-

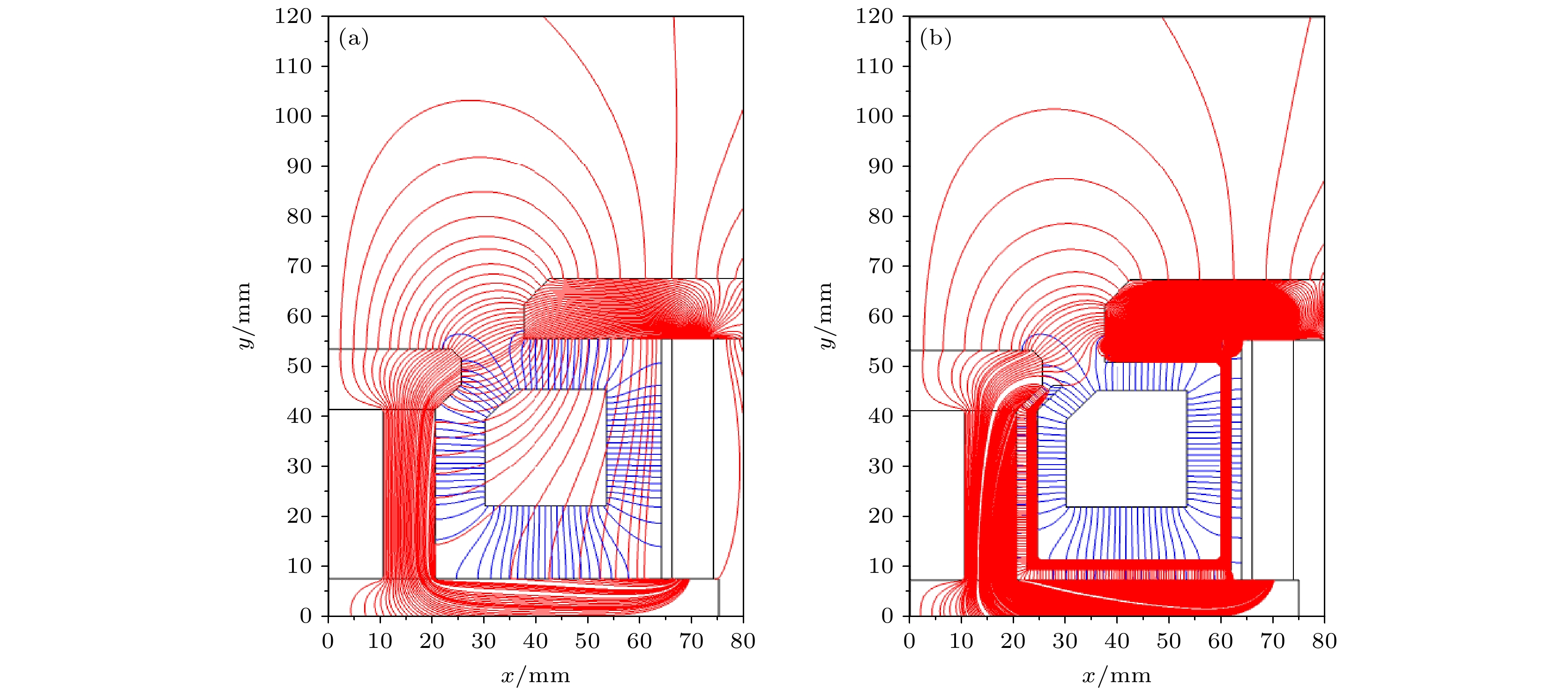

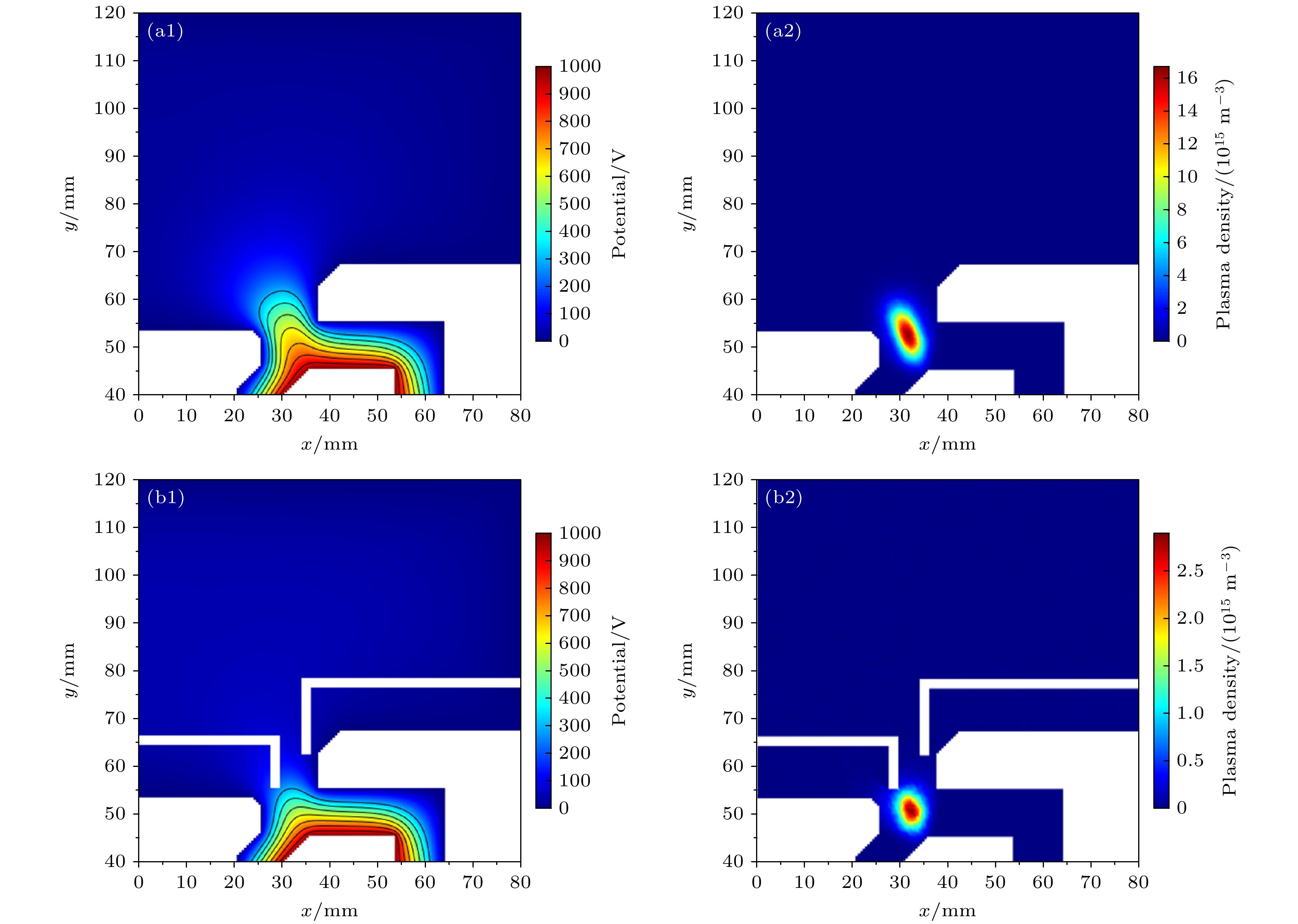

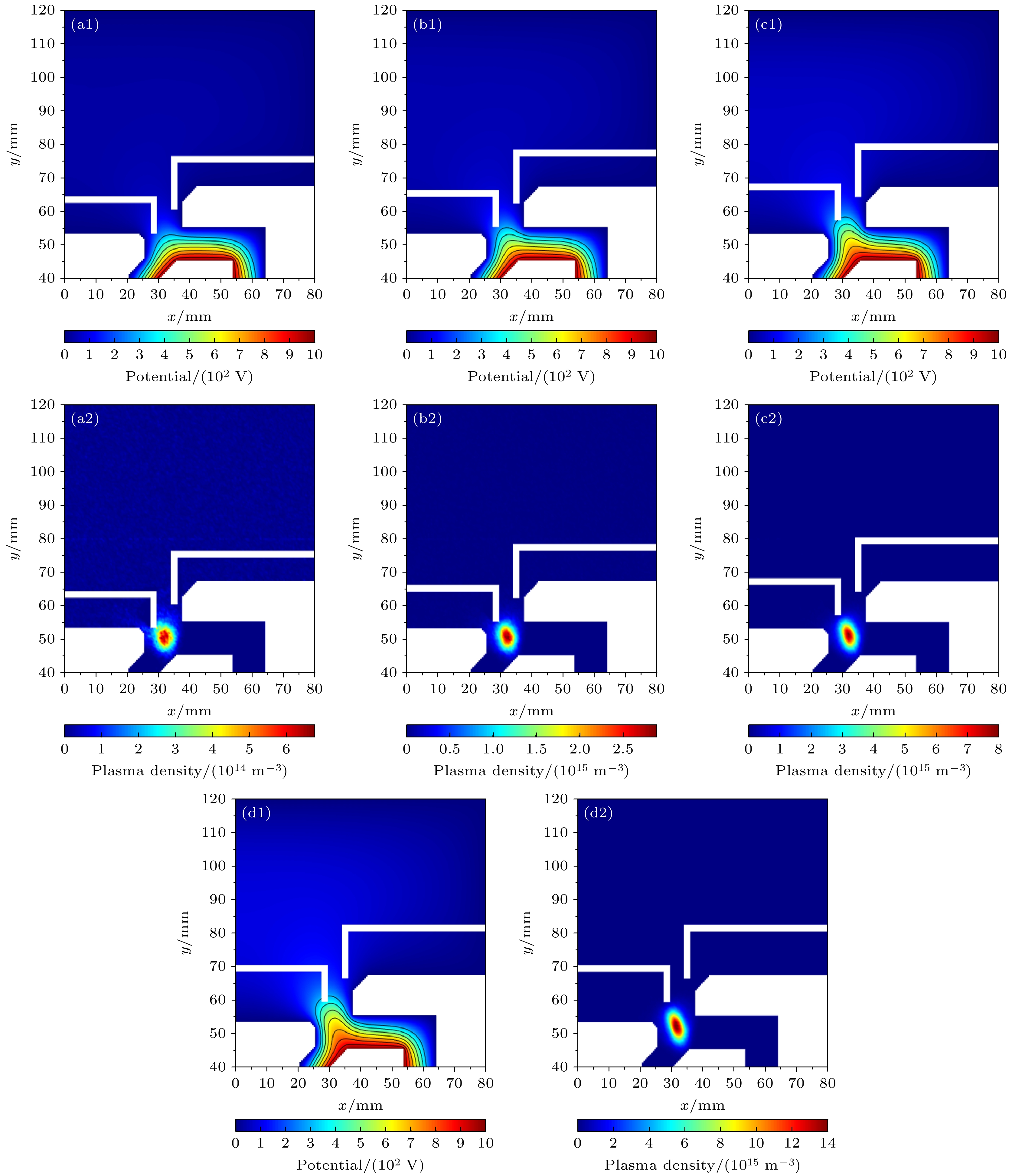

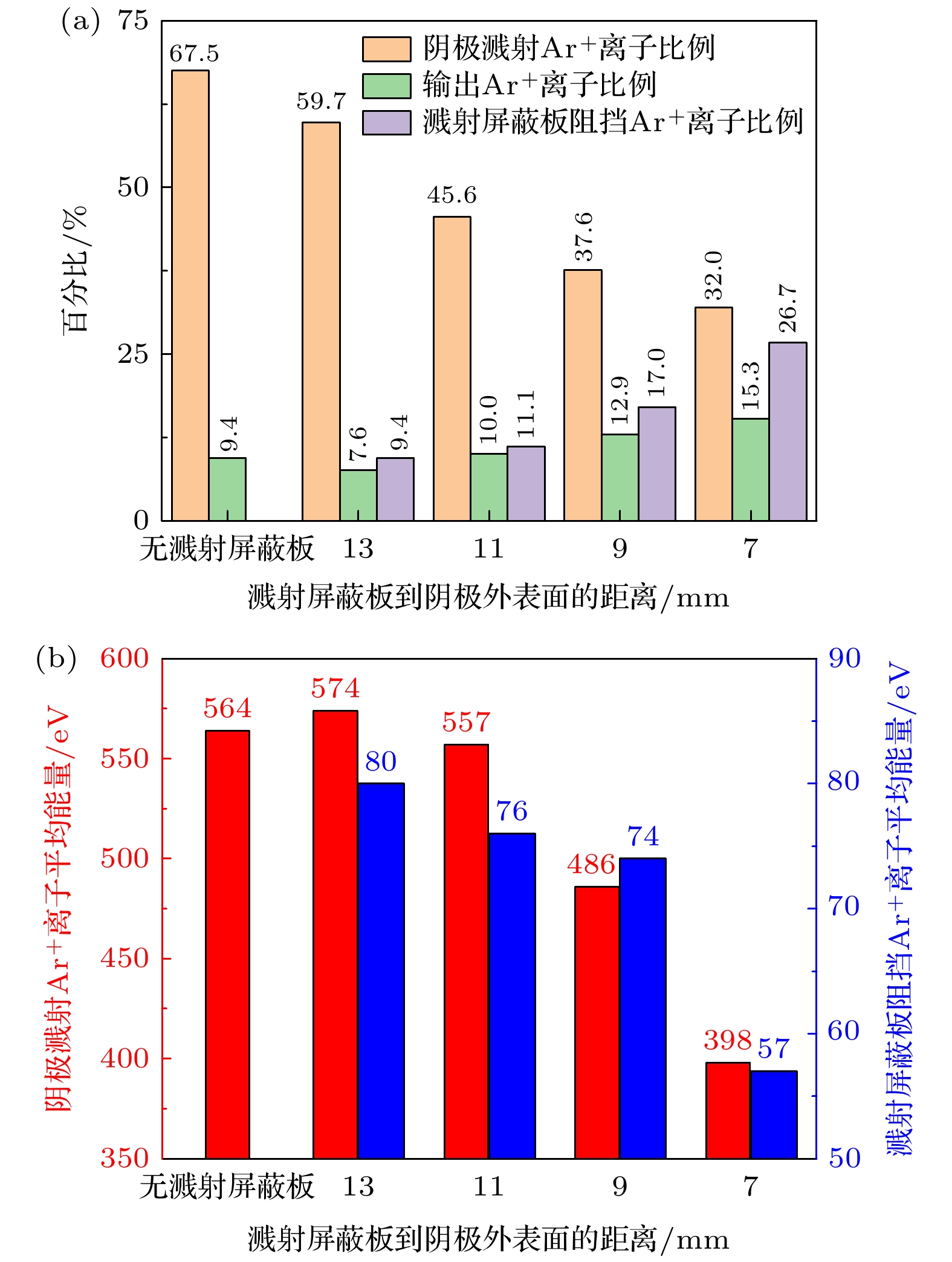

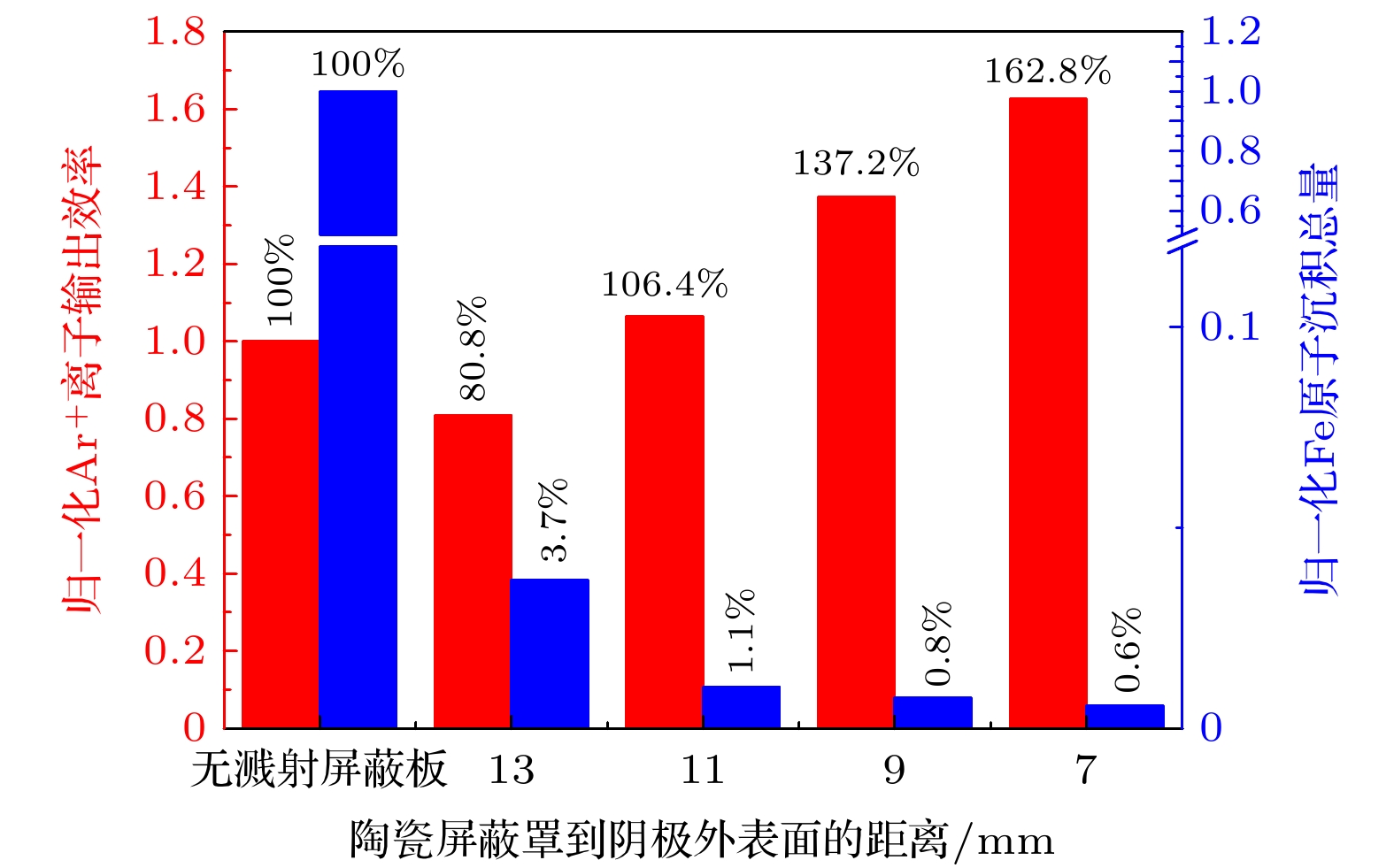

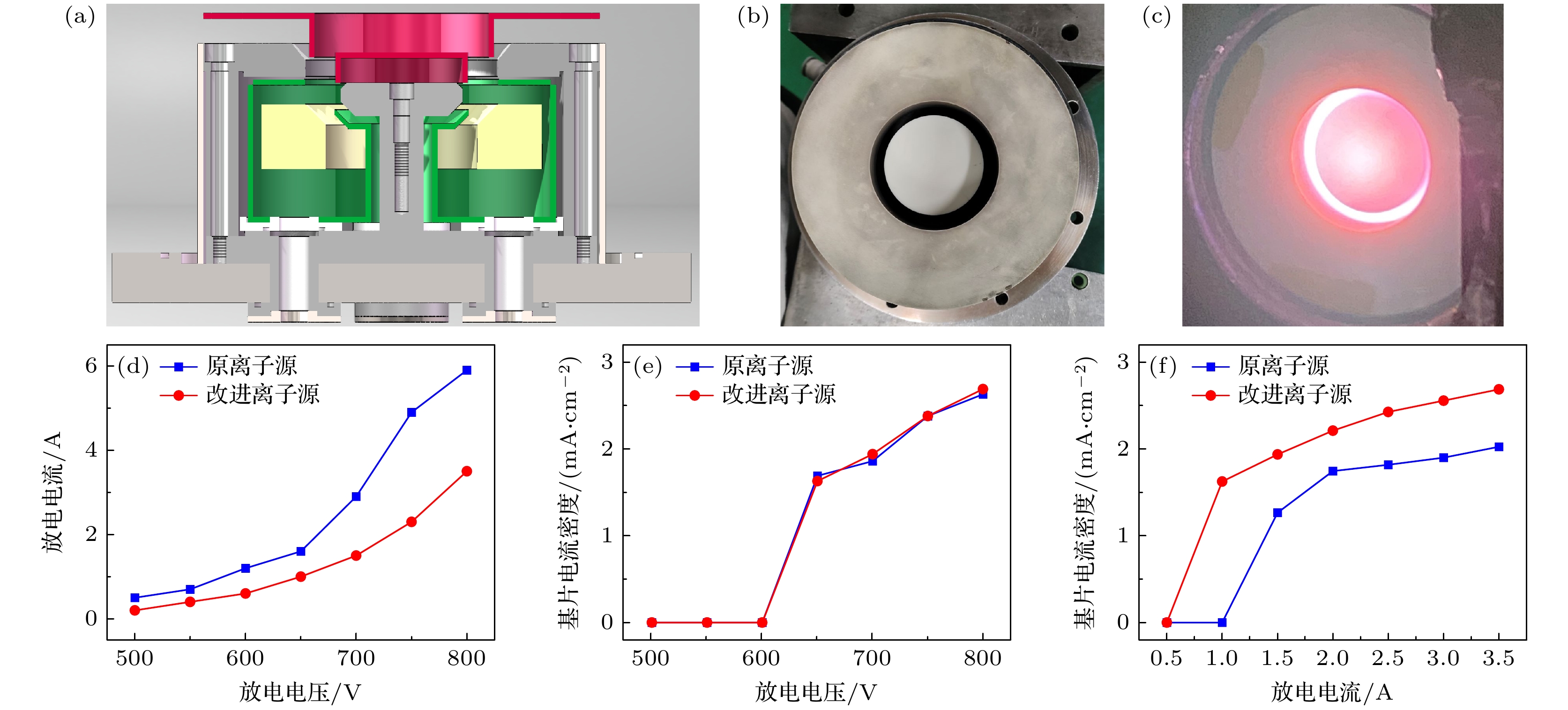

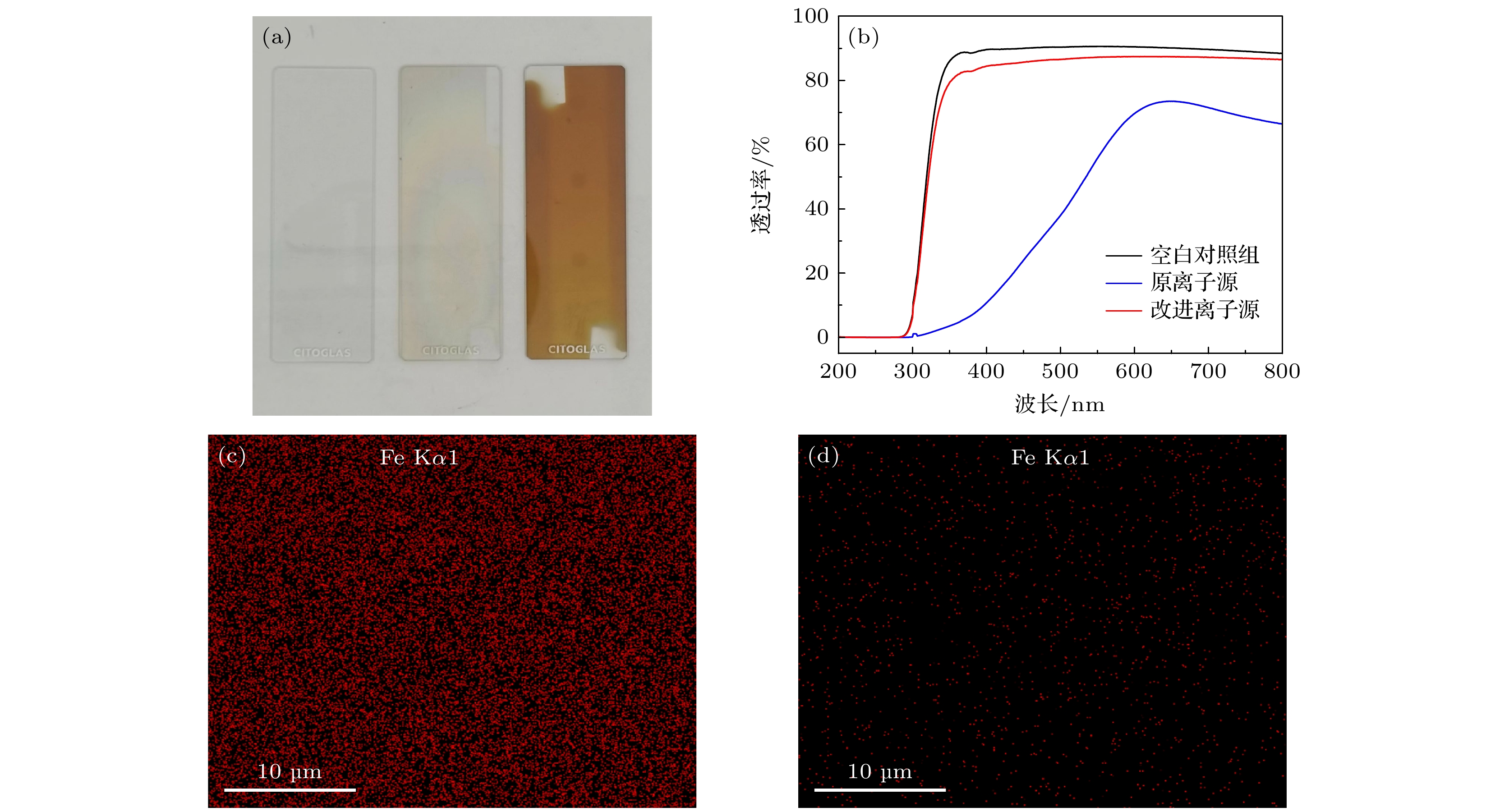

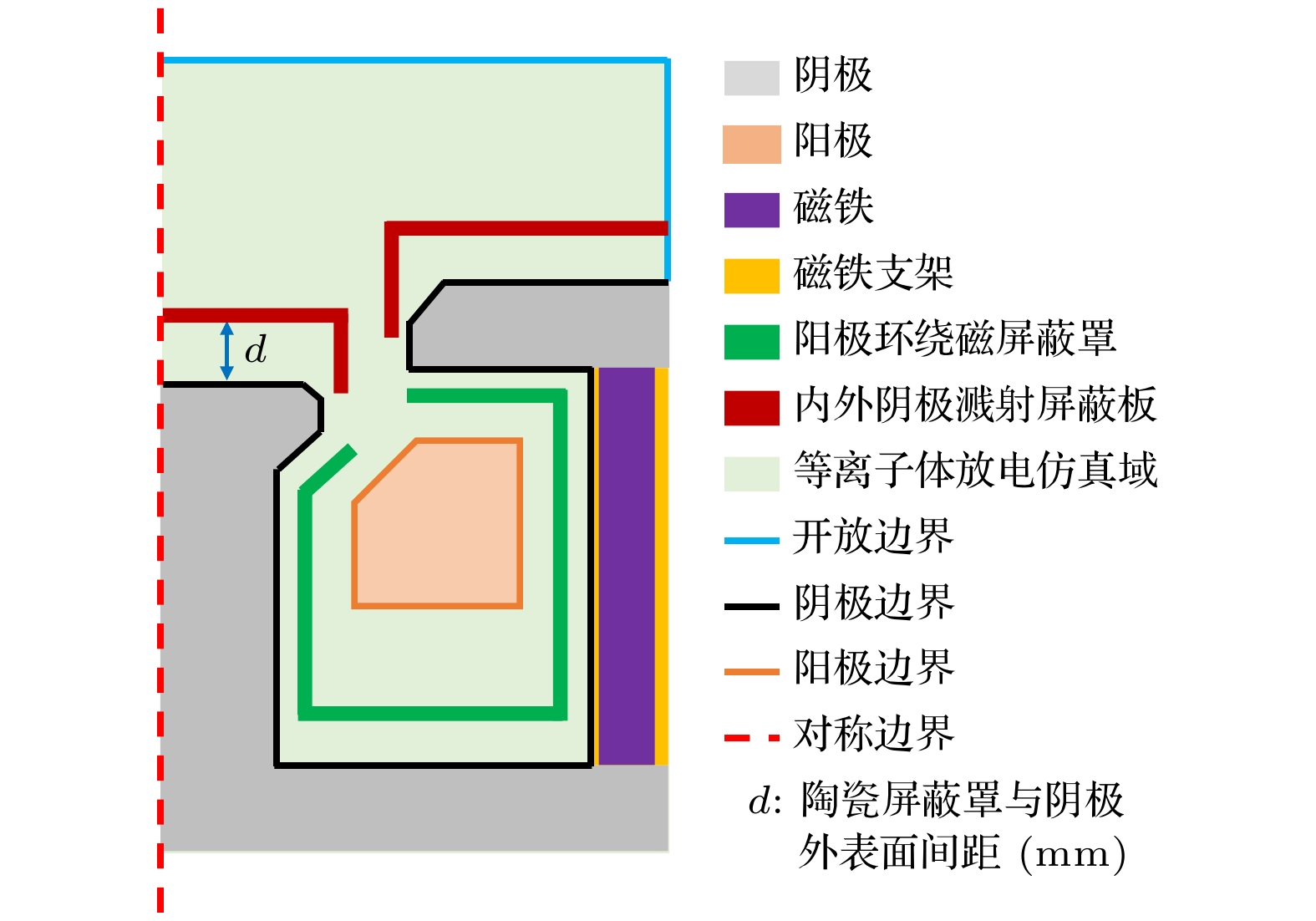

阳极层离子源可输出高密度离子束流, 广泛用于等离子体清洗和辅助沉积, 但大束流下内部易发生放电击穿, 且大量离子轰击内外阴极导致明显刻蚀, 易造成样品污染. 本文提出阳极环绕磁屏蔽罩和内外阴极溅射屏蔽板的设计方案, 并仿真研究了其对离子源电磁场和等离子体放电输运的影响. 发现阳极环绕磁屏蔽罩可切断离子源内部阴阳极间的磁场回路, 消除打火条件. 内外阴极溅射屏蔽板选择溅射产额低且绝缘性能好的氧化铝, 既可阻挡离子溅射, 又能屏蔽阴极外表面电场, 使等离子体放电向阳极压缩, 在抑制阴极刻蚀行为的同时提升离子输出效率. 当距离阴极外表面9 mm时, 溅射屏蔽板的作用效果最优, 不仅能获得稳定放电和高效输出, 还可大幅削弱阴极刻蚀行为并减少污染. 实验结果显示: 改进离子源无内部打火, 输出高效且清洁, 相同电流下离子输出效率较原离子源实际提高36%; 玻璃基片在经过1 h清洗后, 表面成分几乎不变, 来自阴极溅射的Fe元素含量仅为0.03%, 比原离子源低2个数量级, 含量约为原离子源的0.6%, 实验结果验证了理论分析.High beam-anode layer ion source can produce high-density ions, and has been widely used in plasma cleaning and assisted deposition. However, when increasing the ion-beams, arcing always occurs inside the ion source and serious etching will take place on the cathode, which results in sample pollution especially in long-time cleaning. In this work, two structures are designed, which are magnetic shielding around the anode and sputtering shielding on the top of the inner cathode and outer cathode, respectively. Based on the particle-in-cell/Monte Carlo collision method and test particle Monte Carlo method, the influence of designed structure on the electromagnetic field and the plasma properties of the ion source are studied through self-established simulation technique. The results show that the magnetic shielding around the anode cuts off the magnetic induction line between the cathode and anode, eliminating the arcing condition in the ion source. The sputtering shielding for the cathode uses alumina ceramic because of its extremely low sputtering yield and high insulation performance. Therefore, the sputtering shields can not only resist the ion sputtering, but also shield the electric field on the outer surface of the cathode. As a result, the plasma discharge region is compressed towards the anode and away from the cathode simultaneously, which provides a stronger electric field force directing to the output region for Ar+ ions, and also results in a suppressed cathode etching behavior but an improved Ar+ ion output efficiency. The optimized calculation shows that the best distance from the sputtering shield to the cathode surface is 9 mm. The discharge experiments reveal that the modified ion source can eliminate the inside arcing and provide a clean and strong ion beam with a high efficiency. At the same discharge current, the output efficiency of the modified ion source is 36% higher than that of the original ion source. When used in the plasma cleaning, the glass substrate remains transparent and keeps the original element composition ratio unchanged. The detected Fe content, coming from the cathode sputtering, is only 0.03% after the one-hour plasma cleaning, which is 2 orders of magnitude smaller than that cleaned by the original ion source. The Fe content of the modified ion source is about 0.6% of the original ion source, which is in good agreement with the result of simulation optimization.

-

Keywords:

- large beam-anode layer ion source /

- cathode etching /

- electromagnetic shielding /

- output properties

[1] Harper J M E, Cuomo J J, Kaufman H R 1982 J. Vac. Sci. Technol. A 21 737

Google Scholar

Google Scholar

[2] 赵杰, 唐德礼, 程昌明, 耿少飞 2009 核聚变与等离子体物理 29 5

Google Scholar

Google Scholar

Zhao J, Tang D L, Cheng C M, Geng S F 2009 Nucl. Fusion. Plasma. Phys. 29 5

Google Scholar

Google Scholar

[3] Lackner J M, Waldhauser W, Schwarz M, Mahoney L, Major B, 2008 Vacuum. 83 302

Google Scholar

Google Scholar

[4] Lee S, Kim D G 2015 Appl. Sci. Converg. Tec. 24 162

Google Scholar

Google Scholar

[5] Dudnikov V 2012 Rev. Sci. Instrum. 83 02A713

Google Scholar

Google Scholar

[6] Chen L, Cui S H, Tang W, Zhou L, Li T J, Liu L L, An X K, Wu Z C, Ma Z Y, Lin H, Tian X B, Ricky K Y Fu, Paul K Chu, Wu Z Z 2020 Plasma Sources Sci. Technol. 29 025016

Google Scholar

Google Scholar

[7] 郭杏元, 曹永盛, 马金鹏 2021 中国专利 CN112575306A

Guo X Y, Cao Y S, Ma J P 2021 China Patent CN112575306A

[8] 汪礼胜, 唐德礼, 程昌明 2006 核聚变与等离子体物理 26 54

Google Scholar

Google Scholar

Wang L S, Tang D L, Cheng C M 2006 Nucl. Fusion. Plasma. Phys. 26 54

Google Scholar

Google Scholar

[9] 郑军, 周晖, 赵栋才 2019 中国专利 CN108914091B

Zheng J, Zhou H, Zhao D C 2019 China Patent CN108914091B

[10] 王鸣, 陈刚 2020 中国专利 CN109536906A

Wang M, Chen G 2020 China Patent CN109536906A

[11] Brenning N, Gudmundsson J T, Raadu M A, Petty T J, Minea T, Lundin D 2017 Plasma Sources Sci. Technol. 26 125003

Google Scholar

Google Scholar

[12] Jiang Y W, Tang H B, Ren J X, Li M, Cao J B 2018 J. Phys. D: Appl. Phys. 51 035201

Google Scholar

Google Scholar

[13] Yu D R, Zhang F K, Liu H, Li H, Yan G J, Liu J Y 2008 Phys. Plasmas 15 104501

Google Scholar

Google Scholar

[14] Birdsall C K 1991 IEEE Trans. Plasma Sci. 19 65

Google Scholar

Google Scholar

[15] 李体军, 崔岁寒, 刘亮亮, 李晓渊, 吴忠灿, 马正永, 傅劲裕, 田修波, 朱剑豪, 吴忠振 2021 70 045202

Google Scholar

Google Scholar

Li T J, Cui S H, Liu L L, Li X Y, Wu Z C, Ma Z Y, Fu R K Y, Tian X B, Chu P K, Wu Z Z 2021 Acta Phys. Sin. 70 045202

Google Scholar

Google Scholar

[16] Lennon M A, Bell K L, Gilbody H B, Hughes J G, Kingston A E, Murray M J, Smith F J 1988 J. Phys. Chem. Ref. Data 17 1285

Google Scholar

Google Scholar

[17] Cui S H, Chen Q H, Guo Y X, Chen L, Jin Z, Li X T, Yang C, Wu Z C, Su X Y, Ma Z Y, Fu R K Y, Tian X B, Chu P K Chu, Wu Z Z 2022 J. Phys. D. Appl. Phys. 55 325203

Google Scholar

Google Scholar

[18] Bultinck E, Kolev I, Bogaerts A, Depla D 2008 J. Appl. Phys. 103 013309

Google Scholar

Google Scholar

[19] Cui S H, Wu Z Z, Lin H, Xiao S, Zheng B C, Liu L L, An X K, Fu R K Y, Tian X B, Tan W C, Chu P K 2019 J. Appl. Phys. 125 063302

Google Scholar

Google Scholar

[20] Bogaerts A, Bultinck E, Kolev I, Schwaederle L, Van A K, Buyle G, Depla D 2009 J. Phys. D: Appl. Phys. 42 194018

Google Scholar

Google Scholar

[21] 崔岁寒, 郭宇翔, 陈秋皓, 金正, 杨超, 吴忠灿, 苏雄宇, 马正永, 田修波, 吴忠振 2022 71 055203

Google Scholar

Google Scholar

Cui S H, Guo Y X, Chen Q H, Jin Z, Yang C, Wu Z C, Su X Y, Ma Z Y, Tian X B, Wu Z Z 2022 Acta Phys. Sin. 71 055203

Google Scholar

Google Scholar

[22] Samuelsson M, Lundin D, Jensen J, Raadu M A, Gudmundsson J T, Helmersson U 2010 Surf. Coat. Tech. 205 591

Google Scholar

Google Scholar

[23] 崔岁寒, 吴忠振, 肖舒, 陈磊, 李体军, 刘亮亮, 傅劲裕, 田修波, 朱剑豪, 谭文长 2019 68 195204

Google Scholar

Google Scholar

Cui S H, Wu Z Z, Xiao S, Chen S, Li T J, Liu L L, Fu R K Y, Tian X B, Chu P K, Tan W C 2019 Acta Phys. Sin. 68 195204

Google Scholar

Google Scholar

[24] Park D H, Kim J H, Ermakov Y 2008 Rev. Sci. Instrum. 79 02B312

Google Scholar

Google Scholar

[25] Gui B H, Yang L, Zhou H, Luo S L, Xu J, Ma Z J, Zhang Y S 2022 Vacuum 200 111065

Google Scholar

Google Scholar

[26] Ziegler J F, Ziegler M D, Biersack J P 2010 Nucl. Instrum. Methods Phys. Res. B 268 1818

Google Scholar

Google Scholar

-

图 4 不同溅射屏蔽板与内外阴极间距的阳极层离子源的电势与等离子体密度分布 (a) d = 7 mm; (b) d = 9 mm; (c) d = 11 mm; (d) d = 13 mm

Fig. 4. Distribution of potential and plasma density of anode-layer ion source with different distance between the sputtering shield and the cathode: (a) d = 7 mm; (b) d = 9 mm; (c) d = 11 mm; (d) d = 13 mm.

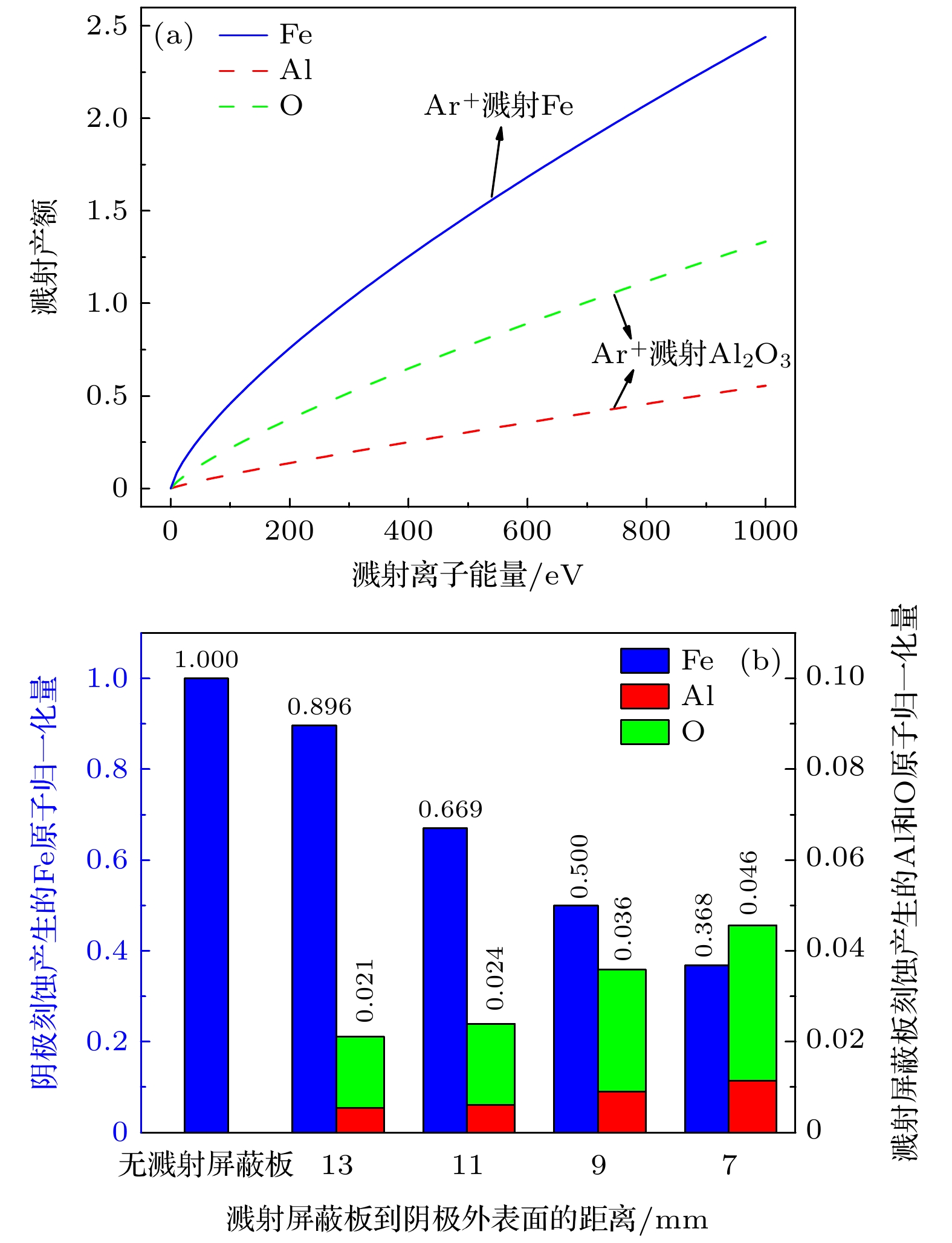

图 6 (a) Ar+离子对阴极材料(Fe)和屏蔽板材料(Al2O3)的溅射产额; (b) 相同条件下阴极和溅射屏蔽板刻蚀产生的Fe, Al和O原子含量(归一化)

Fig. 6. (a) Sputtering yield of Ar+ ion to the cathode material (Fe) and shield material (Al2O3); (b) the normalized atomic content of Fe, Al, and O generated by the cathode and sputtering shields under the same conditions

图 8 改进阳极层离子源的(a)结构图、(b)实物图和(c)辉光图; 改进前后离子源在恒压放电条件的(d)放电电流和(e)基片电流密度; 改进前后离子源在恒流放电条件下的(f)基片电流密度

Fig. 8. (a) Structural diagram, (b) the physical picture and (c) the glow picture of the modified anode-layer ion source; (d) the discharge current and (e) the substrate current density of the original and the modified ion source under the constant discharge voltage; (f) the substrate current density of the original and the modified ion source under the constant discharge current.

图 9 空白玻璃基片和经改进前后离子源清洗1 h的玻璃基片的(a)实物图和(b)透过率; (c)原离子源与(d) 改进离子源清洗的玻璃基片表面Fe元素分布的EDS检测结果

Fig. 9. (a) physical pictures and (b) transmission of blank glass substrates and glass substrates after cleaning by the original and modified ion sources for 1 h; EDS detection results of Fe element distribution on glass substrate surface after cleaning by (c) the original ion source and the (d) modified ion source.

序

号反应方程式 反应速率系数 kr/(m3⋅s–1) 反应能量

阈值/eV反应类型 1 e + Ar → Ar + e $ 2.336 \times {10^{ - 14}}{T_{\text{e}}}^{1.609} \exp [ {0.0618{{( {\ln {T_{\text{e}}}} )}^2} - 0.1171{{ ( {\ln {T_{\text{e}}}} )}^3}} ] $ — 弹性碰撞 2 e + Ar → Ar+ + 2e $ 2.34 \times {10^{ - 14}}{T_{\text{e}}}^{0.59} \exp \left( { - 17.44/{T_{\text{e}}}} \right) $ 15.76 电离碰撞 3 e + Ar → Arm + e $ 2.5 \times {10^{ - 15}}{T_{\text{e}}}^{0.74} \exp \left( { - 11.56/{T_{\text{e}}}} \right) $ 11.56 激发碰撞 4 e + Arm → Ar+ + 2e $ 6.8 \times {10^{ - 15}}{T_{\text{e}}}^{0.67} \exp \left( { - 4.2/{T_{\text{e}}}} \right) $ 4.2 激发态电离 5 e + Arm → Ar + e $ 4.3 \times {10^{ - 16}}{T_{\text{e}}}^{0.74} $ –11.56 退激发碰撞 6 Ar+ + Ar → Ar+ + Ar 硬球碰撞 — 弹性碰撞 7 Ar+ + Ar → Ar + Ar+ 硬球碰撞 — 电荷交换 表 2 等离子体放电特征分析

Table 2. Analysis of plasma discharge properties.

d/mm 峰值密度/m–3 峰值位置

坐标/mm放电面

积/mm2无溅射屏蔽板 1.68×1016 (31.5, 52.5) 170.25 7 6.79×1014 (31.0, 50.5) 10.25 9 2.89×1015 (32.0, 51.0) 66.00 11 8.27×1015 (32.0, 52.0) 115.00 13 1.42×1016 (31.5, 52.5) 153.75 表 3 检验Fe原子MC模型仿真结果

Table 3. Simulation results of the Test Fe atom MC model.

d/mm 输出的Fe

原子比例/%溅射屏蔽板阻挡

Fe原子比例/%返回阴极的Fe

原子比例/%无溅射

屏蔽板19.4 — 80.6 7 0.3 21.1 78.6 9 0.3 24.5 75.2 11 0.3 25.8 73.9 13 0.8 27.3 71.9 表 4 EDS检测结果

Table 4. EDS detection results.

原子百

分比/%空白玻璃

基片原离子源清洗的

玻璃基片改进离子源清洗的

玻璃基片C 12.61 12.83 10.93 O 55.27 57.33 56.73 Na 7.23 4.57 7.23 Mg 1.91 1.41 1.97 Si 20.51 16.69 20.90 Ca 2.46 2.10 2.22 Fe 0 5.08 0.03 -

[1] Harper J M E, Cuomo J J, Kaufman H R 1982 J. Vac. Sci. Technol. A 21 737

Google Scholar

Google Scholar

[2] 赵杰, 唐德礼, 程昌明, 耿少飞 2009 核聚变与等离子体物理 29 5

Google Scholar

Google Scholar

Zhao J, Tang D L, Cheng C M, Geng S F 2009 Nucl. Fusion. Plasma. Phys. 29 5

Google Scholar

Google Scholar

[3] Lackner J M, Waldhauser W, Schwarz M, Mahoney L, Major B, 2008 Vacuum. 83 302

Google Scholar

Google Scholar

[4] Lee S, Kim D G 2015 Appl. Sci. Converg. Tec. 24 162

Google Scholar

Google Scholar

[5] Dudnikov V 2012 Rev. Sci. Instrum. 83 02A713

Google Scholar

Google Scholar

[6] Chen L, Cui S H, Tang W, Zhou L, Li T J, Liu L L, An X K, Wu Z C, Ma Z Y, Lin H, Tian X B, Ricky K Y Fu, Paul K Chu, Wu Z Z 2020 Plasma Sources Sci. Technol. 29 025016

Google Scholar

Google Scholar

[7] 郭杏元, 曹永盛, 马金鹏 2021 中国专利 CN112575306A

Guo X Y, Cao Y S, Ma J P 2021 China Patent CN112575306A

[8] 汪礼胜, 唐德礼, 程昌明 2006 核聚变与等离子体物理 26 54

Google Scholar

Google Scholar

Wang L S, Tang D L, Cheng C M 2006 Nucl. Fusion. Plasma. Phys. 26 54

Google Scholar

Google Scholar

[9] 郑军, 周晖, 赵栋才 2019 中国专利 CN108914091B

Zheng J, Zhou H, Zhao D C 2019 China Patent CN108914091B

[10] 王鸣, 陈刚 2020 中国专利 CN109536906A

Wang M, Chen G 2020 China Patent CN109536906A

[11] Brenning N, Gudmundsson J T, Raadu M A, Petty T J, Minea T, Lundin D 2017 Plasma Sources Sci. Technol. 26 125003

Google Scholar

Google Scholar

[12] Jiang Y W, Tang H B, Ren J X, Li M, Cao J B 2018 J. Phys. D: Appl. Phys. 51 035201

Google Scholar

Google Scholar

[13] Yu D R, Zhang F K, Liu H, Li H, Yan G J, Liu J Y 2008 Phys. Plasmas 15 104501

Google Scholar

Google Scholar

[14] Birdsall C K 1991 IEEE Trans. Plasma Sci. 19 65

Google Scholar

Google Scholar

[15] 李体军, 崔岁寒, 刘亮亮, 李晓渊, 吴忠灿, 马正永, 傅劲裕, 田修波, 朱剑豪, 吴忠振 2021 70 045202

Google Scholar

Google Scholar

Li T J, Cui S H, Liu L L, Li X Y, Wu Z C, Ma Z Y, Fu R K Y, Tian X B, Chu P K, Wu Z Z 2021 Acta Phys. Sin. 70 045202

Google Scholar

Google Scholar

[16] Lennon M A, Bell K L, Gilbody H B, Hughes J G, Kingston A E, Murray M J, Smith F J 1988 J. Phys. Chem. Ref. Data 17 1285

Google Scholar

Google Scholar

[17] Cui S H, Chen Q H, Guo Y X, Chen L, Jin Z, Li X T, Yang C, Wu Z C, Su X Y, Ma Z Y, Fu R K Y, Tian X B, Chu P K Chu, Wu Z Z 2022 J. Phys. D. Appl. Phys. 55 325203

Google Scholar

Google Scholar

[18] Bultinck E, Kolev I, Bogaerts A, Depla D 2008 J. Appl. Phys. 103 013309

Google Scholar

Google Scholar

[19] Cui S H, Wu Z Z, Lin H, Xiao S, Zheng B C, Liu L L, An X K, Fu R K Y, Tian X B, Tan W C, Chu P K 2019 J. Appl. Phys. 125 063302

Google Scholar

Google Scholar

[20] Bogaerts A, Bultinck E, Kolev I, Schwaederle L, Van A K, Buyle G, Depla D 2009 J. Phys. D: Appl. Phys. 42 194018

Google Scholar

Google Scholar

[21] 崔岁寒, 郭宇翔, 陈秋皓, 金正, 杨超, 吴忠灿, 苏雄宇, 马正永, 田修波, 吴忠振 2022 71 055203

Google Scholar

Google Scholar

Cui S H, Guo Y X, Chen Q H, Jin Z, Yang C, Wu Z C, Su X Y, Ma Z Y, Tian X B, Wu Z Z 2022 Acta Phys. Sin. 71 055203

Google Scholar

Google Scholar

[22] Samuelsson M, Lundin D, Jensen J, Raadu M A, Gudmundsson J T, Helmersson U 2010 Surf. Coat. Tech. 205 591

Google Scholar

Google Scholar

[23] 崔岁寒, 吴忠振, 肖舒, 陈磊, 李体军, 刘亮亮, 傅劲裕, 田修波, 朱剑豪, 谭文长 2019 68 195204

Google Scholar

Google Scholar

Cui S H, Wu Z Z, Xiao S, Chen S, Li T J, Liu L L, Fu R K Y, Tian X B, Chu P K, Tan W C 2019 Acta Phys. Sin. 68 195204

Google Scholar

Google Scholar

[24] Park D H, Kim J H, Ermakov Y 2008 Rev. Sci. Instrum. 79 02B312

Google Scholar

Google Scholar

[25] Gui B H, Yang L, Zhou H, Luo S L, Xu J, Ma Z J, Zhang Y S 2022 Vacuum 200 111065

Google Scholar

Google Scholar

[26] Ziegler J F, Ziegler M D, Biersack J P 2010 Nucl. Instrum. Methods Phys. Res. B 268 1818

Google Scholar

Google Scholar

计量

- 文章访问数: 390

- PDF下载量: 13

- 被引次数: 0

下载:

下载: