-

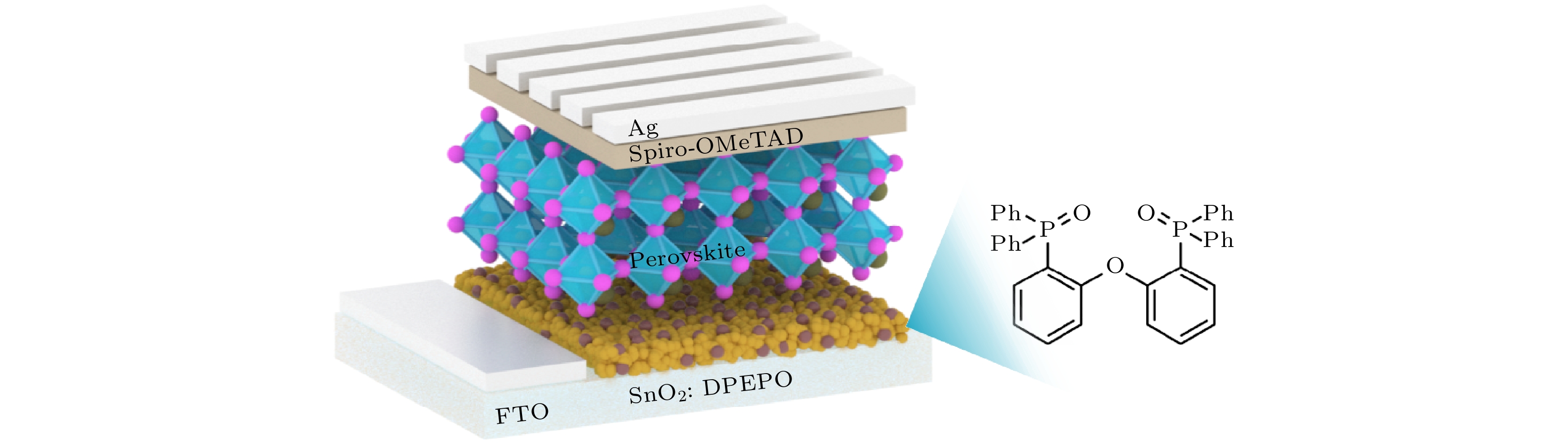

电子传输层是钙钛矿太阳能电池的重要功能层, 其表面及内部缺陷是限制钙钛矿太阳能电池性能提升的重要一环. 双电子传输层(双ETL)策略虽然可以改善电子在功能层之间提取与传输, 但是双ETL内部存在的独立界面以及不同ETL材料晶胞不匹配问题导致了额外的非辐射复合. 基于此, 本文提出了将二[2-((氧代)二苯基膦基)苯基]醚(DPEPO)引入到SnO2中设计混合电子传输层的策略, 该策略在钝化SnO2中本征缺陷的同时, 可以避免由于额外界面的存在而导致的缺陷态, 有效改善了电子的提取与传输. 并且进一步实现了对钙钛矿薄膜的结晶调控, 提升钙钛矿太阳能电池性能, 最终收获了基于宽带隙钙钛矿太阳能电池21.53%的功率转换率, 其中开路电压(VOC)达到了1.220 V, 短路电流(JSC)为23.19 mA/cm2, 填充因子(FF)高达76.11%. 研究表明混合电子传输层策略可以有效优化载流子传输动力学, 促进钙钛矿高质量结晶, 对制备高性能太阳能电池具有一定指导意义.The electron transport layer is an important functional layer of perovskite solar cells, and its surface and internal defects are critical parts of limiting the performance improvement of perovskite solar cells. The double electron transport layer (double ETL) strategy can effectively passivate inherent defects in the electron transport layer (such as SnO2) and improve electron extraction and transport between the functional layers, providing an effective way for developing efficient and stable PSCs. However, due to the existence of independent interfaces in the dual ETL, the cell mismatch in different ETL materials also leads to additional carrier defects, hindering the continuous advancement of the dual ETL strategy. This work proposes a strategy for introducing di[2-((oxo)diphenylphosphino)phenyl]ether (DPEPO) into SnO2 ETL to design a hybrid electron transport layer strategy. Using the hole-blocking effect of DPEPO, which has a higher HOMO energy level and good ability to transfer electrons, the intrinsic defects in SnO2 are successfully passivated, while significantly improving the crystalline quality of the SnO2 film surface. So, avoiding the direct contact between the perovskite photoactive layer and the conductive substrate can effectively improve the extraction and transport of electrons. Due to the preparation of high-quality electron transport layer, the crystallization regulation of perovskite thin film is further achieved, thereby improving the performance of perovskite solar cells. Finally, 21.53% of the power conversion rate is obtained, the open-circuit voltage (VOC) reaches 1.220 V, the short-circuit current (JSC) is 23.19 mA/cm2, and the fill factor (FF) is 76.11%. This efficiency is 1.39% higher than that of the control one. It is shown that the hybrid electron transport layer strategy can not only optimize the carrier transport dynamics efficiently and reduce the device performance affected by the defects in the functional layer significantly, but also regulate the perovskite crystallization, which has the prospect for preparing high-performance solar cells.

-

Keywords:

- perovskite /

- solar cell /

- electron transport layer /

- carrier composite /

- defect passivation

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc 131 6050

Google Scholar

Google Scholar

[2] Liang Z, Zhang Y, Xu H F, Chen W J, Liu B Y, Zhang J Y, Zhang H, Wang Z H, Kang D H, Zeng J R, Gao X Y, Wang Q S, Hu H J, Zhou H M, Cai X B, Tian X Y, Reiss P, Xu B M, Kirchartz T, Xiao Z G, Dai S Y, Park N G, Ye J J, Pan X 2023 Nature 624 557

Google Scholar

Google Scholar

[3] Deng K M, Chen Q H, Li L 2020 Adv. Funct. Mater. 30 2004209

Google Scholar

Google Scholar

[4] Lv J C, Li H X, Chen H Y, Ke L L, Du W J, Xiong J, Zhou C H, Liu G 2023 Appl. Phys. Lett. 122 233501

Google Scholar

Google Scholar

[5] Dahal B, Guo R, Pathak R, Rezaee M D, Elam J W, Mane A U, Li W J 2023 J. Phys. Chem. Solids 181 111532

Google Scholar

Google Scholar

[6] Bai C, Dong W, Cai H Y, Zu C P, Yue W, Li H X, Zhao J, Huang F Z, Cheng Y B, Zhong J 2023 Adv. Energy Mater. 13 2300491

Google Scholar

Google Scholar

[7] Khan U, Iqbal T, Khan M, Wu R 2021 Sol. Energy 223 346

Google Scholar

Google Scholar

[8] Gan Y J, Qiu G X, Qin B Y, Bi X G, Liu Y C, Nie G C, Ning W L, Yang R Z 2023 Nanomaterials 13 1313

Google Scholar

Google Scholar

[9] Zhang Y H, Xu L, Sun J, Wu Y J, Kan Z T, Zhang H, Yang L, Liu B, Dong B, Bai X, Song H W 2022 Adv. Energy Mater. 12 2201269

Google Scholar

Google Scholar

[10] Zhou Y, Ren X G, Yan Y Q, Ren H, Du H M, Cai X Y, Huang Z X 2022 Acta Phys. Sin. 71 208802 [周玚, 任信钢, 闫业强, 任昊, 杜红梅, 蔡雪原, 黄志祥 2022 71 208802]

Google Scholar

Google Scholar

Zhou Y, Ren X G, Yan Y Q, Ren H, Du H M, Cai X Y, Huang Z X 2022 Acta Phys. Sin. 71 208802

Google Scholar

Google Scholar

[11] Jang H J, Lee J Y 2019 J. Phys. Chem. C 123 26856

Google Scholar

Google Scholar

[12] Zhang J, Ding D X, Wei Y, Xu H 2016 Chem. Sci. 7 2870

Google Scholar

Google Scholar

[13] Fan W L, Shen Y, Deng K M, Chen Q H, Bai Y, Li L 2022 Nano Energy 100 107518

Google Scholar

Google Scholar

[14] Zhao L C, Tang P Y, Luo D Y, Dar M I, Eickemeyer F T, Arora N, Hu Q, Luo J S, Liu Y H, Zakeeruddin S M, Hagfeldt A, Arbiol J, Huang W, Gong Q H, Russell T P, Friend R H, Grätzel M, Zhu R 2022 Sci. Adv. 8 eabo3733

Google Scholar

Google Scholar

[15] Hu P, Zhou W B, Chen J L, Xie X, Zhu J W, Zheng Y X, Li Y F, Li J M, Wei M D 2024 Chem. Eng. J. 480 148249

Google Scholar

Google Scholar

[16] Wu J, Li M H, Fan J T, Li Z, Fan X H, Xue D J, Hu J S 2023 J. Am. Chem. Soc. 145 5872

Google Scholar

Google Scholar

[17] Li X D, Zhang W X, Guo X M, Lu C Y, Wei J Y, Fang J F 2022 Science 375 434

Google Scholar

Google Scholar

[18] Khan M T, Hemasiri N H, Kazim S, Ahmad S 2021 Sustain. Energ. Fuels 5 6352

Google Scholar

Google Scholar

[19] Cha J, Kim M K, Lee W, Jin H, Na H, Cung Tien Nguyen D, Lee S, Lim J, Kim M 2023 Chem. Eng. J. 451 138920

Google Scholar

Google Scholar

[20] Tan H R, Che F L, Wei M Y, Zhao Y C, Saidaminov M I, Todorović P, Broberg D, Walters G, Tan F R, Zhuang T T, Sun B, Liang Z Q, Yuan H F, Fron E, Kim J, Yang Z Y, Voznyy O, Asta M, Sargent E H 2018 Nat. Commun. 9 3100

Google Scholar

Google Scholar

-

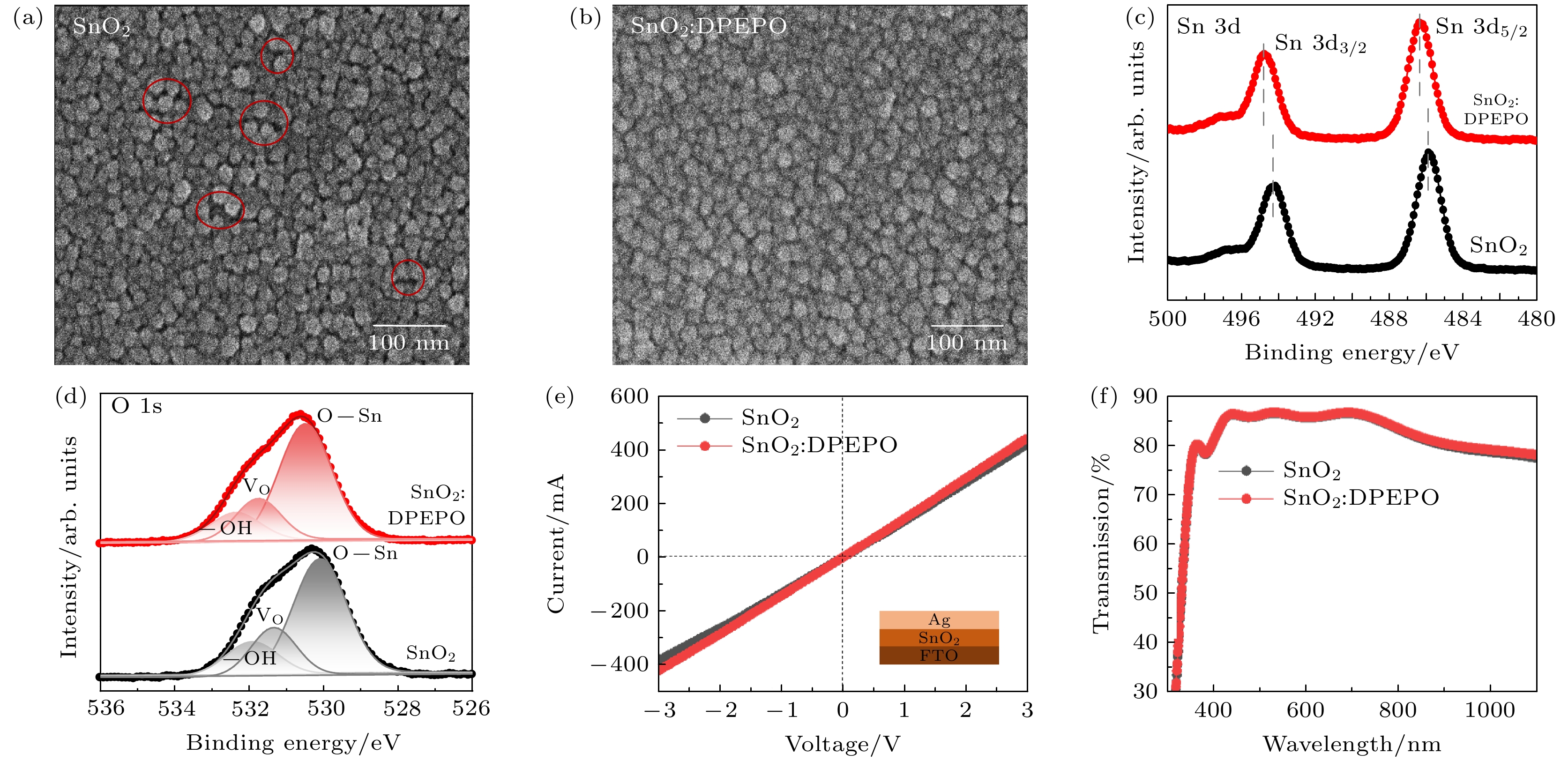

图 2 (a)基于SnO2 ETL的SEM图像; (b)基于SnO2:DPEPO ETL的SEM图像; (c)经过以及未经过DPEPO处理的SnO2 ETL薄膜的XPS光谱, Sn-3d信号; (d)经过以及未经过DPEPO处理的SnO2 ETL薄膜的XPS光谱, O-1s信号; (e) SnO2和SnO2:DPEPO作为ETL的器件的电导率数据; (f) SnO2和SnO2:DPEPO ETL薄膜的紫外-可见光透过光谱

Fig. 2. (a) SEM image of SnO2 electron transport layer; (b) SEM image of SnO2:DPEPO electron transport layer; (c) XPS spectra of SnO2 ETL films with and without DPEPO treatment, Sn-3d signal; (d) XPS spectra of SnO2 ETL films with and without DPEPO treatment, O-1s signal; (e) conductivity data for devices with SnO2 and SnO2:DPEPO as ETLS; (f) the ultraviolet-visible (UV-Vis) transmittance spectra of SnO2 and SnO2:DPEPO as ETLS.

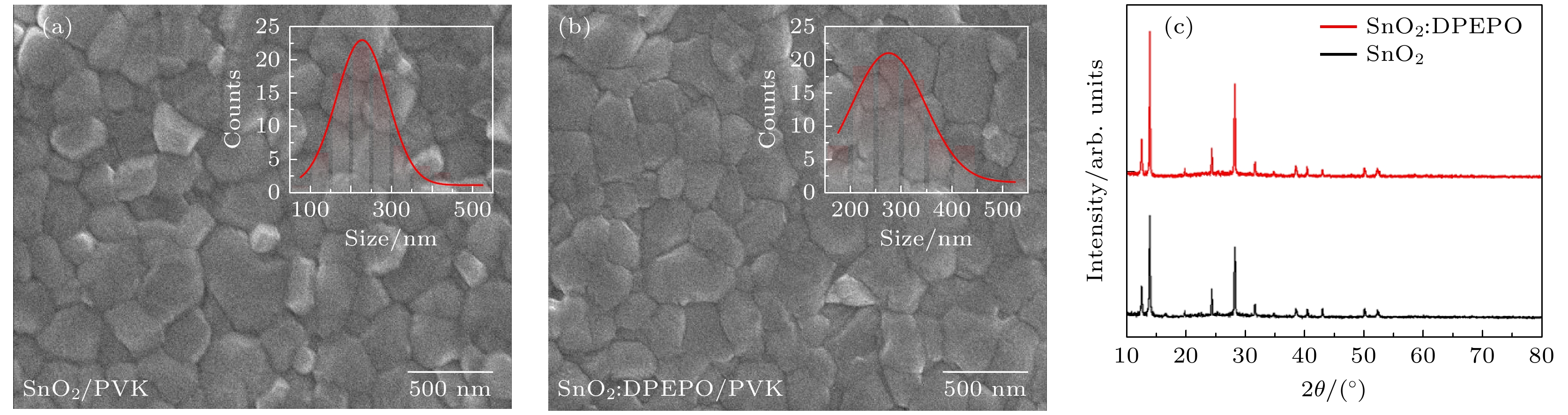

图 3 (a)基于SnO2 ETL的CsFAMA钙钛矿SEM表面俯视图像; (b)基于在SnO2: DPEPO双ETL的CsFAMA钙钛矿SEM表面俯视图像; (c)基于SnO2和SnO2:DPEPO ETL的CsFAMA钙钛矿薄膜XRD图谱

Fig. 3. (a) Top view SEM image of CsFAMA perovskite surface deposited on SnO2 ETL; (b) top view image SEM of CsFAMA perovskite surface deposited on SnO2:DPEPO ETL; (c) XRD images of CsFAMA perovskite films prepared on SnO2 and SnO2:DPEPO ETLs.

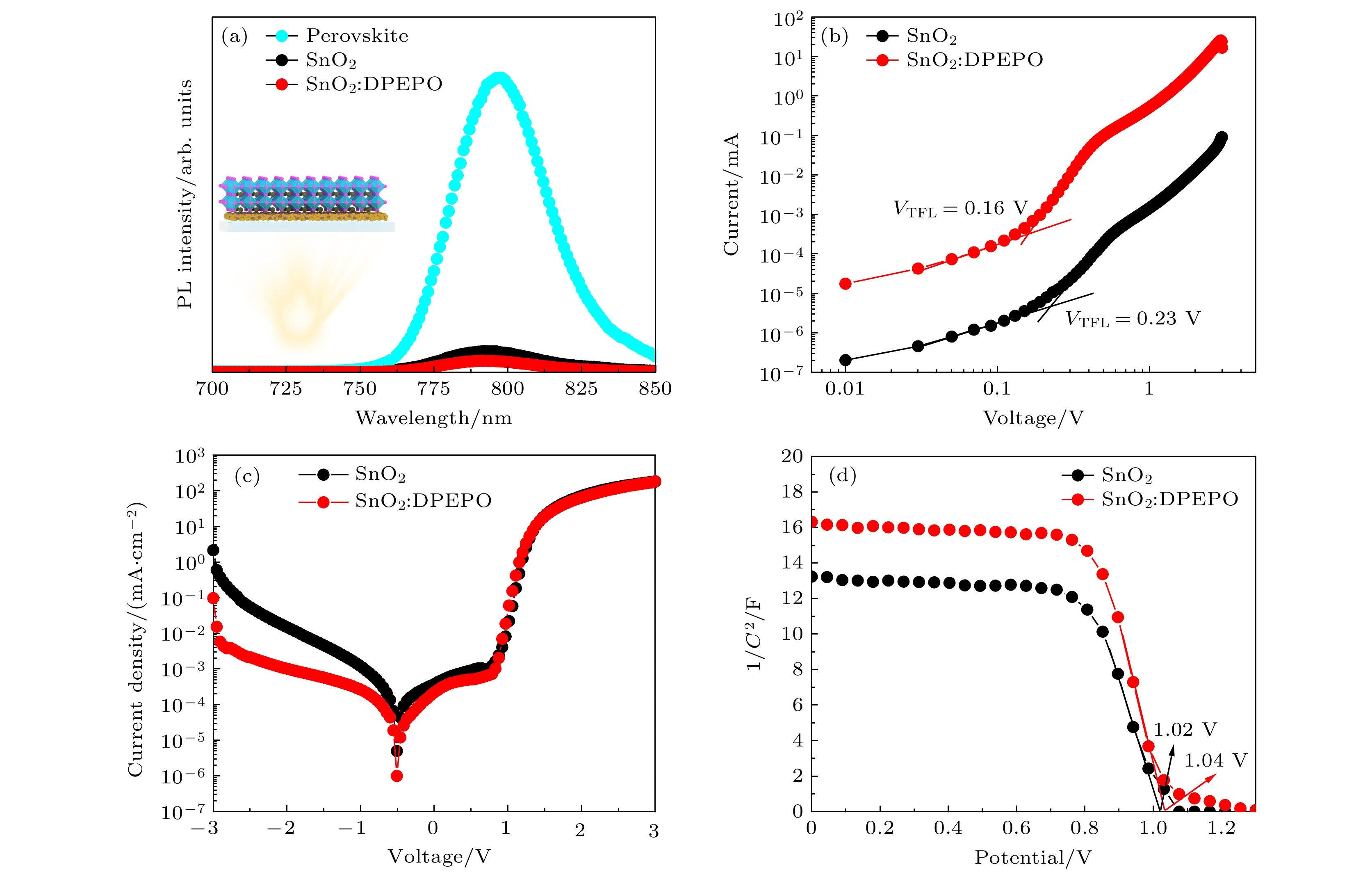

图 4 (a)纯钙钛矿薄膜以及基于SnO2/CsFAMA以及SnO2:DPEPO/CsFAMA的PL光谱; (b)基于SnO2以及SnO2:DPEPO ETL纯电子器件对数J-V特性曲线; (c)基于SnO2以及SnO2:DPEPO ETL结构器件暗J-V分析对数曲线; (d)基于SnO2以及SnO2:DPEPO ETL结构器件在1 kHz频率下的莫特-肖特基分析

Fig. 4. (a) Steady-state PL measurements of pure perovskite thin films and SnO2/CsFAMA and SnO2:DPEPO/CsFAMA; (b) logarithmic J-V characteristic curves of SnO2 and SnO2:DPEPO purely electronic devices; (c) dark J-V analysis of SnO2 and SnO2:DPEPO ETL structured devices; (d) Mott-Schottky analysis of SnO2-based and SnO2:DPEPO ETL structured devices at 1 kHz frequency.

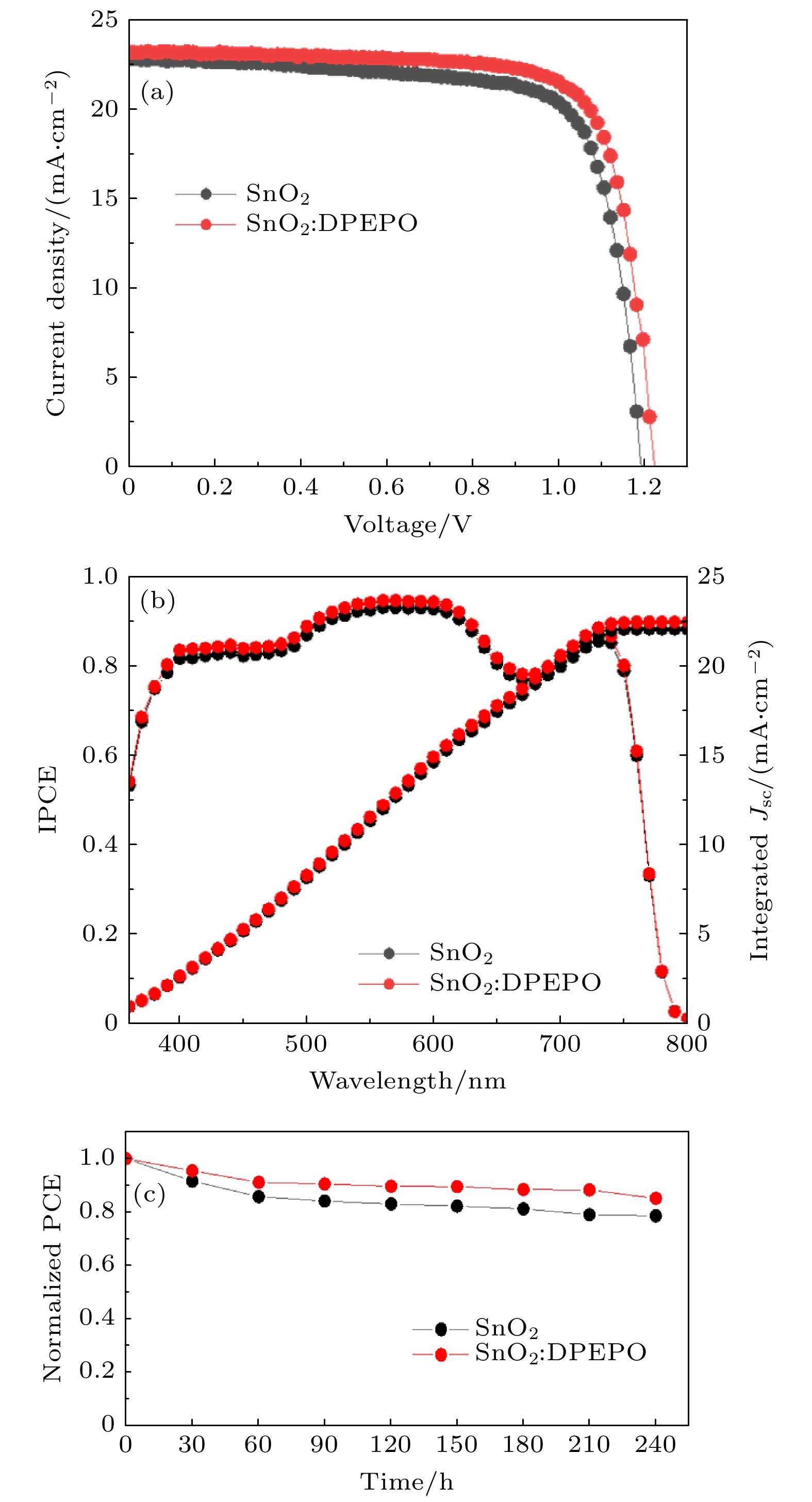

图 5 (a) 基于SnO2和SnO2:DPEPO作为ETL PSCs的J-V曲线; (b) 基于SnO2和SnO2:DPEPO作为ETL PSCs的IPCE曲线; (c) 基于SnO2和SnO2:DPEPO作为ETL PSCs的环境空气中稳定性测试

Fig. 5. (a) J-V curves of PSCs based on SnO2 and SnO2:DPEPO as ETL; (b) IPCE curves based on SnO2 and SnO2:DPEPO as ETL; (c) stability test in ambient air based on SnO2 and SnO2:DPEPO as ETL PSCs.

-

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc 131 6050

Google Scholar

Google Scholar

[2] Liang Z, Zhang Y, Xu H F, Chen W J, Liu B Y, Zhang J Y, Zhang H, Wang Z H, Kang D H, Zeng J R, Gao X Y, Wang Q S, Hu H J, Zhou H M, Cai X B, Tian X Y, Reiss P, Xu B M, Kirchartz T, Xiao Z G, Dai S Y, Park N G, Ye J J, Pan X 2023 Nature 624 557

Google Scholar

Google Scholar

[3] Deng K M, Chen Q H, Li L 2020 Adv. Funct. Mater. 30 2004209

Google Scholar

Google Scholar

[4] Lv J C, Li H X, Chen H Y, Ke L L, Du W J, Xiong J, Zhou C H, Liu G 2023 Appl. Phys. Lett. 122 233501

Google Scholar

Google Scholar

[5] Dahal B, Guo R, Pathak R, Rezaee M D, Elam J W, Mane A U, Li W J 2023 J. Phys. Chem. Solids 181 111532

Google Scholar

Google Scholar

[6] Bai C, Dong W, Cai H Y, Zu C P, Yue W, Li H X, Zhao J, Huang F Z, Cheng Y B, Zhong J 2023 Adv. Energy Mater. 13 2300491

Google Scholar

Google Scholar

[7] Khan U, Iqbal T, Khan M, Wu R 2021 Sol. Energy 223 346

Google Scholar

Google Scholar

[8] Gan Y J, Qiu G X, Qin B Y, Bi X G, Liu Y C, Nie G C, Ning W L, Yang R Z 2023 Nanomaterials 13 1313

Google Scholar

Google Scholar

[9] Zhang Y H, Xu L, Sun J, Wu Y J, Kan Z T, Zhang H, Yang L, Liu B, Dong B, Bai X, Song H W 2022 Adv. Energy Mater. 12 2201269

Google Scholar

Google Scholar

[10] Zhou Y, Ren X G, Yan Y Q, Ren H, Du H M, Cai X Y, Huang Z X 2022 Acta Phys. Sin. 71 208802 [周玚, 任信钢, 闫业强, 任昊, 杜红梅, 蔡雪原, 黄志祥 2022 71 208802]

Google Scholar

Google Scholar

Zhou Y, Ren X G, Yan Y Q, Ren H, Du H M, Cai X Y, Huang Z X 2022 Acta Phys. Sin. 71 208802

Google Scholar

Google Scholar

[11] Jang H J, Lee J Y 2019 J. Phys. Chem. C 123 26856

Google Scholar

Google Scholar

[12] Zhang J, Ding D X, Wei Y, Xu H 2016 Chem. Sci. 7 2870

Google Scholar

Google Scholar

[13] Fan W L, Shen Y, Deng K M, Chen Q H, Bai Y, Li L 2022 Nano Energy 100 107518

Google Scholar

Google Scholar

[14] Zhao L C, Tang P Y, Luo D Y, Dar M I, Eickemeyer F T, Arora N, Hu Q, Luo J S, Liu Y H, Zakeeruddin S M, Hagfeldt A, Arbiol J, Huang W, Gong Q H, Russell T P, Friend R H, Grätzel M, Zhu R 2022 Sci. Adv. 8 eabo3733

Google Scholar

Google Scholar

[15] Hu P, Zhou W B, Chen J L, Xie X, Zhu J W, Zheng Y X, Li Y F, Li J M, Wei M D 2024 Chem. Eng. J. 480 148249

Google Scholar

Google Scholar

[16] Wu J, Li M H, Fan J T, Li Z, Fan X H, Xue D J, Hu J S 2023 J. Am. Chem. Soc. 145 5872

Google Scholar

Google Scholar

[17] Li X D, Zhang W X, Guo X M, Lu C Y, Wei J Y, Fang J F 2022 Science 375 434

Google Scholar

Google Scholar

[18] Khan M T, Hemasiri N H, Kazim S, Ahmad S 2021 Sustain. Energ. Fuels 5 6352

Google Scholar

Google Scholar

[19] Cha J, Kim M K, Lee W, Jin H, Na H, Cung Tien Nguyen D, Lee S, Lim J, Kim M 2023 Chem. Eng. J. 451 138920

Google Scholar

Google Scholar

[20] Tan H R, Che F L, Wei M Y, Zhao Y C, Saidaminov M I, Todorović P, Broberg D, Walters G, Tan F R, Zhuang T T, Sun B, Liang Z Q, Yuan H F, Fron E, Kim J, Yang Z Y, Voznyy O, Asta M, Sargent E H 2018 Nat. Commun. 9 3100

Google Scholar

Google Scholar

计量

- 文章访问数: 4144

- PDF下载量: 117

- 被引次数: 0

下载:

下载: