-

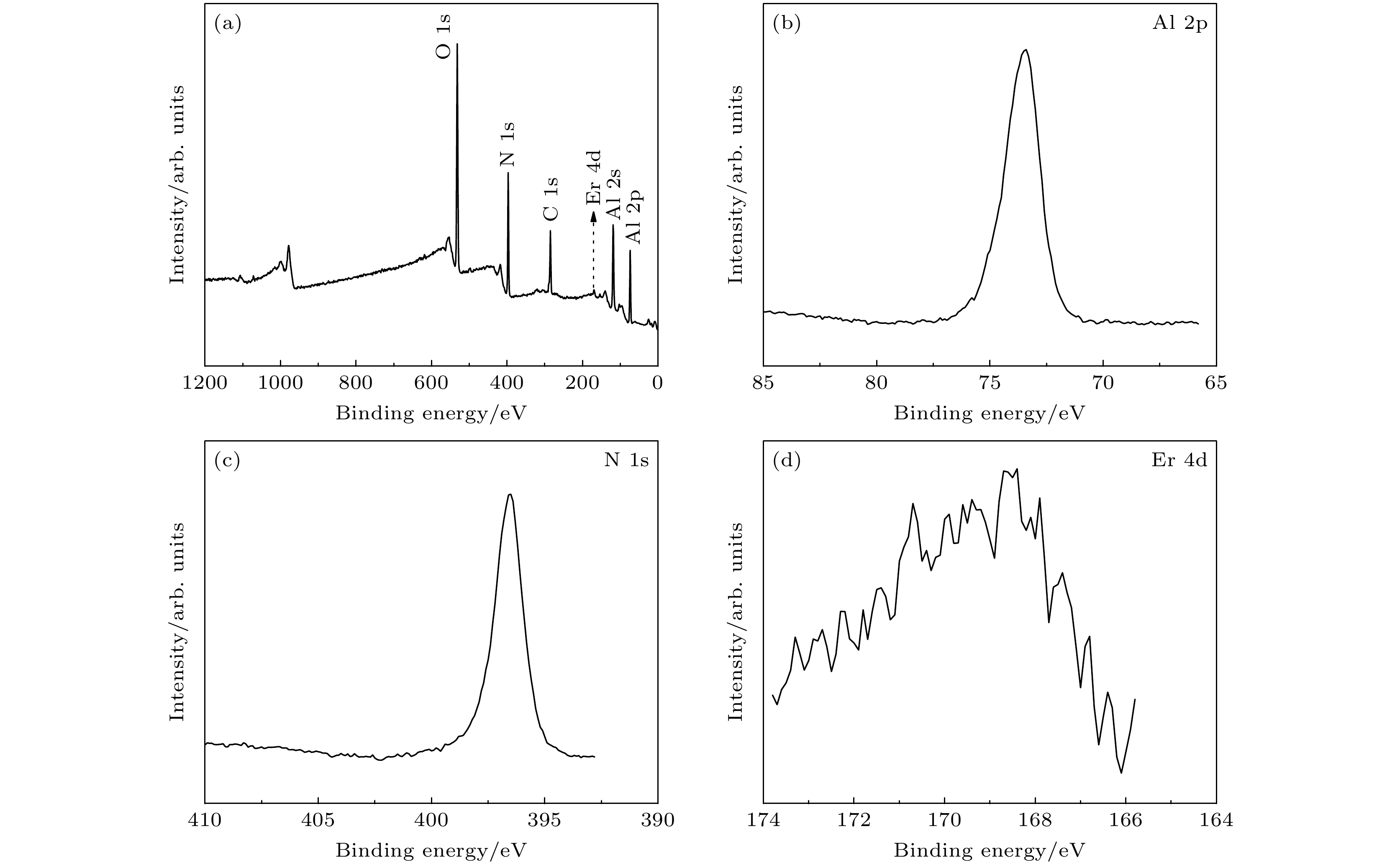

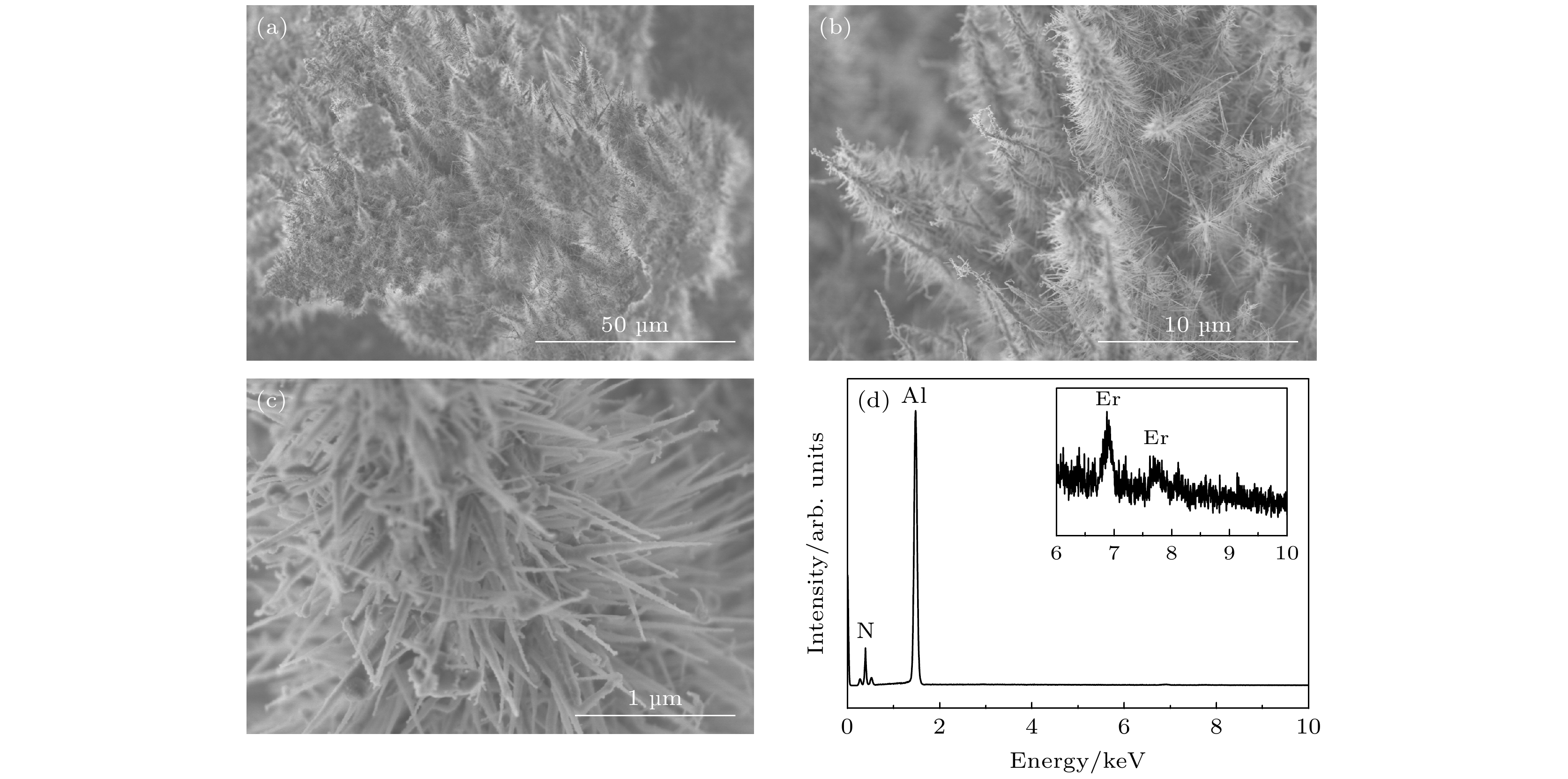

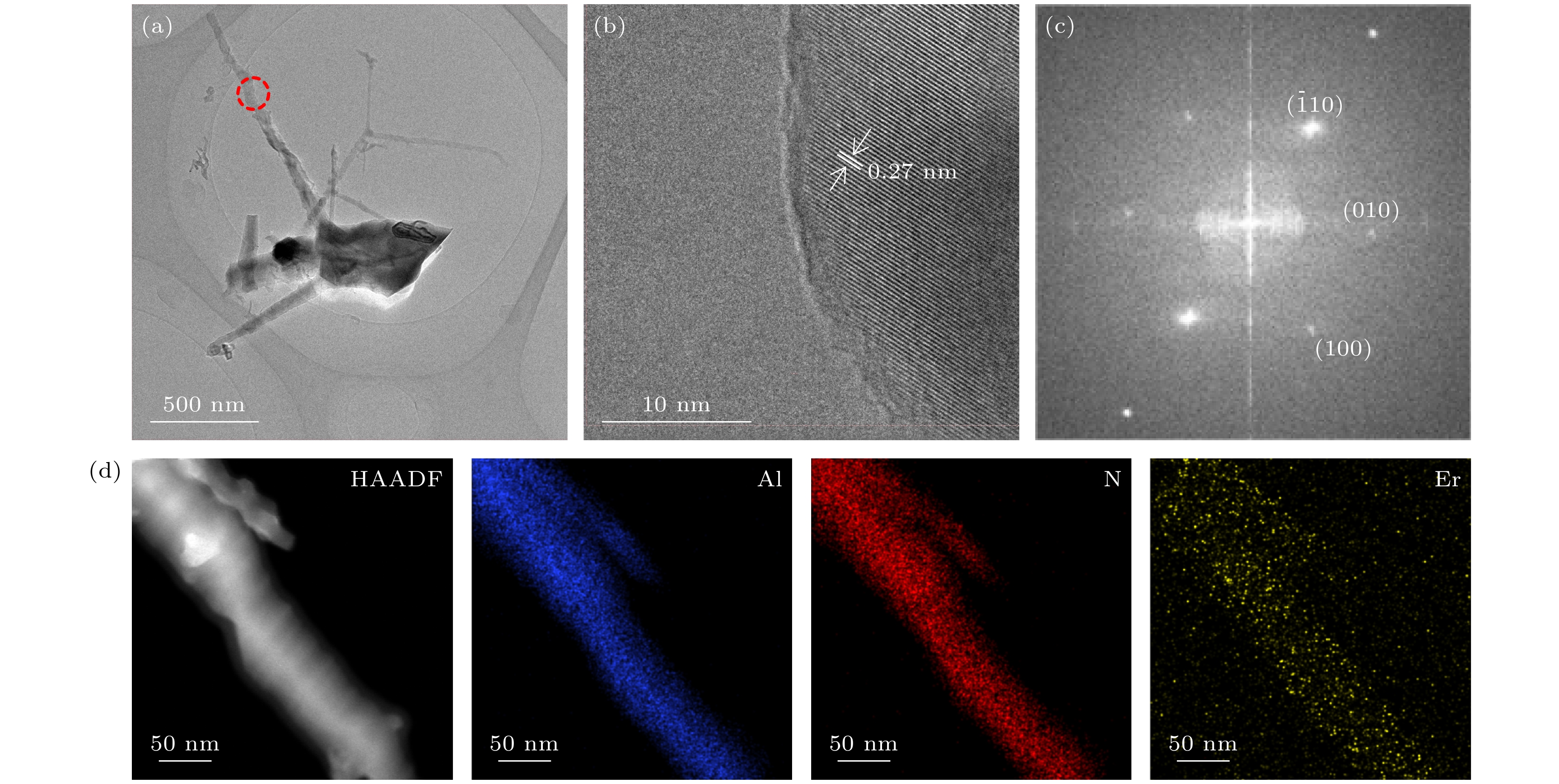

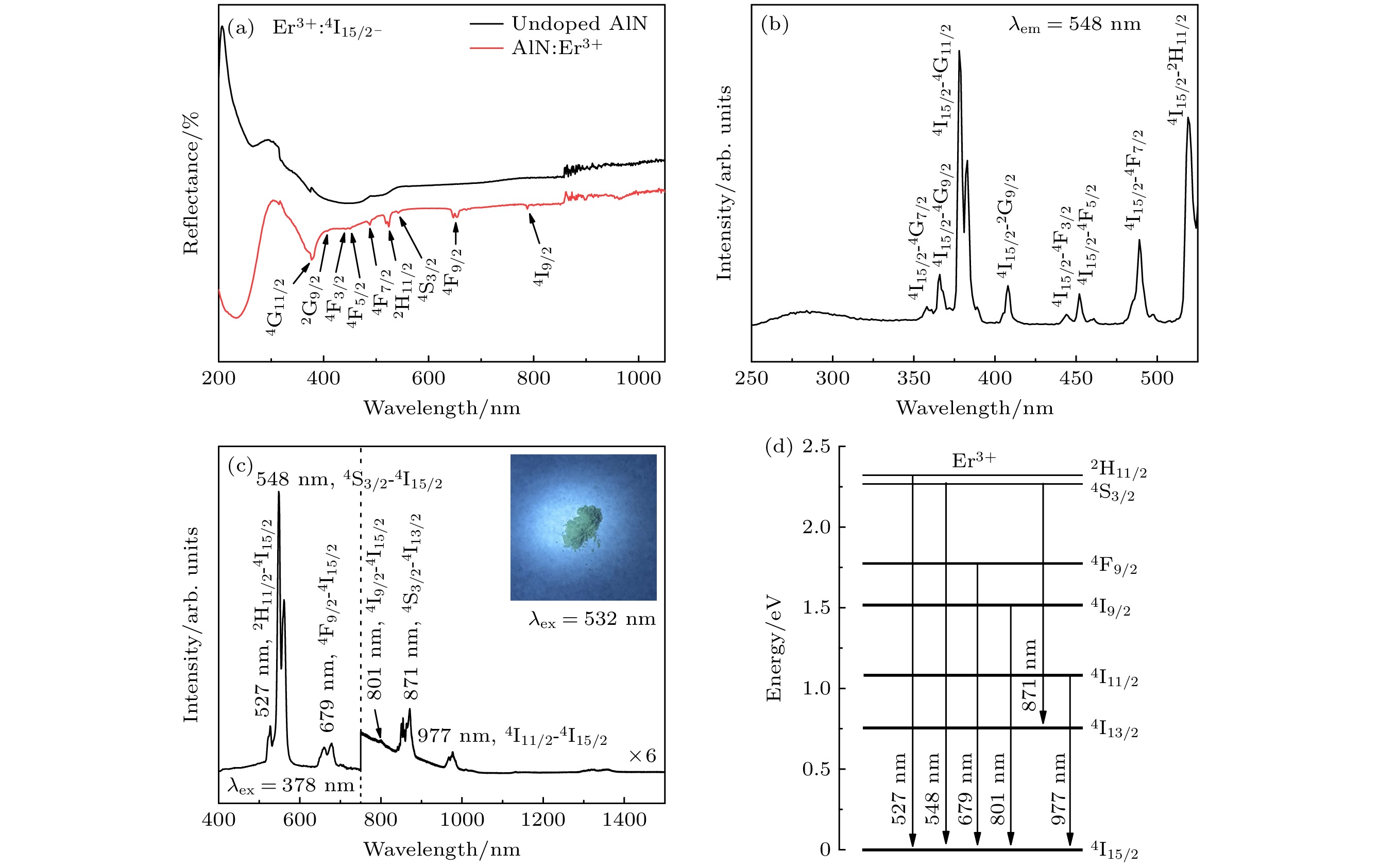

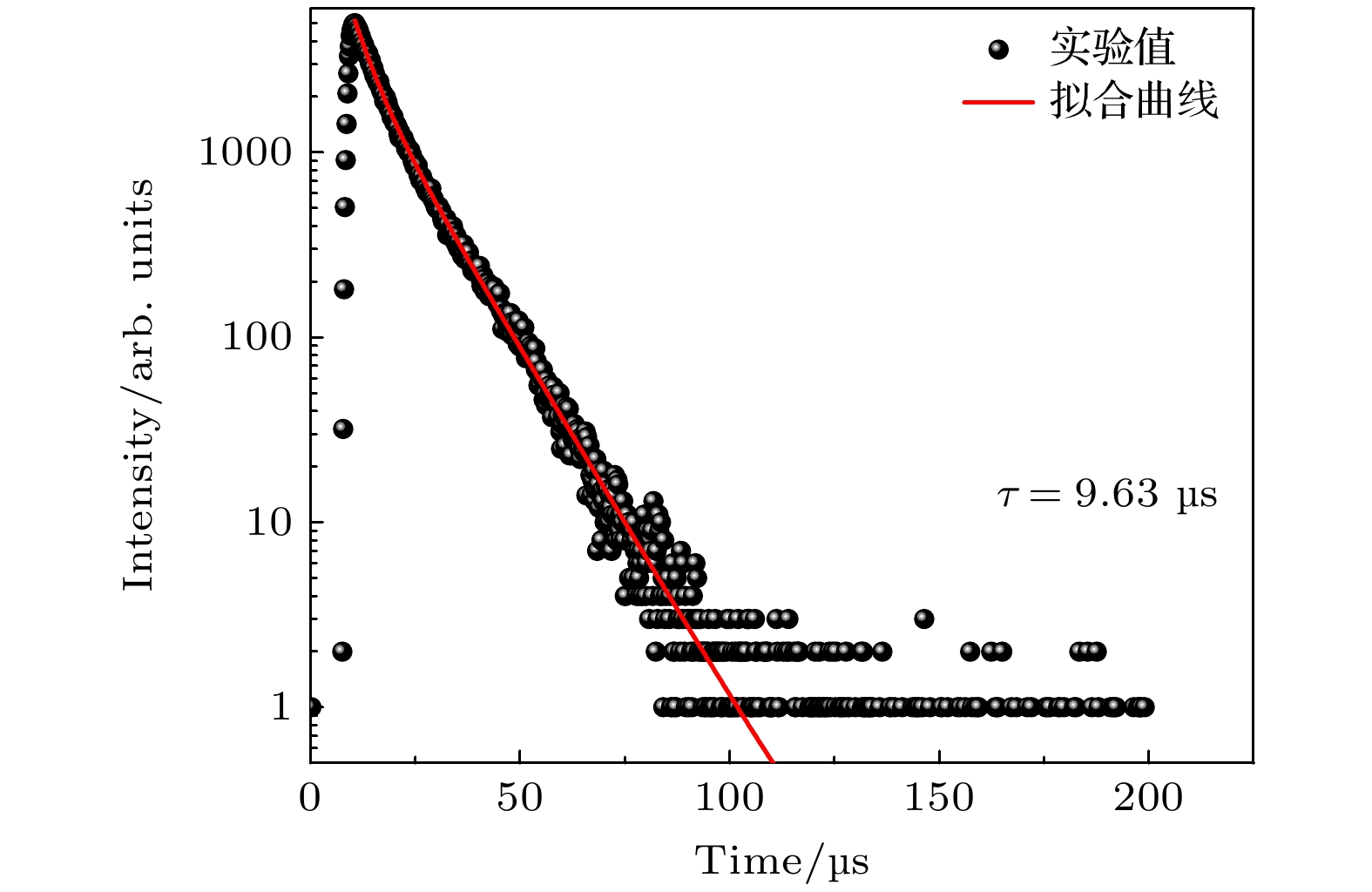

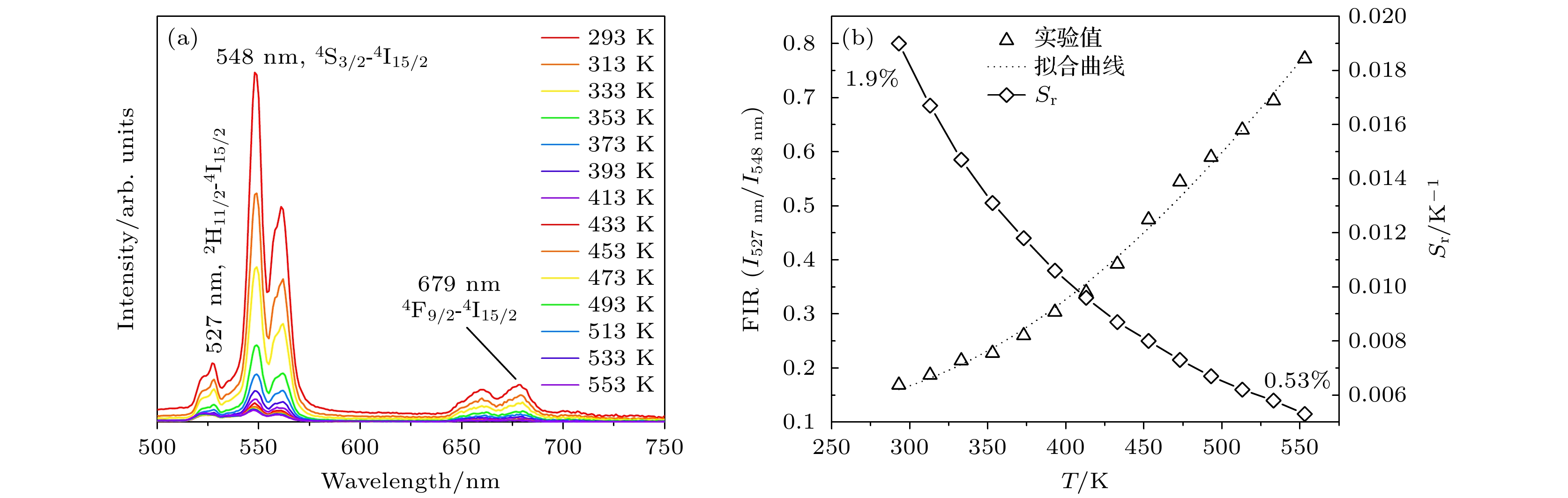

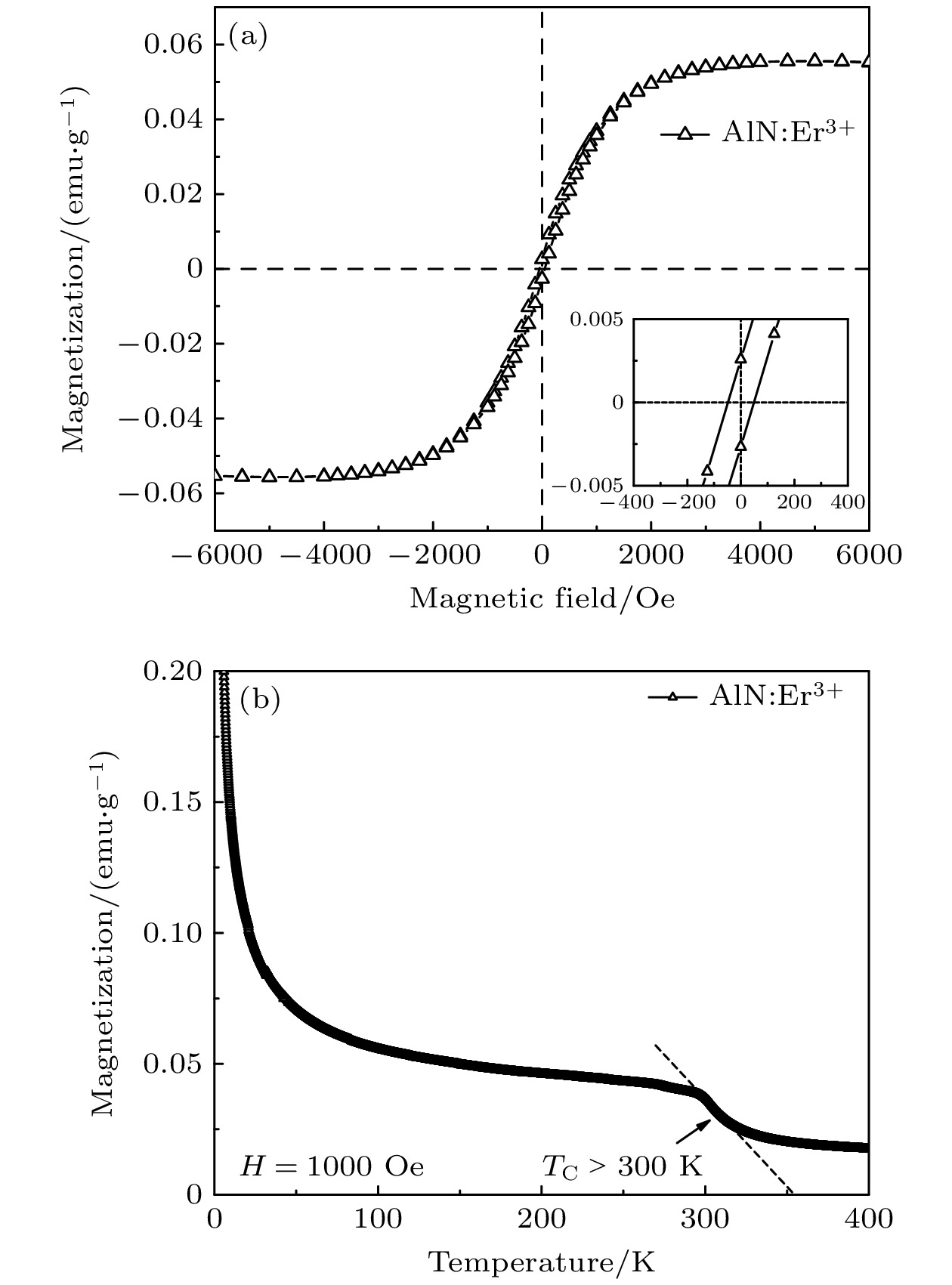

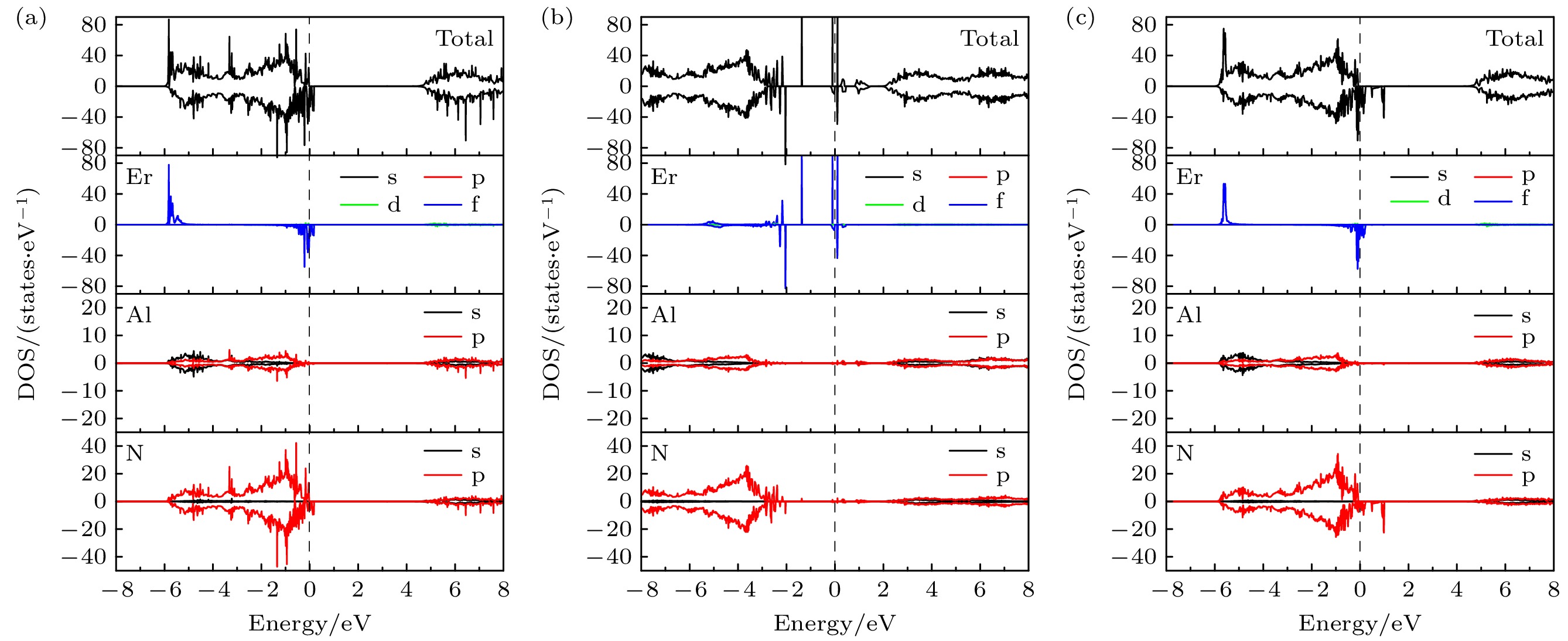

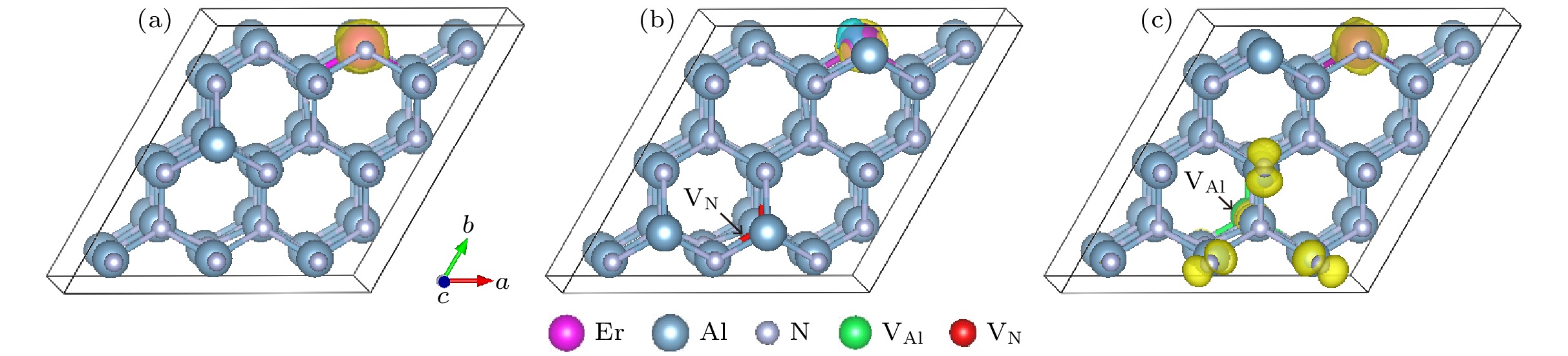

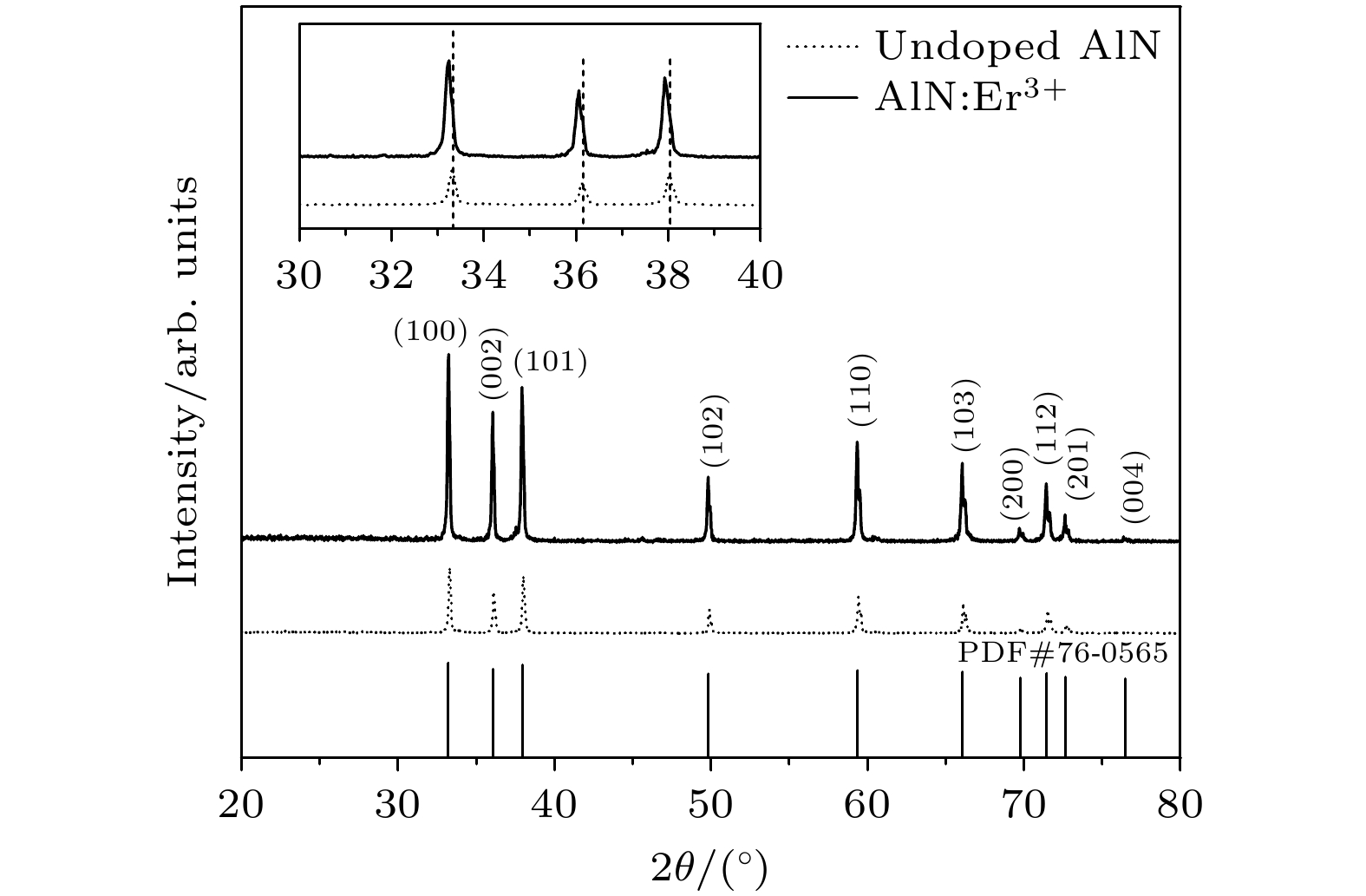

采用直流电弧等离子体法, 以Al粉和Er2O3粉为原料, 在氮气环境下, 成功制备出了具有松树状纳米结构的Er3+掺杂AlN (AlN:Er3+)材料. 通过X射线衍射、X射线光电子能谱、能量色散光谱、扫描电子显微镜、透射电子显微镜和高分辨率透射电子显微镜的分析, 详细测定了松树状纳米结构的成分、形貌特征和显微结构. 结果显示, 该材料呈现出典型的六方纤锌矿晶体结构, 其形态由主干与分支纳米线交织而成, 且证实Er3+成功掺入其晶格中. 光致发光光谱显示, AlN:Er3+能够发出强烈的绿光(~548 nm), 并伴有多个发光峰, 分别对应于Er3+内层4f电子跃迁的特征发光峰. 根据不同温度下热耦合能级(2H11/2/4S3/2→4I15/2)发光光谱强度的比值, 在温度为293 K时获得最高相对灵敏度, 为1.9×10–2 K–1. 磁学测量表明, AlN:Er3+显现出明显的室温铁磁性. 通过第一性原理计算后发现其磁矩主要由Al空位周围N原子的2p轨道电子自旋极化产生. AlN:Er3+松树状纳米结构在光电器件、温敏传感器以及稀磁半导体等多个领域展现出潜在的应用前景.Erbium-doped aluminum nitride (AlN:Er3+) pine-shaped nanostructures are synthesized, through a direct reaction between aluminum (Al) and erbium oxide (Er2O3) mixed powders in a nitrogen (N2) atmosphere, by using a direct current arc discharge plasma method. X-ray diffraction (XRD) analysis reveals that the diffraction peaks of AlN:Er3+ shift towards lower angles for the doped sample compared with those of undoped AlN, indicating lattice expansion due to Er3+ incorporation. X-ray photoelectron spectroscopy (XPS) confirms that Al, N, and Er are coexistent, while energy-dispersive X-ray spectroscopy (EDS) quantitatively shows that the atomic ratio for Al:N:Er is about 46.9∶52.8∶0.3. The nanostructures, resembling pine trees, are measured to be 5–10 μm in height and 1–3 μm in width, with branch nanowires extending 500 nm–1 μm in length and 50–100 nm in diameter. These branches, radiating at about 60° from the main trunk, are found to grow along the [100] direction of wurtzite-structured AlN, as evidenced by high-resolution transmission electron microscopy (HRTEM) showing lattice spacing of 0.27 nm corresponding to the (100) plane. Photoluminescence studies identify distinct emission peaks in the visible region (527, 548, and 679 nm) and near-infrared region (801, 871, and 977 nm), which is attributed to intra-4f electron transitions of Er3+ ions. The average lifetime of the excited state at 548 nm is measured to be 9.63 μs, slightly shorter than those of other Er3+-doped materials. The nanostructures demonstrate that the superior temperature sensing capability possesses a maximum relative sensitivity of 1.9×10–2 K–1 at 293 K, based on the fluorescence intensity ratio of thermal-coupled levels (2H11/2/4S3/2). Magnetic characterization reveals that the room-temperature ferromagnetism has a saturation magnetization of 0.055 emu/g and a coercive field of 49 Oe, with a Curie temperature exceeding 300 K, which shows the potential for room-temperature spintronic applications. First-principle calculations attribute the observed ferromagnetism to Al vacancies, whose formation energy is significantly reduced by Er doping, leading to a high concentration of Al vacancies. These findings highlight the potential of AlN:Er3+ pine-shaped nanostructures in various applications, including optoelectronics, temperature sensing, and dilute magnetic semiconductors.

-

Keywords:

- aluminum nitride /

- photoluminescence /

- temperature sensitive /

- dilute magnetic semiconductor

[1] 李志杰, 田鸣, 贺连龙 2011 60 098101

Google Scholar

Google Scholar

Li Z J, Tian M, He L L 2011 Acta Phys. Sin. 60 098101

Google Scholar

Google Scholar

[2] 蓝雷雷, 胡新宇, 顾广瑞, 姜丽娜, 吴宝嘉 2013 62 217504

Google Scholar

Google Scholar

Lan L L, Hu X Y, Gu G R, Jiang L N, Wu B J 2013 Acta Phys. Sin. 62 217504

Google Scholar

Google Scholar

[3] 程赛, 吕惠民, 石振海, 崔静雅 2012 61 126201

Google Scholar

Google Scholar

Cheng S, Lv H M, Shi Z H, Cui J Y 2012 Acta Phys. Sin. 61 126201

Google Scholar

Google Scholar

[4] 余森, 许晟瑞, 陶鸿昌, 王海涛, 安瑕, 杨赫, 许钪, 张进成, 郝跃 2024 73 196101

Google Scholar

Google Scholar

Yu S, Xu S R, Tao H C, Wang H T, An X, Yang H, Xu K, Zhang J C, Hao Y 2024 Acta Phys. Sin. 73 196101

Google Scholar

Google Scholar

[5] 赵罡, 梁汉普, 段益峰 2023 72 096301

Google Scholar

Google Scholar

Zhao G, Liang H P, Duan Y F 2023 Acta Phys. Sin. 72 096301

Google Scholar

Google Scholar

[6] Liu H, Shao P F, Chen S L, Tao T, Yan Y, Xie Z L, Liu B, Chen D J, Lu H, Zhang R, Wang K 2024 Chin. Phys. B 33 106801

Google Scholar

Google Scholar

[7] Jia W, Han P D, Chi M, Dang S H, Xu B S, Liu X G 2007 J. Appl. Phys. 101 113918

Google Scholar

Google Scholar

[8] Nepal N, Nakarmi M L, Jang H U, Lin J Y, Jiang H X 2006 Appl. Phys. Lett. 89 192111

Google Scholar

Google Scholar

[9] Zhao H L, Zou Z L, Yao J, Guo S W, Wang T, Shen X M, Fu Y C, He H 2021 Optik 243 167455

Google Scholar

Google Scholar

[10] Li X, Wang X D, Ma H, Chen F F, Zeng X H 2019 Chin. Opt. Lett. 17 111602

Google Scholar

Google Scholar

[11] Wang D, Wang X D, Ma H, Gao X D, Chen J F, Zheng S N, Mao H M, Chen H J, Zeng X H, Xu K 2022 Opt. Mater. 128 112366

Google Scholar

Google Scholar

[12] Ma H, Wang X D, Chen F F, Chen J F, Zeng X H, Gao X D, Wang D, Mao H M, Xu K 2021 J. Lumin. 236 118082

Google Scholar

Google Scholar

[13] Vermeersch R, Jacopin G, Robin E, Pernot J, Gayral B, Daudin B 2023 Appl. Phys. Lett. 122 091106

Google Scholar

Google Scholar

[14] Elhamra F, Rougab M, Gueddouh A 2025 J. Phys. Chem. Solids 197 112442

Google Scholar

Google Scholar

[15] Rougab M, Gueddouh A 2021 Appl. Phys. A 127 969

Google Scholar

Google Scholar

[16] Osetsky Y, Du M H, Samolyuk G, Zinkle S J, Zarkadoula E 2022 Phys. Rev. Mater. 6 094603

Google Scholar

Google Scholar

[17] Wang Z Y, Golovynskyi S, Dong D, Zhang F H, Yue Z Y, Jin L, Wang S, Li B K, Sun Z H, Wu H L 2023 J. Lumin. 255 119605

Google Scholar

Google Scholar

[18] MacKenzie J D, Abernathy C R, Pearton S J, Hommerich U, Wu X, Schwartz R N, Wilson R G, Zavada J M 1996 Appl. Phys. Lett. 69 2083

Google Scholar

Google Scholar

[19] Wu X, Hommerich U, Mackenzie J D, Abernathy C R, Pearton S J, Wilson R G, Schwartz R N, Zavada J M 1997 J. Lumin. 72-74 284

Google Scholar

Google Scholar

[20] Wilson R G, Schwartz R N, Abernathy C R, Pearton S J, Newman N, Rubin M, Fu T, Zavada J M 1994 Appl. Phys. Lett. 65 992

Google Scholar

Google Scholar

[21] Gurumurugan K, Chen H, Harp G R, Jadwisienczak W M, Lozykowski H J 1999 Appl. Phys. Lett. 74 3008

Google Scholar

Google Scholar

[22] Oliveira J C, Cavaleiro A, Vieira M T 2000 Surf. Coat. Tech. 132 99

Google Scholar

Google Scholar

[23] Oliveira J C, Cavaleiro A, Vieira M T, Bigot L, Garapon C, Jacquier B, Mugnier J 2003 Opt. Mater. 24 321

Google Scholar

Google Scholar

[24] Dimitrova V I, Van Patten P G, Richardson H, Kordesch M E 2001 Appl. Surf. Sci. 175-176 480

Google Scholar

Google Scholar

[25] Zanatta A R, Ribeiro C T M, Jahn U 2005 J. Appl. Phys. 98 093514

Google Scholar

Google Scholar

[26] Rinnert H, Hussain S S, Brien V, Legrand J, Pigeat P 2012 J. Lumin. 132 2367

Google Scholar

Google Scholar

[27] Legrand J, Pigeat P, Easwarakhanthan T, Rinnert H 2014 Appl. Surf. Sci. 307 189

Google Scholar

Google Scholar

[28] Hussain S S, Pigeat P 2015 Mater. Today. Proc. 2 5236

Google Scholar

Google Scholar

[29] Hussain S S, Pigeat P 2015 Mater. Today. Proc. 2 5361

Google Scholar

Google Scholar

[30] Kallel T, Koubaa T, Dammak M, Pandya S G, Kordesch M E, Wang J, Jadwisienczak W M, Wang Y 2016 J. Lumin. 171 42

Google Scholar

Google Scholar

[31] Fang L P, Yin A Y, Zhu S F, Ding J J, Chen L, Zhang D X, Pu Z, Liu T W 2017 J. Alloys Compd. 727 735

Google Scholar

Google Scholar

[32] Hu X W, Tai Z W, Yang C T 2018 Mater. Lett. 217 281

Google Scholar

Google Scholar

[33] Ge S W, Zhang B Z, Yang C T 2019 Surf. Coat. Tech. 358 404

Google Scholar

Google Scholar

[34] Wang Z Y, Zhang F H, Datsenko O I, Golovynskyi S, Sun Z H, Li B K, Wu H L 2023 J. Alloys Compd. 946 169350

Google Scholar

Google Scholar

[35] Lei W W, Liu D, Zhu P W, Chen X H, Zhao Q, Wen G H, Cui Q L, Zou G T 2009 Appl. Phys. Lett. 95 162501

Google Scholar

Google Scholar

[36] Han H C, Wang J Q, Xu C Y, Wang Q S, Zheng H L 2022 J. Alloys Compd. 907 164461

Google Scholar

Google Scholar

[37] Narang V, Korakakis D, Seehra M S 2014 J. Appl. Phys. 116 213911

Google Scholar

Google Scholar

[38] Zhu G, Wu W Z, Xin S Y, Zhang J, Wang Q S 2019 J. Lumin. 206 33

Google Scholar

Google Scholar

[39] 类伟巍 2009 博士学位论文 (长春: 吉林大学)

Lei W W 2009 Ph. D. Dissertation (Changchun: Jilin University

[40] Xu Y S, Yao B B, Cui Q L 2016 RSC Adv. 6 113204

Google Scholar

Google Scholar

[41] Xiao Y, Chen J, Deng S Z, Xu N S, Yang S H 2008 J. Nanosci. Nanotechno. 8 237

Google Scholar

Google Scholar

[42] Lei W W, Liu D, Zhu P W, Chen X H, Hao J, Wang Q S, Cui Q L, Zou G T 2010 Crystengcomm 12 511

Google Scholar

Google Scholar

[43] Lei W W, Liu D, Zhu P W, Wang Q S, Liang G, Hao J, Chen X H, Cui Q L, Zou G T 2008 J. Phys. Chem. C 112 13353

Google Scholar

Google Scholar

[44] Wang Q S, Wu W Z, Zhang J, Zhu G, Cong R D 2019 J. Alloys Compd. 775 498

Google Scholar

Google Scholar

[45] Deng Y M, Yi S P, Wang Y H, Xian J Q 2014 Opt. Mater. 36 1378

Google Scholar

Google Scholar

[46] Zou H, Wang X S, Hu Y F, Zhu X Q, Sui Y X, Shen D H, Song Z T 2015 J. Mater. Sci-Mater. EI 26 6502

Google Scholar

Google Scholar

[47] Liang Y, Zhang X T, Qin L, Zhang E, Gao H, Zhang Z G 2006 J. Phys. Chem. B 110 21593

Google Scholar

Google Scholar

[48] Kumari S, Rao A S, Sinha R K 2024 ChemPhotoChem 8 e202300226

Google Scholar

Google Scholar

[49] 陈宝玖, 吕少哲, 黄世华 2001 无机材料学报 16 223

Chen B J, Lv S Z, Huang S H 2001 J. Inorg. Mater. 16 223

[50] 肖凯, 杨中民 2008 稀有金属材料与工程 37 80

Xiao K, Yang Z M 2008 Rare Metal Mat. Eng. 37 80

[51] Wang L X, Tuo J, Ye Y, Zhao H Q 2019 Chin. Opt. 12 112

Google Scholar

Google Scholar

[52] 赵延 2022 博士学位论文 (上海: 同济大学)

Zhao Y 2022 Ph. D. Dissertation (Shanghai: Tongji University

[53] Singh S K, Kumar K, Rai S B 2009 Sensor Actuat A-Phys. 149 16

Google Scholar

Google Scholar

[54] Hua Y B, Yu J S 2021 ACS Sustainable Chem. Eng. 9 5105

Google Scholar

Google Scholar

[55] Gutierrez-Cano V, Rodriguez F, Gonzalez J A, Valiente R 2019 J. Phys. Chem. C 123 29818

Google Scholar

Google Scholar

[56] Zhou K, Zhang H Y, Liu Y J, Bu Y Y, Wang X F, Yan X H 2019 J. Am. Ceram. Soc. 102 6564

Google Scholar

Google Scholar

[57] Li X M, Cao J K, Wei Y L, Yang Z R, Guo H 2015 J. Am. Ceram. Soc. 98 3824

Google Scholar

Google Scholar

[58] Wang Q S, Li J H, Zhang W, Zheng H L, Cong R D 2021 J. Lumin. 236 118089

Google Scholar

Google Scholar

[59] Wang Q S, Li J H, Zhang J, Zhu G, Zheng H L, Cong R D 2020 Appl. Surf. Sci. 527 146825

Google Scholar

Google Scholar

[60] 修向前, 李斌斌, 张荣, 陈琳, 谢自力, 韩平, 施毅, 郑有炓 2007 半导体学报 28 145

Xiu X Q, Li B B, Zhang R, Chen L, Xie Z L, Han P, Shi Y, Zheng Y D 2007 Chin. J. Semicond. 28 145

[61] Ravi S, Shashikanth F W 2020 Mater. Lett. 264 127331

Google Scholar

Google Scholar

[62] Lei W W, Liu D, Ma Y M, Chen X, Tian F B, Zhu P W, Chen X H, Cui Q L, Zou G T 2010 Angew. Chem. Int. Ed. 49 173

Google Scholar

Google Scholar

[63] Lei W W, Liu D, Chen X, Zhu P W, Cui Q L, Zou G T 2010 J. Phys. Chem. C 114 15574

Google Scholar

Google Scholar

-

图 5 (a)未掺杂的AlN和AlN:Er3+松树状纳米结构的漫反射光谱; (b) AlN:Er3+松树状纳米结构在548 nm处的激发光谱; (c)室温下AlN:Er3+松树状纳米结构在可见光(378 nm激发)到红外光(532 nm激发)范围内的发射光谱(插图为可见光范围内的光致发光成像); (d) Er3+能级跃迁图

Fig. 5. (a) DRSs of undoped AlN and AlN:Er3+ pine-shaped nanostructure; (b) excitation spectrum of AlN:Er3+ pine-shaped nanostructure at 548 nm; (c) the room-temperature Vis-NIR emission spectrum of AlN:Er3+ pine-shaped nanostructure (the visible PL imaging in inset); (d) the schematic energy level diagram for Er3+ ions.

图 7 (a)不同温度下AlN:Er3+松树状纳米结构的PL光谱; (b) AlN:Er3+松树状纳米结构在293—553 K的FIR (I527 nm/I548 nm)及对其随温度变化线性拟合结果(三角形标记代表FIR的实验值, 虚线为拟合曲线); 相对灵敏度Sr随温度的变化(菱形标记代表Sr的值)

Fig. 7. (a) Temperature-dependence spectra of AlN:Er3+ pine-shaped nanostructure; (b) FIR values of AlN:Er3+ pine-shaped nanostructure at the temperature of 293−553 K and the linear fitted results between the FIR and the temperature (the triangular markers represent the experimental values of FIR, and the dashed line is the fitting curve); the variation of relative sensitivity (Sr) with temperature (the diamond markers represent the values of Sr).

表 1 基于FIR技术对Er3+掺杂不同材料的相对灵敏度(Sr)进行比较

Table 1. Comparison of relative sensitivity (Sr) of Er3+ doped different materials based on FIR technology.

表 2 VAl和ErAl + VAl体系在富Al和富N条件下的形成能

Table 2. Formation energy under the Al-rich and N-rich conditions of the VAl and ErAl + VAl systems.

体系 形成能/eV 富Al 富N VAl 9.1935 6.1735 ErAl + VAl 10.35831 4.31831 -

[1] 李志杰, 田鸣, 贺连龙 2011 60 098101

Google Scholar

Google Scholar

Li Z J, Tian M, He L L 2011 Acta Phys. Sin. 60 098101

Google Scholar

Google Scholar

[2] 蓝雷雷, 胡新宇, 顾广瑞, 姜丽娜, 吴宝嘉 2013 62 217504

Google Scholar

Google Scholar

Lan L L, Hu X Y, Gu G R, Jiang L N, Wu B J 2013 Acta Phys. Sin. 62 217504

Google Scholar

Google Scholar

[3] 程赛, 吕惠民, 石振海, 崔静雅 2012 61 126201

Google Scholar

Google Scholar

Cheng S, Lv H M, Shi Z H, Cui J Y 2012 Acta Phys. Sin. 61 126201

Google Scholar

Google Scholar

[4] 余森, 许晟瑞, 陶鸿昌, 王海涛, 安瑕, 杨赫, 许钪, 张进成, 郝跃 2024 73 196101

Google Scholar

Google Scholar

Yu S, Xu S R, Tao H C, Wang H T, An X, Yang H, Xu K, Zhang J C, Hao Y 2024 Acta Phys. Sin. 73 196101

Google Scholar

Google Scholar

[5] 赵罡, 梁汉普, 段益峰 2023 72 096301

Google Scholar

Google Scholar

Zhao G, Liang H P, Duan Y F 2023 Acta Phys. Sin. 72 096301

Google Scholar

Google Scholar

[6] Liu H, Shao P F, Chen S L, Tao T, Yan Y, Xie Z L, Liu B, Chen D J, Lu H, Zhang R, Wang K 2024 Chin. Phys. B 33 106801

Google Scholar

Google Scholar

[7] Jia W, Han P D, Chi M, Dang S H, Xu B S, Liu X G 2007 J. Appl. Phys. 101 113918

Google Scholar

Google Scholar

[8] Nepal N, Nakarmi M L, Jang H U, Lin J Y, Jiang H X 2006 Appl. Phys. Lett. 89 192111

Google Scholar

Google Scholar

[9] Zhao H L, Zou Z L, Yao J, Guo S W, Wang T, Shen X M, Fu Y C, He H 2021 Optik 243 167455

Google Scholar

Google Scholar

[10] Li X, Wang X D, Ma H, Chen F F, Zeng X H 2019 Chin. Opt. Lett. 17 111602

Google Scholar

Google Scholar

[11] Wang D, Wang X D, Ma H, Gao X D, Chen J F, Zheng S N, Mao H M, Chen H J, Zeng X H, Xu K 2022 Opt. Mater. 128 112366

Google Scholar

Google Scholar

[12] Ma H, Wang X D, Chen F F, Chen J F, Zeng X H, Gao X D, Wang D, Mao H M, Xu K 2021 J. Lumin. 236 118082

Google Scholar

Google Scholar

[13] Vermeersch R, Jacopin G, Robin E, Pernot J, Gayral B, Daudin B 2023 Appl. Phys. Lett. 122 091106

Google Scholar

Google Scholar

[14] Elhamra F, Rougab M, Gueddouh A 2025 J. Phys. Chem. Solids 197 112442

Google Scholar

Google Scholar

[15] Rougab M, Gueddouh A 2021 Appl. Phys. A 127 969

Google Scholar

Google Scholar

[16] Osetsky Y, Du M H, Samolyuk G, Zinkle S J, Zarkadoula E 2022 Phys. Rev. Mater. 6 094603

Google Scholar

Google Scholar

[17] Wang Z Y, Golovynskyi S, Dong D, Zhang F H, Yue Z Y, Jin L, Wang S, Li B K, Sun Z H, Wu H L 2023 J. Lumin. 255 119605

Google Scholar

Google Scholar

[18] MacKenzie J D, Abernathy C R, Pearton S J, Hommerich U, Wu X, Schwartz R N, Wilson R G, Zavada J M 1996 Appl. Phys. Lett. 69 2083

Google Scholar

Google Scholar

[19] Wu X, Hommerich U, Mackenzie J D, Abernathy C R, Pearton S J, Wilson R G, Schwartz R N, Zavada J M 1997 J. Lumin. 72-74 284

Google Scholar

Google Scholar

[20] Wilson R G, Schwartz R N, Abernathy C R, Pearton S J, Newman N, Rubin M, Fu T, Zavada J M 1994 Appl. Phys. Lett. 65 992

Google Scholar

Google Scholar

[21] Gurumurugan K, Chen H, Harp G R, Jadwisienczak W M, Lozykowski H J 1999 Appl. Phys. Lett. 74 3008

Google Scholar

Google Scholar

[22] Oliveira J C, Cavaleiro A, Vieira M T 2000 Surf. Coat. Tech. 132 99

Google Scholar

Google Scholar

[23] Oliveira J C, Cavaleiro A, Vieira M T, Bigot L, Garapon C, Jacquier B, Mugnier J 2003 Opt. Mater. 24 321

Google Scholar

Google Scholar

[24] Dimitrova V I, Van Patten P G, Richardson H, Kordesch M E 2001 Appl. Surf. Sci. 175-176 480

Google Scholar

Google Scholar

[25] Zanatta A R, Ribeiro C T M, Jahn U 2005 J. Appl. Phys. 98 093514

Google Scholar

Google Scholar

[26] Rinnert H, Hussain S S, Brien V, Legrand J, Pigeat P 2012 J. Lumin. 132 2367

Google Scholar

Google Scholar

[27] Legrand J, Pigeat P, Easwarakhanthan T, Rinnert H 2014 Appl. Surf. Sci. 307 189

Google Scholar

Google Scholar

[28] Hussain S S, Pigeat P 2015 Mater. Today. Proc. 2 5236

Google Scholar

Google Scholar

[29] Hussain S S, Pigeat P 2015 Mater. Today. Proc. 2 5361

Google Scholar

Google Scholar

[30] Kallel T, Koubaa T, Dammak M, Pandya S G, Kordesch M E, Wang J, Jadwisienczak W M, Wang Y 2016 J. Lumin. 171 42

Google Scholar

Google Scholar

[31] Fang L P, Yin A Y, Zhu S F, Ding J J, Chen L, Zhang D X, Pu Z, Liu T W 2017 J. Alloys Compd. 727 735

Google Scholar

Google Scholar

[32] Hu X W, Tai Z W, Yang C T 2018 Mater. Lett. 217 281

Google Scholar

Google Scholar

[33] Ge S W, Zhang B Z, Yang C T 2019 Surf. Coat. Tech. 358 404

Google Scholar

Google Scholar

[34] Wang Z Y, Zhang F H, Datsenko O I, Golovynskyi S, Sun Z H, Li B K, Wu H L 2023 J. Alloys Compd. 946 169350

Google Scholar

Google Scholar

[35] Lei W W, Liu D, Zhu P W, Chen X H, Zhao Q, Wen G H, Cui Q L, Zou G T 2009 Appl. Phys. Lett. 95 162501

Google Scholar

Google Scholar

[36] Han H C, Wang J Q, Xu C Y, Wang Q S, Zheng H L 2022 J. Alloys Compd. 907 164461

Google Scholar

Google Scholar

[37] Narang V, Korakakis D, Seehra M S 2014 J. Appl. Phys. 116 213911

Google Scholar

Google Scholar

[38] Zhu G, Wu W Z, Xin S Y, Zhang J, Wang Q S 2019 J. Lumin. 206 33

Google Scholar

Google Scholar

[39] 类伟巍 2009 博士学位论文 (长春: 吉林大学)

Lei W W 2009 Ph. D. Dissertation (Changchun: Jilin University

[40] Xu Y S, Yao B B, Cui Q L 2016 RSC Adv. 6 113204

Google Scholar

Google Scholar

[41] Xiao Y, Chen J, Deng S Z, Xu N S, Yang S H 2008 J. Nanosci. Nanotechno. 8 237

Google Scholar

Google Scholar

[42] Lei W W, Liu D, Zhu P W, Chen X H, Hao J, Wang Q S, Cui Q L, Zou G T 2010 Crystengcomm 12 511

Google Scholar

Google Scholar

[43] Lei W W, Liu D, Zhu P W, Wang Q S, Liang G, Hao J, Chen X H, Cui Q L, Zou G T 2008 J. Phys. Chem. C 112 13353

Google Scholar

Google Scholar

[44] Wang Q S, Wu W Z, Zhang J, Zhu G, Cong R D 2019 J. Alloys Compd. 775 498

Google Scholar

Google Scholar

[45] Deng Y M, Yi S P, Wang Y H, Xian J Q 2014 Opt. Mater. 36 1378

Google Scholar

Google Scholar

[46] Zou H, Wang X S, Hu Y F, Zhu X Q, Sui Y X, Shen D H, Song Z T 2015 J. Mater. Sci-Mater. EI 26 6502

Google Scholar

Google Scholar

[47] Liang Y, Zhang X T, Qin L, Zhang E, Gao H, Zhang Z G 2006 J. Phys. Chem. B 110 21593

Google Scholar

Google Scholar

[48] Kumari S, Rao A S, Sinha R K 2024 ChemPhotoChem 8 e202300226

Google Scholar

Google Scholar

[49] 陈宝玖, 吕少哲, 黄世华 2001 无机材料学报 16 223

Chen B J, Lv S Z, Huang S H 2001 J. Inorg. Mater. 16 223

[50] 肖凯, 杨中民 2008 稀有金属材料与工程 37 80

Xiao K, Yang Z M 2008 Rare Metal Mat. Eng. 37 80

[51] Wang L X, Tuo J, Ye Y, Zhao H Q 2019 Chin. Opt. 12 112

Google Scholar

Google Scholar

[52] 赵延 2022 博士学位论文 (上海: 同济大学)

Zhao Y 2022 Ph. D. Dissertation (Shanghai: Tongji University

[53] Singh S K, Kumar K, Rai S B 2009 Sensor Actuat A-Phys. 149 16

Google Scholar

Google Scholar

[54] Hua Y B, Yu J S 2021 ACS Sustainable Chem. Eng. 9 5105

Google Scholar

Google Scholar

[55] Gutierrez-Cano V, Rodriguez F, Gonzalez J A, Valiente R 2019 J. Phys. Chem. C 123 29818

Google Scholar

Google Scholar

[56] Zhou K, Zhang H Y, Liu Y J, Bu Y Y, Wang X F, Yan X H 2019 J. Am. Ceram. Soc. 102 6564

Google Scholar

Google Scholar

[57] Li X M, Cao J K, Wei Y L, Yang Z R, Guo H 2015 J. Am. Ceram. Soc. 98 3824

Google Scholar

Google Scholar

[58] Wang Q S, Li J H, Zhang W, Zheng H L, Cong R D 2021 J. Lumin. 236 118089

Google Scholar

Google Scholar

[59] Wang Q S, Li J H, Zhang J, Zhu G, Zheng H L, Cong R D 2020 Appl. Surf. Sci. 527 146825

Google Scholar

Google Scholar

[60] 修向前, 李斌斌, 张荣, 陈琳, 谢自力, 韩平, 施毅, 郑有炓 2007 半导体学报 28 145

Xiu X Q, Li B B, Zhang R, Chen L, Xie Z L, Han P, Shi Y, Zheng Y D 2007 Chin. J. Semicond. 28 145

[61] Ravi S, Shashikanth F W 2020 Mater. Lett. 264 127331

Google Scholar

Google Scholar

[62] Lei W W, Liu D, Ma Y M, Chen X, Tian F B, Zhu P W, Chen X H, Cui Q L, Zou G T 2010 Angew. Chem. Int. Ed. 49 173

Google Scholar

Google Scholar

[63] Lei W W, Liu D, Chen X, Zhu P W, Cui Q L, Zou G T 2010 J. Phys. Chem. C 114 15574

Google Scholar

Google Scholar

计量

- 文章访问数: 3742

- PDF下载量: 90

- 被引次数: 0

下载:

下载: