-

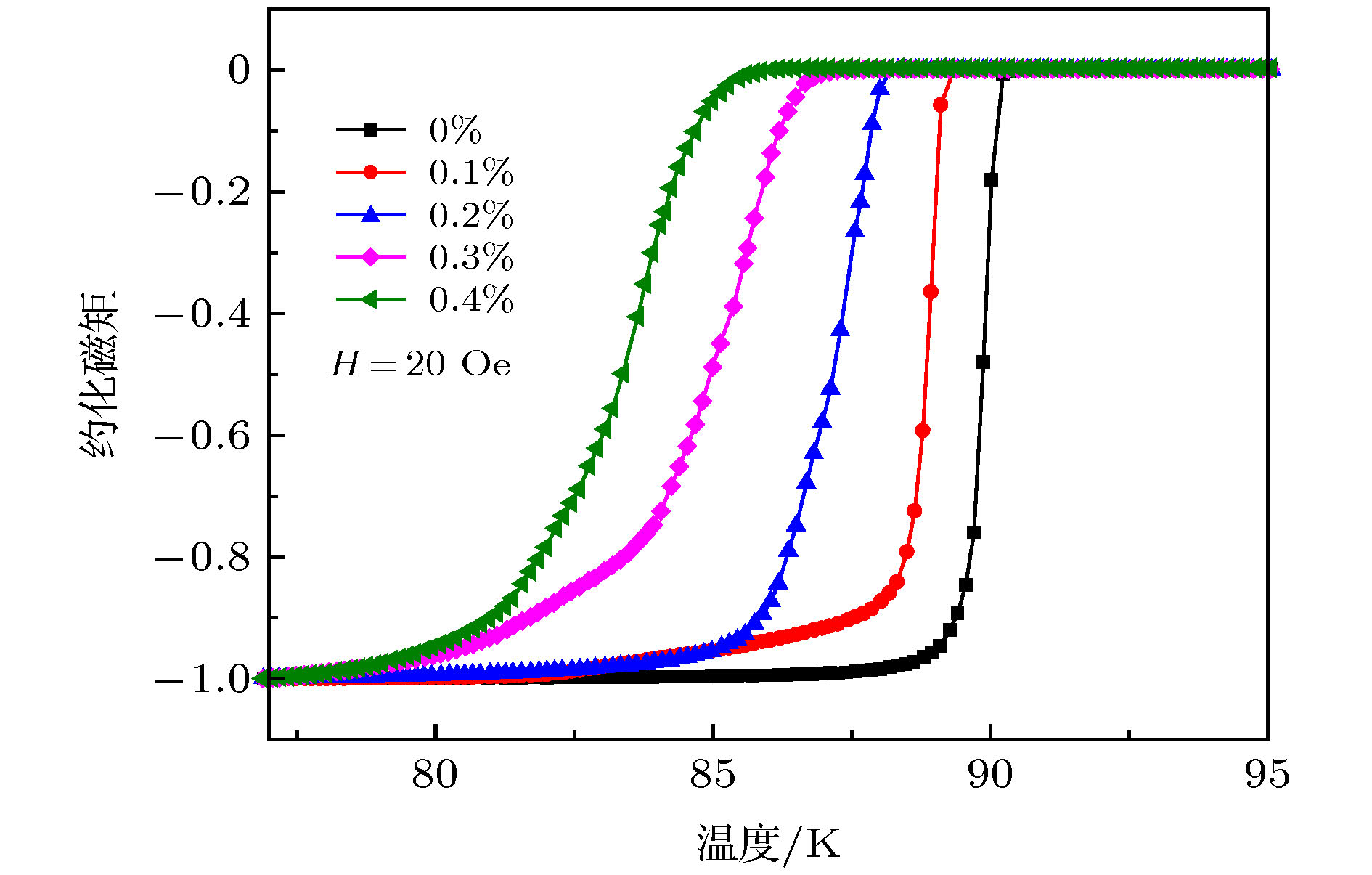

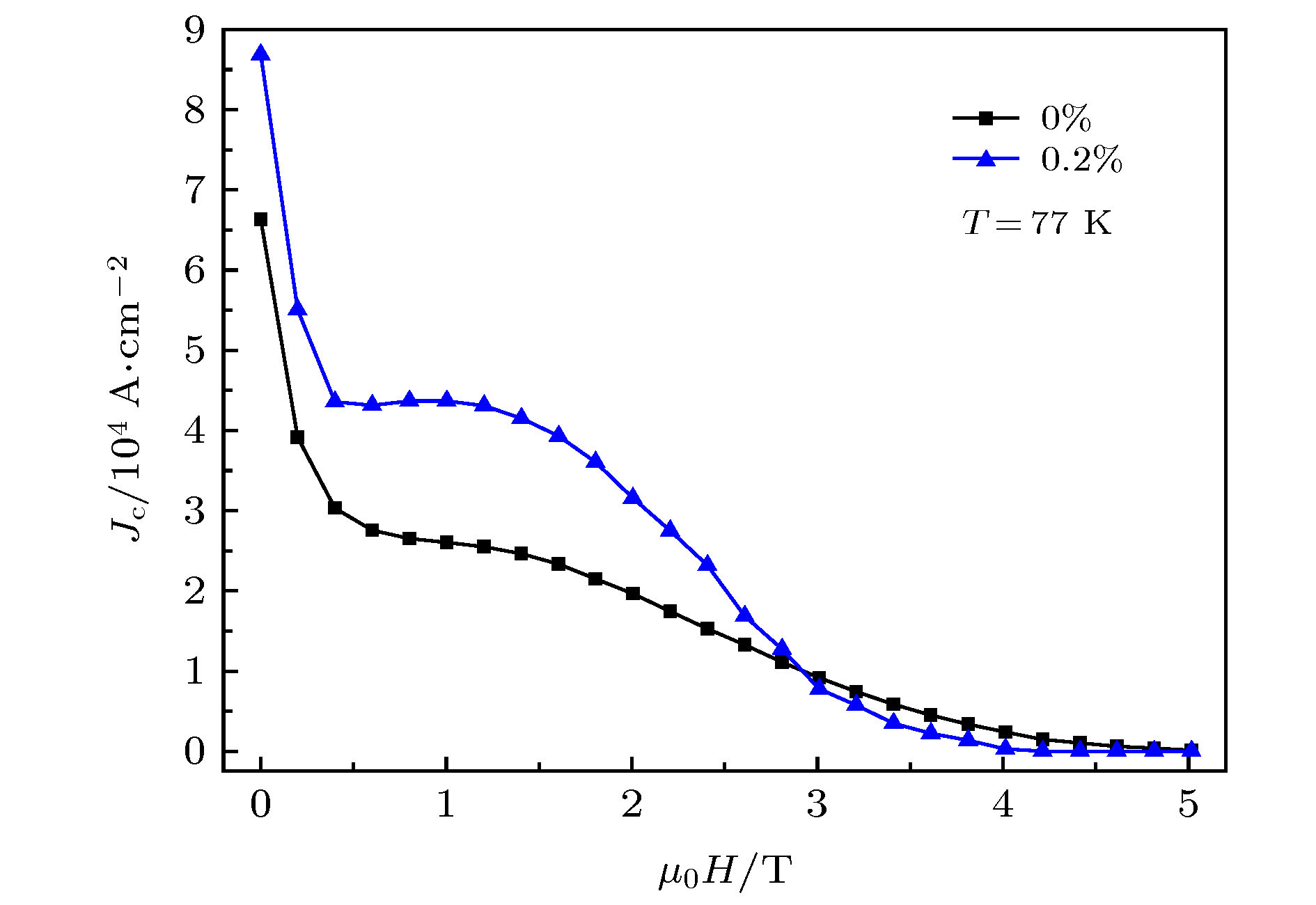

采用一种新型的顶部籽晶熔渗生长(TSIG)工艺制备了铁酸镍(NiFe2O4, NFO)纳米粒子掺杂的YBCO超导块材, 并对其生长形貌、微观结构、超导性能进行了研究. 结果表明, 在低掺杂量下, YBCO单畴体的正常生长不会受NFO掺杂的影响, 但是在高掺杂水平下样品边缘开始出现明显的随机成核. 磁悬浮力性能测试结果表明, 随着NFO掺杂量的增加, 样品的最大磁悬浮力先增大后减小, 掺杂重量百分比为0.2%的样品表现出最大的磁悬浮力(33.93 N). 低温磁性测试结果表明, 随着NFO掺杂量的增加, 样品的Tc值逐渐降低, 而且超导转变宽度(ΔTc)也逐渐变宽. 最佳掺杂下(重量百分比为0.2%)样品的零场Jc值为8.68 × 104 A/cm2, 比未掺杂样品提高了31%. 电子探针微区分析(EPMA)结果表明, YBCO体系中掺杂的纳米NFO在热处理过程中发生了分解, 而溶解出的Ni和Fe离子最终以元素替代的方式存在于YBCO块材内, 这可以在超导基体中引入晶格畸变和弱超导区作为有效的磁通钉扎中心, 从而提高样品的超导性能.

-

关键词:

- 单畴YBCO /

- 顶部籽晶熔渗生长 /

- NiFe2O4纳米粒子掺杂 /

- 超导性能

NiFe2O4 (NFO) nanoparticle doped YBCO bulk superconductors are fabricated by using a novel top-seed infiltration growth (TSIG) technique. The growth morphology, microstructure and superconducting properties are investigated. The results show that at low doping levels, the normal growth of YBCO single domain is not affected by the NFO doping, but at high doping levels, obvious random nucleation appears at the edge of the sample. The measurement of levitation force indicates that the maximum levitation force on the sample first increases and then decreases with the increase of the NFO doping amount, and the largest levitation force is obtained to be 33.93 N for the sample with a doping level of 0.2% (weight percent). Low-temperature magnetization measurement shows that the YBCO sample exhibits that Tc value decreases with NFO amount increasing, and the superconducting transition width (ΔTc) also broadens gradually. The sample with the optimal doping (0.2% weight percent) presents an enhanced zero-field Jc value of 8.68 × 104 A/cm2, which is 31% higher than the sample without dopant. In addition, a more obvious secondary peak of 4.37 × 104 A/cm2 at a field of 1 T is observed for the 0.2 wt.% NFO doped sample, which indicates the existence of enhancedδTc pinning in the bulk. The SEM measurement shows that two types of particles are trapped in the Y-123 matrix for YBCO sample doped with 0.2% weight percent NFO: one is the large particle with a size mainly ranging from 0.5 μm to 2.0 μm, and the other is small nano-inclusion mainly ranging from dozens of nanometers to about several hundreds of nanometers. Such a microstructure is very similar to the microstructure of the undoped sample we reported earlier. So whether the NFO nanoparticles exist in the microstructure cannot be judged just from the morphology of the nano-inclusions. The electron probe microarea analysis (EPMA) result shows that different concentration distributions of Ni and Fe elements are observed in the sample doped with 0.2% weight percent NFO, which indicates the separation of NFO nanoparticles in the heat treatment process, and the dissolved Ni and Fe ions finally exist in the form of element substitutions in the YBCO bulk. Such element substitutions can introduce local lattice distortions and weak-superconducting regions into the superconducting matrix, which can act as effective flux pinning centers, and hence improving the properties of the samples. -

Keywords:

- single-domain YBCO /

- top-seeded infiltration growth /

- NiFe2O4 nanoparticle doping /

- superconducting property

[1] Tomita M, Murakami M 2003 Nature 421 517

Google Scholar

Google Scholar

[2] Yang W M, Li G Z, Ma J, Chao X X, Li J W 2010 IEEE Trans. Appl. Supercond. 20 2317

Google Scholar

Google Scholar

[3] Kenfaui D, Sibeud P F, Louradour E, Chaud X, Noudem J G 2014 Adv. Funct. Mater. 24 3996

Google Scholar

Google Scholar

[4] Namburi D K, Durrell J H, Jaroszynski J, Shi Y, Ainslie M, Huang K, Dennis, A R, Hellstrom E E, Cardwell D A 2018 Supercond. Sci. Technol. 31 125004

Google Scholar

Google Scholar

[5] 王妙, 杨万民, 张晓菊, 唐艳妮, 王高峰 2012 61 196102

Google Scholar

Google Scholar

Wang M, Yang W M, Zhang X J, Tang Y N, Wang G F 2012 Acta Phys. Sin. 61 196102

Google Scholar

Google Scholar

[6] 王妙, 杨万民, 杨芃焘, 王小梅, 张明, 胡成西 2016 65 227401

Google Scholar

Google Scholar

Wang M, Yang W M, Yang P T, Wang X M, Zhang M, Hu C X 2016 Acta Phys. Sin. 65 227401

Google Scholar

Google Scholar

[7] Delamare, M P, Monot I, Wang J, Provost J, Desgardin G 1996 Supercond. Sci. Technol. 9 534

Google Scholar

Google Scholar

[8] 王妙, 杨万民, 马俊, 唐艳妮, 张晓菊, 王高峰 2012 中国科学: 物理学 力学 天文学 42 346

Google Scholar

Google Scholar

Wang M, Yang W M, Ma J, Tang Y N, Zhang X J, Wang G F 2012 Sci. Sin.Phys. Mech. Astron. 42 346

Google Scholar

Google Scholar

[9] Chen S Y, Chen I G, Wu M K 2005 Supercond. Sci. Technol. 18 916

Google Scholar

Google Scholar

[10] Tsuzuki K, Hara S, Xu Y, Morita M, Teshima H, Yanagisawa O, Noudem J, Harnois C, Izumi M 2011 IEEE Trans. Appl. Supercond. 21 2714

Google Scholar

Google Scholar

[11] Hara S, Zhou D, Li B, Izumi M 2013 IEEE Trans. Appl. Supercond. 23 7200804

Google Scholar

Google Scholar

[12] 郭莉萍, 杨万民, 郭玉霞, 陈丽平, 李强 2015 64 077401

Google Scholar

Google Scholar

Guo L P, Yang W M, Guo Y X, Chen L P, Li Q 2015 Acta Phys. Sin. 64 077401

Google Scholar

Google Scholar

[13] 张晓娟, 张玉凤, 彭里其, 周文礼, 徐燕, 周迪帆, 和泉充 2015 64 247401

Google Scholar

Google Scholar

Zhang X J, Zhang Y F, Peng L Q, Zhou W L, Xu Y, Zhou D F, Izumi M 2015 Acta Phys. Sin. 64 247401

Google Scholar

Google Scholar

[14] Li G Z, Dong L, Deng X Y 2016 J. Am. Ceram. Soc. 99 388

Google Scholar

Google Scholar

[15] Li G Z, Dong L, Deng X Y 2015 J. Am. Ceram. Soc. 98 2707

Google Scholar

Google Scholar

[16] 李国政, 杨万民 2011 60 037401

Google Scholar

Google Scholar

Li G Z, Yang W M 2011 Acta Phys. Sin. 60 037401

Google Scholar

Google Scholar

[17] Chen S L, Yang W M, Li J W, Yuan X C, Ma J, Wang M 2014 Physica C 496 39

Google Scholar

Google Scholar

[18] Shang M, Feng Q, Jiao Y L, Xiao L, Zheng M H, Yan Q Z, Ge C C 2010 Physica C 470 491

Google Scholar

Google Scholar

[19] Chen Z, Xue R, Li T, Dai H, Zhang Z 2013 J Alloy. Compd. 553 53

Google Scholar

Google Scholar

[20] Zhou Y X, Scruggs S, Salama K 2006 Supercond. Sci. Technol. 19 S556

Google Scholar

Google Scholar

[21] Huhtinen H, Awana V P S, Gupta A, Kishan H, Laiho R, Narlikar A V 2007 Supercond. Sci. Technol. 20 S159

Google Scholar

Google Scholar

[22] Chen D X, Goldfarb R B 1989 J. Appl. Phys. 66 2489

Google Scholar

Google Scholar

-

-

[1] Tomita M, Murakami M 2003 Nature 421 517

Google Scholar

Google Scholar

[2] Yang W M, Li G Z, Ma J, Chao X X, Li J W 2010 IEEE Trans. Appl. Supercond. 20 2317

Google Scholar

Google Scholar

[3] Kenfaui D, Sibeud P F, Louradour E, Chaud X, Noudem J G 2014 Adv. Funct. Mater. 24 3996

Google Scholar

Google Scholar

[4] Namburi D K, Durrell J H, Jaroszynski J, Shi Y, Ainslie M, Huang K, Dennis, A R, Hellstrom E E, Cardwell D A 2018 Supercond. Sci. Technol. 31 125004

Google Scholar

Google Scholar

[5] 王妙, 杨万民, 张晓菊, 唐艳妮, 王高峰 2012 61 196102

Google Scholar

Google Scholar

Wang M, Yang W M, Zhang X J, Tang Y N, Wang G F 2012 Acta Phys. Sin. 61 196102

Google Scholar

Google Scholar

[6] 王妙, 杨万民, 杨芃焘, 王小梅, 张明, 胡成西 2016 65 227401

Google Scholar

Google Scholar

Wang M, Yang W M, Yang P T, Wang X M, Zhang M, Hu C X 2016 Acta Phys. Sin. 65 227401

Google Scholar

Google Scholar

[7] Delamare, M P, Monot I, Wang J, Provost J, Desgardin G 1996 Supercond. Sci. Technol. 9 534

Google Scholar

Google Scholar

[8] 王妙, 杨万民, 马俊, 唐艳妮, 张晓菊, 王高峰 2012 中国科学: 物理学 力学 天文学 42 346

Google Scholar

Google Scholar

Wang M, Yang W M, Ma J, Tang Y N, Zhang X J, Wang G F 2012 Sci. Sin.Phys. Mech. Astron. 42 346

Google Scholar

Google Scholar

[9] Chen S Y, Chen I G, Wu M K 2005 Supercond. Sci. Technol. 18 916

Google Scholar

Google Scholar

[10] Tsuzuki K, Hara S, Xu Y, Morita M, Teshima H, Yanagisawa O, Noudem J, Harnois C, Izumi M 2011 IEEE Trans. Appl. Supercond. 21 2714

Google Scholar

Google Scholar

[11] Hara S, Zhou D, Li B, Izumi M 2013 IEEE Trans. Appl. Supercond. 23 7200804

Google Scholar

Google Scholar

[12] 郭莉萍, 杨万民, 郭玉霞, 陈丽平, 李强 2015 64 077401

Google Scholar

Google Scholar

Guo L P, Yang W M, Guo Y X, Chen L P, Li Q 2015 Acta Phys. Sin. 64 077401

Google Scholar

Google Scholar

[13] 张晓娟, 张玉凤, 彭里其, 周文礼, 徐燕, 周迪帆, 和泉充 2015 64 247401

Google Scholar

Google Scholar

Zhang X J, Zhang Y F, Peng L Q, Zhou W L, Xu Y, Zhou D F, Izumi M 2015 Acta Phys. Sin. 64 247401

Google Scholar

Google Scholar

[14] Li G Z, Dong L, Deng X Y 2016 J. Am. Ceram. Soc. 99 388

Google Scholar

Google Scholar

[15] Li G Z, Dong L, Deng X Y 2015 J. Am. Ceram. Soc. 98 2707

Google Scholar

Google Scholar

[16] 李国政, 杨万民 2011 60 037401

Google Scholar

Google Scholar

Li G Z, Yang W M 2011 Acta Phys. Sin. 60 037401

Google Scholar

Google Scholar

[17] Chen S L, Yang W M, Li J W, Yuan X C, Ma J, Wang M 2014 Physica C 496 39

Google Scholar

Google Scholar

[18] Shang M, Feng Q, Jiao Y L, Xiao L, Zheng M H, Yan Q Z, Ge C C 2010 Physica C 470 491

Google Scholar

Google Scholar

[19] Chen Z, Xue R, Li T, Dai H, Zhang Z 2013 J Alloy. Compd. 553 53

Google Scholar

Google Scholar

[20] Zhou Y X, Scruggs S, Salama K 2006 Supercond. Sci. Technol. 19 S556

Google Scholar

Google Scholar

[21] Huhtinen H, Awana V P S, Gupta A, Kishan H, Laiho R, Narlikar A V 2007 Supercond. Sci. Technol. 20 S159

Google Scholar

Google Scholar

[22] Chen D X, Goldfarb R B 1989 J. Appl. Phys. 66 2489

Google Scholar

Google Scholar

计量

- 文章访问数: 7020

- PDF下载量: 73

- 被引次数: 0

下载:

下载: