-

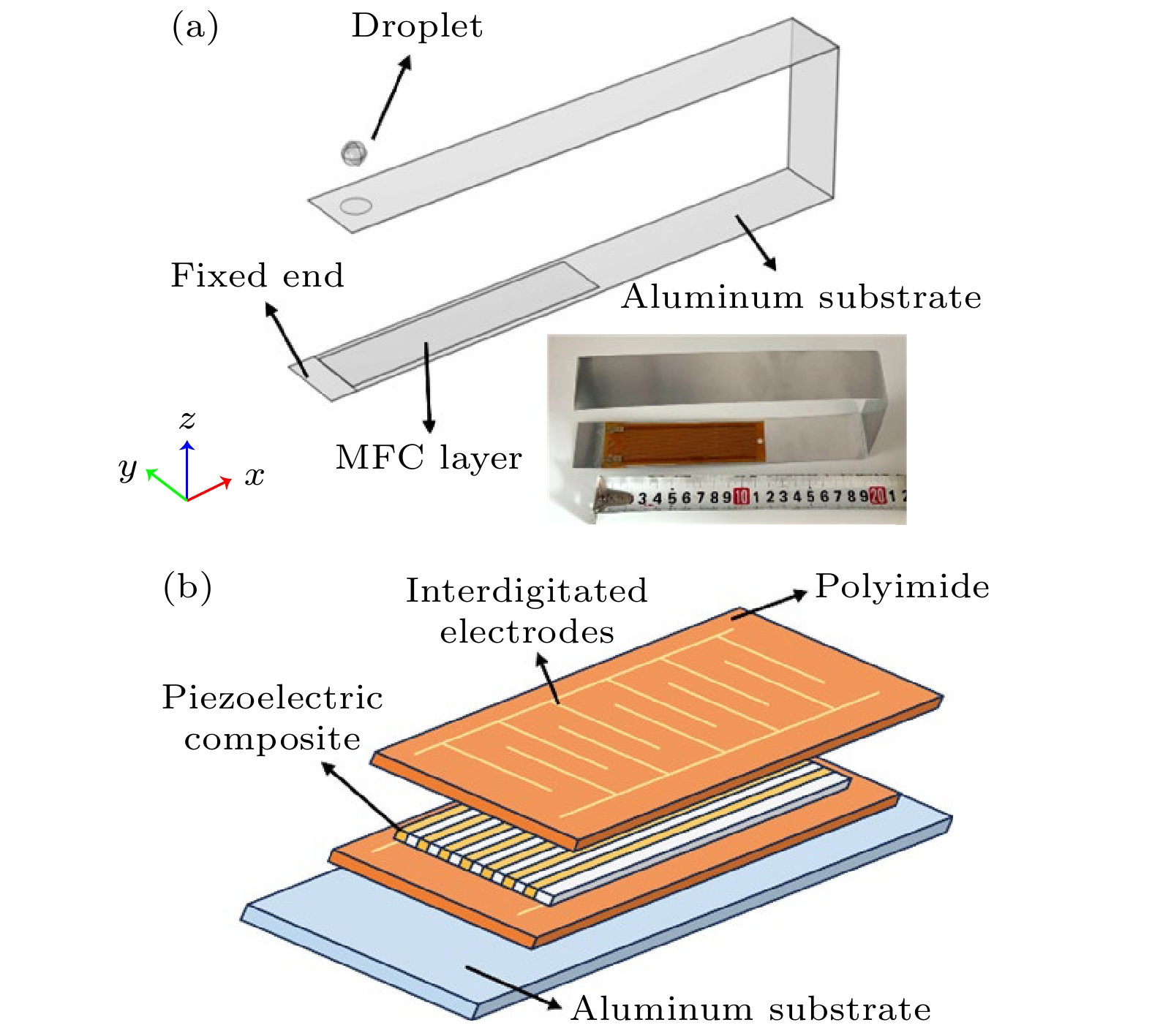

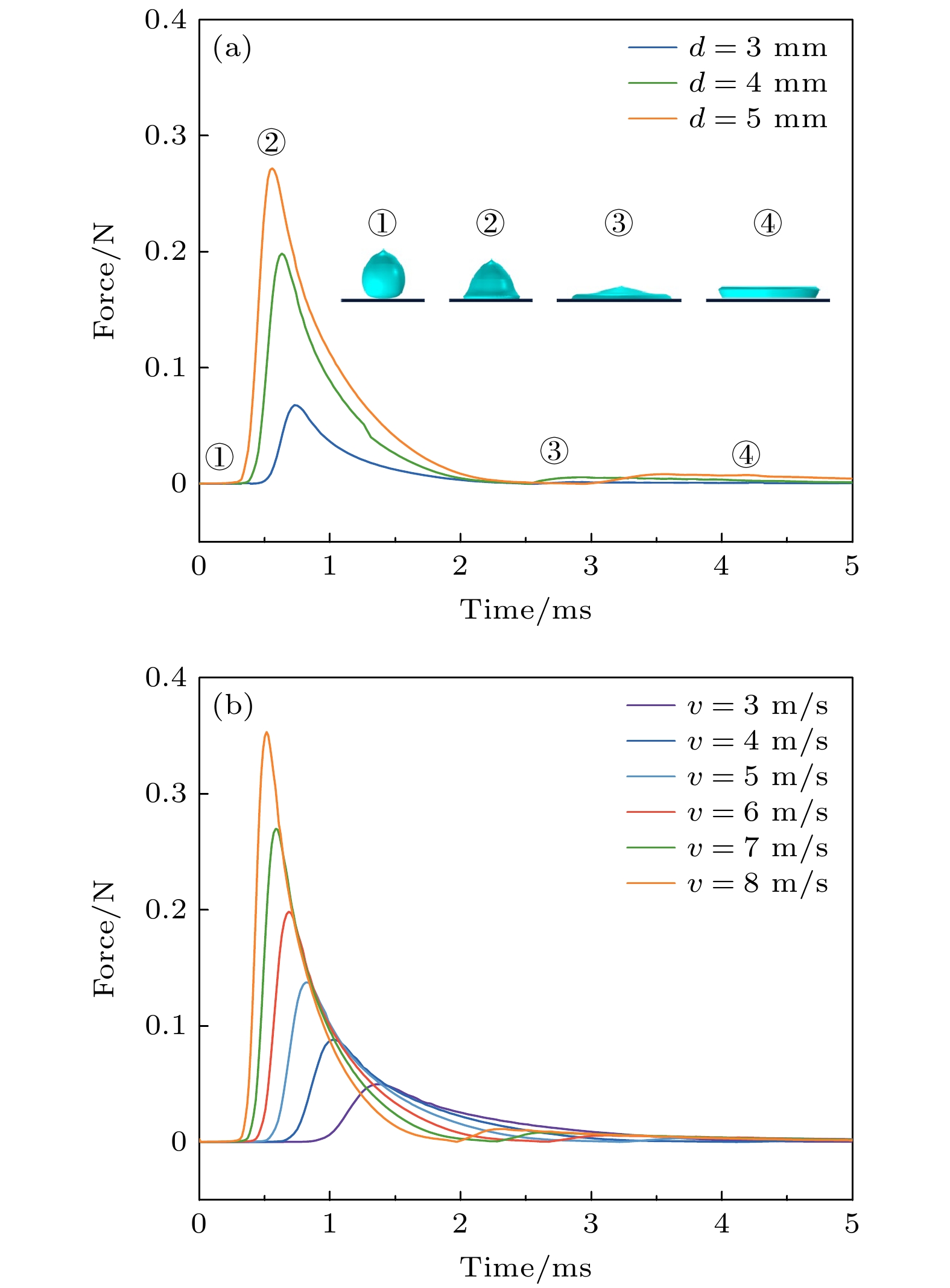

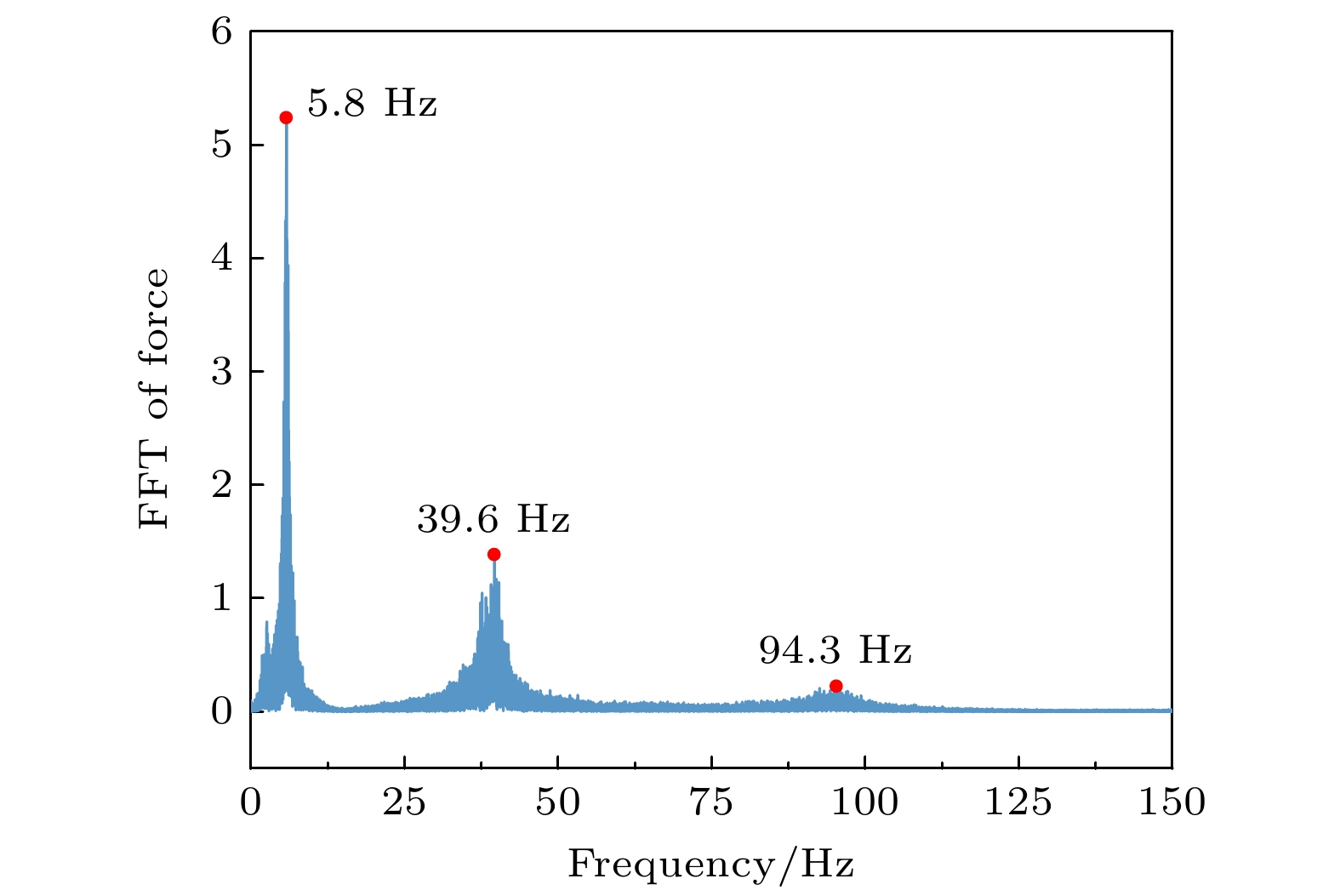

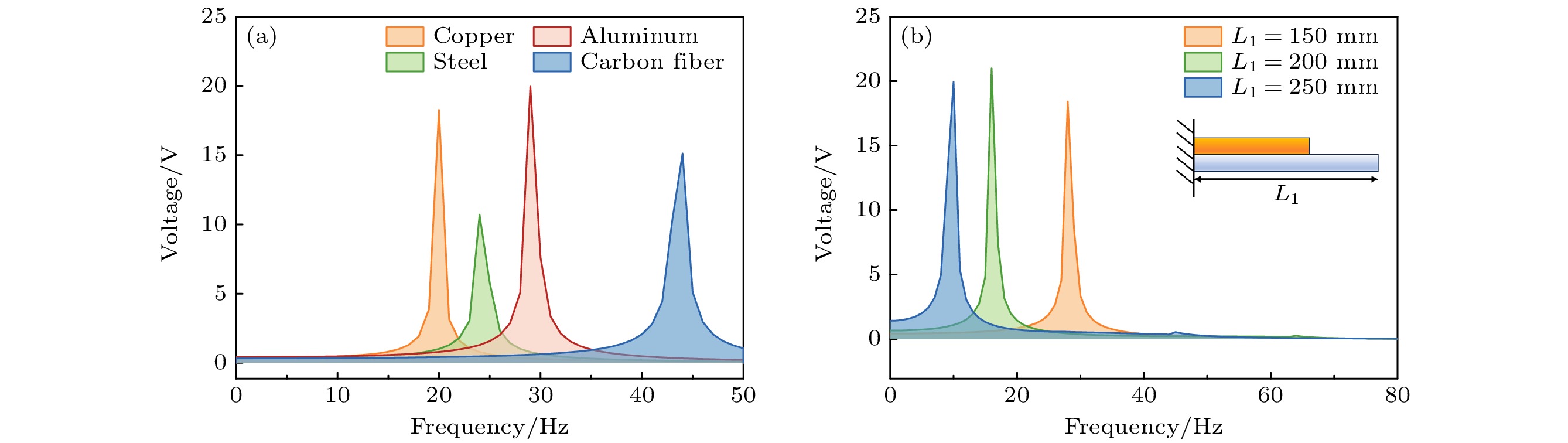

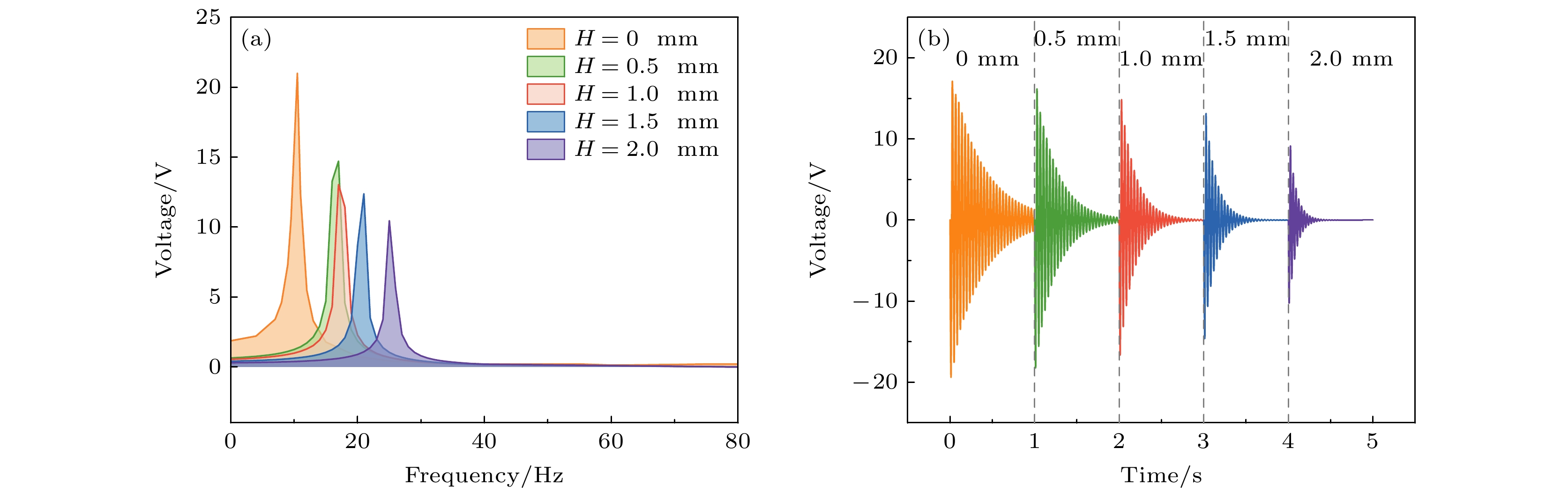

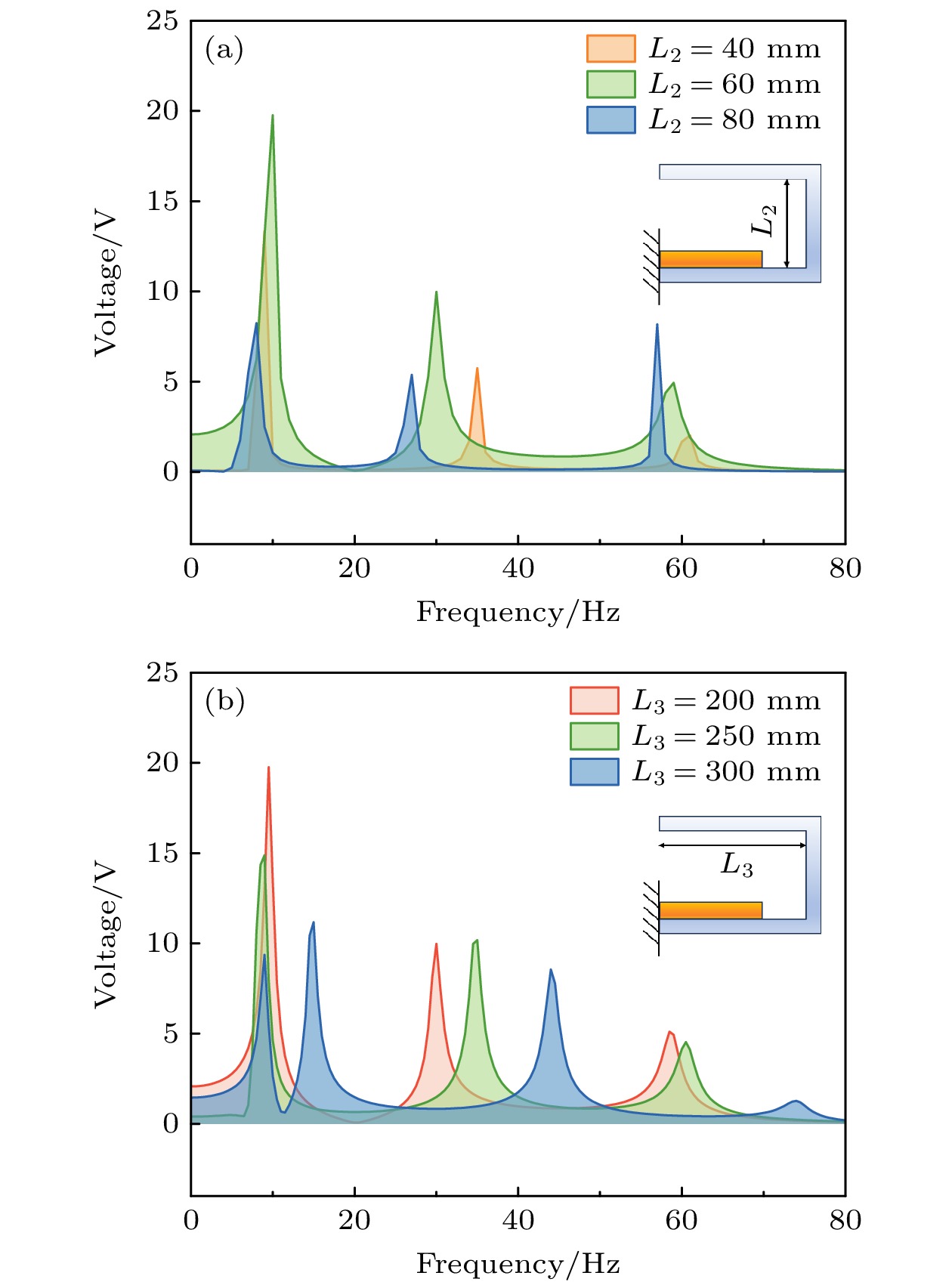

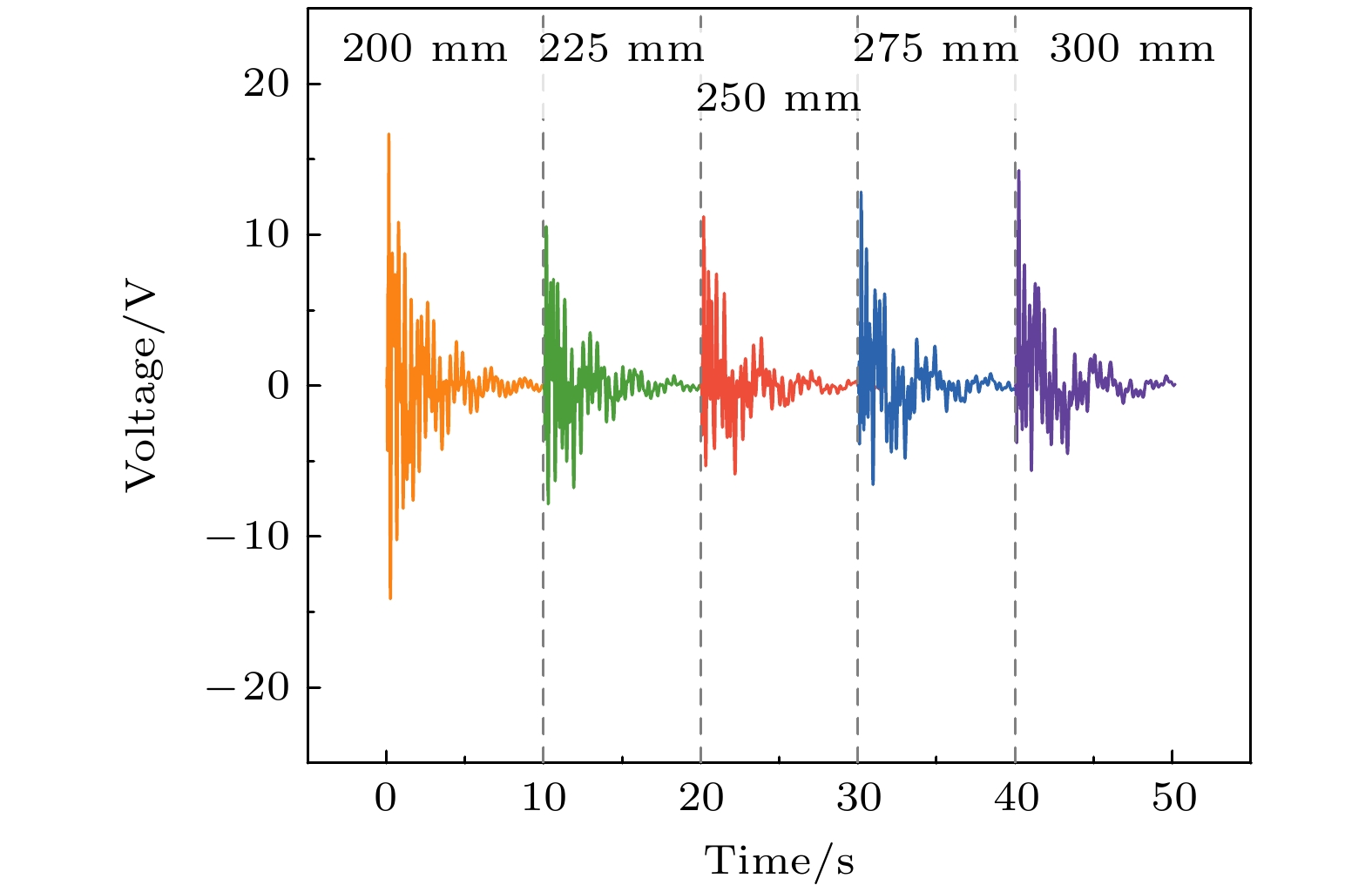

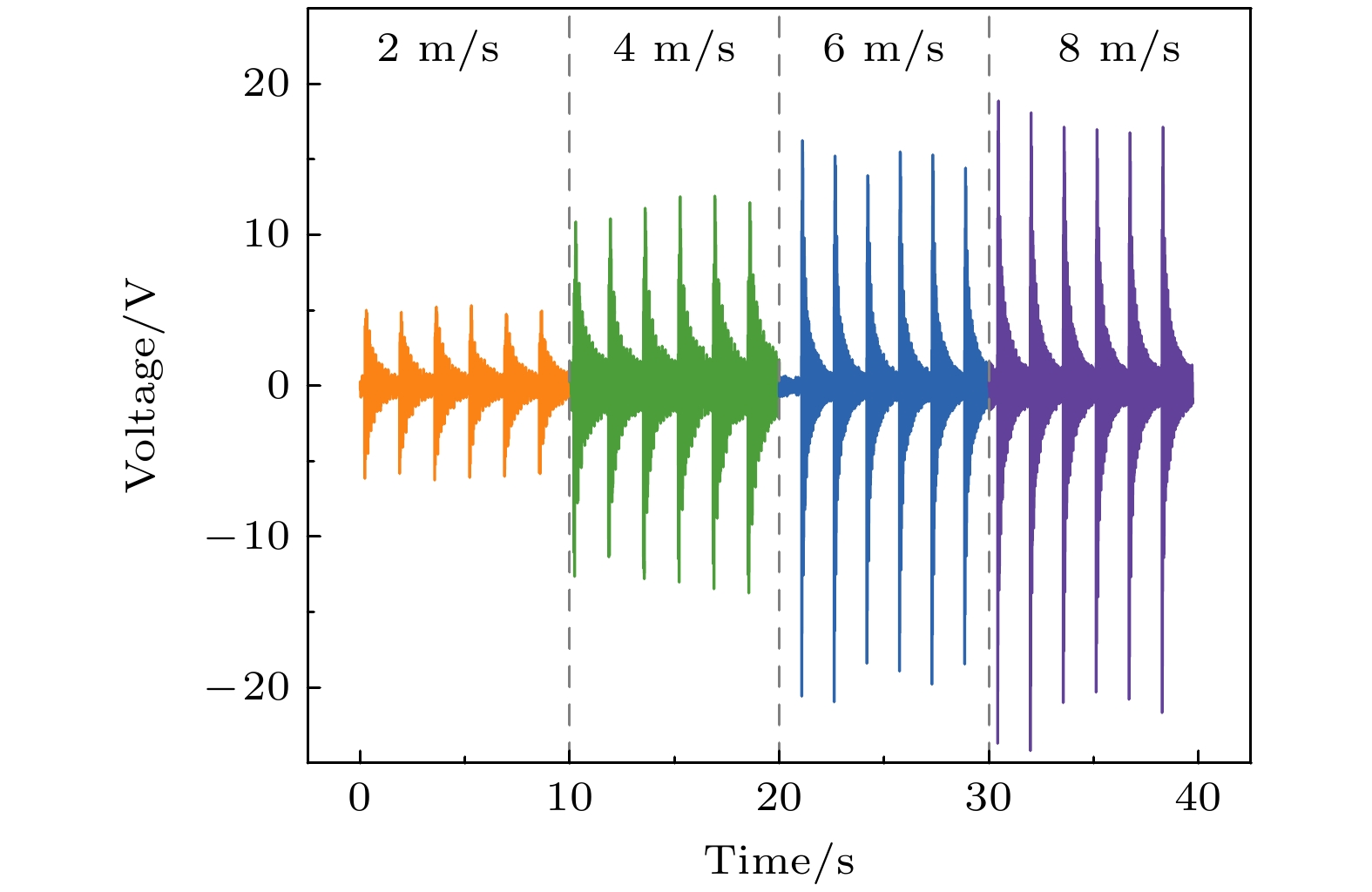

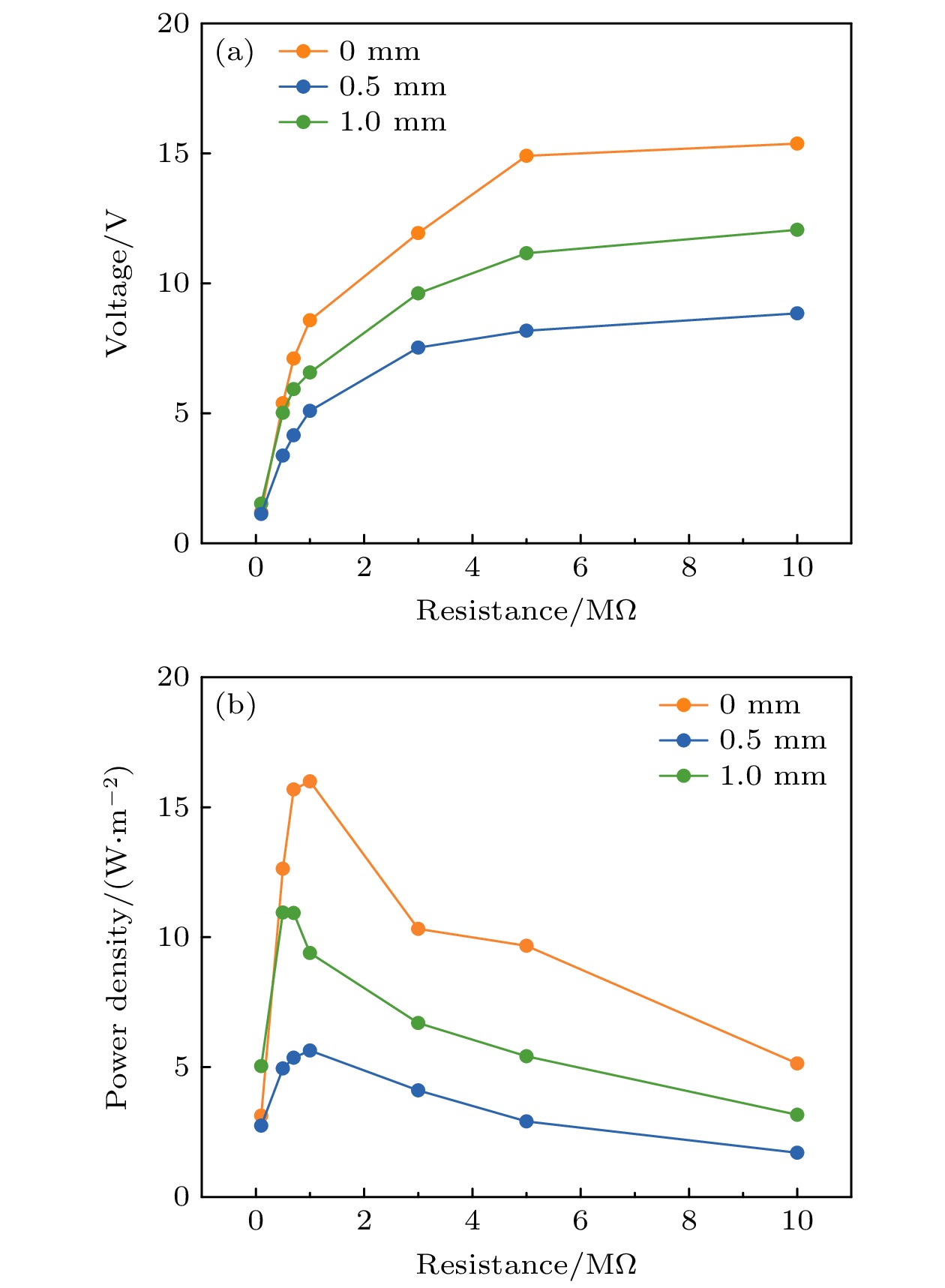

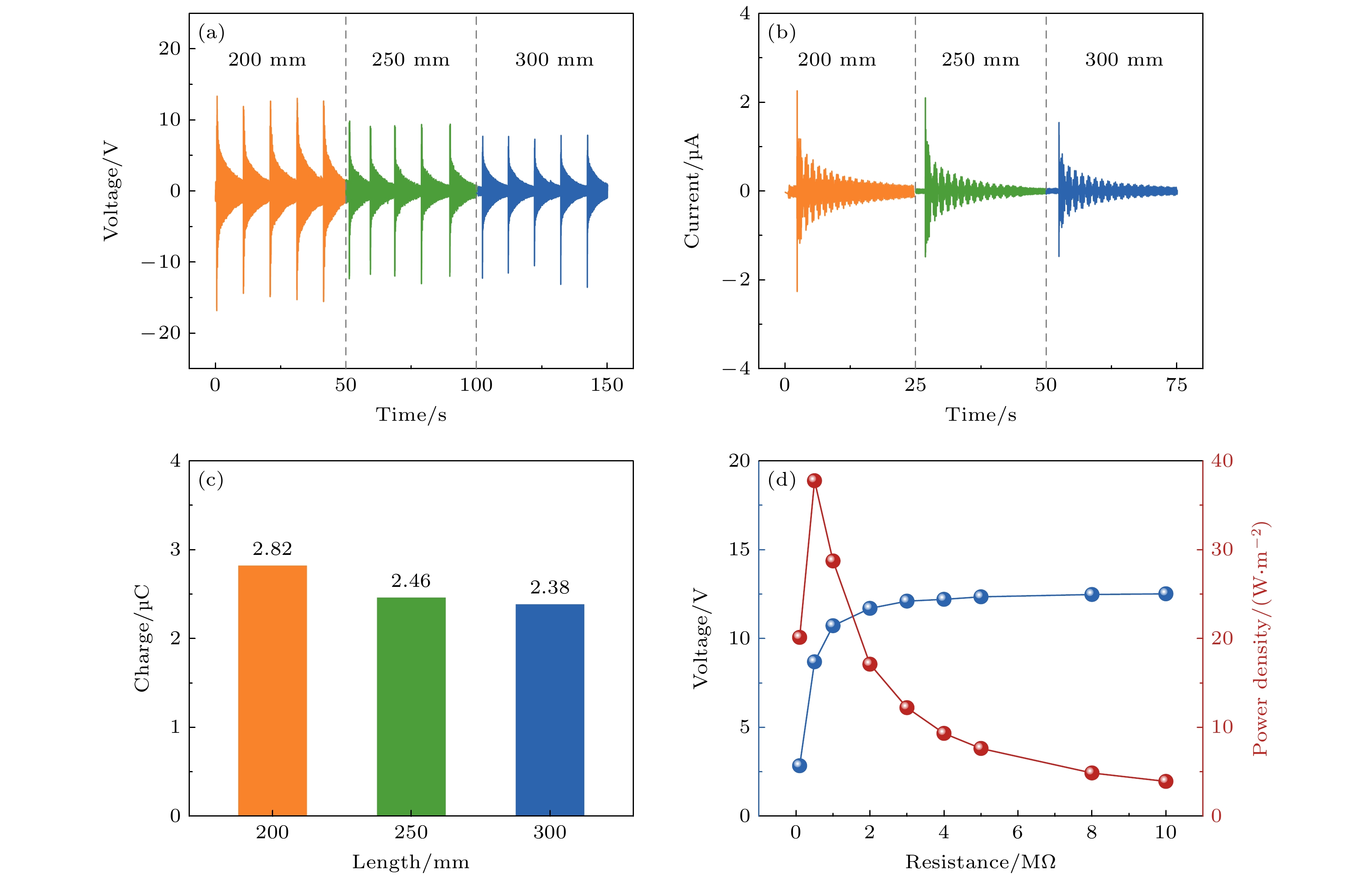

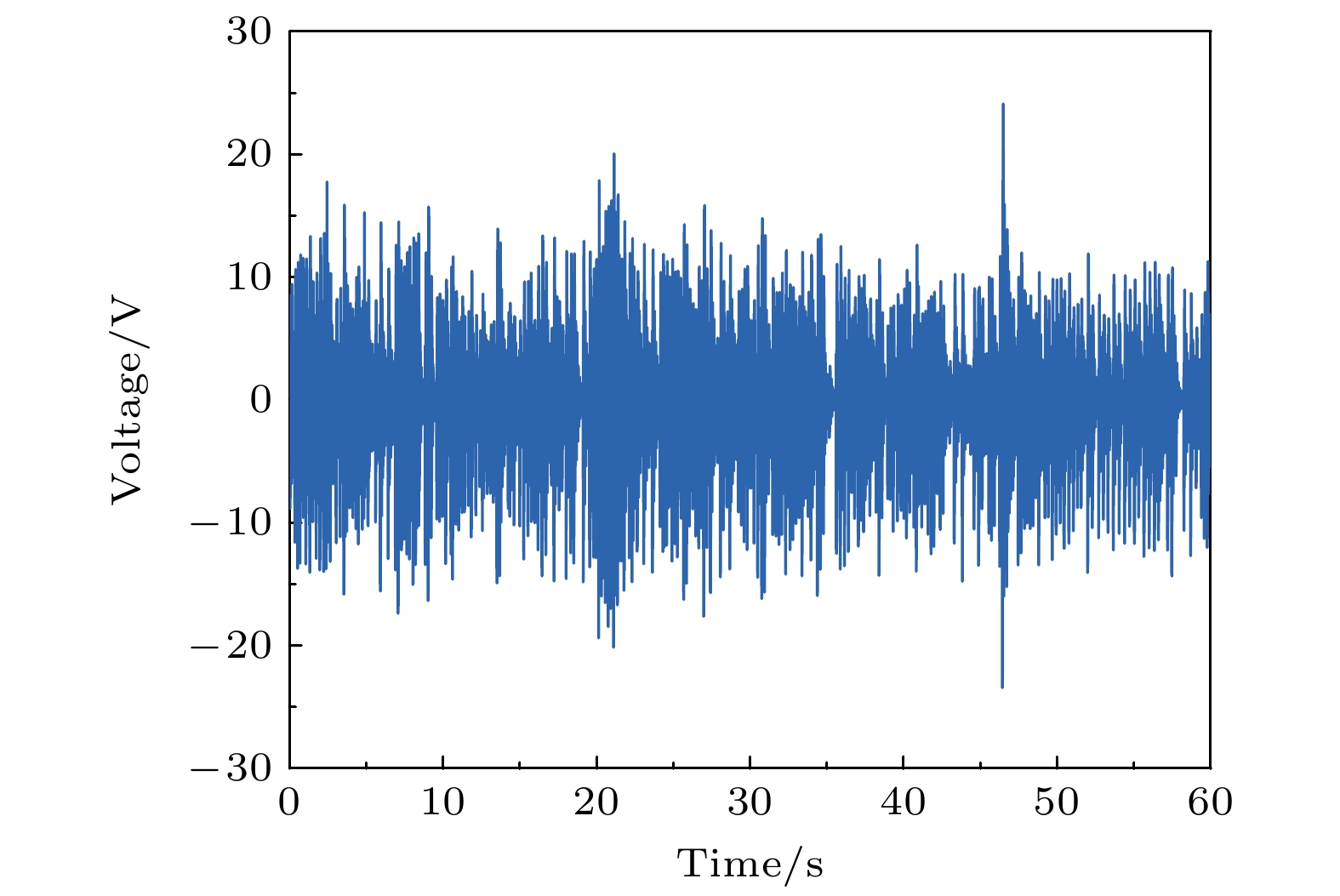

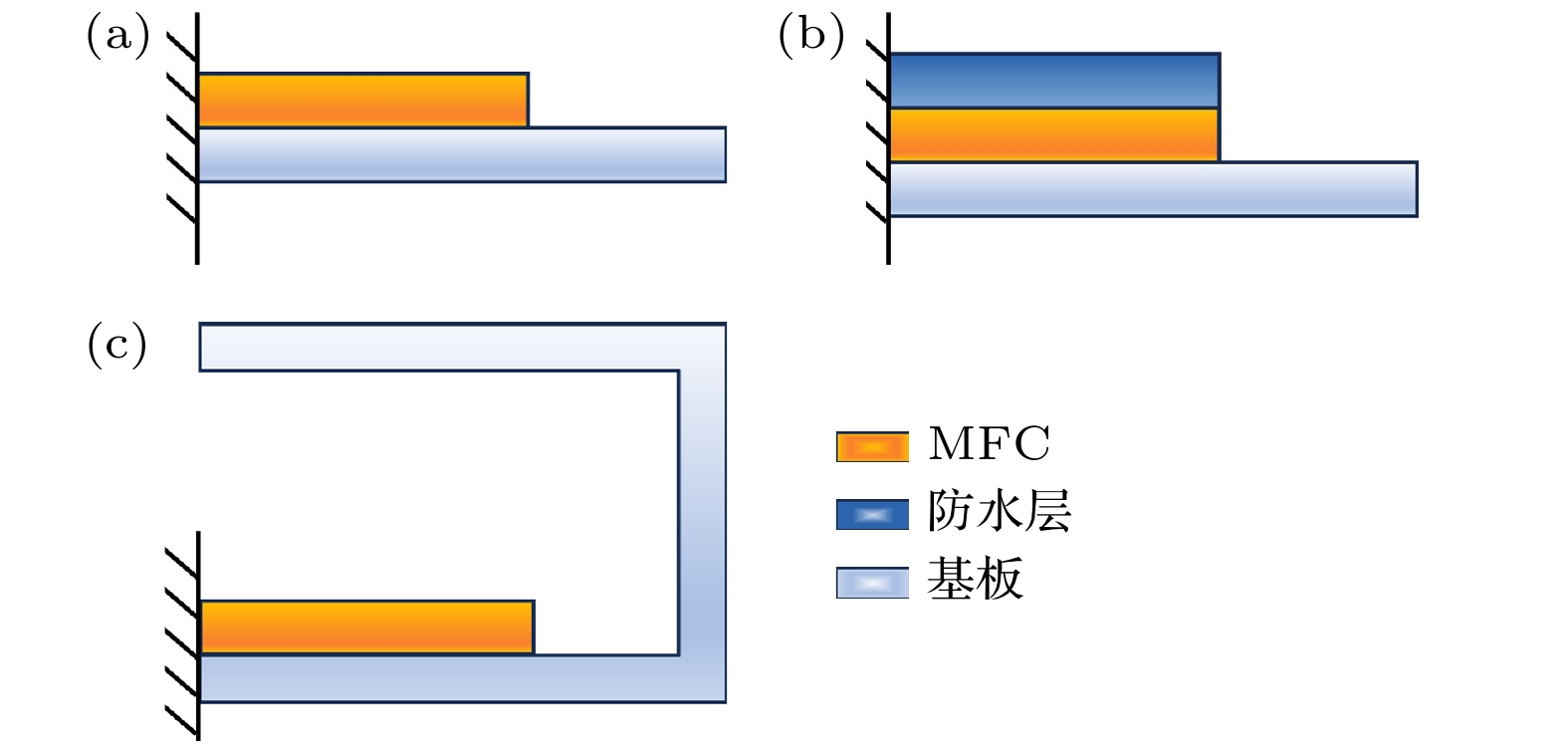

随着全球对可再生能源需求的持续增长, 雨水资源的开发利用逐渐成为研究热点. 压电俘能技术因其结构简单、能量转换效率高且无需外部电源等优势而备受关注. 然而传统压电俘能器受限于单一谐振频率, 难以适应复杂多变的环境激励. 本研究设计了多种用于雨水能量收集的宽频压电悬臂梁俘能器, 通过理论分析和数值模拟, 对压电悬臂梁的结构参数进行优化. COMSOL仿真和实验结果表明, U形压电俘能器在拓宽谐振频率范围和延长振荡时间方面显著优于其余俘能器结构设计, 可以实现单次冲击下23.7 s的振荡时间、2.82 μC的电荷俘获及37.76 W/m2的输出功率密度, 展现了其在宽谐振范围下的高效能量俘获能力. 此外, U形设计还可以实现结构防水, 增强了其在雨水环境中的适用性. 本研究为雨水能量收集提供了具有普适性的新方法, 拓展了压电能量俘获技术的应用场景, 为宽频能量收集器的设计及应用提供了理论参考和实践指导.With the continuous growth of global demand for renewable energy, the utilization of rainwater resources has gradually become a focal point of research. Piezoelectric energy harvesting has received significant attention because the harvester has simple structure, high energy conversion efficiency, and self-powering capability. However, traditional piezoelectric energy harvesters are limited by the narrow resonance frequency bandwidth and the insufficient waterproofing ability, which restricts the adaptability of energy conversion to variable environmental excitations. To solve this problem, a broadband piezoelectric cantilever energy harvester for rainwater energy harvesting is designed in this work. The influence mechanisms of droplet impact parameters, waterproof encapsulation technology, and MFC cantilever structure on the electrical output performance are studied through theoretical analysis, numerical simulation, and experimental validation. It reveals that the droplet’s Weber number exhibits a direct proportionality with the impact force, which is distributed within the 0–80 Hz frequency range. Simulations and experimental results demonstrate that the U-shaped piezoelectric energy harvester significantly outperforms other designs in terms of broadening the resonant frequency range and extending oscillation duration, achieving an oscillation time of 23.7 s, a charge transfer of 2.82 μC, and an output power density of 37.76 W/m2 under a single impact. It demonstrates its efficient energy harvesting capability in a wide resonance frequency range. Additionally, the U-shaped design also improves its waterproof performance, thus further enhancing its applicability in rainwater environments. This study provides a novel, universally applicable approach for collecting rainwater energy, expands the application scenarios of piezoelectric energy harvesting technology, and provides theoretical references and practical guidance for designing and applying broadband energy harvesters.

-

Keywords:

- finite element model /

- rainwater energy harvesting /

- piezoelectric energy harvester /

- structure design

[1] Zheng Y, Liu T, Wu J P, Xu T T, Wang X D, Han X, Cui H Z, Xu X F, Pan C F, Li X Y 2022 Adv. Mater. 34 2202238

Google Scholar

Google Scholar

[2] Sezer N, Koç M 2021 Nano Energy 80 105567

Google Scholar

Google Scholar

[3] Ilyas M A, Swingler J 2015 Energy 90 796

Google Scholar

Google Scholar

[4] Wong V K, Ho J H, Chai A B 2017 Energy 124 364

Google Scholar

Google Scholar

[5] Kumar B, Upadhyay G, Bhardwaj R 2023 Langmuir 39 18768

Google Scholar

Google Scholar

[6] Guigon R, Chaillout J J, Jager T, Despesse G 2008 Smart Mater. Struct. 17 015038

Google Scholar

Google Scholar

[7] Kim J H, Rothstein J P, Shang J K 2018 Phys. Fluids 30 072102

Google Scholar

Google Scholar

[8] Yao M H, Liu P F, Ma L, Wang H B, Zhang W 2020 Acta Mech. Sin. 36 557

Google Scholar

Google Scholar

[9] 陈南南 2020 硕士学位论文 (淮南: 安徽理工大学)

Chen N N 2020 M. S. Thesis (Huainan: Anhui University of Technology

[10] Huang X H, Zhang C, Dai K R 2021 Micromachines 12 203

Google Scholar

Google Scholar

[11] Wang J, Fan B, Fang J W, Zhao J C, Li C 2022 Energy Rep. 8 11638

Google Scholar

Google Scholar

[12] Wang L, Lu D J, Jiang Z D, Jia C, Wu Y M, Zhou X Y, Zhao L B, Zhao Y L 2018 AIP Adv. 8 115205

Google Scholar

Google Scholar

[13] Upadrashta D, Yang Y 2015 Smart Mater. Struct. 24 045042

Google Scholar

Google Scholar

[14] Cao D X, Zhan C H, Guo X Y, Yao M H 2024 J. Vib. Eng. Technol. 12 5073

Google Scholar

Google Scholar

[15] 孙帅令, 冷永刚, 张雨阳, 苏徐昆, 范胜波 2020 69 140502

Google Scholar

Google Scholar

Sun S L, Leng Y G, Zhang Y Y, Su X K, Fan S B 2020 Acta Phys. Sin. 69 140502

Google Scholar

Google Scholar

[16] 高裕昆, 赵洁, 周晶晶, 周静 2025 74 057701

Google Scholar

Google Scholar

Gao Y K, Zhao J, Zhou J J, Zhou J 2025 Acta Phys. Sin. 74 057701

Google Scholar

Google Scholar

[17] Zhou J J, Zhou J, Yu Y, Shen J, Zhang P C, Chen W 2023 Ceram. Int. 49 32528

Google Scholar

Google Scholar

[18] Zhou J J, Zhou J, Chen W, Tian J, Shen J, Zhang P C 2022 Compos. Struct. 299 116019

Google Scholar

Google Scholar

[19] Zhang B, Sanjay V, Shi S L, Zhao Y G, Lv C J, Feng X Q, Lohse D 2022 Phys. Rev. Lett. 129 104501

Google Scholar

Google Scholar

[20] Li X J, Zhang L Q, Feng Y G, Zhang Y L, Xu H Z, Zhou F, Wang D A 2023 ACS Nano 17 23977

Google Scholar

Google Scholar

[21] Doria A, Fanti G, Filipi G, Moro F 2019 Sensors 19 3653

Google Scholar

Google Scholar

[22] Hao G N, Dong X W, Li Z L 2021 Energy 232 121071

Google Scholar

Google Scholar

[23] Xu W H, Zheng H X, Liu Y, Zhou X F, Zhang C, Song Y X, Deng X, Leung M, Yang Z B, Xu R X, Wang Z L, Zeng X C, Wang Z K 2020 Nature 578 392

Google Scholar

Google Scholar

[24] Xu X T, Wang Y L, Li P Y, Xu W H, Wei L, Wang Z K, Yang Z B 2021 Nano Energy 90 106573

Google Scholar

Google Scholar

[25] Wang H C, Feng M, Wang W P, Wang W Q, Meng J, Liu Y P, Wang Q, Wang D A 2024 J. Mater. Chem. A 12 4727

Google Scholar

Google Scholar

-

表 1 水滴能量收集装置性能数据

Table 1. Performance of the droplet energy harvesting devices from studies.

-

[1] Zheng Y, Liu T, Wu J P, Xu T T, Wang X D, Han X, Cui H Z, Xu X F, Pan C F, Li X Y 2022 Adv. Mater. 34 2202238

Google Scholar

Google Scholar

[2] Sezer N, Koç M 2021 Nano Energy 80 105567

Google Scholar

Google Scholar

[3] Ilyas M A, Swingler J 2015 Energy 90 796

Google Scholar

Google Scholar

[4] Wong V K, Ho J H, Chai A B 2017 Energy 124 364

Google Scholar

Google Scholar

[5] Kumar B, Upadhyay G, Bhardwaj R 2023 Langmuir 39 18768

Google Scholar

Google Scholar

[6] Guigon R, Chaillout J J, Jager T, Despesse G 2008 Smart Mater. Struct. 17 015038

Google Scholar

Google Scholar

[7] Kim J H, Rothstein J P, Shang J K 2018 Phys. Fluids 30 072102

Google Scholar

Google Scholar

[8] Yao M H, Liu P F, Ma L, Wang H B, Zhang W 2020 Acta Mech. Sin. 36 557

Google Scholar

Google Scholar

[9] 陈南南 2020 硕士学位论文 (淮南: 安徽理工大学)

Chen N N 2020 M. S. Thesis (Huainan: Anhui University of Technology

[10] Huang X H, Zhang C, Dai K R 2021 Micromachines 12 203

Google Scholar

Google Scholar

[11] Wang J, Fan B, Fang J W, Zhao J C, Li C 2022 Energy Rep. 8 11638

Google Scholar

Google Scholar

[12] Wang L, Lu D J, Jiang Z D, Jia C, Wu Y M, Zhou X Y, Zhao L B, Zhao Y L 2018 AIP Adv. 8 115205

Google Scholar

Google Scholar

[13] Upadrashta D, Yang Y 2015 Smart Mater. Struct. 24 045042

Google Scholar

Google Scholar

[14] Cao D X, Zhan C H, Guo X Y, Yao M H 2024 J. Vib. Eng. Technol. 12 5073

Google Scholar

Google Scholar

[15] 孙帅令, 冷永刚, 张雨阳, 苏徐昆, 范胜波 2020 69 140502

Google Scholar

Google Scholar

Sun S L, Leng Y G, Zhang Y Y, Su X K, Fan S B 2020 Acta Phys. Sin. 69 140502

Google Scholar

Google Scholar

[16] 高裕昆, 赵洁, 周晶晶, 周静 2025 74 057701

Google Scholar

Google Scholar

Gao Y K, Zhao J, Zhou J J, Zhou J 2025 Acta Phys. Sin. 74 057701

Google Scholar

Google Scholar

[17] Zhou J J, Zhou J, Yu Y, Shen J, Zhang P C, Chen W 2023 Ceram. Int. 49 32528

Google Scholar

Google Scholar

[18] Zhou J J, Zhou J, Chen W, Tian J, Shen J, Zhang P C 2022 Compos. Struct. 299 116019

Google Scholar

Google Scholar

[19] Zhang B, Sanjay V, Shi S L, Zhao Y G, Lv C J, Feng X Q, Lohse D 2022 Phys. Rev. Lett. 129 104501

Google Scholar

Google Scholar

[20] Li X J, Zhang L Q, Feng Y G, Zhang Y L, Xu H Z, Zhou F, Wang D A 2023 ACS Nano 17 23977

Google Scholar

Google Scholar

[21] Doria A, Fanti G, Filipi G, Moro F 2019 Sensors 19 3653

Google Scholar

Google Scholar

[22] Hao G N, Dong X W, Li Z L 2021 Energy 232 121071

Google Scholar

Google Scholar

[23] Xu W H, Zheng H X, Liu Y, Zhou X F, Zhang C, Song Y X, Deng X, Leung M, Yang Z B, Xu R X, Wang Z L, Zeng X C, Wang Z K 2020 Nature 578 392

Google Scholar

Google Scholar

[24] Xu X T, Wang Y L, Li P Y, Xu W H, Wei L, Wang Z K, Yang Z B 2021 Nano Energy 90 106573

Google Scholar

Google Scholar

[25] Wang H C, Feng M, Wang W P, Wang W Q, Meng J, Liu Y P, Wang Q, Wang D A 2024 J. Mater. Chem. A 12 4727

Google Scholar

Google Scholar

计量

- 文章访问数: 709

- PDF下载量: 26

- 被引次数: 0

下载:

下载: