlled color temperature and closer to the color coordinates of white light. According to the principle of colorimetry and luminescence, light of two or more wavelengths may be combined to obtain white light emission. Under the UV excitation, the Sm3+ ions emit relatively strong green, yellow, orange and red light at 580–670 nm. Under UV excitation, the broadband spectrum of ${\rm{WO}}_{4}^{2-} $ self-activated emission covers almost the whole visible region, but the blue-green light is strong in the short wavelength region and the yellow-orange-red light is weak in the long wavelength region. When Sm3+ ions are doped into tungstate, Sm3+ ions’ luminescence can effectively supplement the weak luminescence intensity of tungstate in the long-wave region, and white light can be obtained. Under the excitation of 250 nm, the phosphor emits cold white light, and warm white light under the excitation of 403 nm. The experimental results show that Sm3+ ions have a significant effect on the correlated color temperature adjustment of self-activated luminescence of NLW phosphors. All the prepared samples are crystallized into the tetragonal crystal phase structures and that their morphologies present rhombic sheet. By analyzing the experimental data, the type of energy transfer between Sm3+ ions is determined to be electrical dipole–electrical dipole interaction. The NLW: xSm3+ phosphor has high stability and can be effectively excited by ultraviolet/near-ultraviolet light, which can be used as a potential candidate of single matrix single-ion doped white phosphors.-

Keywords:

- NaLa(WO4)2: Sm3+ /

- photoluminescence /

- white light phosphors

[1] 郭伟玲, 邓杰, 王嘉露, 王乐, 邰建鹏 2019 68 247303

Google Scholar

Google Scholar

Guo W L, Deng J, Wang J L, Wang L, Tai J P 2019 Acta Phys. Sin. 68 247303

Google Scholar

Google Scholar

[2] Xia H, Lei L, Hong W Q, Xu S Q 2018 J. Alloy Compd. 757 239

Google Scholar

Google Scholar

[3] 苏小娜, 万英, 周芷萱, 胡莲莲 2017 66 230701

Google Scholar

Google Scholar

Su X N, Wan Y, Zhou Z X, Hu L L 2017 Acta Phys. Sin. 66 230701

Google Scholar

Google Scholar

[4] Jiang G C, Wei X T, Chen Y H, Duan C K, Yin M, Yang B, Cao W W 2015 Mater. Lett. 143 98

Google Scholar

Google Scholar

[5] Du P, Wu Y F, Yu J S 2018 RSC Adv. 12 6419

Google Scholar

Google Scholar

[6] Du P, Yu J S 2016 Mater. Res. Bull. 84 303

Google Scholar

Google Scholar

[7] Du P, Huang X Y, Yu J S 2018 Chem. Eng. J. 337 91

Google Scholar

Google Scholar

[8] 梁思思, 尚蒙蒙, 林君 2018 物理化学学报 34 237

Google Scholar

Google Scholar

Liang S S, Shang M M, Lin J 2018 Acta Phys-Chem. Sin. 34 237

Google Scholar

Google Scholar

[9] 曹逊, 曹翠翠, 孙光耀, 金平实 2019 无机材料学报 34 1145

Google Scholar

Google Scholar

Cao X, Cao C C, Sun G Y, Jin P S 2019 J. Inorg. Mater. 34 1145

Google Scholar

Google Scholar

[10] Tian L, Wang L X, Zhang L, Zhang Q T, Ding W H, Yu M X 2015 J. Mater. Sci-Mater El. 26 8507

Google Scholar

Google Scholar

[11] Hsu C H, Das S, Lu C H 2012 J. Electro. Chem. Soc. 159 193

Google Scholar

Google Scholar

[12] Meng J X, Yang C T, Chen Q Q 2010 J. Lumin. 130 1320

Google Scholar

Google Scholar

[13] Wu Z C, Liu J, Hou W G 2010 J. Alloy Compd. 498 139

Google Scholar

Google Scholar

[14] Du P, Yu J S 2017 Dyes. Pigments. 147 16

Google Scholar

Google Scholar

[15] Luwang M N, Ningthoujam R S, Srivastava S K 2011 J. Mater. Chem. 21 5326

Google Scholar

Google Scholar

[16] 任艳东, 吕树臣 2011 60 087804

Google Scholar

Google Scholar

Ren Y D, Lü S C 2011 Acta Phys. Sin. 60 087804

Google Scholar

Google Scholar

[17] 孟庆裕, 李明, 刘林峰, 曲秀荣, 万维龙, 孙江亭 2012 61 107804

Google Scholar

Google Scholar

Meng Q Y, Li M, Liu L F, Qu X R, Wan W L, Sun J T 2012 Acta Phys. Sin. 61 107804

Google Scholar

Google Scholar

[18] 刘艳, 姜莹莹, 刘桂霞, 王进贤 2013 无机化学学报 29 277

Google Scholar

Google Scholar

Liu Y, Jiang Y Y, Liu G X, Wang J X 2013 Inorg. Chem. 29 277

Google Scholar

Google Scholar

[19] Du P, Wu S Q, Yu J S 2016 J. Lumin. 173 192

Google Scholar

Google Scholar

[20] Jiang H X, Lü S C 2021 Mater. Res. Bull. 135 111123

Google Scholar

Google Scholar

[21] Li L L, Yang X Y, Li J Q, et al. 2020 J. Lumin. 173 117377

Google Scholar

Google Scholar

[22] 毕长虹, 孟庆裕 2013 19 197804

Google Scholar

Google Scholar

Bi C H, Meng Q Y 2013 Acta Phys. Sin. 19 197804

Google Scholar

Google Scholar

[23] Chanu T T T, Singh N R 2016 J. Mater. Sci-Mater. El. 28 3909

Google Scholar

Google Scholar

[24] Liu Y, Liu G X, Dong X T, Wang J X, Yu W S 2014 RSC Adv. 4 58708

Google Scholar

Google Scholar

[25] Cao R P, Xu H D, Peng D D, Jiang S H 2015 Supperlattice Microst. 88 5

Google Scholar

Google Scholar

[26] Zhai Y Q, Wang M, Zhao Q, Yang H L, Ding H H 2016 J. Mater. Sci-Mater. El. 27 279

Google Scholar

Google Scholar

[27] Durirajan A, Balaji D, Kavi Rasu K, et al. 2016 J. Lumin. 170 743

Google Scholar

Google Scholar

[28] 陈炳炎, 刘粤惠, 陈东丹, 姜中宏 2005 54 3418

Google Scholar

Google Scholar

Chen B Y, Liu Y H, Chen D D, Jiang Z H 2005 Acta Phys. Sin. 54 3418

Google Scholar

Google Scholar

[29] 孟庆裕, 刘志鑫, 孙文军 2013 62 097801

Google Scholar

Google Scholar

Meng Q Y, Liu Z X, Sun W J 2013 Acta Phys. Sin. 62 097801

Google Scholar

Google Scholar

[30] Dexter D L, Schulman J H 1954 J. Chem. Phys. 22 1063

Google Scholar

Google Scholar

-

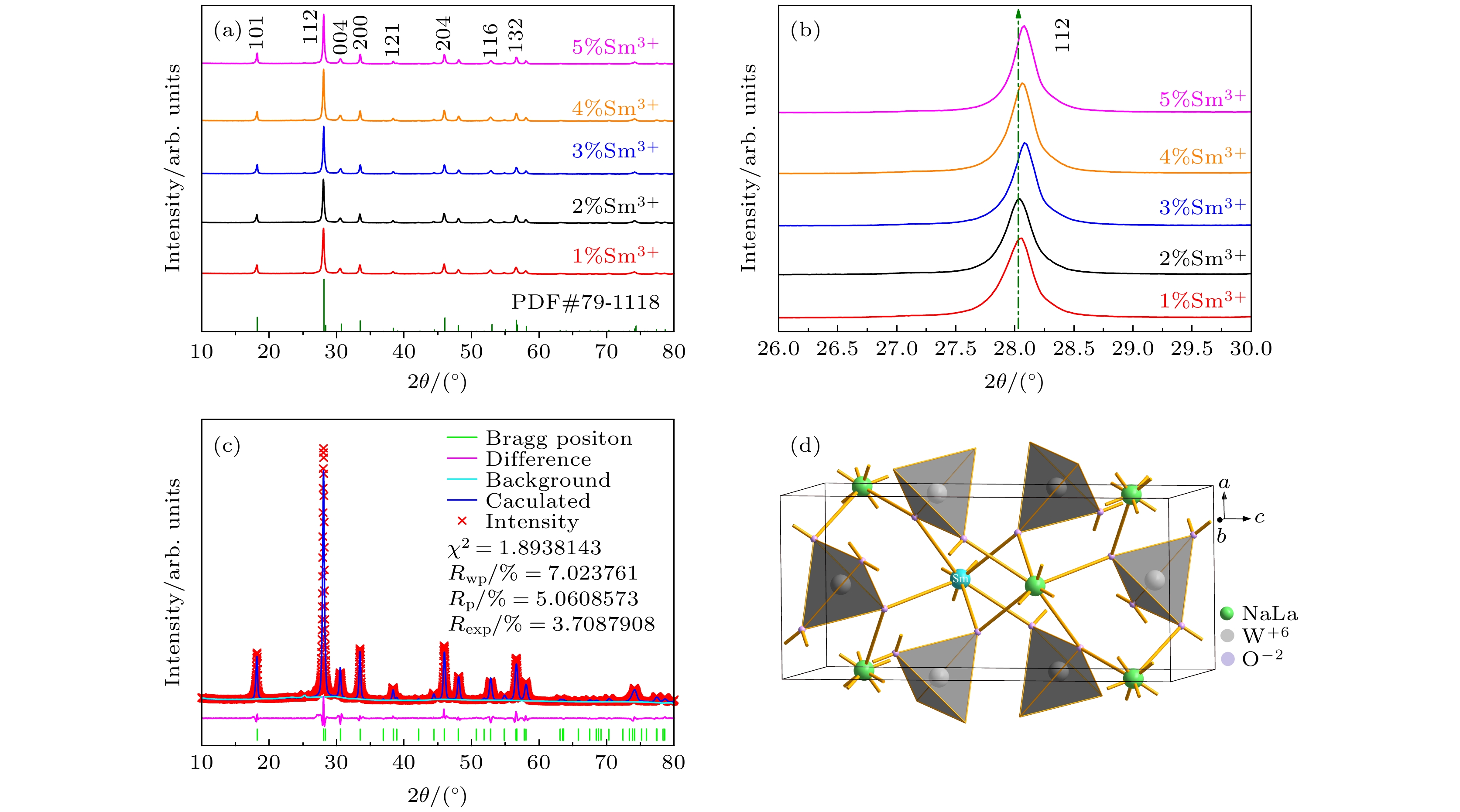

图 1 晶体结构信息 (a) NLW:x Sm3+荧光粉的XRD谱; (b) (112)峰位置随Sm3+浓度变化偏移; (c) NLW:2%Sm3+ XRD谱的Rietveld精修; (d) NLW:x Sm3+晶体结构图

Figure 1. Crystal structure information: (a) XRD patterns of NLW:x Sm3+ phosphors; (b) offset of the (112) peak position with the Sm3+ concentration; (c) rietveld refinement of XRD pattern of NLW:2%Sm3+; (d) the crystal structure of NLW:x Sm3+.

表 1 NLW:x Sm3+晶格参数

Table 1. Lattice constants of NLW:x Sm3+.

NLW:xSm3+

concentrationsa/Å c/Å unit cell

volume/Å31% 5.542 11.692 359.1 2% 5.539 11.699 358.9 3% 5.531 11.692 357.7 4% 5.530 11.691 357.5 5% 5.528 11.690 357.2 表 2 在403 nm激发下NLW:x Sm3+的I644/I604比值

Table 2. Ratios of I644 to I604 of NLW:x Sm3+ excited at 403 nm.

Sm3+ concentrations/% 1 2 3 4 5 I644/I604 0.93 1.07 1.05 1.04 1.02 表 3 NLW:x Sm3+色坐标和相对色温

Table 3. Color coordinates and relative color temperatures of NLW:x Sm3+ samples.

Sm3+ concentrations/% 1 2 3 4 5 λex = 250 nm (0.270, 0.249)

16618 K(0.287, 0.248)

12435 K(0.288, 0.258)

11032 K(0.283, 0.255)

12346 K(0.313, 0.280)

6971 Kλex = 403 nm (0.298, 0.251)

9963 K(0.374, 0.286)

3057 K(0.377, 0.282)

2911 K(0.376, 0.286)

3004 K(0.357, 0.279)

3798 K -

[1] 郭伟玲, 邓杰, 王嘉露, 王乐, 邰建鹏 2019 68 247303

Google Scholar

Google Scholar

Guo W L, Deng J, Wang J L, Wang L, Tai J P 2019 Acta Phys. Sin. 68 247303

Google Scholar

Google Scholar

[2] Xia H, Lei L, Hong W Q, Xu S Q 2018 J. Alloy Compd. 757 239

Google Scholar

Google Scholar

[3] 苏小娜, 万英, 周芷萱, 胡莲莲 2017 66 230701

Google Scholar

Google Scholar

Su X N, Wan Y, Zhou Z X, Hu L L 2017 Acta Phys. Sin. 66 230701

Google Scholar

Google Scholar

[4] Jiang G C, Wei X T, Chen Y H, Duan C K, Yin M, Yang B, Cao W W 2015 Mater. Lett. 143 98

Google Scholar

Google Scholar

[5] Du P, Wu Y F, Yu J S 2018 RSC Adv. 12 6419

Google Scholar

Google Scholar

[6] Du P, Yu J S 2016 Mater. Res. Bull. 84 303

Google Scholar

Google Scholar

[7] Du P, Huang X Y, Yu J S 2018 Chem. Eng. J. 337 91

Google Scholar

Google Scholar

[8] 梁思思, 尚蒙蒙, 林君 2018 物理化学学报 34 237

Google Scholar

Google Scholar

Liang S S, Shang M M, Lin J 2018 Acta Phys-Chem. Sin. 34 237

Google Scholar

Google Scholar

[9] 曹逊, 曹翠翠, 孙光耀, 金平实 2019 无机材料学报 34 1145

Google Scholar

Google Scholar

Cao X, Cao C C, Sun G Y, Jin P S 2019 J. Inorg. Mater. 34 1145

Google Scholar

Google Scholar

[10] Tian L, Wang L X, Zhang L, Zhang Q T, Ding W H, Yu M X 2015 J. Mater. Sci-Mater El. 26 8507

Google Scholar

Google Scholar

[11] Hsu C H, Das S, Lu C H 2012 J. Electro. Chem. Soc. 159 193

Google Scholar

Google Scholar

[12] Meng J X, Yang C T, Chen Q Q 2010 J. Lumin. 130 1320

Google Scholar

Google Scholar

[13] Wu Z C, Liu J, Hou W G 2010 J. Alloy Compd. 498 139

Google Scholar

Google Scholar

[14] Du P, Yu J S 2017 Dyes. Pigments. 147 16

Google Scholar

Google Scholar

[15] Luwang M N, Ningthoujam R S, Srivastava S K 2011 J. Mater. Chem. 21 5326

Google Scholar

Google Scholar

[16] 任艳东, 吕树臣 2011 60 087804

Google Scholar

Google Scholar

Ren Y D, Lü S C 2011 Acta Phys. Sin. 60 087804

Google Scholar

Google Scholar

[17] 孟庆裕, 李明, 刘林峰, 曲秀荣, 万维龙, 孙江亭 2012 61 107804

Google Scholar

Google Scholar

Meng Q Y, Li M, Liu L F, Qu X R, Wan W L, Sun J T 2012 Acta Phys. Sin. 61 107804

Google Scholar

Google Scholar

[18] 刘艳, 姜莹莹, 刘桂霞, 王进贤 2013 无机化学学报 29 277

Google Scholar

Google Scholar

Liu Y, Jiang Y Y, Liu G X, Wang J X 2013 Inorg. Chem. 29 277

Google Scholar

Google Scholar

[19] Du P, Wu S Q, Yu J S 2016 J. Lumin. 173 192

Google Scholar

Google Scholar

[20] Jiang H X, Lü S C 2021 Mater. Res. Bull. 135 111123

Google Scholar

Google Scholar

[21] Li L L, Yang X Y, Li J Q, et al. 2020 J. Lumin. 173 117377

Google Scholar

Google Scholar

[22] 毕长虹, 孟庆裕 2013 19 197804

Google Scholar

Google Scholar

Bi C H, Meng Q Y 2013 Acta Phys. Sin. 19 197804

Google Scholar

Google Scholar

[23] Chanu T T T, Singh N R 2016 J. Mater. Sci-Mater. El. 28 3909

Google Scholar

Google Scholar

[24] Liu Y, Liu G X, Dong X T, Wang J X, Yu W S 2014 RSC Adv. 4 58708

Google Scholar

Google Scholar

[25] Cao R P, Xu H D, Peng D D, Jiang S H 2015 Supperlattice Microst. 88 5

Google Scholar

Google Scholar

[26] Zhai Y Q, Wang M, Zhao Q, Yang H L, Ding H H 2016 J. Mater. Sci-Mater. El. 27 279

Google Scholar

Google Scholar

[27] Durirajan A, Balaji D, Kavi Rasu K, et al. 2016 J. Lumin. 170 743

Google Scholar

Google Scholar

[28] 陈炳炎, 刘粤惠, 陈东丹, 姜中宏 2005 54 3418

Google Scholar

Google Scholar

Chen B Y, Liu Y H, Chen D D, Jiang Z H 2005 Acta Phys. Sin. 54 3418

Google Scholar

Google Scholar

[29] 孟庆裕, 刘志鑫, 孙文军 2013 62 097801

Google Scholar

Google Scholar

Meng Q Y, Liu Z X, Sun W J 2013 Acta Phys. Sin. 62 097801

Google Scholar

Google Scholar

[30] Dexter D L, Schulman J H 1954 J. Chem. Phys. 22 1063

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7040

- PDF Downloads: 96

- Cited By: 0

DownLoad:

DownLoad: