-

With the advent of the post-Moore era, the demand for large-capacity and high-speed information processing has caused the application of semiconductor devices to shift from electronic integration to photonic integration. High-performance micro-nano lasers are an important part of achieving photonic integration. Varieties of semiconductor materials have promoted the rapid development of semiconductor micro-nano lasers. In recent years, with the advent of a large number of new semiconductor materials (such as two-dimensional semiconductors, lead halide perovskites, etc.), it is expected that the performances of semiconductor micro-nano lasers will be further improved. Perovskite materials have excellent optical properties such as high light absorptions, high defect tolerances, and large exciton binding energy, which make them excellent candidate materials for high-gain, low-threshold semiconductor micro-nano lasers. The Fabry-Perot (F-P) resonator laser is a type of perovskite laser with extensive research, simple structure and high application value. In this paper, we take lead halide perovskite F-P resonator laser for example, and summarize its working mechanism and recent research results, by starting from two aspects of photon laser with exciton and photon weak coupling and strong coupling polariton laser. And we introduce the lasing principle and influencing factors of F-P structure lasers with perovskite materials as both gain medium and resonant cavity and F-P cavity lasers with perovskite as only gain medium in detail. Finally, the current challenges of perovskite F-P resonant lasers are summarized, and the possible prospects of its further development are also presented.

-

Keywords:

- perovskite /

- Fabry-Pérot cavity /

- lasing /

- polariton

[1] Liao Q, Jin X, Fu H B 2019 Adv. Opt. Mater. 7 1900099

Google Scholar

Google Scholar

[2] Min H, Kim M, Lee S U, Kim H, Kim G, Choi K, Lee J H, Seok S I 2019 Science 366 749

Google Scholar

Google Scholar

[3] Xu W D, Hu Q, Bai S, Bao C X, Miao Y F, Yuan Z C, Borzda T, Barker A J, Tyukalova E, Hu Z J, Kawecki M, Wang H Y, Yan Z B, Liu X J, Shi X B, Uvdal K, Fahlman M, Zhang W J, Duchamp M, Liu JM, Petrozza A, Wang J P, Liu LM, Huang W, Gao F 2019 Nat. Photonics 13 418

Google Scholar

Google Scholar

[4] Zhang Y, Lim C K, Dai Z, Yu G, Haus J W, Zhang H, Prasad P N 2019 Phys. Rep. 795 1

Google Scholar

Google Scholar

[5] Xing G C, Mathews N, Lim S S, Yantara N, Liu X F, Sabba D, Gratzel M, Mhaisalkar S, Sum T C 2014 Nat. Mater. 13 476

Google Scholar

Google Scholar

[6] 王兰, 董渊, 嵩高, 陈奎一, 房法成, 金光勇 2019 中国光学 12 993

Google Scholar

Google Scholar

Wang L, Dong Y, Gao S, Chen K Y, Fang F C, Jin G Y, 2019 Chin. Opt. 12 993

Google Scholar

Google Scholar

[7] Li G H, Chen K Q, Cui Y X, Zhang Y P, Tian Y, Tian B N, Hao Y Y, Wu Y C, Zhang H 2020 Adv. Opt. Mater. 8 1902012

Google Scholar

Google Scholar

[8] Liu Y, Siron M, Lu D, Yang J J, dos Reis R, Cui F, Gao M Y, Lai M L, Lin J, Kong Q, Lei T, Kang J, Jin J B, Ciston J, Yang P D 2019 J. Am. Chem. Soc. 141 13028

Google Scholar

Google Scholar

[9] Fu Y P, Zhu H M, Stoumpos C C, Ding Q, Wang J, Kanatzidis M G, Zhu X Y, Jin S 2016 ACS Nano 10 7963

Google Scholar

Google Scholar

[10] 楼浩然, 叶志镇, 何海平 2019 68 36

Google Scholar

Google Scholar

Lou H R, Ye Z Z, He H P 2019 Acta.Phys. Sin. 68 36

Google Scholar

Google Scholar

[11] Lei L, Seyitliyev D, Stuard S, Mendes J, Dong Q, Fu X Y, Chen YA, He S L, Yi X P, Zhu L P, Chang CH, Ade H, Gundogdu K, So F 2020 Adv. Mater. 32 1906571

Google Scholar

Google Scholar

[12] Doherty T A S, Winchester A J, Macpherson S, Johnstone D N, Pareek V, Tennyson E M, Kosar S, Kosasih F U, Anaya M, Abdi-Jalebi M, Andaji-Garmaroudi Z, Wong E L, Madeo J, Chiang Y H, Park J S, Jung Y K, Petoukhoff C E, Divitini G, Man M K L, Ducati C, Walsh A, Midgley P A, Dani K M, Stranks S D 2020 Nature 580 360

Google Scholar

Google Scholar

[13] Gunnarsson W B, Rand B P 2020 Appl. Mater. 8 030902

Google Scholar

Google Scholar

[14] 霍成学, 王子明, 李晓明, 曾海波 2017 中国激光 44 120

Google Scholar

Google Scholar

Huo C X, Wang Z M, Li X M, Zeng H B 2017 Chin. Opt. 44 120

Google Scholar

Google Scholar

[15] 黄斯豪, 刘征征, 杜鹃, 冷雨欣 2020 激光与光电子学进展 57 071602

Google Scholar

Google Scholar

Huang S H, Liu Z Z, Du J, Leng Y X 2020 Laser & Optoelectronics Progress 57 071602

Google Scholar

Google Scholar

[16] Zhang Q, Su R, Du W N, Liu X F, Zhao L Y, Ha S T, Xiong Q H 2017 Small Methods 1 Unsp 1700163

Google Scholar

Google Scholar

[17] Li M L, Gao Q G, Liu P, Liao Q, Zhang H H, Yao J N, Hu W P, Wu Y S, Fu H B 2018 Adv. Funct. Mater. 28 1707006

Google Scholar

Google Scholar

[18] Dong H Y, Zhang C H, Liu X L, Yao J N, Zhao Y S 2020 Chem. Soc. Rev. 49 951

Google Scholar

Google Scholar

[19] Wang J, Da P M, Zhang Z, Luo S, Liao L M, Sun Z Y, Shen X C, Wu S W, Zheng G F, Chen Z H 2018 Nanoscale 10 10371

Google Scholar

Google Scholar

[20] Baranov D G, Wersall M, Cuadra J, Antosiewicz T J, Shegai T 2018 ACS Photonics 5 24

Google Scholar

Google Scholar

[21] De Giorgi M L, Anni M 2019 Appl. Sci.-Basel 9 4591

Google Scholar

Google Scholar

[22] Schlaus A P, Spencer M S, Zhu X Y 2019 Acc. Chem. Res. 52 2950

Google Scholar

Google Scholar

[23] Eaton S W, Fu A, Wong A B, Ning C Z, Yang P D 2016 Nat. Rev. Mater. 1 16028

Google Scholar

Google Scholar

[24] Sasaki F, Zhou Y, Sonoda Y, Azumi R, Mochizuki H, Van-Cao N, Yanagi H 2017 Jpn. J. Appl. Phys. 56 04cl07

Google Scholar

Google Scholar

[25] Shen X M, Chen M M, Shi L J, Chen F, Liu Y, Cao D W, Xu C X 2019 Opt. Commun. 45. Unsp 124354

Google Scholar

Google Scholar

[26] Chen S T, Zhang C, Lee J, Han J, Nurmikko A 2017 Adv. Mater. 29 1604781

Google Scholar

Google Scholar

[27] Arash R-I 2020 Polariton Physics (Vol. 229) (Springer Series in Optical Sciences: Springer, Cham) pp33–64

[28] Li B B, Zhou T J, Fang X, Zhang W L, Li X M, Guan Z Q, Li J Y, Wang L, Hark S, Zhang Z Y 2019 J. Mater. Chem. C 7 4102

Google Scholar

Google Scholar

[29] Chen F, Xu C X, Xu Q Y, Zhu Z, Qin F F, Manohari A G, Zhu Y Z 2017 J. Mater. Chem. C 5 9238

Google Scholar

Google Scholar

[30] Liu Z Z, Yang J, Du J, Hu Z P, Shi T C, Zhang Z Y, Liu Y Q, Tang X S, Leng Y X, Li R X 2018 ACS Nano 12 5923

Google Scholar

Google Scholar

[31] Li C, Liu Z, Shang Q Y, Zhang Q 2019 Adv. Opt. Mater. 7 1900279

Google Scholar

Google Scholar

[32] Yang L, Li Z Q, Liu C, Yao X R, Li H Q, Liu X X, Liu J S, Zhu P W, Liu B B, Cui T, Sun C, Bao Y J 2019 J. Phys. Chem. Lett. 10 7056

Google Scholar

Google Scholar

[33] Liu Z, Shang Q Y, Li C, Zhao L Y, Gao Y, Li Q, Chen J, Zhang S, Liu X F, Fu Y S, Zhang Q 2019 Appl. Phys. Lett. 114 101902

Google Scholar

Google Scholar

[34] Eaton S W, Lai M L, Gibson N A, Wong A B, Dou L T, Ma J, Wang LW, Leone S R, Yang P D 2016 Proc. Natl. Acad. Sci. U.S.A. 113 1993

Google Scholar

Google Scholar

[35] Liu P, He X X, Ren J H, Liao Q, Yao J N, Fu H B 2017 ACS Nano 11 5766

Google Scholar

Google Scholar

[36] Schlaus A P, Spencer M S, Miyata K, Liu F, Wang X X, Datta I, Lipson M, Pan A L, Zhu X Y 2019 Nat. Commun. 10 265

Google Scholar

Google Scholar

[37] Mi Y, Zhong Y G, Zhang Q, Liu X F 2019 Adv. Opt. Mater. 7 1900544

Google Scholar

Google Scholar

[38] Chen S T, Nurmikko A 2017 ACS Photonics 4 2486

Google Scholar

Google Scholar

[39] Zhang L, Yuan F, Dong H, Jiao B, Zhang W W, Hou X, Wang S F, Gong Q H, Wu Z X 2018 ACS Appl. Mater. Interfaces 10 40661

Google Scholar

Google Scholar

[40] Zhai W H, Tian C, Yuan K, Ge C Y, Zhao S Q, Yu H R, Li Y P, Chen W X, Ran G Z 2019 Appl. Phys. Lett. 114 131107

Google Scholar

Google Scholar

[41] Chen S T, Nurmikko A 2018 Optica 5 1141

Google Scholar

Google Scholar

[42] Huang CY, Zou C, Mao C, Corp K L, Yao YC, Lee YJ, Schlenker C W, Jen A K Y, Lin L Y 2017 ACS Photonics 4 2281

Google Scholar

Google Scholar

[43] Snoke D 2012 Exciton Polariton in Microcavities (Vol. 172) (Springer Series in Solid-State Sciences: Springer, Berlin, Heidelberg) pp307−327

[44] Nespolo J, Carusotto I 2019 Phys. Rev. B 100 035305

Google Scholar

Google Scholar

[45] Su R, Ghosh S, Wang J, Liu S, Diederichs C, Liew T C H, Xiong Q H 2020 Nat. Phys. 16 301

Google Scholar

Google Scholar

[46] Du W N, Zhang S, Shi J, Chen J, Wu Z Y, Mi Y, Liu Z X, Li Y Z, Sui X Y, Wang R, Qiu X H, Wu T, Xiao Y F, Zhang Q, Liu X F 2018 ACS Photonics 5 2051

Google Scholar

Google Scholar

[47] Evans T J S, Schlaus A, Fu Y P, Zhong X J, Atallah T L, Spencer M S, Brus L E, Jin S, Zhu X Y 2018 Adv. Opt. Mater. 6 1700982

Google Scholar

Google Scholar

[48] Park K, Lee J W, Kim J D, Han N S, Jang D M, Jeong S, Park J, Song J K 2016 J. Phys. Chem. Lett. 7 3703

Google Scholar

Google Scholar

[49] Zhang S, Shang Q Y, Du W N, Shi J, Wu Z Y, Mi Y, Chen J, Liu F J, Li Y Z, Liu M, Zhang Q, Liu X F 2018 Adv. Opt. Mater. 6 1701032

Google Scholar

Google Scholar

[50] Wang X X, Shoaib M, Wang X, Zhang X H, He M, Luo Z Y, Zheng W H, Li H L, Yang T F, Zhu X L, Ma L B, Pan A L 2018 ACS Nano 12 6170

Google Scholar

Google Scholar

[51] Shang Q Y, Li C, Zhang S, Liang Y, Liu Z, Liu X F, Zhang Q 2020 Nano Lett. 20 1023

Google Scholar

Google Scholar

[52] Zhao Z, Zhong M Y, Zhou W C, Peng Y H, Yin Y L, Tang D S, Zou B S 2019 J. Phys. Chem. C 123 25349

Google Scholar

Google Scholar

[53] Du W N, Zhang S, Zhang Q, Liu X F 2019 Adv. Mater. 31 1804894

Google Scholar

Google Scholar

[54] Han Q, Wang J, Lu J, Sun L, Lyu F, Wang H, Chen Z, Wang Z 2020 ACS Photonics 7 454

Google Scholar

Google Scholar

[55] Zhang X, Shi H, Dai H, Zhang X, Sun X W, Zhang Z 2020 ACS Appl. Mater. Interfaces 12 5081

Google Scholar

Google Scholar

[56] Fieramosca A, Polimeno L, Ardizzone V, De Marco L, Pugliese M, Maiorano V, De Giorgi M, Dominici L, Gigli G, Gerace D, Ballarini D, Sanvitto D 2019 Sci. Adv. 5 eaav9967

Google Scholar

Google Scholar

[57] Liang Y, Shang Q Y, Wei Q, Zhao L Y, Liu Z, Shi J, Zhong Y G, Chen J, Gao Y, Li M L, Liu X F, Xing G C, Zhang Q 2019 Adv. Mater. 31 1903030

Google Scholar

Google Scholar

[58] Su R, Diederichs C, Wang J, Liew T C H, Zhao J, Liu S, Xu W G, Chen Z, Xiong Q H 2017 Nano Lett. 17 3982

Google Scholar

Google Scholar

[59] Wang J, Su R, Xing J, Bao D, Diederichs C, Liu S, Liew T C H, Chen Z H, Xiong Q H 2018 ACS Nano 12 8382

Google Scholar

Google Scholar

[60] Zhang S, Chen J, Shi J, Fu L, Du W N, Sui X Y, Mi Y, Jia Z L, Liu F J, Shi J W, Wu X X, Tang N, Zhang Q, Liu X F 2020 ACS Photonics 7 327

Google Scholar

Google Scholar

[61] Tian C, guo T, Zhao S Q, Zhai W H, Ge C Y, Ran G Z 2019 RSC Adv. 9 35984

Google Scholar

Google Scholar

-

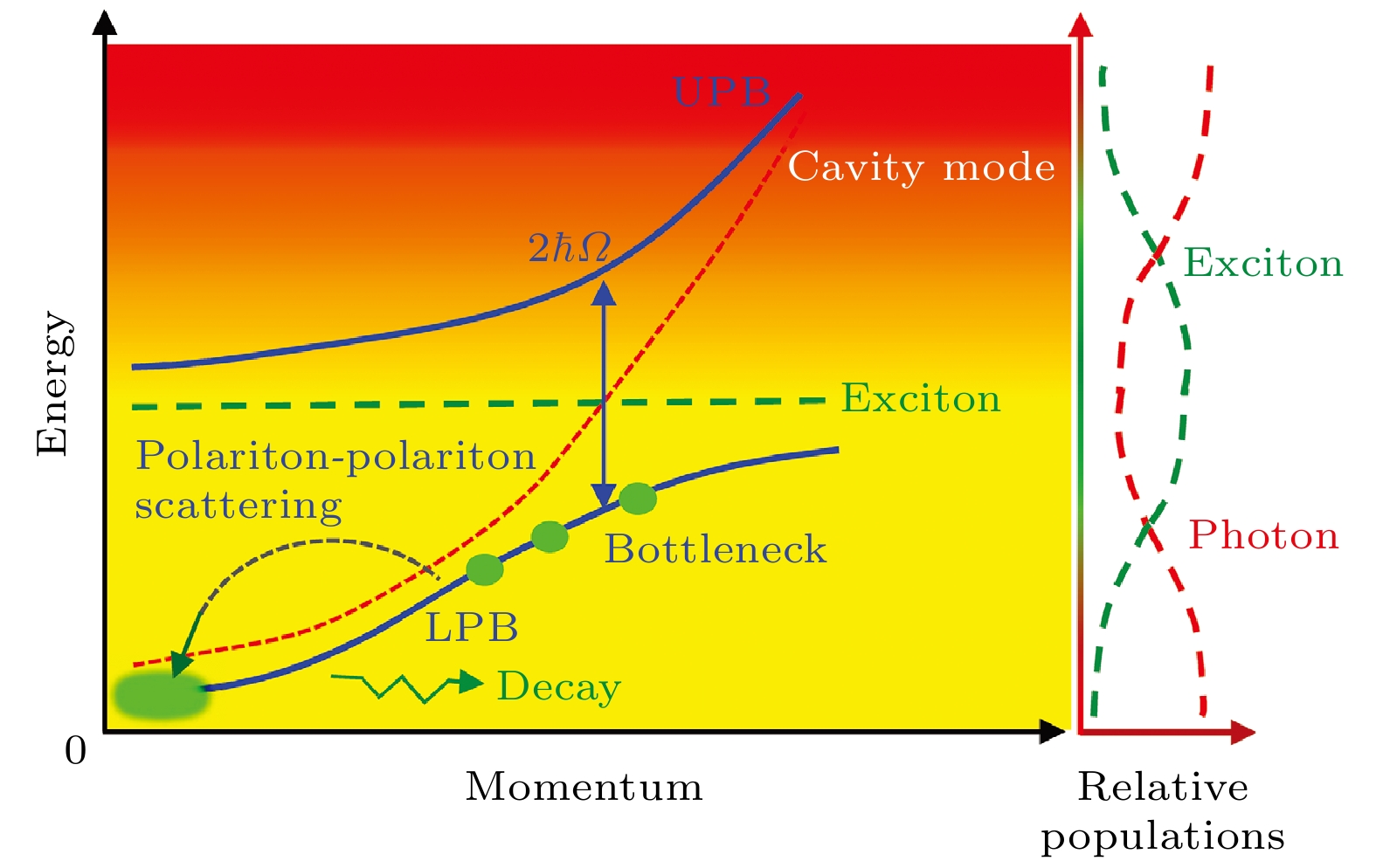

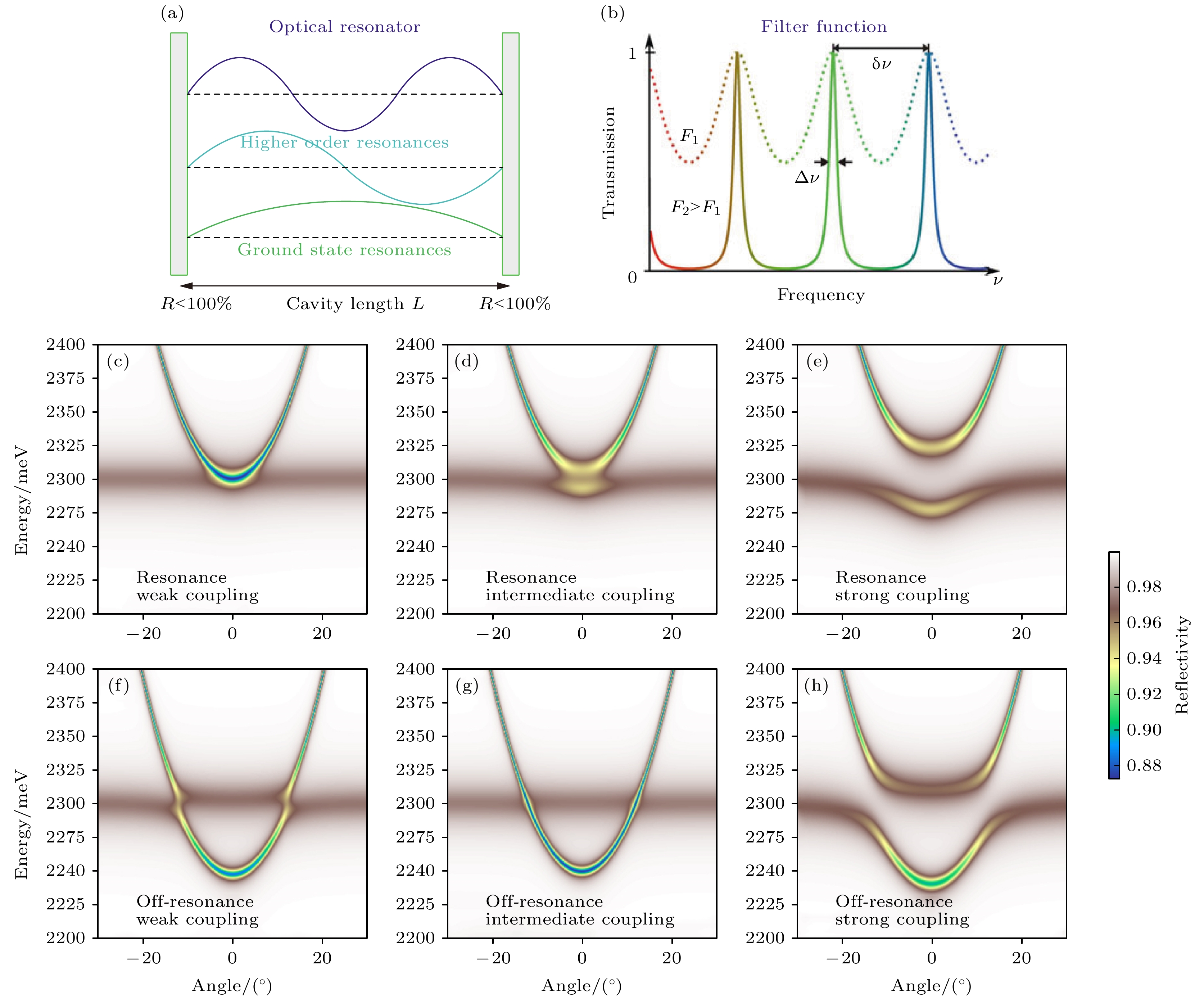

图 1 (a) F-P腔结构与共振波形; (b) F-P腔振荡频谱; (c)−(h)激子与F-P腔光子共振和非共振下弱耦合、临界与强耦合的角分辨光致发光谱[22,23]

Figure 1. (a) F-P cavity structure and resonant waveform; (b) frequency spectrum of F-P resonant cavity; (c)−(h) angle-resolved photoluminescence spectra of exciton and F-P cavity photon in resonant/off-resonant weak coupling, intermediate coupling and strong coupling[22,23].

图 2 (a) CH3NH3PbBr3微片不同宽度 (L) 的激光光谱; (b) 微片的宽度与

${\lambda }^{2}/(2{\Delta }\lambda$ )的拟合曲线($ \lambda = $ 554.4 nm)[29]Figure 2. (a) Laser spectra of CH3NH3PbBr3 microsheets with different widths (L); (b) fitting curve of

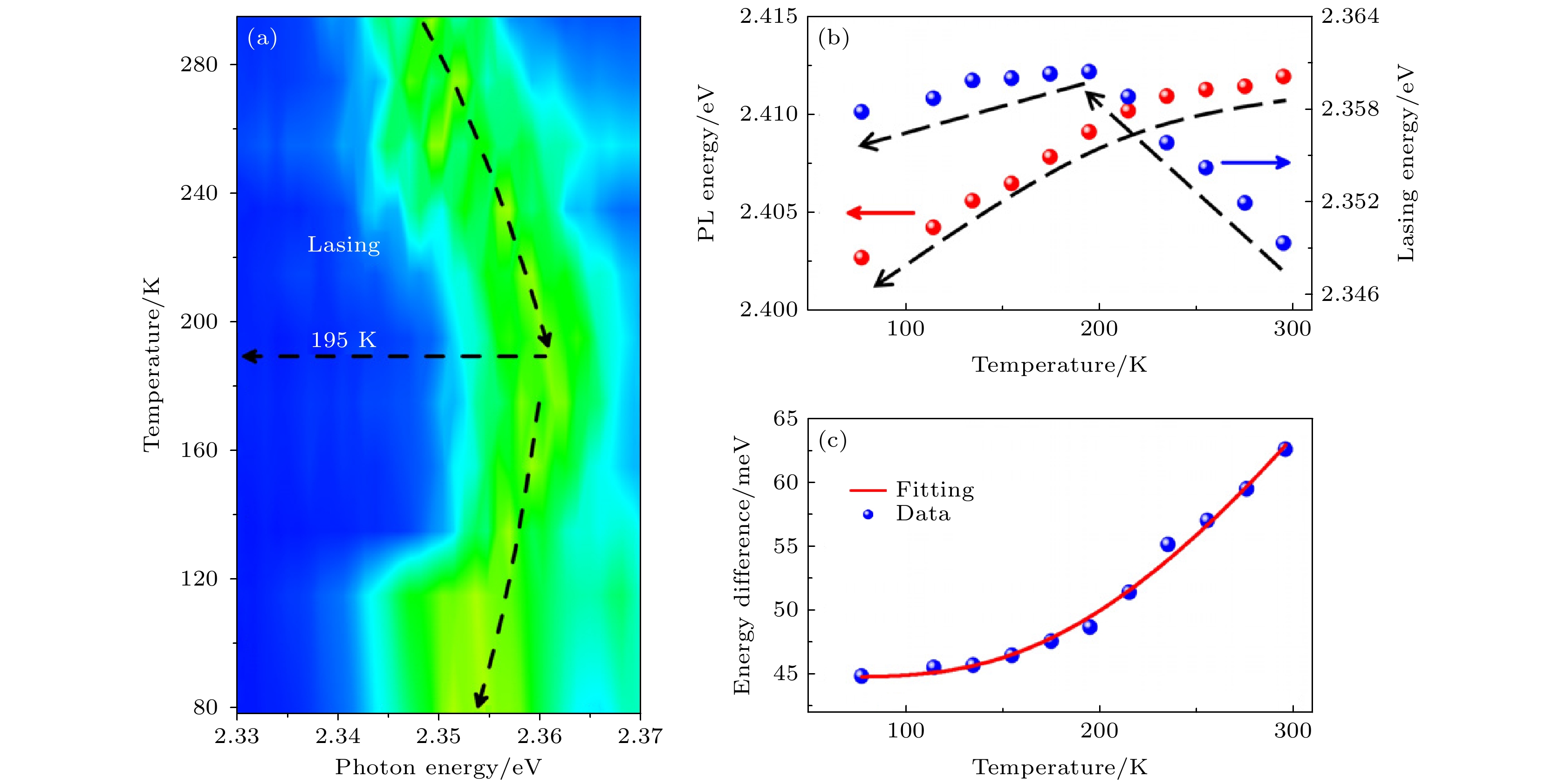

${\lambda }^{2}/(2{\Delta }\lambda)$ versus width of microsheets ($ \lambda = $ 554.4 nm)[29].图 3 CsPbBr3纳米线的温度依赖性激光行为 (a) 78 −295 K的不同温度下, 纳米线的2D伪色彩图的激光光谱; (b) 提取的SE (红点)和激光(蓝点)能量随温度变化; (c) SE与激光峰的能量差在温度从78 K增加到295 K的变化图. 红色实线为拟合结果[33]

Figure 3. Temperature-dependent lasing behavior of a CsPbBr3 NW: (a) The lasing spectra of a 2D pseudo-color plot of the NW at different temperatures from 78 K to 295 K; (b) the extracted SE (red dots) and lasing (blue dots) energies as a function of temperature; (c) plot of the change in the energy difference with temperature increasing from 78 K to 295 K. The red solid line is the fitting result[33].

图 4 (a)在蓝宝石衬底上生长的三棱柱纳米线的扫描电子显微镜图像; (b) 纳米线中最低阶波导模式的有限元模拟图(电场极化方向由青色箭头表示); (c) 用于时间分辨的Kerr门控实验的光学装置的图示. 线性偏振 (I)在脉冲光穿过Kerr介质时变为椭圆偏振光 (II), 经过偏振器变为垂直于原始入射偏振的偏振光 (III); (d) 光激发的载流子动力学过程示意图, 激光来源于冷EHP与等离子基元的耦合的受激发射[36]

Figure 4. (a) Scanning electron microscopy images of triangular nanowires grown on sapphire substrate; (b) FEM simulation of the lowest order waveguiding mode in a nanowire (The electric field polarization is depicted by the cyan arrows); (c) illustration of the optical setup for time-resolved Kerr gating experiment. The linear polarization (I) becomes elliptical (II) as it passes through the Kerr medium with the pump pulse. A final polarizer (III) filters polarization perpendicular to the original incident polarization; (d) cartoon describing the carrier dynamics from photoexcitation which results in a hot electron hole plasma (hot EHP) through carrier cooling to a cold electron hole plasma (cold EHP) finishing with stimulated emission coupled with plasmon emission[36].

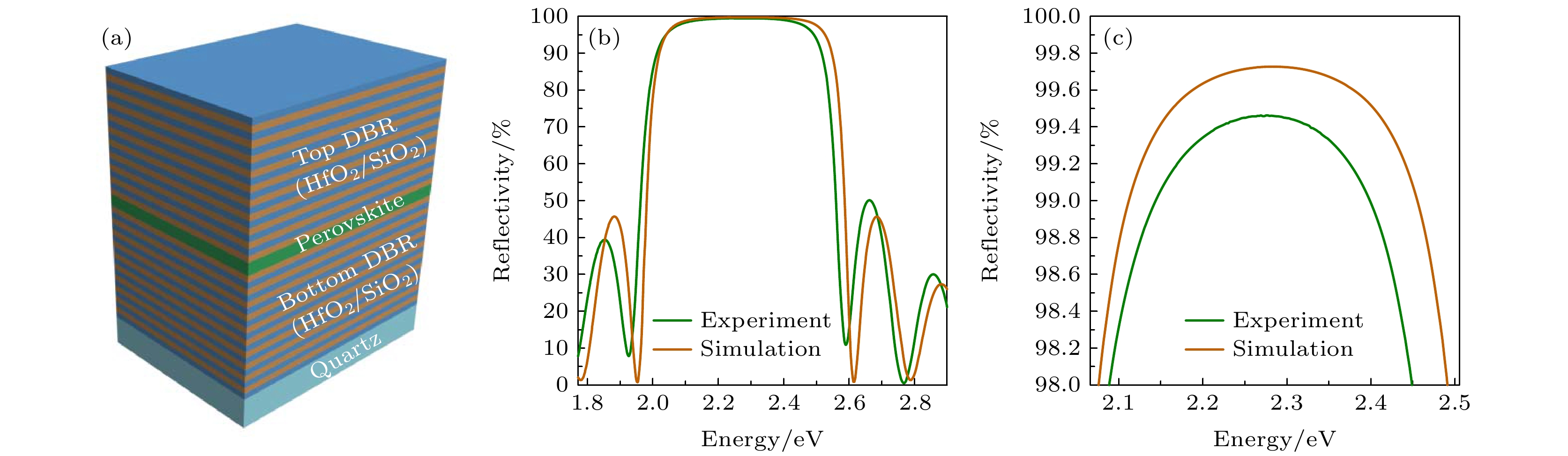

图 5 (a) 钙钛矿DBR激光器的示意图结构, DBR叠层由10对HfO2·SiO2组成; (b) HfO2·SiO2 DBR的实测反射率光谱与设计模拟值匹配较好; (c) 高反射率部分的放大图, 显示峰值反射率为99.5%, 光谱范围覆盖在2.145−2.398 eV (517−578 nm)[38]

Figure 5. (a) Schematic structure of mixed-cation perovskite DBR laser. The sputtered dielectric DBR stack consists of 10 pairs of HfO2/SiO2; (b) measuredreflectivity spectrum of a standalone HfO2/SiO2 DBR showing a reasonably good match with pre-deposition design simulation; (c) zoom-in view of the high-reflection band showing peak reflectivity of 99.5%, and a broad spectral window covering from 2.145 eV to 2.398 eV (517−578 nm) wherein reflectivity exceeds 99% [38].

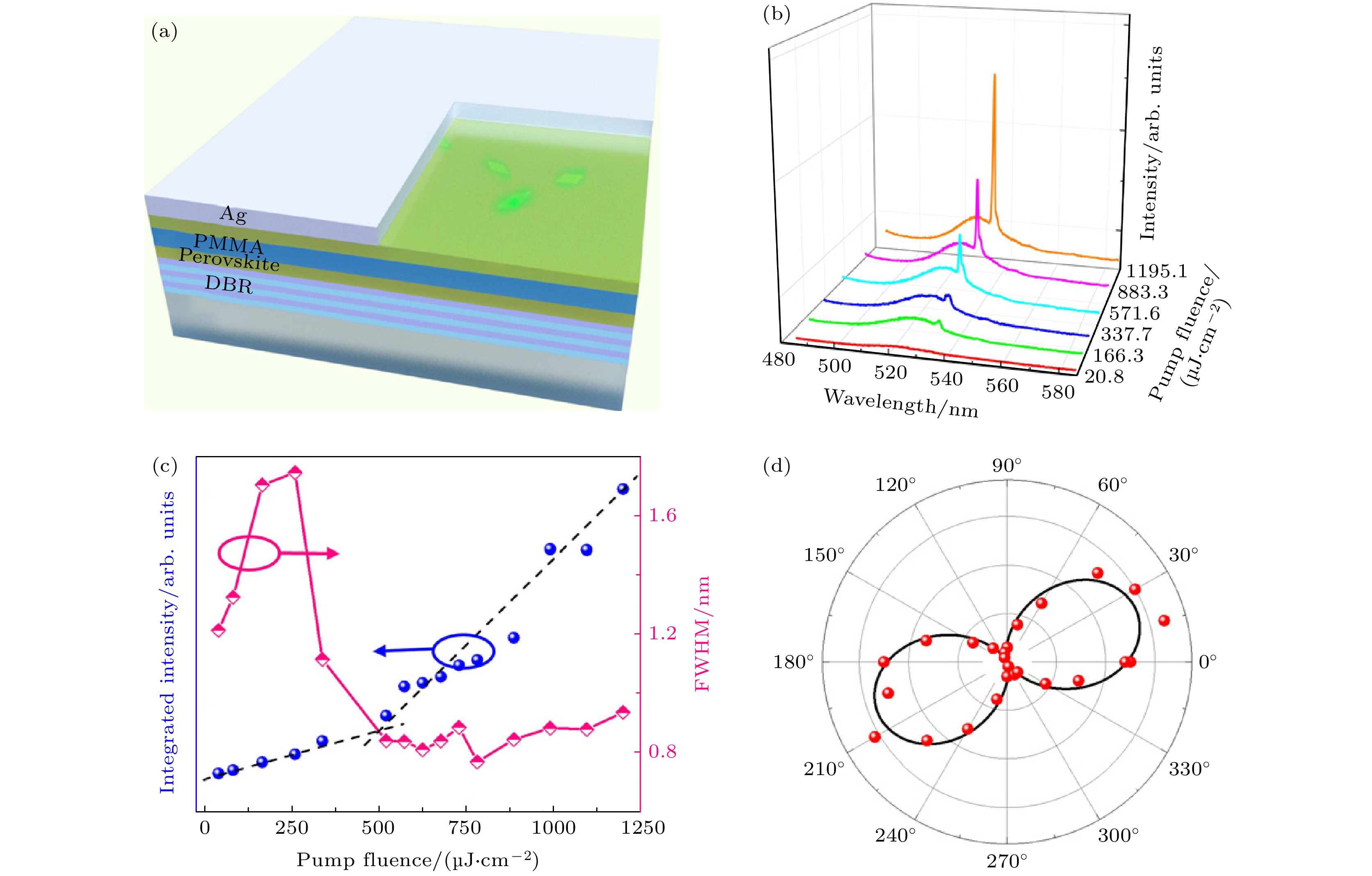

图 6 (a) Ruddlesden-Popper钙钛矿DBR腔体结构示意图; (b)器件发射光谱随泵浦强度的变化; (c)腔模式的积分强度强度(蓝色球)和半高宽(粉红色菱形)与泵浦强度的关系图; (d)旋转分析仪测得的强度极坐标图(红球), 黑线为马吕斯定律拟合曲线[36]

Figure 6. (a) Schematic diagram of cavity architecture; (b) pump fluence dependence of the emission spectra for the device; (c) the plots of integrated intensity (blue ball) and FWHM (pink diamond) of the cavity mode and the resulting lasing peak as a function of the pump fluence; (d) intensity polar plot through a rotational analyzer (red ball). The black line is the fitting curve from Malus’s law [36].

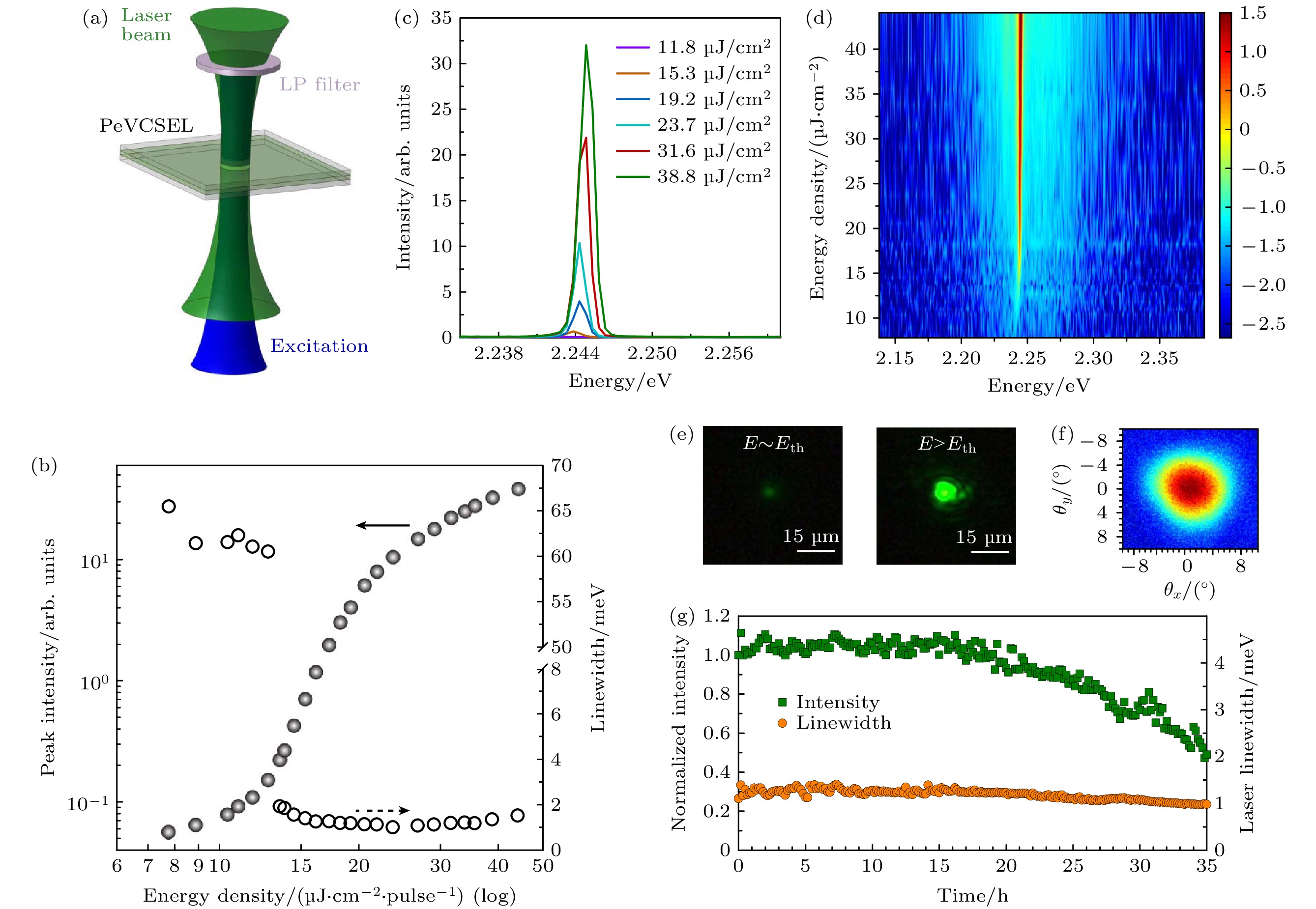

图 7 (a) 激光泵浦钙钛矿激光器的示意图(脉冲激光波长为3.493 eV,

${\tau }_{\mathrm{p}\mathrm{u}\mathrm{l}\mathrm{s}\mathrm{e}}=0.34~\mathrm{n}\mathrm{s}$ , 重复频率1 kHz); (b) 以对数值表示的器件光输出, 阈值能量密度为13.5$ \pm $ 1.4 μJ/cm2, 空圆圈表示发射光谱的半高宽; (c) 不同激发强度下的发射光谱, 观察到2.244 eV (λ = 552.5 nm)的单模激光, 半高宽为0.996 meV (Δλ = 0.245 nm); (d) 在对数值下在不同激发强度下器件发射的伪彩色图, 显示了单模操作和大背景抑制比(> 20 dB); (e) 泵能量密度接近或高于阈值时的器件的近场图像; (f) 器件发射的远场方向图, 在横向发散约5°; (g) 相同泵浦下(1.5倍阈值强度)测得的器件寿命. 绿色正方形为激光输出强度, 橙色圆圈为激光峰半高宽, 显示了持续的激光操作[41]Figure 7. (a) Schematic structure of a vertically pumped perovskite laser with a long-pass filter to block the pump residue. The pulsed pump source is acompact diode-pumped solid state laser (3.493 eV, τpulse= 0.34 ns, 1 kHz repetition rate). (b) Device light output with increasing pump fluence expressed in a log–log plot with threshold energy density of 13.5

$ \pm $ 1.4 μJ/cm2. The empty circles record the FWHM linewidth of the emission spectrum. (c) Emission spectra under different excitation levels. Spectrally coherent single-mode lasing at 2.244 eV (λ = 552.5 nm) with FWHM linewidth of 0.996 meV (Δλ = 0.245 nm) is observed. (d) Pseudo-color plot of laser emission under different levels of excitation in a logarithmic scale demonstrating the single mode operation and large background suppression ratio (>20 dB). (e) Near-field images of a device with pump energy densities near and above the threshold. (f) Far-field pattern of laser emission, with ~5° divergence in the transverse plane. (g) Device (longevity) lifetime measured under the same subnanosecond pumping source (1.5 times the threshold intensity). Green squares monitor the lasing output intensity, while the orange circles track the FWHM linewidth of the emission, indicating persistent lasing operation [41].图 9 (a) 20 μm的纳米线PL光谱图, 泵浦强度范围为0.25−7.80 kW/cm2; (b) 积分能量强度与泵浦强度的关系, 阈值为6 kW/cm2; (c)−(e) 20, 14和5 μm的纳米线阈值处的极化子激光荧光图; (f) 14 μm 纳米线腔光子(蓝线虚线)与激子(绿线)在77 K下的能量色散图, 红点表示LPB瓶颈处实验测得的极化子模式[46]

Figure 9. (a) PL spectra of a 20 μm long NW obtained with increasing excitation light power densities in the range of 0.25−7.80 kW/cm2. Inset (b) shows the integrated power density plotted against the power density, showing threshold near 6 kW/cm2. The right side shows fluorescence images above the polariton lasing threshold for NWs with length of (c) 20 μm, (d) 14 μm and (e) 5 μm. Thescale bad in (c) is 5 μm. (f) Dispersions of the cavity photon (blue dashed) and exciton(green) at 77 K of the 14 μm long NW without coupling, the red dots show the experimental CW polaritonmodes near the bottleneck region of the LPB [46].

图 10 CsPbBr3纳米线尺寸依赖的耦合强度 (a)−(d)宽度为3.31, 1.99, 1.19和0.78 μm, 长度为11.01, 14.02, 16.41和20.77 μm的纳米线从一端激发在另一端收集的发光光谱. 光谱在洛伦兹拟合下展现出多个F-P模式峰; (e)−(f)上方对应的纳米线Z方向的能量-波矢曲线, 内部图片为对应纳米线横向电场分布图[50]

Figure 10. Size-dependent light-matter coupling strength in CsPbBr3micro/nanowires: (a)−(d) Emission spectra acquired from the waveguided end and excited from the other end of CsPbBr3 nanowires with width of 3.31, 1.99, 1.19 and 0.78 μm and lengths of 11.01, 14.02, 16.41 and 20.77 μm, respectively. The spectra show multiple Fabry-Pérot interference peaks which have been fitted by Lorentzian line shapes to determine the resonance energies. (e)−(f) Corresponding energy-wavevector dispersion curves in the Z-direction (along nanowire length) of above four CsPbBr3 nanowires, respectively. The insets are normalized electric field distribution at the cross-section of these four CsPbBr3 nanowires [50].

图 11 CsPbCl3微腔极化子激光 (a) 不同泵浦强度下的基态发光光谱; (b) 基态发光强度与半高宽与泵浦强度的关系图, 半高宽的变化拐点位于阈值Pth= 12 µJ/cm2附近; (c) 极化子发光能量蓝移与泵浦强度关系图, 阈值处蓝移趋势发生变化, 从极化子-激子相互作用转变为极化子-极化子相互作用[58]

Figure 11. Characterizations of CsPbCl3 microcavity polariton lasing: (a) Ground-state emission spectra under different pumping fluences; (b) ground-state emission intensity and full width at half maximum as a function of pump fluence. A line width narrowing occurs near the threshold of Pth= 12 µJ/cm2, along with a sharp increase of emission intensity; (c) energy blueshift with respect to the polariton emission energy at the lowest pump fluence as a function of pump fluence. The blueshift trend below the threshold is attributed to polariton–reservoir interaction while the trend above the threshold corresponds to polariton–polariton interaction [58].

图 12 不同失谐值下极化子在不同能量和动量的分布 (a) 失谐值为–36 meV(蓝色方块)、–85 meV(绿色圆圈)、–118 meV(红色三角)的极化子数量(取对数)在低于阈值和阈值处不同能量分布, 其中–36 meV失谐值下的分布可在阈值下和阈值处拟合为玻尔兹曼分布和玻色分布; (b) 极化子凝聚的阈值与耦合强度与失谐值的关系, 不同颜色区域表示在亚稳态(零动量)和稳态(有限动量)产生的极化子凝聚; (c) 钙钛矿DBR结构的发光光谱(低于阈值, 黑色线)和反射光谱(红色线), 从下到上钙钛矿厚度不断增加(负失谐能增加). 区域Ⅰ 为–28和–56 meV, 区域Ⅱ 为–64, –80, –103和–114 meV, 区域Ⅲ 为–129和–182 meV[60]

Figure 12. Polariton distributions at different energy and momentum with different detuning energy: (a) Polariton population (log scale) versus energy at threshold and below threshold for detuning energies of –36 (blue squares), –85 (green circles), and –118 meV (red triangles), respectively. The values are normalized to the population of the emission peak at the threshold. The polariton population at a detuning energy of –36 meV can be fitted (blue solid line) using the Maxwell–Boltzmann distribution below threshold or Bose–Einstein distribution at threshold; (b) threshold (blue dots and circles) of the polariton condensation and corresponding coupling strength (pink squares) as a function of detuning energy. Two different regions indicated by different colors of the background and green dash line represent detuning for generating polariton condensation at stationary (at finite momentum) and metastable states (zero momentum); (c) normalized emission (below threshold, black solid line) and reflection spectral (red solid line) of perovskite/DBR cavity with increasing perovskite thickness (also the more negative detuned energy) from bottom to up. Based on different relaxation processes of polaritons at different detuning energies, three different regions (I–III) are introduced. Region I: Δ = –28 and –56 meV. Region II: Δ = –64, –80, –103, and –114 meV. Region III: Δ = –129 and –182 meV [60].

-

[1] Liao Q, Jin X, Fu H B 2019 Adv. Opt. Mater. 7 1900099

Google Scholar

Google Scholar

[2] Min H, Kim M, Lee S U, Kim H, Kim G, Choi K, Lee J H, Seok S I 2019 Science 366 749

Google Scholar

Google Scholar

[3] Xu W D, Hu Q, Bai S, Bao C X, Miao Y F, Yuan Z C, Borzda T, Barker A J, Tyukalova E, Hu Z J, Kawecki M, Wang H Y, Yan Z B, Liu X J, Shi X B, Uvdal K, Fahlman M, Zhang W J, Duchamp M, Liu JM, Petrozza A, Wang J P, Liu LM, Huang W, Gao F 2019 Nat. Photonics 13 418

Google Scholar

Google Scholar

[4] Zhang Y, Lim C K, Dai Z, Yu G, Haus J W, Zhang H, Prasad P N 2019 Phys. Rep. 795 1

Google Scholar

Google Scholar

[5] Xing G C, Mathews N, Lim S S, Yantara N, Liu X F, Sabba D, Gratzel M, Mhaisalkar S, Sum T C 2014 Nat. Mater. 13 476

Google Scholar

Google Scholar

[6] 王兰, 董渊, 嵩高, 陈奎一, 房法成, 金光勇 2019 中国光学 12 993

Google Scholar

Google Scholar

Wang L, Dong Y, Gao S, Chen K Y, Fang F C, Jin G Y, 2019 Chin. Opt. 12 993

Google Scholar

Google Scholar

[7] Li G H, Chen K Q, Cui Y X, Zhang Y P, Tian Y, Tian B N, Hao Y Y, Wu Y C, Zhang H 2020 Adv. Opt. Mater. 8 1902012

Google Scholar

Google Scholar

[8] Liu Y, Siron M, Lu D, Yang J J, dos Reis R, Cui F, Gao M Y, Lai M L, Lin J, Kong Q, Lei T, Kang J, Jin J B, Ciston J, Yang P D 2019 J. Am. Chem. Soc. 141 13028

Google Scholar

Google Scholar

[9] Fu Y P, Zhu H M, Stoumpos C C, Ding Q, Wang J, Kanatzidis M G, Zhu X Y, Jin S 2016 ACS Nano 10 7963

Google Scholar

Google Scholar

[10] 楼浩然, 叶志镇, 何海平 2019 68 36

Google Scholar

Google Scholar

Lou H R, Ye Z Z, He H P 2019 Acta.Phys. Sin. 68 36

Google Scholar

Google Scholar

[11] Lei L, Seyitliyev D, Stuard S, Mendes J, Dong Q, Fu X Y, Chen YA, He S L, Yi X P, Zhu L P, Chang CH, Ade H, Gundogdu K, So F 2020 Adv. Mater. 32 1906571

Google Scholar

Google Scholar

[12] Doherty T A S, Winchester A J, Macpherson S, Johnstone D N, Pareek V, Tennyson E M, Kosar S, Kosasih F U, Anaya M, Abdi-Jalebi M, Andaji-Garmaroudi Z, Wong E L, Madeo J, Chiang Y H, Park J S, Jung Y K, Petoukhoff C E, Divitini G, Man M K L, Ducati C, Walsh A, Midgley P A, Dani K M, Stranks S D 2020 Nature 580 360

Google Scholar

Google Scholar

[13] Gunnarsson W B, Rand B P 2020 Appl. Mater. 8 030902

Google Scholar

Google Scholar

[14] 霍成学, 王子明, 李晓明, 曾海波 2017 中国激光 44 120

Google Scholar

Google Scholar

Huo C X, Wang Z M, Li X M, Zeng H B 2017 Chin. Opt. 44 120

Google Scholar

Google Scholar

[15] 黄斯豪, 刘征征, 杜鹃, 冷雨欣 2020 激光与光电子学进展 57 071602

Google Scholar

Google Scholar

Huang S H, Liu Z Z, Du J, Leng Y X 2020 Laser & Optoelectronics Progress 57 071602

Google Scholar

Google Scholar

[16] Zhang Q, Su R, Du W N, Liu X F, Zhao L Y, Ha S T, Xiong Q H 2017 Small Methods 1 Unsp 1700163

Google Scholar

Google Scholar

[17] Li M L, Gao Q G, Liu P, Liao Q, Zhang H H, Yao J N, Hu W P, Wu Y S, Fu H B 2018 Adv. Funct. Mater. 28 1707006

Google Scholar

Google Scholar

[18] Dong H Y, Zhang C H, Liu X L, Yao J N, Zhao Y S 2020 Chem. Soc. Rev. 49 951

Google Scholar

Google Scholar

[19] Wang J, Da P M, Zhang Z, Luo S, Liao L M, Sun Z Y, Shen X C, Wu S W, Zheng G F, Chen Z H 2018 Nanoscale 10 10371

Google Scholar

Google Scholar

[20] Baranov D G, Wersall M, Cuadra J, Antosiewicz T J, Shegai T 2018 ACS Photonics 5 24

Google Scholar

Google Scholar

[21] De Giorgi M L, Anni M 2019 Appl. Sci.-Basel 9 4591

Google Scholar

Google Scholar

[22] Schlaus A P, Spencer M S, Zhu X Y 2019 Acc. Chem. Res. 52 2950

Google Scholar

Google Scholar

[23] Eaton S W, Fu A, Wong A B, Ning C Z, Yang P D 2016 Nat. Rev. Mater. 1 16028

Google Scholar

Google Scholar

[24] Sasaki F, Zhou Y, Sonoda Y, Azumi R, Mochizuki H, Van-Cao N, Yanagi H 2017 Jpn. J. Appl. Phys. 56 04cl07

Google Scholar

Google Scholar

[25] Shen X M, Chen M M, Shi L J, Chen F, Liu Y, Cao D W, Xu C X 2019 Opt. Commun. 45. Unsp 124354

Google Scholar

Google Scholar

[26] Chen S T, Zhang C, Lee J, Han J, Nurmikko A 2017 Adv. Mater. 29 1604781

Google Scholar

Google Scholar

[27] Arash R-I 2020 Polariton Physics (Vol. 229) (Springer Series in Optical Sciences: Springer, Cham) pp33–64

[28] Li B B, Zhou T J, Fang X, Zhang W L, Li X M, Guan Z Q, Li J Y, Wang L, Hark S, Zhang Z Y 2019 J. Mater. Chem. C 7 4102

Google Scholar

Google Scholar

[29] Chen F, Xu C X, Xu Q Y, Zhu Z, Qin F F, Manohari A G, Zhu Y Z 2017 J. Mater. Chem. C 5 9238

Google Scholar

Google Scholar

[30] Liu Z Z, Yang J, Du J, Hu Z P, Shi T C, Zhang Z Y, Liu Y Q, Tang X S, Leng Y X, Li R X 2018 ACS Nano 12 5923

Google Scholar

Google Scholar

[31] Li C, Liu Z, Shang Q Y, Zhang Q 2019 Adv. Opt. Mater. 7 1900279

Google Scholar

Google Scholar

[32] Yang L, Li Z Q, Liu C, Yao X R, Li H Q, Liu X X, Liu J S, Zhu P W, Liu B B, Cui T, Sun C, Bao Y J 2019 J. Phys. Chem. Lett. 10 7056

Google Scholar

Google Scholar

[33] Liu Z, Shang Q Y, Li C, Zhao L Y, Gao Y, Li Q, Chen J, Zhang S, Liu X F, Fu Y S, Zhang Q 2019 Appl. Phys. Lett. 114 101902

Google Scholar

Google Scholar

[34] Eaton S W, Lai M L, Gibson N A, Wong A B, Dou L T, Ma J, Wang LW, Leone S R, Yang P D 2016 Proc. Natl. Acad. Sci. U.S.A. 113 1993

Google Scholar

Google Scholar

[35] Liu P, He X X, Ren J H, Liao Q, Yao J N, Fu H B 2017 ACS Nano 11 5766

Google Scholar

Google Scholar

[36] Schlaus A P, Spencer M S, Miyata K, Liu F, Wang X X, Datta I, Lipson M, Pan A L, Zhu X Y 2019 Nat. Commun. 10 265

Google Scholar

Google Scholar

[37] Mi Y, Zhong Y G, Zhang Q, Liu X F 2019 Adv. Opt. Mater. 7 1900544

Google Scholar

Google Scholar

[38] Chen S T, Nurmikko A 2017 ACS Photonics 4 2486

Google Scholar

Google Scholar

[39] Zhang L, Yuan F, Dong H, Jiao B, Zhang W W, Hou X, Wang S F, Gong Q H, Wu Z X 2018 ACS Appl. Mater. Interfaces 10 40661

Google Scholar

Google Scholar

[40] Zhai W H, Tian C, Yuan K, Ge C Y, Zhao S Q, Yu H R, Li Y P, Chen W X, Ran G Z 2019 Appl. Phys. Lett. 114 131107

Google Scholar

Google Scholar

[41] Chen S T, Nurmikko A 2018 Optica 5 1141

Google Scholar

Google Scholar

[42] Huang CY, Zou C, Mao C, Corp K L, Yao YC, Lee YJ, Schlenker C W, Jen A K Y, Lin L Y 2017 ACS Photonics 4 2281

Google Scholar

Google Scholar

[43] Snoke D 2012 Exciton Polariton in Microcavities (Vol. 172) (Springer Series in Solid-State Sciences: Springer, Berlin, Heidelberg) pp307−327

[44] Nespolo J, Carusotto I 2019 Phys. Rev. B 100 035305

Google Scholar

Google Scholar

[45] Su R, Ghosh S, Wang J, Liu S, Diederichs C, Liew T C H, Xiong Q H 2020 Nat. Phys. 16 301

Google Scholar

Google Scholar

[46] Du W N, Zhang S, Shi J, Chen J, Wu Z Y, Mi Y, Liu Z X, Li Y Z, Sui X Y, Wang R, Qiu X H, Wu T, Xiao Y F, Zhang Q, Liu X F 2018 ACS Photonics 5 2051

Google Scholar

Google Scholar

[47] Evans T J S, Schlaus A, Fu Y P, Zhong X J, Atallah T L, Spencer M S, Brus L E, Jin S, Zhu X Y 2018 Adv. Opt. Mater. 6 1700982

Google Scholar

Google Scholar

[48] Park K, Lee J W, Kim J D, Han N S, Jang D M, Jeong S, Park J, Song J K 2016 J. Phys. Chem. Lett. 7 3703

Google Scholar

Google Scholar

[49] Zhang S, Shang Q Y, Du W N, Shi J, Wu Z Y, Mi Y, Chen J, Liu F J, Li Y Z, Liu M, Zhang Q, Liu X F 2018 Adv. Opt. Mater. 6 1701032

Google Scholar

Google Scholar

[50] Wang X X, Shoaib M, Wang X, Zhang X H, He M, Luo Z Y, Zheng W H, Li H L, Yang T F, Zhu X L, Ma L B, Pan A L 2018 ACS Nano 12 6170

Google Scholar

Google Scholar

[51] Shang Q Y, Li C, Zhang S, Liang Y, Liu Z, Liu X F, Zhang Q 2020 Nano Lett. 20 1023

Google Scholar

Google Scholar

[52] Zhao Z, Zhong M Y, Zhou W C, Peng Y H, Yin Y L, Tang D S, Zou B S 2019 J. Phys. Chem. C 123 25349

Google Scholar

Google Scholar

[53] Du W N, Zhang S, Zhang Q, Liu X F 2019 Adv. Mater. 31 1804894

Google Scholar

Google Scholar

[54] Han Q, Wang J, Lu J, Sun L, Lyu F, Wang H, Chen Z, Wang Z 2020 ACS Photonics 7 454

Google Scholar

Google Scholar

[55] Zhang X, Shi H, Dai H, Zhang X, Sun X W, Zhang Z 2020 ACS Appl. Mater. Interfaces 12 5081

Google Scholar

Google Scholar

[56] Fieramosca A, Polimeno L, Ardizzone V, De Marco L, Pugliese M, Maiorano V, De Giorgi M, Dominici L, Gigli G, Gerace D, Ballarini D, Sanvitto D 2019 Sci. Adv. 5 eaav9967

Google Scholar

Google Scholar

[57] Liang Y, Shang Q Y, Wei Q, Zhao L Y, Liu Z, Shi J, Zhong Y G, Chen J, Gao Y, Li M L, Liu X F, Xing G C, Zhang Q 2019 Adv. Mater. 31 1903030

Google Scholar

Google Scholar

[58] Su R, Diederichs C, Wang J, Liew T C H, Zhao J, Liu S, Xu W G, Chen Z, Xiong Q H 2017 Nano Lett. 17 3982

Google Scholar

Google Scholar

[59] Wang J, Su R, Xing J, Bao D, Diederichs C, Liu S, Liew T C H, Chen Z H, Xiong Q H 2018 ACS Nano 12 8382

Google Scholar

Google Scholar

[60] Zhang S, Chen J, Shi J, Fu L, Du W N, Sui X Y, Mi Y, Jia Z L, Liu F J, Shi J W, Wu X X, Tang N, Zhang Q, Liu X F 2020 ACS Photonics 7 327

Google Scholar

Google Scholar

[61] Tian C, guo T, Zhao S Q, Zhai W H, Ge C Y, Ran G Z 2019 RSC Adv. 9 35984

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 12130

- PDF Downloads: 263

- Cited By: 0

DownLoad:

DownLoad: