-

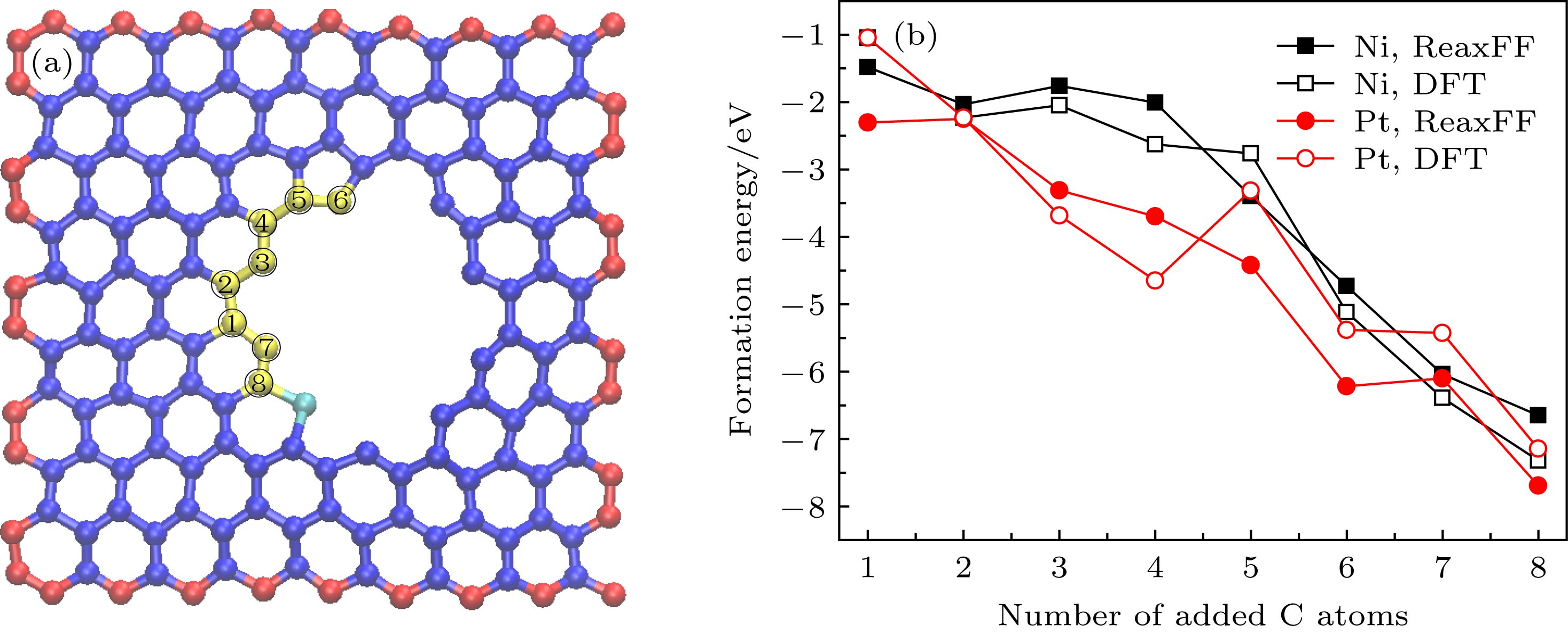

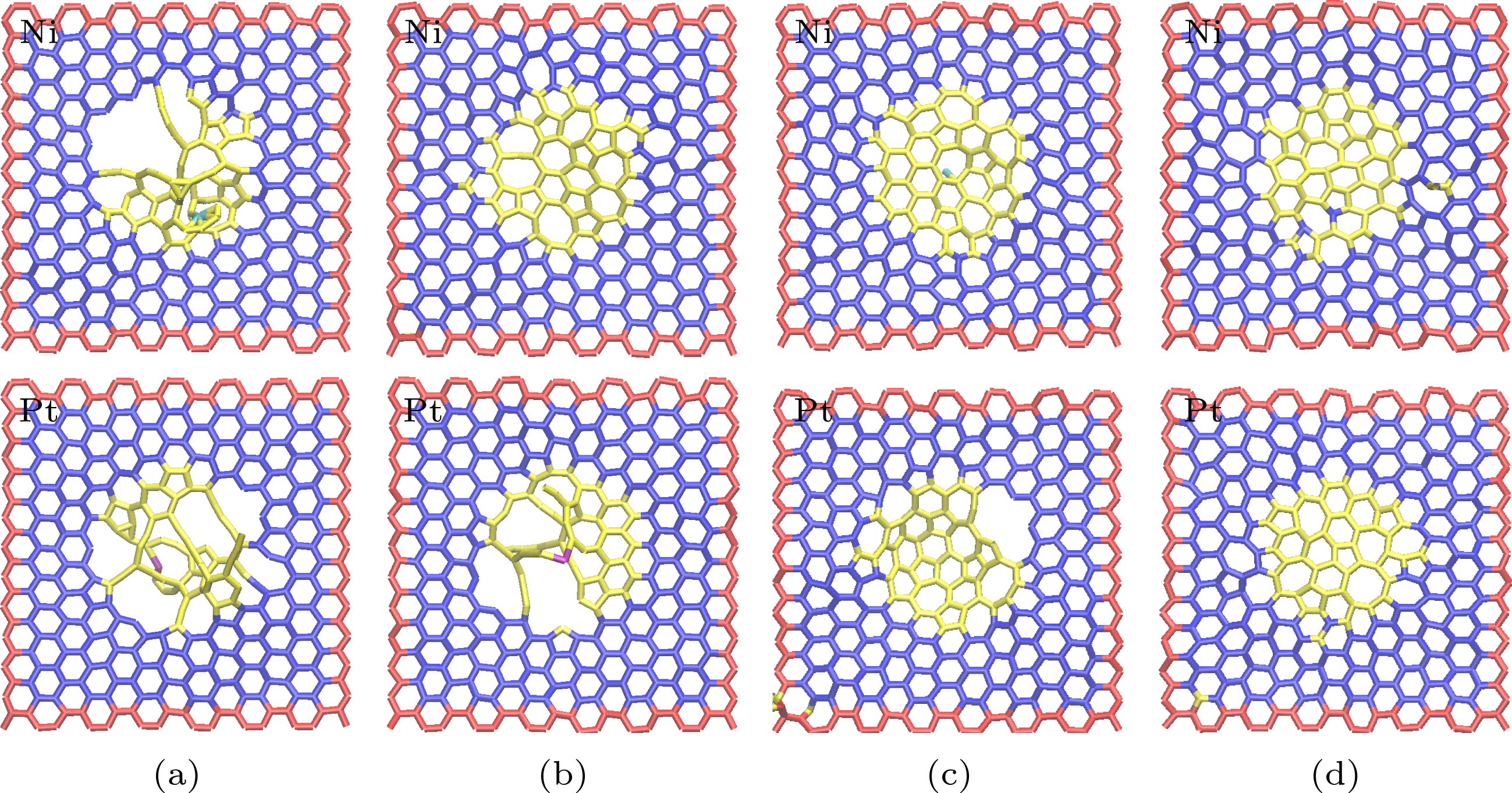

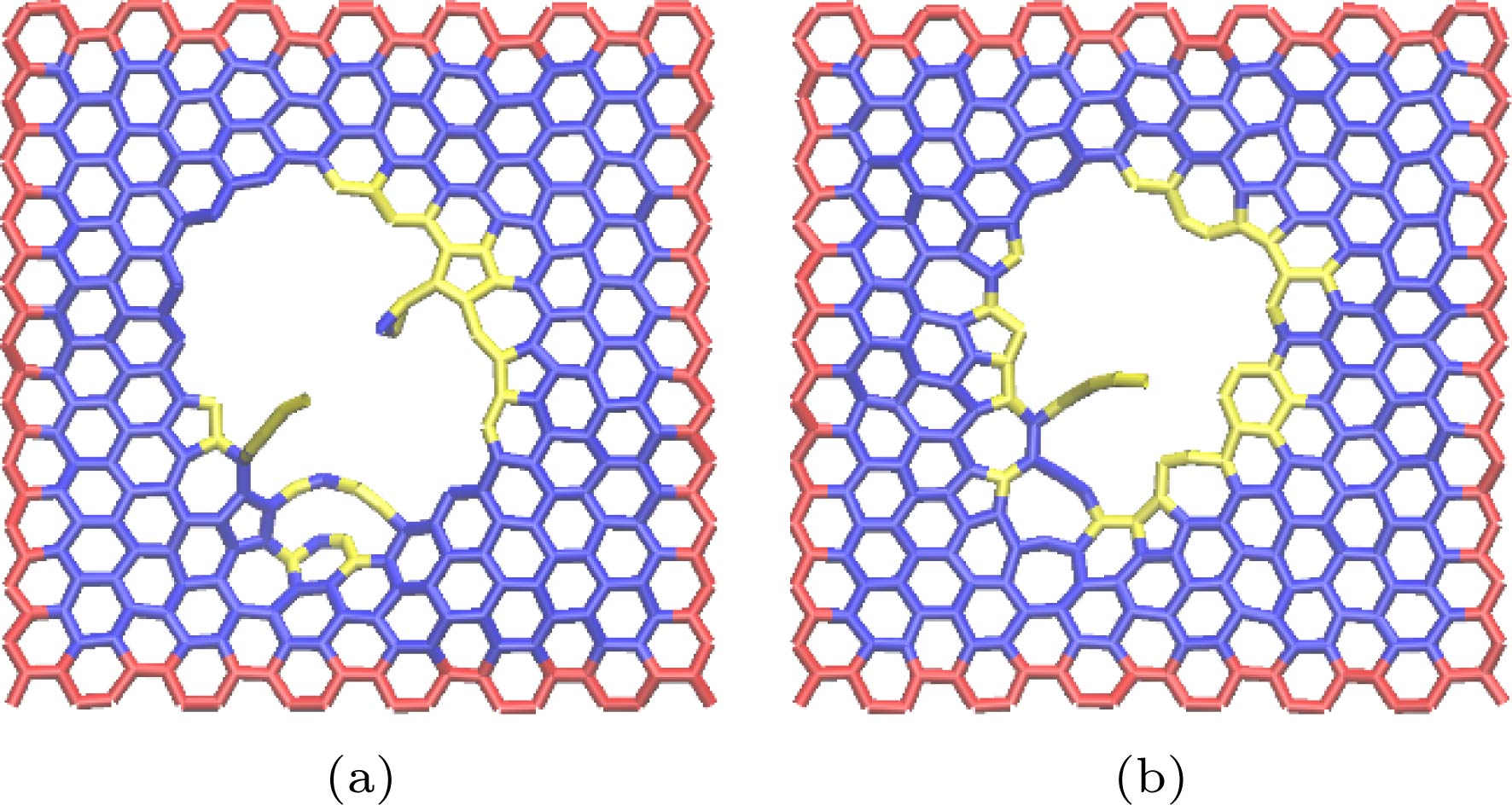

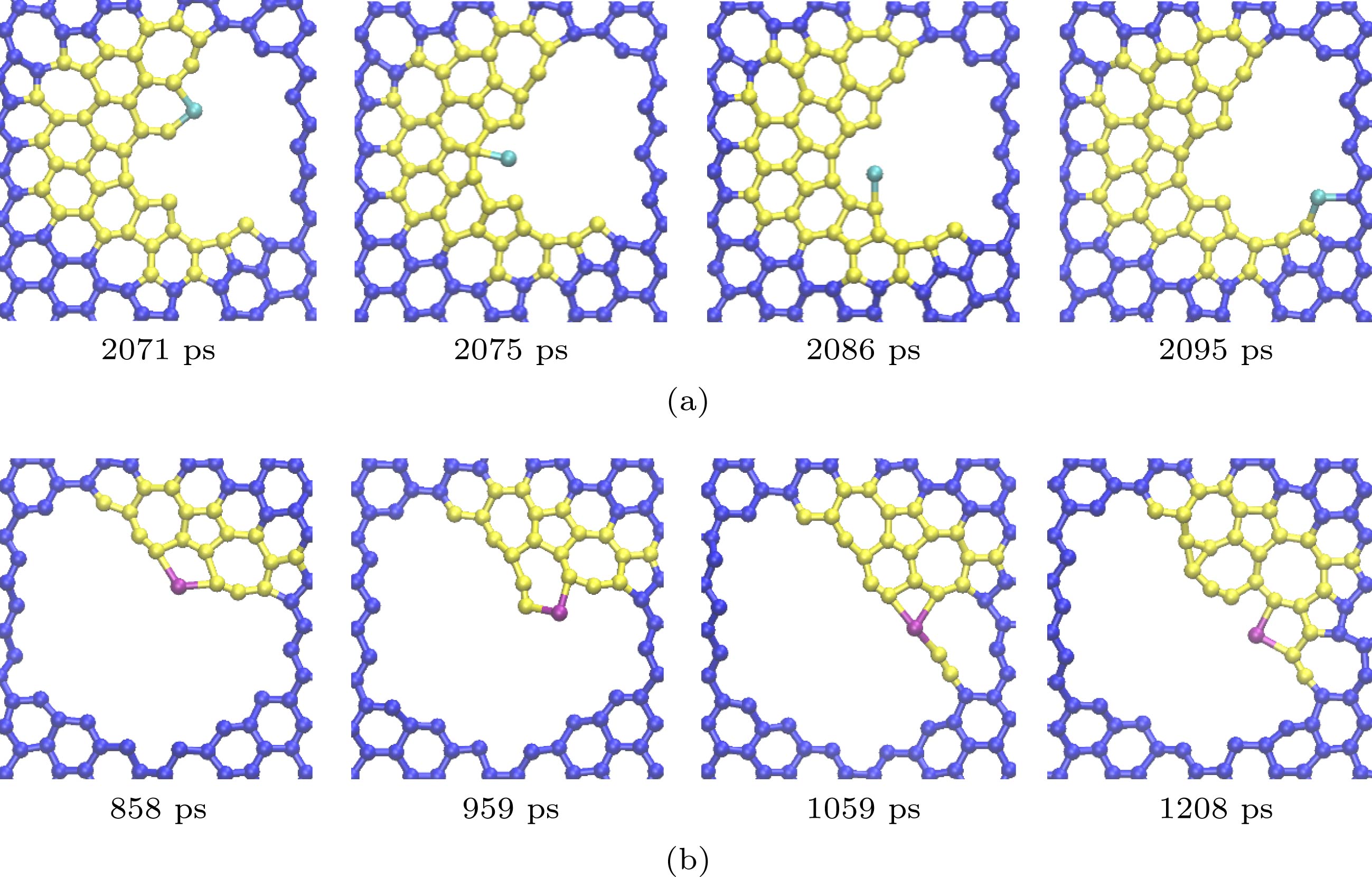

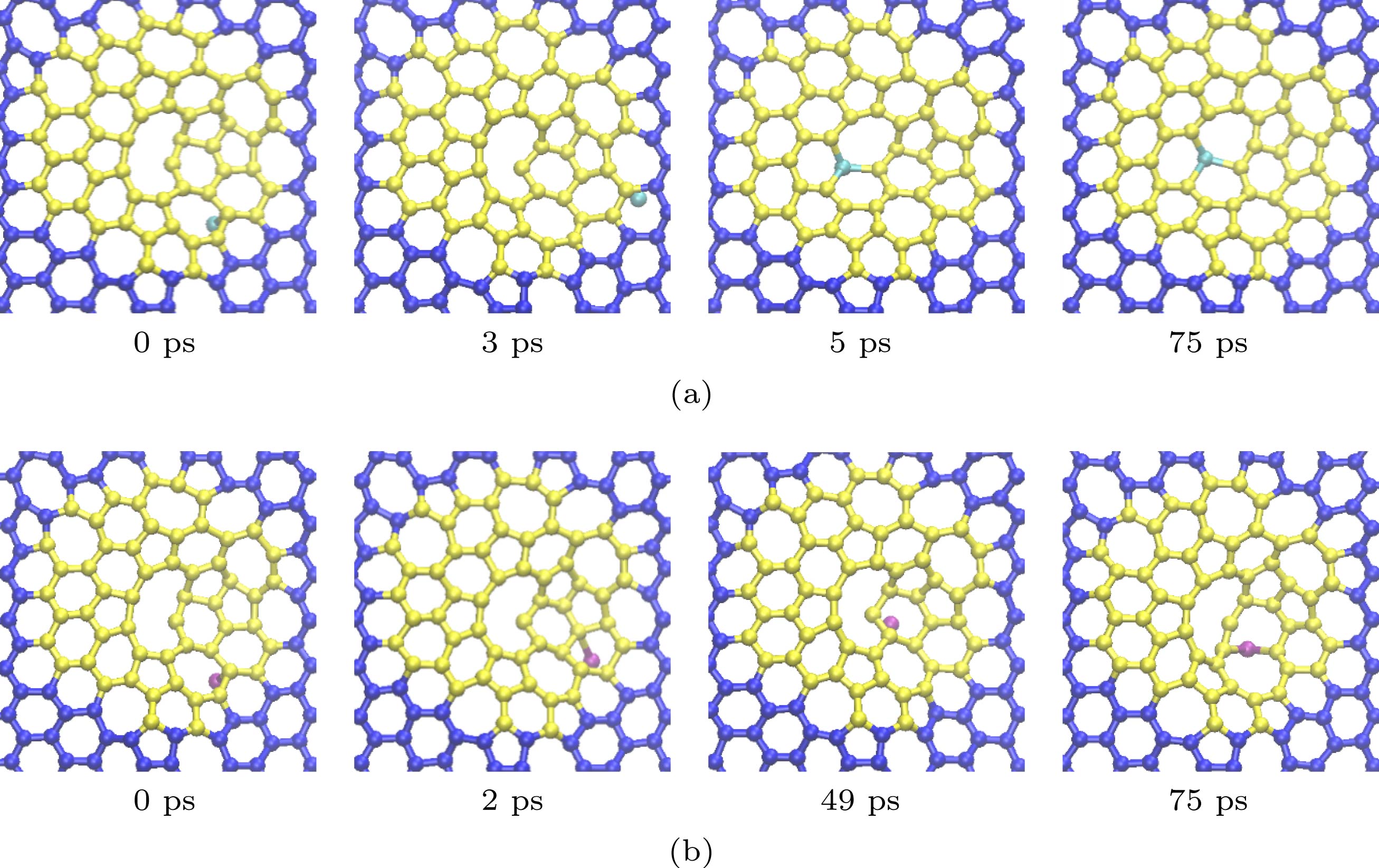

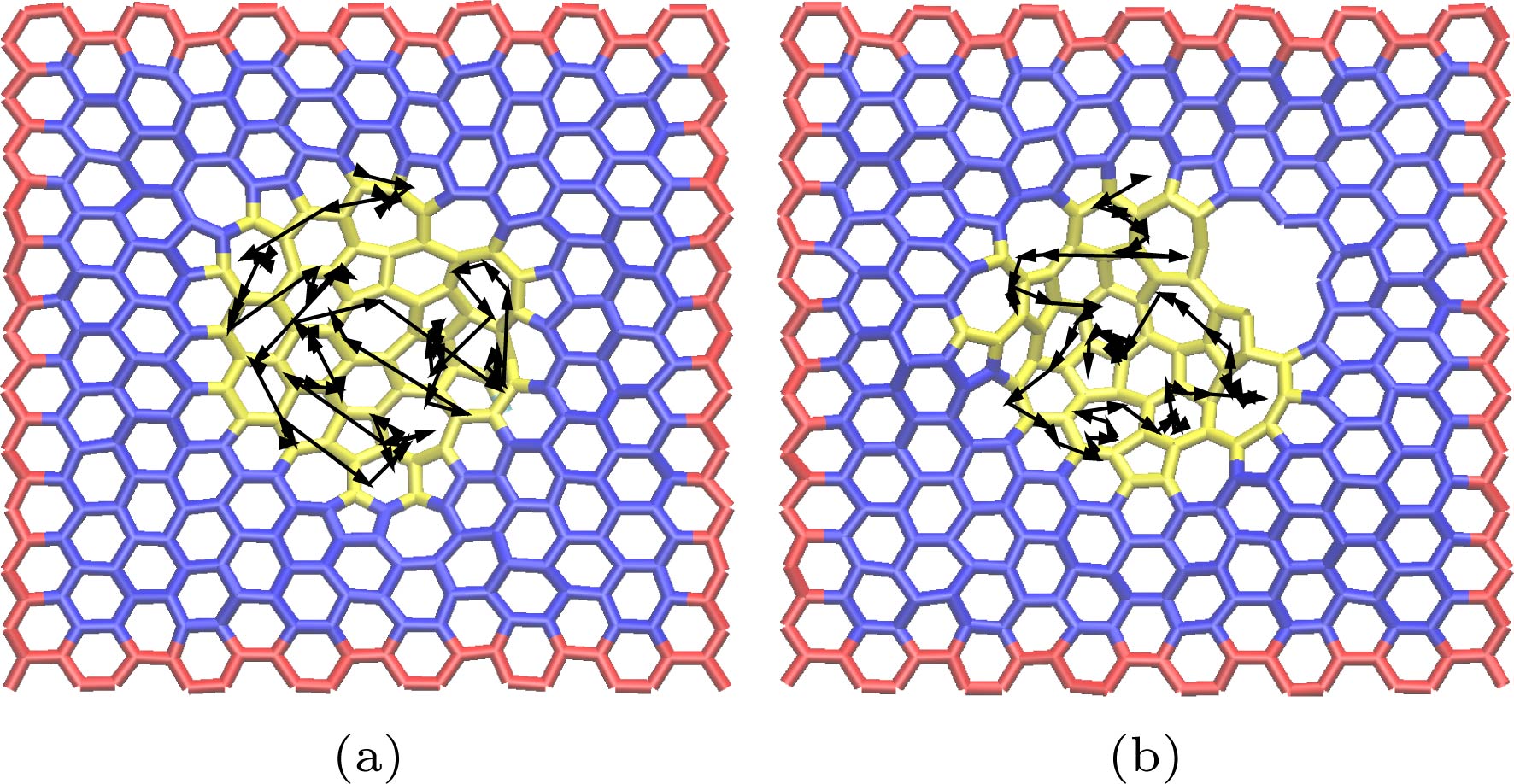

Single-atom catalysts play a crucial role in repairing defective graphene, but the existing research on the single-atom catalysts focuses on the reduction of energy barriers. The unique repairing behavior of the single-atom catalysts in the graphene-healing process and the different repair mechanisms between different catalyst atoms have not been studied in depth. In this paper, the molecular dynamics simulation is used to study the the self-repairing process of defective graphene in the presence of Ni and Pt atoms. By changing the system temperature, multiple sets of simulations are obtained. By observing the atomistic structure obtained at the end of the simulations, the different catalytic repair effects are studied. We calculate the variation of 5, 6 and 7-member rings of graphene in the repair process, it is found that at the appropriate temperatures (1600 K and 2000 K), Ni atom shows stronger catalytic repair capability than Pt atom, and as the temperature increases, the repair effect on defects is also improved. By comparing with the repair process without metal atoms, we find that the effect of metal atoms is significant especially in repairing the carbon chain. To figure out the reason, some typical structure evolutions are simulated. The simulations show that when Ni atom can capture carbon chains at 1600 K, Pt atom needs higher temperature at least 2000 K. Apart from that, Ni and Pt atoms respectively lead to local structural transformations of " jump from the ring” and " bond breakage”. This may be the reason why the 5, 6, and 7-membered rings in the final structure of Pt catalytic system are less than those of Ni catalytic system at 1600 K and 2000 K. In addition, we map the migration route of metal atoms and calculate the migration distance. By observing the different migration behaviors of the two metal atoms in and out of the plane, the different catalytic mechanisms are further studied. The research results in this paper conduce to understanding the catalytic mechanism of metal atoms in the repair of defective graphene. It is of theoretical significance for selecting the external conditions and catalysts for the repairing of defective graphene.

-

Keywords:

- multi-vacancy defect graphene /

- metal atom /

- repair /

- molecular dynamics simulation

[1] Oberlin A 1984 Carbon 22 521

Google Scholar

Google Scholar

[2] Hishiyama Y, Inagaki M, Kimura S, Yamada S 1974 Carbon 12 249

Google Scholar

Google Scholar

[3] Ljima S 1991 Nature 354 56

Google Scholar

Google Scholar

[4] 康朝阳, 唐军, 李利民, 闫文盛, 徐彭寿, 韦世强 2012 61 037302

Google Scholar

Google Scholar

Kang C Y, Tang J, Li L M, Yan W S, Xu P S, Wei S Q 2012 Acta Phys. Sin. 61 037302

Google Scholar

Google Scholar

[5] 于海玲, 朱嘉琦, 曹文鑫, 韩杰才 2013 62 028201

Google Scholar

Google Scholar

Yu H L, Zhu J Q, Cao W X, Han J C 2013 Acta Phys. Sin. 62 028201

Google Scholar

Google Scholar

[6] Ōya A, Ōtani S 1981 Carbon 19 391

Google Scholar

Google Scholar

[7] Zan R, Ramasse Q M, Bangert U, Novoselov K S 2012 Nano Lett. 12 3936

Google Scholar

Google Scholar

[8] Chan K T, Neaton J B, Cohen M L 2008 Phys. Rev. B 77 235430

Google Scholar

Google Scholar

[9] Krasheninnikov A V, Lehtinen P O, Foster A S, Pyykkö P, Nieminen R M 2009 Phys. Rev. Lett. 102 126807

Google Scholar

Google Scholar

[10] Cretu O, Krasheninnikov A V, Rodriguez-Manzo J A, Sun L, Nieminen R M, Banhart F 2010 Phys. Rev. Lett. 105 196102

Google Scholar

Google Scholar

[11] Gan Y, Sun L, Banhart F 2008 Small 4 587

Google Scholar

Google Scholar

[12] Rodríguez-Manzo J A, Cretu O, Banhart F 2010 ACS Nano Lett. 4 3422

Google Scholar

Google Scholar

[13] Jin C, Lan H, Suenaga K, Peng L, Iijima S 2008 Phys. Rev. Lett. 101 1761102

[14] Charlier J C, Amara H, Lambin P 2007 ACS Nano Lett. 1 202

Google Scholar

Google Scholar

[15] Lee Y H, Kim S G, Tomanek D 1997 Phys. Rev. Lett. 78 2393

Google Scholar

Google Scholar

[16] Page A J, Ohta Y, Okamoto Y, Irle S, Morokuma K 2009 J. Phys. Chem. C 113 20198

Google Scholar

Google Scholar

[17] Yuan Q, Xu Z, Yakobson B I, Ding F 2012 Phys. Rev. Lett. 108 245505

Google Scholar

Google Scholar

[18] Li H, Zhang H, Yan X, Xu B, Guo J 2018 New Carbon Mater. 33 1

Google Scholar

Google Scholar

[19] Jovanović Z, Pašti I, Kalijadis A, Jovanović S, Laušević Z 2013 Mater. Chem. Phys. 141 27

Google Scholar

Google Scholar

[20] Karoui S, Amara H 2010 ACS Nano 4 6114

Google Scholar

Google Scholar

[21] Meng L, Jiang J, Wang J, Ding F 2014 J. Phys. Chem. C 118 720

Google Scholar

Google Scholar

[22] Mueller J E, van Duin A C T, Goddard III W A 2010 J. Phys. Chem. C 114 4939

[23] Song B, Schneider G F, Xu Q, Pandraud G, Dekker C, Zandbergen H 2011 Nano Lett. 11 2247

Google Scholar

Google Scholar

[24] Chen J, Shi T, Cai T, Xu T, Sun L, Wu X, Yu D 2013 Appl. Phys. Lett. 102 103107

[25] Zhu J, Shi D 2013 Comput. Mater. Sci. 68 391

Google Scholar

Google Scholar

[26] Patera L L, Bianchini F, Africh C, Dri C, Soldano G, Mariscal M M, Peressi M, Comelli G 2018 Science 359 1243

Google Scholar

Google Scholar

[27] Botari T, Paupitz R, Alves da Silva Autreto, Galvao D S 2016 Carbon 99 302

Google Scholar

Google Scholar

[28] Zakharchenko K V, Balatsky A V 2014 Carbon 80 12

Google Scholar

Google Scholar

[29] Tsetseris L, Pantelides S T 2009 Carbon 47 901

Google Scholar

Google Scholar

[30] Wang L, Duan F 2019 Fullerenes, Nanotubes and Carbon Nanostructures 27 247

Google Scholar

Google Scholar

-

表 1 不同修复条件下最终结构中典型缺陷结构的统计数据

Table 1. The statistics of the typical structures appeared on the final configurationsunder different repair conditions.

温度/K 1000 1600 2000 2500 催化剂类型 Ni 碳链 (5) 空缺 (1) 空缺 (0) 空缺 (0) 碳链 (1) Pt 碳链 (5) 空缺 (4) 空缺 (4) 空缺 (1) 碳链 (4) 表 2 不同条件下两种局部结构转变出现次数

Table 2. Number of occurrences of two local structural evolutions under different conditions.

环内跳出 断环 Ni 1600 K 2 0 2000 K 4 0 Pt 1600 K 0 3 2000 K 0 5 -

[1] Oberlin A 1984 Carbon 22 521

Google Scholar

Google Scholar

[2] Hishiyama Y, Inagaki M, Kimura S, Yamada S 1974 Carbon 12 249

Google Scholar

Google Scholar

[3] Ljima S 1991 Nature 354 56

Google Scholar

Google Scholar

[4] 康朝阳, 唐军, 李利民, 闫文盛, 徐彭寿, 韦世强 2012 61 037302

Google Scholar

Google Scholar

Kang C Y, Tang J, Li L M, Yan W S, Xu P S, Wei S Q 2012 Acta Phys. Sin. 61 037302

Google Scholar

Google Scholar

[5] 于海玲, 朱嘉琦, 曹文鑫, 韩杰才 2013 62 028201

Google Scholar

Google Scholar

Yu H L, Zhu J Q, Cao W X, Han J C 2013 Acta Phys. Sin. 62 028201

Google Scholar

Google Scholar

[6] Ōya A, Ōtani S 1981 Carbon 19 391

Google Scholar

Google Scholar

[7] Zan R, Ramasse Q M, Bangert U, Novoselov K S 2012 Nano Lett. 12 3936

Google Scholar

Google Scholar

[8] Chan K T, Neaton J B, Cohen M L 2008 Phys. Rev. B 77 235430

Google Scholar

Google Scholar

[9] Krasheninnikov A V, Lehtinen P O, Foster A S, Pyykkö P, Nieminen R M 2009 Phys. Rev. Lett. 102 126807

Google Scholar

Google Scholar

[10] Cretu O, Krasheninnikov A V, Rodriguez-Manzo J A, Sun L, Nieminen R M, Banhart F 2010 Phys. Rev. Lett. 105 196102

Google Scholar

Google Scholar

[11] Gan Y, Sun L, Banhart F 2008 Small 4 587

Google Scholar

Google Scholar

[12] Rodríguez-Manzo J A, Cretu O, Banhart F 2010 ACS Nano Lett. 4 3422

Google Scholar

Google Scholar

[13] Jin C, Lan H, Suenaga K, Peng L, Iijima S 2008 Phys. Rev. Lett. 101 1761102

[14] Charlier J C, Amara H, Lambin P 2007 ACS Nano Lett. 1 202

Google Scholar

Google Scholar

[15] Lee Y H, Kim S G, Tomanek D 1997 Phys. Rev. Lett. 78 2393

Google Scholar

Google Scholar

[16] Page A J, Ohta Y, Okamoto Y, Irle S, Morokuma K 2009 J. Phys. Chem. C 113 20198

Google Scholar

Google Scholar

[17] Yuan Q, Xu Z, Yakobson B I, Ding F 2012 Phys. Rev. Lett. 108 245505

Google Scholar

Google Scholar

[18] Li H, Zhang H, Yan X, Xu B, Guo J 2018 New Carbon Mater. 33 1

Google Scholar

Google Scholar

[19] Jovanović Z, Pašti I, Kalijadis A, Jovanović S, Laušević Z 2013 Mater. Chem. Phys. 141 27

Google Scholar

Google Scholar

[20] Karoui S, Amara H 2010 ACS Nano 4 6114

Google Scholar

Google Scholar

[21] Meng L, Jiang J, Wang J, Ding F 2014 J. Phys. Chem. C 118 720

Google Scholar

Google Scholar

[22] Mueller J E, van Duin A C T, Goddard III W A 2010 J. Phys. Chem. C 114 4939

[23] Song B, Schneider G F, Xu Q, Pandraud G, Dekker C, Zandbergen H 2011 Nano Lett. 11 2247

Google Scholar

Google Scholar

[24] Chen J, Shi T, Cai T, Xu T, Sun L, Wu X, Yu D 2013 Appl. Phys. Lett. 102 103107

[25] Zhu J, Shi D 2013 Comput. Mater. Sci. 68 391

Google Scholar

Google Scholar

[26] Patera L L, Bianchini F, Africh C, Dri C, Soldano G, Mariscal M M, Peressi M, Comelli G 2018 Science 359 1243

Google Scholar

Google Scholar

[27] Botari T, Paupitz R, Alves da Silva Autreto, Galvao D S 2016 Carbon 99 302

Google Scholar

Google Scholar

[28] Zakharchenko K V, Balatsky A V 2014 Carbon 80 12

Google Scholar

Google Scholar

[29] Tsetseris L, Pantelides S T 2009 Carbon 47 901

Google Scholar

Google Scholar

[30] Wang L, Duan F 2019 Fullerenes, Nanotubes and Carbon Nanostructures 27 247

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 12875

- PDF Downloads: 162

- Cited By: 0

DownLoad:

DownLoad: