-

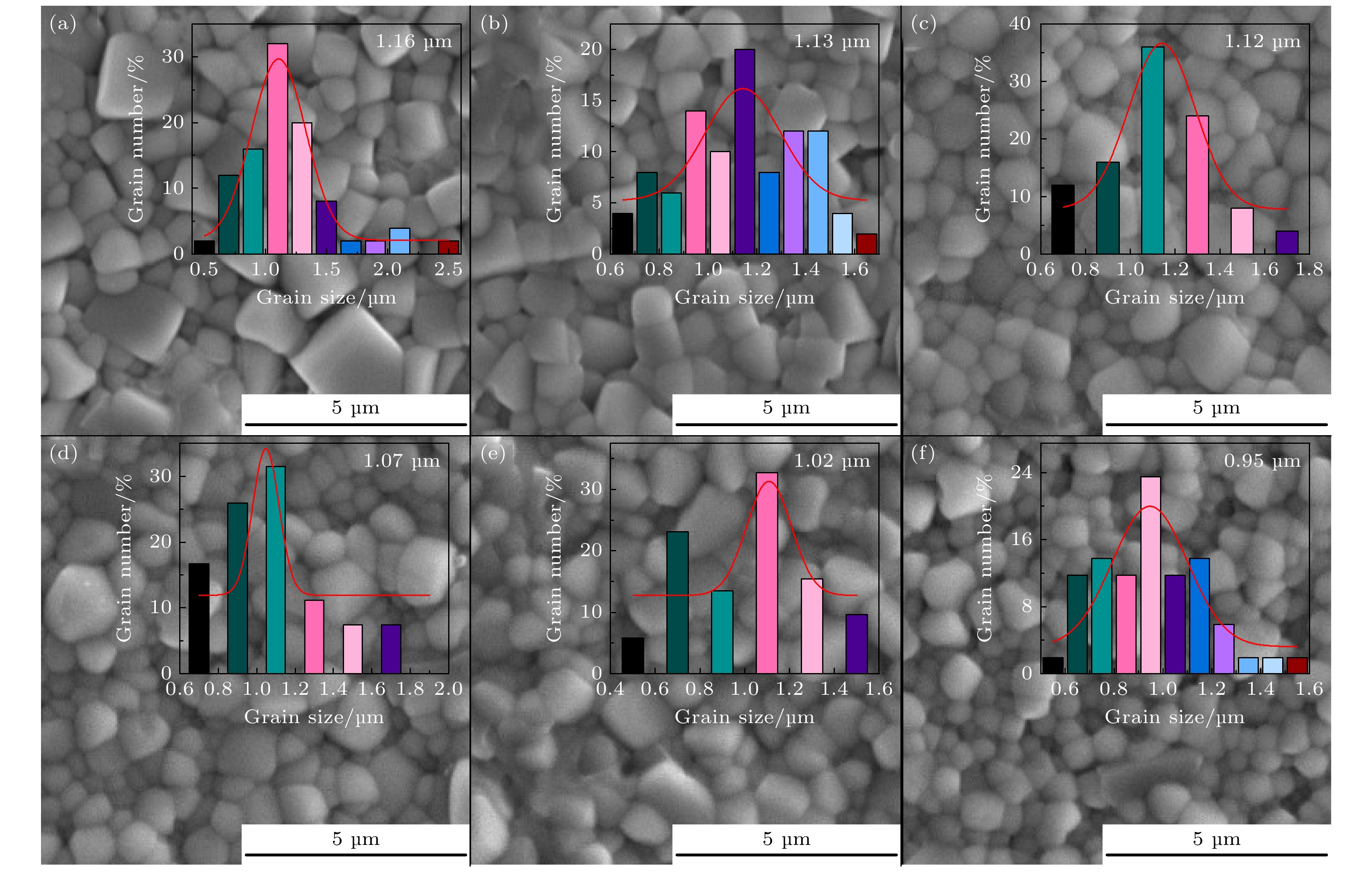

近年来, 无机多功能材料在各个领域得到了广泛的应用. 掺杂稀土的铁电材料作为一种新型的无机多功能材料具有很大的潜力. 本文系统地研究了Sm3+掺杂的0.94Bi0.5Na0.5TiO3-0.06BaTiO3(BNTBT)陶瓷的铁电、储能行为和光致发光性能. 结果表明, Sm3+的引入有效地抑制了BNTBT的晶粒生长, 导致剩余极化(Pr)和矫顽场(Ec)明显下降. 在60 kV/cm的外加电场下, 当Sm3+掺杂浓度为0.6%时, Wrec达到最大值0.27 J/cm3. 储能效率(η)随着电场的增加而逐渐降低, 在掺杂浓度大于0.6%时稳定在45%附近. 此外, 在408 nm的近紫外光的激发下, 所有Sm3+掺杂的样品都表现出可见光的输出, 当Sm3+的掺杂量为1.0%时发光强度达到最大, 在701 nm处(4G5/2→6H11/2)发光强度的相对变化(ΔI/I)达到700%. 本文制备了一种同时具有储能和光致发光特性的新型陶瓷, 为无机多功能材料的开发提供了一种有希望的策略.In recent years, inorganic multifunctional ferroelectric ceramics have been widely utilized in various fields, including aerospace, optical communication, and capacitors, owing to their high stability, easy synthesis, and flexibility. Rare-earth doped ferroelectric materials hold immense potential as a new type of inorganic multifunctional material. This work focuses on the synthesis of x%Sm3+-doped 0.94Bi0.5Na0.5TiO3-0.06BaTiO3 (BNTBT:x%Sm3+ in short) ceramics by using the conventional solid-state sintering method, aiming to comprehensively investigate their ferroelectric, energy storage, and photoluminescence (PL) properties. The X-ray diffraction analysis reveals that the introduction of Sm3+ does not trigger off the appearing of secondary phases or changing of the original perovskite structure. The scanning electron microscope (SEM) images demonstrate that Sm3+ incorporation effectively restrains the grain growth in BNTBT, resulting in the average grain size decreasing from 1.16 to 0.95 μm. The reduction in remanent polarization (Pr) and coercive field (Ec) can be attributed to both the grain size refinement and the formation of morphotropic phase boundaries (MPBs). Under an applied field of 60 kV/cm, the maximum value of energy storage density (Wrec) reaches to 0.27 J/cm3 at an Sm3+ doping concentration of 0.6%. The energy storage efficiency (η) gradually declines with electric field increasing and stabilizes at approximately 45% for Sm3+ doping concentrations exceeding 0.6%. This result can be ascribed to the decrease in ΔP (Pmax – Pr) due to the growth of ferroelectric domains as the electric field increases. Additionally, all Sm3+-doped BNTBT ceramics exhibit outstanding PL performance upon being excited with near-ultraviolet (NUV) light at 408 nm, without peak position shifting. The PL intensity peaks when the Sm3+ doping concentration is 1.0%, with a relative change (ΔI/I) reaching to 700% at 701 nm (4G5/2→6H11/2). However, the relative change in PL intensity is minimum at 562 nm (4G5/2→6H5/2) due to the fact that the 4G5/2→6H5/2 transition represents a magnetic dipole transition, and the PL intensity remains relatively stable despite variations in the crystal field environment surrounding Sm3+. Our successful synthesis of this novel ceramic material, endowed with both energy storage and PL properties, offers a promising avenue for developing inorganic multifunctional materials. The Sm3+-doped BNTBT ceramics hold considerable potential applications in optical memory and multifunctional capacitors.

-

Keywords:

- rare earth /

- ferroelectric /

- energy storage /

- photoluminescence

[1] Famprikis T, Canepa P, Dawson J A, Islam M S, Masquelier C 2019 Nat. Mater. 18 1278

Google Scholar

Google Scholar

[2] Guo P F, Su L, Peng K, Lu D, Xu L, Li M Z, Wang H J 2022 ACS Nano 16 6625

Google Scholar

Google Scholar

[3] Zheng B Z, Fan J Y, Chen B, Qin X, Wang J, Wang F, Deng R R, Liu X G 2022 Chem. Rev. 122 5519

Google Scholar

Google Scholar

[4] Nazir H, Batool M, Osorio F J B, Isaza-Ruiz M, Xu X H, Vignarooban K, Phelan P, Inamuddin, Kannan A M 2019 Int. J. Heat Mass Transfer 129 491

Google Scholar

Google Scholar

[5] Wen Q B, Qu F M, Yu Z J, Graczyk Zajac M, Xiong X, Riedel R 2022 J. Adv. Ceram. 11 197

Google Scholar

Google Scholar

[6] Yu R, Zhang H L, Guo B L 2022 Nano-Micro Lett. 14 1

Google Scholar

Google Scholar

[7] Zheng X T, Ananthanarayanan A, Luo K Q, Chen P 2015 Small 11 1620

Google Scholar

Google Scholar

[8] Zhang X Q, Zhang K Q, Zhang B, Li Y, He R J 2022 J. Adv. Ceram. 11 1918

Google Scholar

Google Scholar

[9] 包定华 2020 69 127712

Google Scholar

Google Scholar

Bao D H 2020 Acta Phys. Sin. 69 127712

Google Scholar

Google Scholar

[10] Zhu D Y, Nikl M, Chewpraditkul W, Li J 2022 J. Adv. Ceram. 11 1825

Google Scholar

Google Scholar

[11] Zou H, Yu Y, Li J, Cao Q F, Wang X S, Hou J W 2015 Mater. Res. Bull. 69 112

Google Scholar

Google Scholar

[12] Hao S L, Li J H, Sung Q B, Wei L L, Yang Z P 2019 J. Mater. Sci. -Mater. Electron. 30 13372

Google Scholar

Google Scholar

[13] Hao S L, Li J H, Yang P, Wei L L, Yang Z P 2017 J. Am. Ceram. Soc. 100 5620

Google Scholar

Google Scholar

[14] He J Y, Zhang J J, Xing H J, Pan H L, Jia X R, Wang J Y, Zheng P 2017 Ceram. Int. 43 250

Google Scholar

Google Scholar

[15] Jia Q, Zhang Q, Sun H, Hao X 2021 J. Eur. Ceram. Soc. 41 1211

Google Scholar

Google Scholar

[16] Jia Q N, Li Y, Guan L L, Sun H Q, Zhang Q W, Hao X H 2020 J. Mater. Sci. -Mater. Electron. 31 19277

Google Scholar

Google Scholar

[17] Hui X W, Peng D F, Zou H, Li J, Cao Q F, Li Y X, Wang X S, Yao X 2014 Ceram. Int. 40 12477

Google Scholar

Google Scholar

[18] Li W, Wang Z, Hao J G, Fu P, Du J, Chu R Q, Xu Z J 2018 J. Mater. Chem. C 6 11312

Google Scholar

Google Scholar

[19] Liu Y, Luo H, Zhai D, Zeng L, Xiao Z, Hu Z, Wang X, Zhang D 2022 ACS Appl. Mater. Interfaces 14 19376

Google Scholar

Google Scholar

[20] Qin Y L, Zhang S J, Wu Y Q, Lu C J, Zhang J L 2017 J. Eur. Ceram. Soc. 37 3493

Google Scholar

Google Scholar

[21] Yang Z T, Du H L, Jin L, Poelman D 2021 J. Mater. Chem. A 9 18026

Google Scholar

Google Scholar

[22] Cao R P, Wang W H, Ren Y, Hu Z F, Zhou X C, Xu Y C, Luo Z Y, Liang A H 2021 J. Lumin. 235 118054

Google Scholar

Google Scholar

[23] Sun H Q, Liu J, Wang X S, Zhang Q W, Hao X H, An S L 2017 J. Mater. Chem. C 5 9080

Google Scholar

Google Scholar

[24] Lü J W, Li Q, Li Y, Tang M Y, Jin D L, Yan Y, Fan B Y, Jin L, Liu G 2021 Chem. Eng. J. 420 129900

Google Scholar

Google Scholar

[25] Du P, Yu J S 2015 Ceram. Int. 41 6710

Google Scholar

Google Scholar

[26] Said S, Marchet P, Merle Mejean T, Mercurio J P 2004 Mater. Lett. 58 1405

Google Scholar

Google Scholar

[27] Choi H, Cho S H, Khan S, Lee K R, Kim S 2014 J. Mater. Chem. C 2 6017

Google Scholar

Google Scholar

[28] Lun M M, Wang W, Xing Z F, Wan Z, Wu W Y, Song H Z, Wang Y Z, Li W, Chu B L, He Q Y 2019 J. Am. Ceram. Soc. 102 5243

Google Scholar

Google Scholar

[29] Xue J P, Noh H M, Choi B C, Park S H, Kim J H, Jeong J H, Du P 2020 Chem. Eng. J. 382 122861

Google Scholar

Google Scholar

[30] Li F F, Liu Y F, Lyu Y N, Qi Y H, Yu Z L, Lu C G 2017 Ceram. Int. 43 106

Google Scholar

Google Scholar

[31] Han K, Luo N N, Chen Z P, Ma L, Chen X Y, Feng Q, Hu C Z, Zhou H F, Wei Y Z, Toyohisa F 2020 J. Eur. Ceram. Soc. 40 3562

Google Scholar

Google Scholar

[32] Zhang M H, Qi J L, Liu Y Q, Lan S, Luo Z X, Pan H, Lin Y H 2022 Rare Metals 41 730

Google Scholar

Google Scholar

[33] Huang Y, Zhao C, Wu B, Zhang X 2022 J. Eur. Ceram. Soc. 42 2764

Google Scholar

Google Scholar

[34] Muthuramalingam M, Ruth D E J, Babu M V G, Ponpandian N, Mangalaraj D, Sundarakannan B 2016 Scr. Mater. 112 58

Google Scholar

Google Scholar

[35] Zheng M, Guan P, Ji X 2023 CrystEngComm 25 541

Google Scholar

Google Scholar

[36] Guan P F, Zhang Y X, Yang J, Zheng M 2023 Ceram. Int. 49 11796

Google Scholar

Google Scholar

[37] Ma C L, Wang X Y, Tan W S, Zhou W P, Wang X X, Cheng Z Z, Chen G B, Zhai Z Y 2020 Dalton Trans. 49 5581

Google Scholar

Google Scholar

[38] Yang Z T, Du H L, Qu S B, Hou Y D, Ma H, Wang J F, Wang J, Wei X Y, Xu Z 2016 J. Mater. Chem. A 4 13778

Google Scholar

Google Scholar

[39] Zhang Y M, Liang G C, Tang S L, Peng B L, Zhang Q, Liu L J, Sun W H 2020 Ceram. Int. 46 1343

Google Scholar

Google Scholar

[40] 杜金华, 李雍, 孙宁宁, 赵烨, 郝喜红 2020 69 127703

Google Scholar

Google Scholar

Du J H, Li Y, Sun N N, Zhao Y, Hao X H 2020 Acta Phys. Sin. 69 127703

Google Scholar

Google Scholar

[41] Wei T, Sun F C, Zhao C Z, Li C P, Yang M, Wang Y Q 2013 Ceram. Int. 39 9823

Google Scholar

Google Scholar

[42] Singh V, Watanabe S, Rao T K G, Chubaci J F D, Kwak H Y 2010 J. Non-Cryst. Solids 356 1185

Google Scholar

Google Scholar

[43] Raju G S R, Pavitra E, Patnam H, Varaprasad G L, Chodankar N R, Patil S J, Ranjith K S, Rao M V B, Yu J S, Park J Y, Huh Y S, Han Y K 2022 J. Alloys Compd. 903 163881

Google Scholar

Google Scholar

-

图 5 (a) BNTBT:0.2%Sm3+陶瓷PL激发光谱; (b) 不同掺杂浓度在408 nm光激发下的发射光谱; (c) 不同发射峰的PL强度变化图; (d) ΔI/I图

Fig. 5. (a) PLE spectrum of BNTBT:0.2%Sm3+ ceramic; (b) PL spectrum under 408 nm excitation with diverse doping concentrations; (c) the PL intensity change diagram at different emission peaks; (d) the diagram of ΔI/I.

-

[1] Famprikis T, Canepa P, Dawson J A, Islam M S, Masquelier C 2019 Nat. Mater. 18 1278

Google Scholar

Google Scholar

[2] Guo P F, Su L, Peng K, Lu D, Xu L, Li M Z, Wang H J 2022 ACS Nano 16 6625

Google Scholar

Google Scholar

[3] Zheng B Z, Fan J Y, Chen B, Qin X, Wang J, Wang F, Deng R R, Liu X G 2022 Chem. Rev. 122 5519

Google Scholar

Google Scholar

[4] Nazir H, Batool M, Osorio F J B, Isaza-Ruiz M, Xu X H, Vignarooban K, Phelan P, Inamuddin, Kannan A M 2019 Int. J. Heat Mass Transfer 129 491

Google Scholar

Google Scholar

[5] Wen Q B, Qu F M, Yu Z J, Graczyk Zajac M, Xiong X, Riedel R 2022 J. Adv. Ceram. 11 197

Google Scholar

Google Scholar

[6] Yu R, Zhang H L, Guo B L 2022 Nano-Micro Lett. 14 1

Google Scholar

Google Scholar

[7] Zheng X T, Ananthanarayanan A, Luo K Q, Chen P 2015 Small 11 1620

Google Scholar

Google Scholar

[8] Zhang X Q, Zhang K Q, Zhang B, Li Y, He R J 2022 J. Adv. Ceram. 11 1918

Google Scholar

Google Scholar

[9] 包定华 2020 69 127712

Google Scholar

Google Scholar

Bao D H 2020 Acta Phys. Sin. 69 127712

Google Scholar

Google Scholar

[10] Zhu D Y, Nikl M, Chewpraditkul W, Li J 2022 J. Adv. Ceram. 11 1825

Google Scholar

Google Scholar

[11] Zou H, Yu Y, Li J, Cao Q F, Wang X S, Hou J W 2015 Mater. Res. Bull. 69 112

Google Scholar

Google Scholar

[12] Hao S L, Li J H, Sung Q B, Wei L L, Yang Z P 2019 J. Mater. Sci. -Mater. Electron. 30 13372

Google Scholar

Google Scholar

[13] Hao S L, Li J H, Yang P, Wei L L, Yang Z P 2017 J. Am. Ceram. Soc. 100 5620

Google Scholar

Google Scholar

[14] He J Y, Zhang J J, Xing H J, Pan H L, Jia X R, Wang J Y, Zheng P 2017 Ceram. Int. 43 250

Google Scholar

Google Scholar

[15] Jia Q, Zhang Q, Sun H, Hao X 2021 J. Eur. Ceram. Soc. 41 1211

Google Scholar

Google Scholar

[16] Jia Q N, Li Y, Guan L L, Sun H Q, Zhang Q W, Hao X H 2020 J. Mater. Sci. -Mater. Electron. 31 19277

Google Scholar

Google Scholar

[17] Hui X W, Peng D F, Zou H, Li J, Cao Q F, Li Y X, Wang X S, Yao X 2014 Ceram. Int. 40 12477

Google Scholar

Google Scholar

[18] Li W, Wang Z, Hao J G, Fu P, Du J, Chu R Q, Xu Z J 2018 J. Mater. Chem. C 6 11312

Google Scholar

Google Scholar

[19] Liu Y, Luo H, Zhai D, Zeng L, Xiao Z, Hu Z, Wang X, Zhang D 2022 ACS Appl. Mater. Interfaces 14 19376

Google Scholar

Google Scholar

[20] Qin Y L, Zhang S J, Wu Y Q, Lu C J, Zhang J L 2017 J. Eur. Ceram. Soc. 37 3493

Google Scholar

Google Scholar

[21] Yang Z T, Du H L, Jin L, Poelman D 2021 J. Mater. Chem. A 9 18026

Google Scholar

Google Scholar

[22] Cao R P, Wang W H, Ren Y, Hu Z F, Zhou X C, Xu Y C, Luo Z Y, Liang A H 2021 J. Lumin. 235 118054

Google Scholar

Google Scholar

[23] Sun H Q, Liu J, Wang X S, Zhang Q W, Hao X H, An S L 2017 J. Mater. Chem. C 5 9080

Google Scholar

Google Scholar

[24] Lü J W, Li Q, Li Y, Tang M Y, Jin D L, Yan Y, Fan B Y, Jin L, Liu G 2021 Chem. Eng. J. 420 129900

Google Scholar

Google Scholar

[25] Du P, Yu J S 2015 Ceram. Int. 41 6710

Google Scholar

Google Scholar

[26] Said S, Marchet P, Merle Mejean T, Mercurio J P 2004 Mater. Lett. 58 1405

Google Scholar

Google Scholar

[27] Choi H, Cho S H, Khan S, Lee K R, Kim S 2014 J. Mater. Chem. C 2 6017

Google Scholar

Google Scholar

[28] Lun M M, Wang W, Xing Z F, Wan Z, Wu W Y, Song H Z, Wang Y Z, Li W, Chu B L, He Q Y 2019 J. Am. Ceram. Soc. 102 5243

Google Scholar

Google Scholar

[29] Xue J P, Noh H M, Choi B C, Park S H, Kim J H, Jeong J H, Du P 2020 Chem. Eng. J. 382 122861

Google Scholar

Google Scholar

[30] Li F F, Liu Y F, Lyu Y N, Qi Y H, Yu Z L, Lu C G 2017 Ceram. Int. 43 106

Google Scholar

Google Scholar

[31] Han K, Luo N N, Chen Z P, Ma L, Chen X Y, Feng Q, Hu C Z, Zhou H F, Wei Y Z, Toyohisa F 2020 J. Eur. Ceram. Soc. 40 3562

Google Scholar

Google Scholar

[32] Zhang M H, Qi J L, Liu Y Q, Lan S, Luo Z X, Pan H, Lin Y H 2022 Rare Metals 41 730

Google Scholar

Google Scholar

[33] Huang Y, Zhao C, Wu B, Zhang X 2022 J. Eur. Ceram. Soc. 42 2764

Google Scholar

Google Scholar

[34] Muthuramalingam M, Ruth D E J, Babu M V G, Ponpandian N, Mangalaraj D, Sundarakannan B 2016 Scr. Mater. 112 58

Google Scholar

Google Scholar

[35] Zheng M, Guan P, Ji X 2023 CrystEngComm 25 541

Google Scholar

Google Scholar

[36] Guan P F, Zhang Y X, Yang J, Zheng M 2023 Ceram. Int. 49 11796

Google Scholar

Google Scholar

[37] Ma C L, Wang X Y, Tan W S, Zhou W P, Wang X X, Cheng Z Z, Chen G B, Zhai Z Y 2020 Dalton Trans. 49 5581

Google Scholar

Google Scholar

[38] Yang Z T, Du H L, Qu S B, Hou Y D, Ma H, Wang J F, Wang J, Wei X Y, Xu Z 2016 J. Mater. Chem. A 4 13778

Google Scholar

Google Scholar

[39] Zhang Y M, Liang G C, Tang S L, Peng B L, Zhang Q, Liu L J, Sun W H 2020 Ceram. Int. 46 1343

Google Scholar

Google Scholar

[40] 杜金华, 李雍, 孙宁宁, 赵烨, 郝喜红 2020 69 127703

Google Scholar

Google Scholar

Du J H, Li Y, Sun N N, Zhao Y, Hao X H 2020 Acta Phys. Sin. 69 127703

Google Scholar

Google Scholar

[41] Wei T, Sun F C, Zhao C Z, Li C P, Yang M, Wang Y Q 2013 Ceram. Int. 39 9823

Google Scholar

Google Scholar

[42] Singh V, Watanabe S, Rao T K G, Chubaci J F D, Kwak H Y 2010 J. Non-Cryst. Solids 356 1185

Google Scholar

Google Scholar

[43] Raju G S R, Pavitra E, Patnam H, Varaprasad G L, Chodankar N R, Patil S J, Ranjith K S, Rao M V B, Yu J S, Park J Y, Huh Y S, Han Y K 2022 J. Alloys Compd. 903 163881

Google Scholar

Google Scholar

计量

- 文章访问数: 3876

- PDF下载量: 72

- 被引次数: 0

下载:

下载: