-

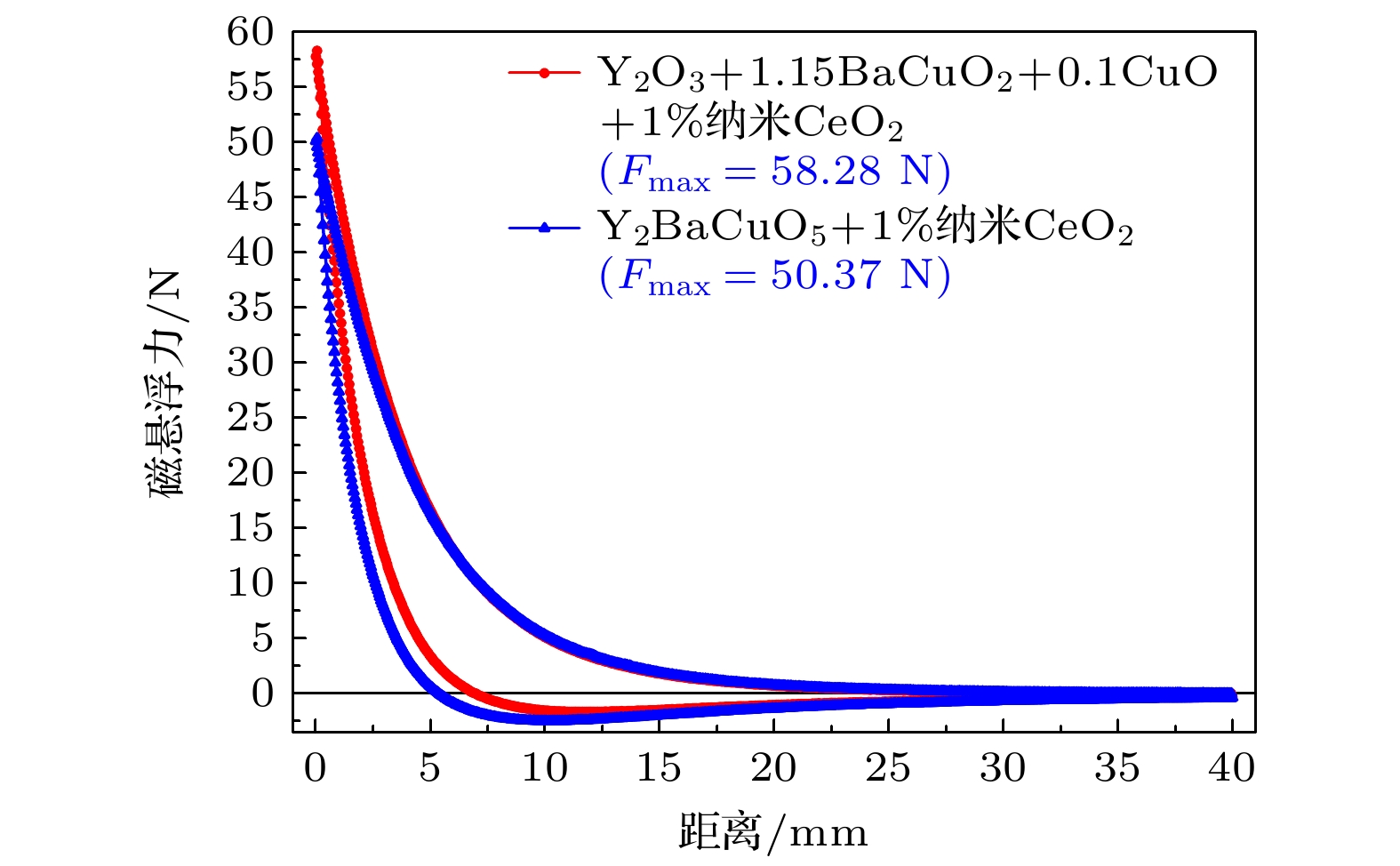

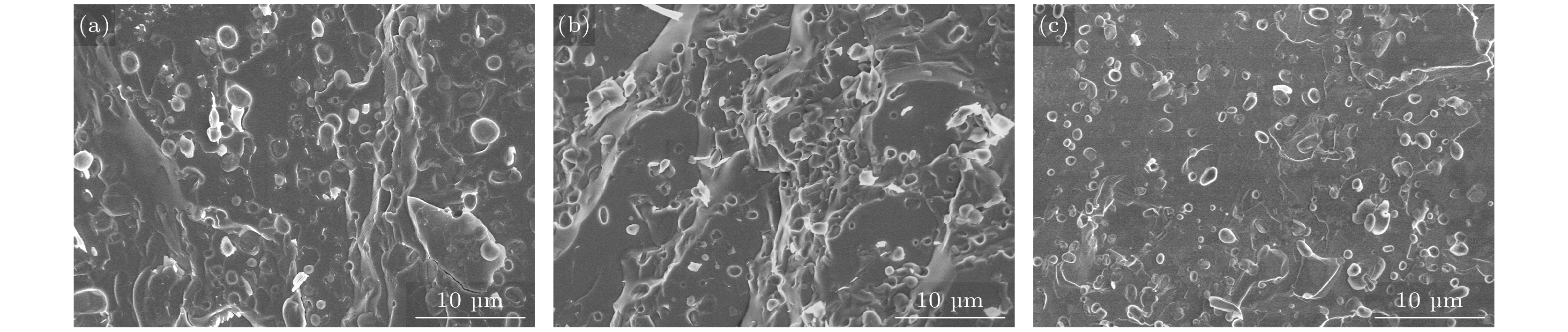

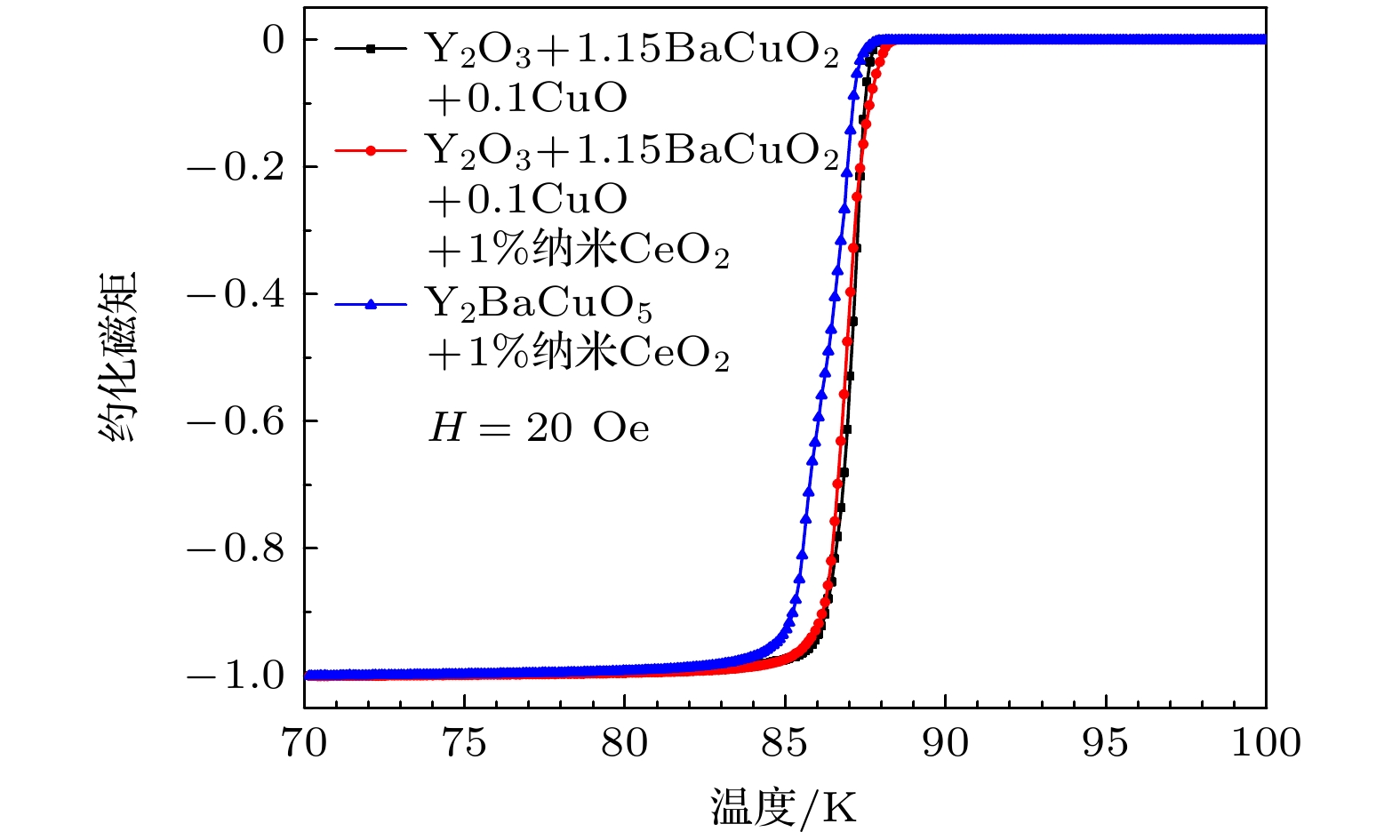

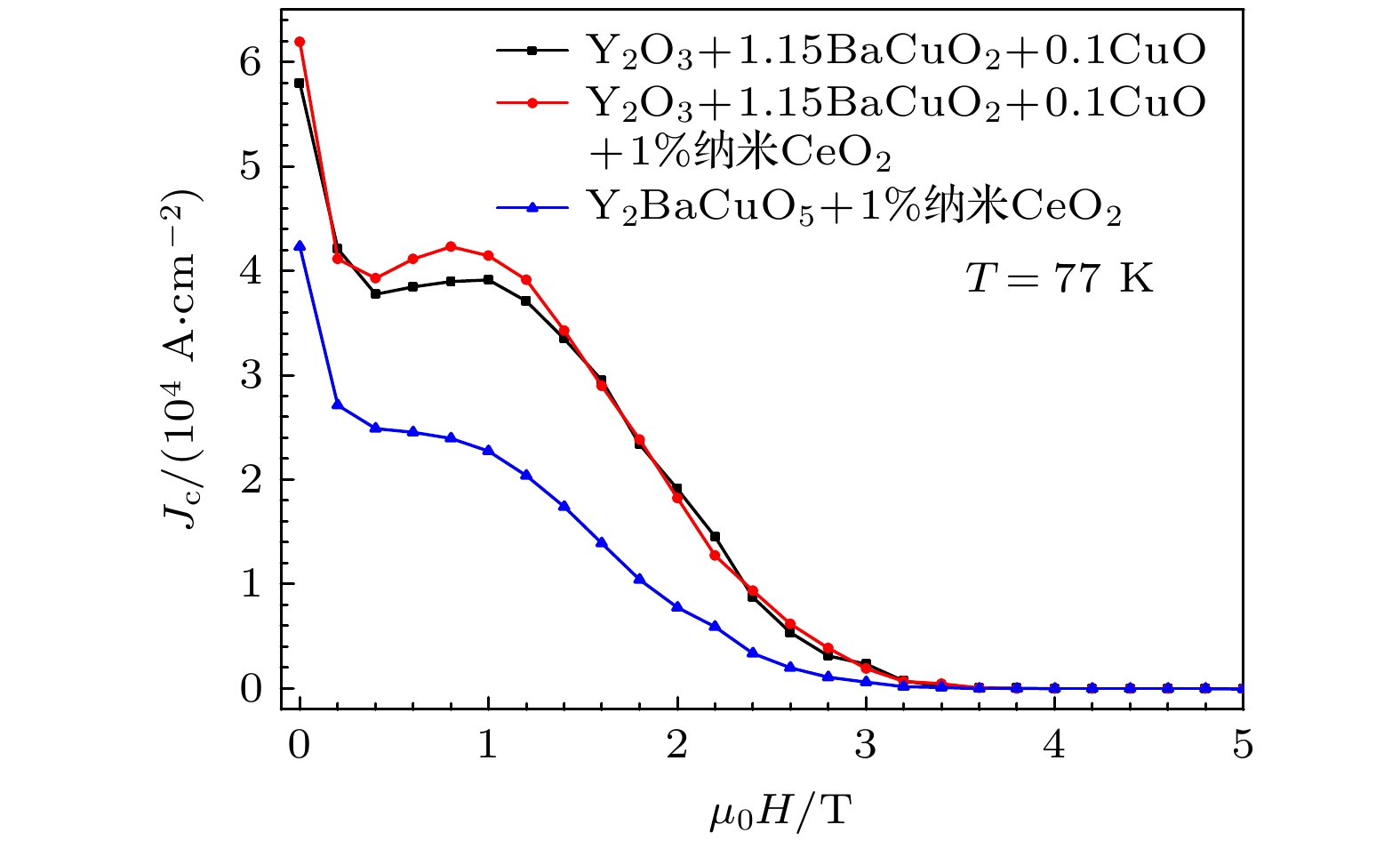

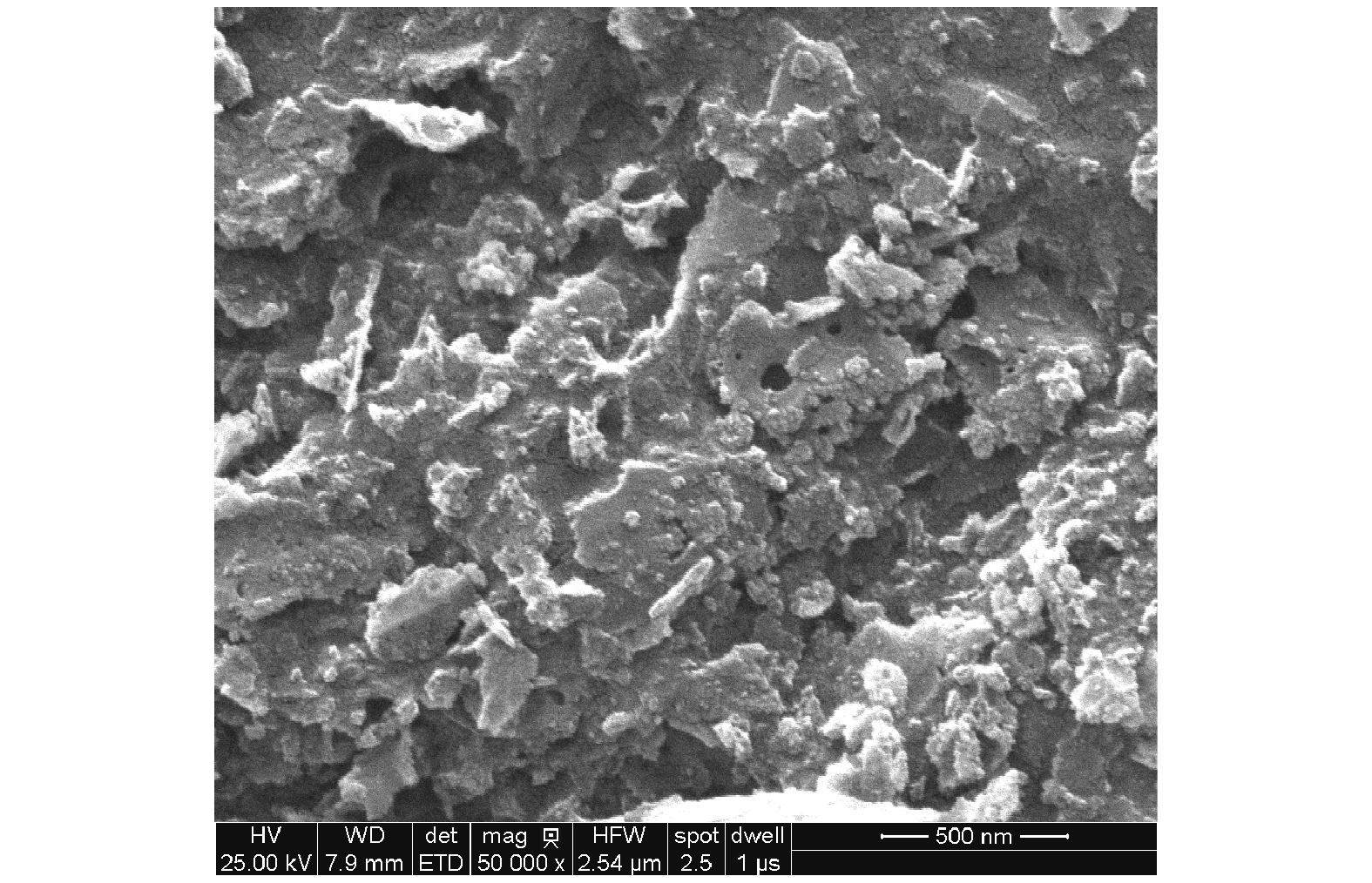

本文采用两种熔渗生长工艺(011-IG和211-IG)制备纳米CeO2掺杂的Y-Ba-Cu-O (YBCO)超导块材, 同时使用一种坑式籽晶模式来阻止薄膜籽晶在热处理过程中的移动, 随后对样品的生长形貌、微观结构和超导性能进行研究. 结果表明, 在低掺杂量(质量分数为1%)下, YBCO晶体的正常生长不会受到影响, 用两种工艺均能成功制备生长完全的单畴YBCO超导块材, 且籽晶的位置没有发生任何移动, 证明了新籽晶模式的有效性. 扫描电子显微镜结果表明, 纳米CeO2掺杂可以有效细化超导块材内Y2BaCuO5(Y-211)微米级粒子的尺寸, 且该方法对两种工艺均有效. 低温磁性测试结果表明, 011-IG法制备的纳米CeO2掺杂的样品在低外场下呈现出比未掺杂样品明显优越的Jc性能, 说明细化的Y-211粒子可以有效地提高δl型钉扎. 此外, 相比211-IG法制备的样品, 011-IG法制备的样品在磁悬浮力、微观形貌和Jc性能等方面表现更优越, 因此011-IG法是一种更有潜力的制备工艺. 本文结果对进一步提高YBCO超导块材的性能和优化制备工艺有重要意义.

-

关键词:

- 单畴Y-Ba-Cu-O /

- 熔渗生长 /

- 纳米CeO2掺杂 /

- 超导性能

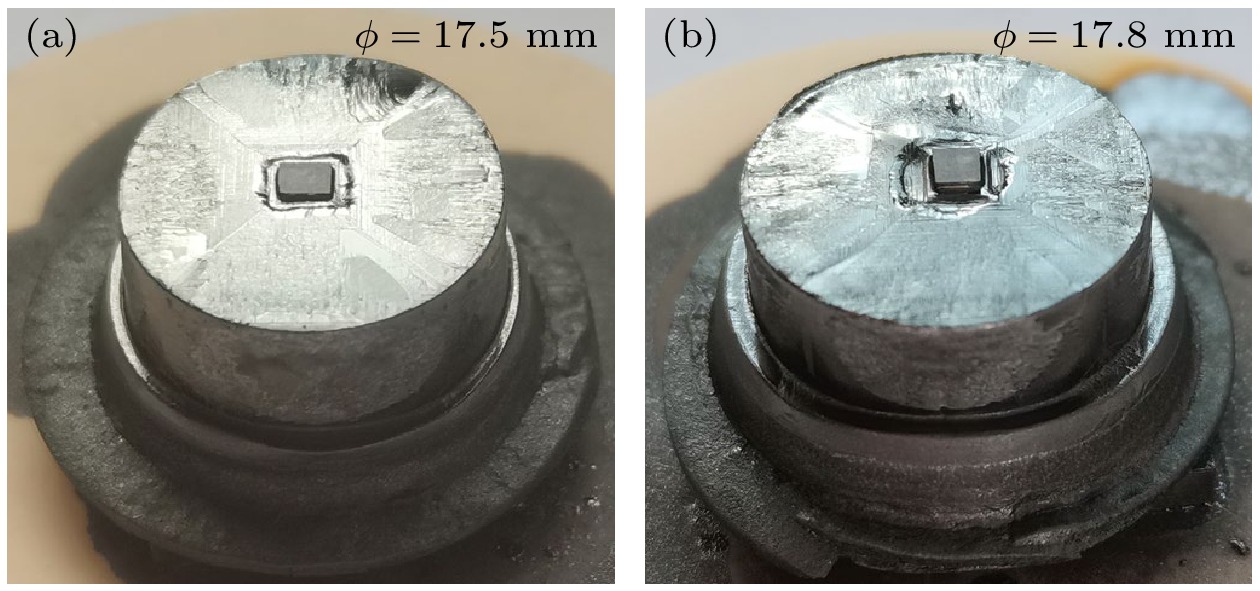

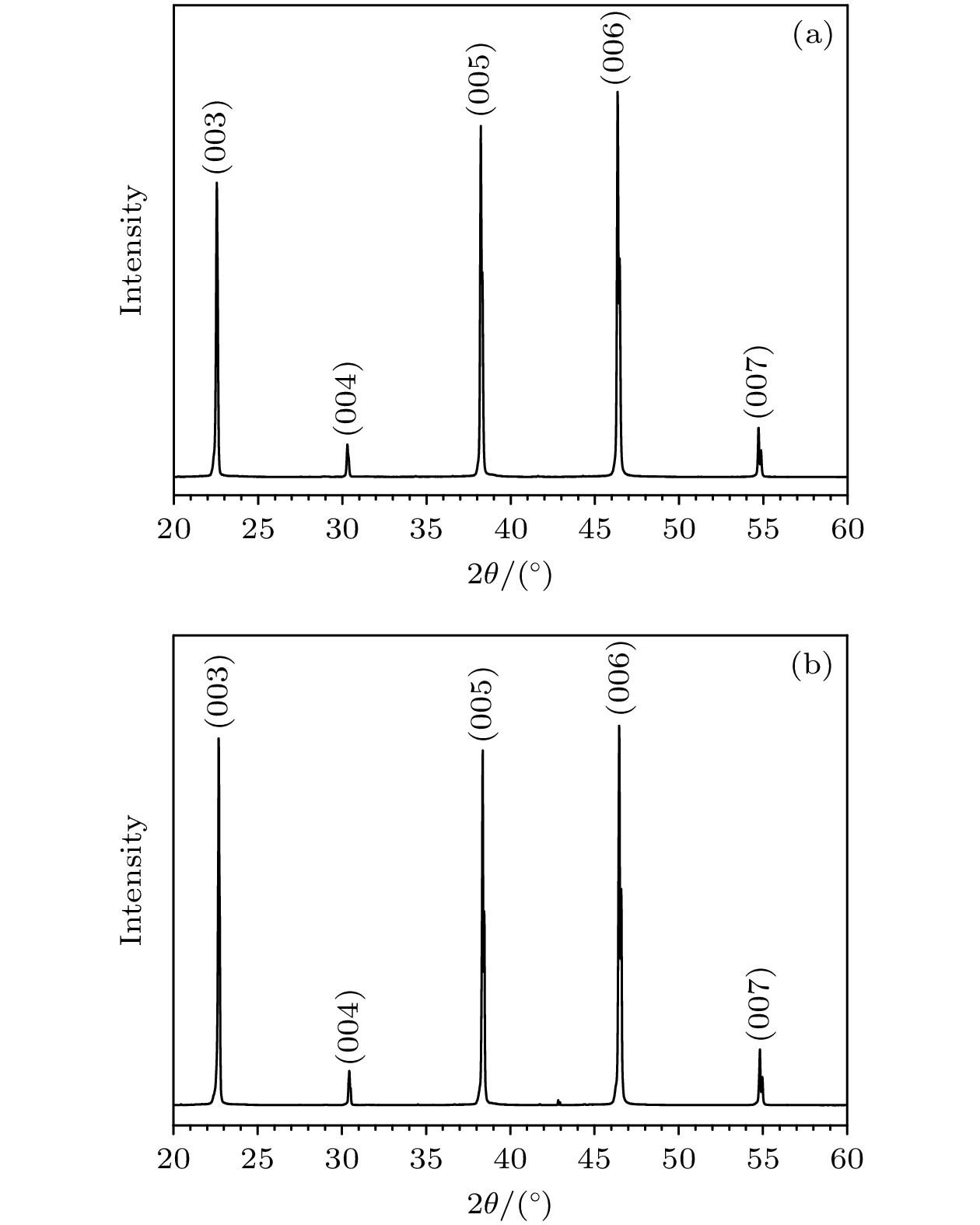

Single-domain Y-Ba-Cu-O (YBCO) bulk superconductors can be widely used in the superconducting maglev, cryomagnets, motors/generators fields. In order to improve the performance of the YBCO bulk superconductors further, in this work, nano-CeO2 doped YBCO bulk superconductors are fabricated by two infiltration growth techniques (011-IG and 211-IG) respectively, in which two solid pellets of compositions Y2O3+1.15BaCuO2+0.1CuO+1wt.% nano-CeO2 and Y2BaCuO5 (Y-211)+1 wt.% nano-CeO2 are employed. And a novel pit-type seeding mode is used to prevent the film seed from moving in the heat treatment process, then the growth morphologies, microstructures and superconducting properties of the samples are investigated. The results show that at a low doping level (1 wt.%), the normal growth of the YBCO crystal is not affected, and fully-grown single-domain YBCO bulk superconductors can be successfully prepared by the two techniques. Furthermore, the positions of the seeds do not move at all, which proves the effectiveness of the new seeding mode. The perpendicular growth sector boundaries on the top surfaces of the samples and clear (00l) series X-ray diffraction (XRD) peaks both prove the high c-axis orientations and high growth quality of the samples. The scanning electron microscopy (SEM) results indicate that the nano-CeO2 doping can effectively refine the sizes of the Y-211 micro-particles in the bulk superconductors, and this method is applicable to both techniques. Low-temperature magnetization measurement shows that the nano-CeO2 doped sample prepared by the 011-IG method shows obviously better Jc property than the undoped sample at low fields, indicating that the refined Y-211 particles can effectively enhance the δl-type pinning. In addition, compared with the 211-IG-processed sample, the 011-IG-processed sample performs better in terms of levitation force, microstructure and Jc property, thus the 011-IG method is a more promising preparation process. The results of this study are important in improving the performance of the YBCO bulk superconductors and optimizing the fabrication technique further.-

Keywords:

- single-domain Y-Ba-Cu-O /

- infiltration growth /

- nano-CeO2 doping /

- superconducting property

[1] Durrell J H, Ainslie M D, Zhou D, Vanderbemden P, Bradshaw T, Speller S, Filipenko M, Cardwell D A 2018 Supercond. Sci. Technol. 31 103501

Google Scholar

Google Scholar

[2] Kenfaui D, Sibeud P F, Louradour E, Chaud X, Noudem J G 2014 Adv. Funct. Mater. 24 3996

Google Scholar

Google Scholar

[3] 马俊, 杨万民, 王妙, 陈森林, 冯忠岭 2013 62 227401

Google Scholar

Google Scholar

Ma J, Yang W M, Wang M, Chen S L, Feng Z L 2013 Acta Phys. Sin. 62 227401

Google Scholar

Google Scholar

[4] 马俊, 陈章龙, 县涛, 魏学刚, 杨万民, 陈森林, 李佳伟 2018 67 077401

Google Scholar

Google Scholar

Ma J, Chen Z L, Xian T, Wei X G, Yang W M, Chen S L, Li J W 2018 Acta Phys. Sin. 67 077401

Google Scholar

Google Scholar

[5] 李国政, 杨万民 2010 59 5028

Google Scholar

Google Scholar

Li G Z, Yang W M 2010 Acta Phys. Sin. 59 5028

Google Scholar

Google Scholar

[6] Yang W M, Zhi X, Chen S L, Wang M, Li J W, Ma J, Chao X X 2014 Physica C 496 1

Google Scholar

Google Scholar

[7] Yang P T, Yang W M, Chen J L 2017 Supercond. Sci. Technol. 30 085003

Google Scholar

Google Scholar

[8] Yang P, Fagnard J F, Vanderbemden P, Yang W 2019 Supercond. Sci. Technol. 32 115015

Google Scholar

Google Scholar

[9] Wang M, Liu Y, Wang X, Xian H, Yang W 2021 Crystals 11 150

Google Scholar

Google Scholar

[10] Wang M, Yang W M, Li J W, Feng Z L, Yang P T 2015 Supercond. Sci. Technol. 28 035004

Google Scholar

Google Scholar

[11] Yang P, Yang W, Zhang L, Chen L 2018 Supercond. Sci. Technol. 31 085005

Google Scholar

Google Scholar

[12] 李国政, 陈超 2020 69 237402

Google Scholar

Google Scholar

Li G Z, Chen C 2020 Acta Phys. Sin. 69 237402

Google Scholar

Google Scholar

[13] Li G Z, Wang M 2021 J. Cryst. Growth 570 126198

Google Scholar

Google Scholar

[14] Li G Z, Wang M 2022 Supercond. Sci. Technol. 35 015005

Google Scholar

Google Scholar

[15] Li G Z, Wang M 2022 Ceram. Int. 48 25034

Google Scholar

Google Scholar

[16] Chen S Y, Chen I G, Wu M K 2005 Supercond. Sci. Technol. 18 916

Google Scholar

Google Scholar

[17] 王妙, 杨万民, 张晓菊, 唐艳妮, 王高峰 2012 61 196102

Google Scholar

Google Scholar

Wang M, Yang W M, Zhang X J, Tang Y N, Wang G F 2012 Acta Phys. Sin. 61 196102

Google Scholar

Google Scholar

[18] Chen S L, Yang W M, Li J W, Yuan X C, Ma J, Wang M 2014 Physica C 496 39

Google Scholar

Google Scholar

[19] Chen D X, Goldfarb R B 1989 J. Appl. Phys. 66 2489

Google Scholar

Google Scholar

[20] 王妙, 杨万民, 马俊, 唐艳妮, 张晓菊, 王高峰 2012 中国科学: 物理学 力学 天文学 42 346

Google Scholar

Google Scholar

Wang M, Yang W M, Ma J, Tang Y N, Zhang X J, Wang G F 2012 Sci. Sin. Phys. Mech. Astron. 42 346

Google Scholar

Google Scholar

[21] Wang M, Yang W M, Fan J, Li G Z, Zhang X J, Tang Y N, Wang G F 2012 J. Supercond. Novel Magn. 25 867

Google Scholar

Google Scholar

[22] Wang M, Yang W M, Wang M Z, Wang X J 2013 J. Supercond. Novel Magn. 26 3221

Google Scholar

Google Scholar

[23] Li G Z, Wang M 2021 Mater. Today Commun. 29 102771

Google Scholar

Google Scholar

[24] Koblischka M R, Murakami M 2000 Supercond. Sci. Technol. 13 738

Google Scholar

Google Scholar

-

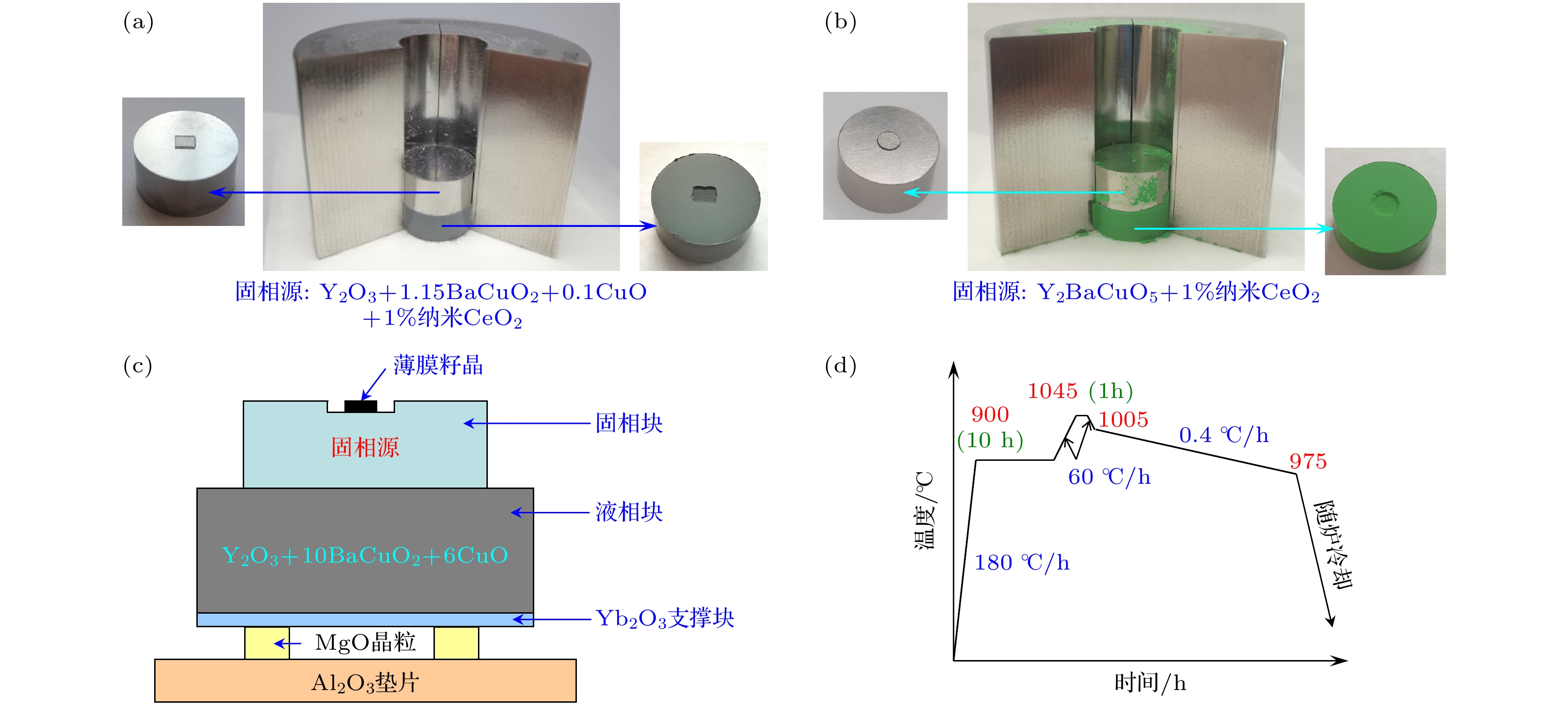

图 2 (a), (b) 带有顶部方坑或圆坑的固相块的压制方法; (c) 前驱块和薄膜籽晶的装配方法示意图; (d) 用于熔渗生长YBCO单畴样品的热处理方式

Fig. 2. (a), (b) Methods for pressing the preforms with the top square pit or round pit; (c) schematic illustration showing the configuration method of the precursor pellets and the film seed; (d) the heat treatment profile used for the IG process of the YBCO single-domain samples.

-

[1] Durrell J H, Ainslie M D, Zhou D, Vanderbemden P, Bradshaw T, Speller S, Filipenko M, Cardwell D A 2018 Supercond. Sci. Technol. 31 103501

Google Scholar

Google Scholar

[2] Kenfaui D, Sibeud P F, Louradour E, Chaud X, Noudem J G 2014 Adv. Funct. Mater. 24 3996

Google Scholar

Google Scholar

[3] 马俊, 杨万民, 王妙, 陈森林, 冯忠岭 2013 62 227401

Google Scholar

Google Scholar

Ma J, Yang W M, Wang M, Chen S L, Feng Z L 2013 Acta Phys. Sin. 62 227401

Google Scholar

Google Scholar

[4] 马俊, 陈章龙, 县涛, 魏学刚, 杨万民, 陈森林, 李佳伟 2018 67 077401

Google Scholar

Google Scholar

Ma J, Chen Z L, Xian T, Wei X G, Yang W M, Chen S L, Li J W 2018 Acta Phys. Sin. 67 077401

Google Scholar

Google Scholar

[5] 李国政, 杨万民 2010 59 5028

Google Scholar

Google Scholar

Li G Z, Yang W M 2010 Acta Phys. Sin. 59 5028

Google Scholar

Google Scholar

[6] Yang W M, Zhi X, Chen S L, Wang M, Li J W, Ma J, Chao X X 2014 Physica C 496 1

Google Scholar

Google Scholar

[7] Yang P T, Yang W M, Chen J L 2017 Supercond. Sci. Technol. 30 085003

Google Scholar

Google Scholar

[8] Yang P, Fagnard J F, Vanderbemden P, Yang W 2019 Supercond. Sci. Technol. 32 115015

Google Scholar

Google Scholar

[9] Wang M, Liu Y, Wang X, Xian H, Yang W 2021 Crystals 11 150

Google Scholar

Google Scholar

[10] Wang M, Yang W M, Li J W, Feng Z L, Yang P T 2015 Supercond. Sci. Technol. 28 035004

Google Scholar

Google Scholar

[11] Yang P, Yang W, Zhang L, Chen L 2018 Supercond. Sci. Technol. 31 085005

Google Scholar

Google Scholar

[12] 李国政, 陈超 2020 69 237402

Google Scholar

Google Scholar

Li G Z, Chen C 2020 Acta Phys. Sin. 69 237402

Google Scholar

Google Scholar

[13] Li G Z, Wang M 2021 J. Cryst. Growth 570 126198

Google Scholar

Google Scholar

[14] Li G Z, Wang M 2022 Supercond. Sci. Technol. 35 015005

Google Scholar

Google Scholar

[15] Li G Z, Wang M 2022 Ceram. Int. 48 25034

Google Scholar

Google Scholar

[16] Chen S Y, Chen I G, Wu M K 2005 Supercond. Sci. Technol. 18 916

Google Scholar

Google Scholar

[17] 王妙, 杨万民, 张晓菊, 唐艳妮, 王高峰 2012 61 196102

Google Scholar

Google Scholar

Wang M, Yang W M, Zhang X J, Tang Y N, Wang G F 2012 Acta Phys. Sin. 61 196102

Google Scholar

Google Scholar

[18] Chen S L, Yang W M, Li J W, Yuan X C, Ma J, Wang M 2014 Physica C 496 39

Google Scholar

Google Scholar

[19] Chen D X, Goldfarb R B 1989 J. Appl. Phys. 66 2489

Google Scholar

Google Scholar

[20] 王妙, 杨万民, 马俊, 唐艳妮, 张晓菊, 王高峰 2012 中国科学: 物理学 力学 天文学 42 346

Google Scholar

Google Scholar

Wang M, Yang W M, Ma J, Tang Y N, Zhang X J, Wang G F 2012 Sci. Sin. Phys. Mech. Astron. 42 346

Google Scholar

Google Scholar

[21] Wang M, Yang W M, Fan J, Li G Z, Zhang X J, Tang Y N, Wang G F 2012 J. Supercond. Novel Magn. 25 867

Google Scholar

Google Scholar

[22] Wang M, Yang W M, Wang M Z, Wang X J 2013 J. Supercond. Novel Magn. 26 3221

Google Scholar

Google Scholar

[23] Li G Z, Wang M 2021 Mater. Today Commun. 29 102771

Google Scholar

Google Scholar

[24] Koblischka M R, Murakami M 2000 Supercond. Sci. Technol. 13 738

Google Scholar

Google Scholar

计量

- 文章访问数: 2627

- PDF下载量: 55

- 被引次数: 0

下载:

下载: