-

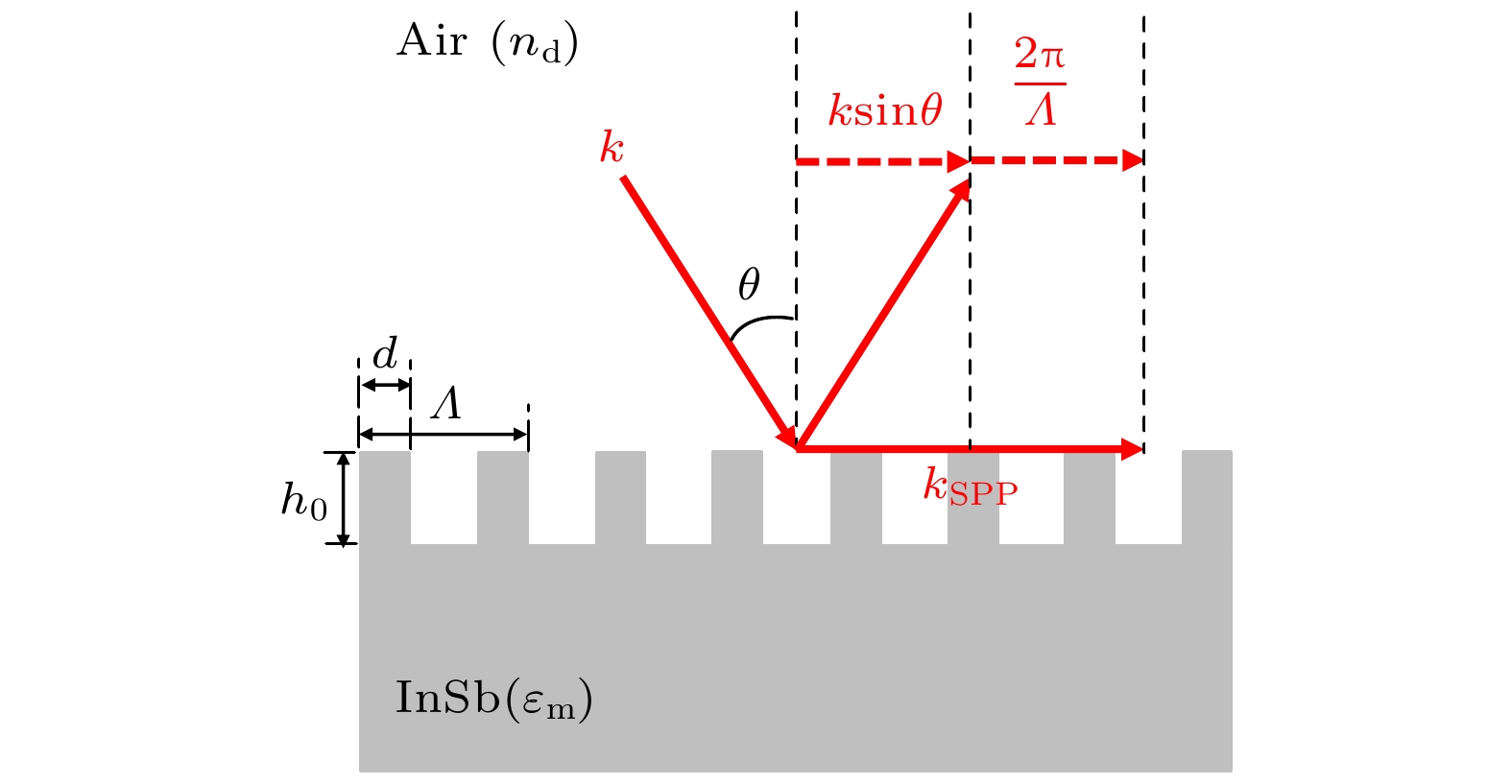

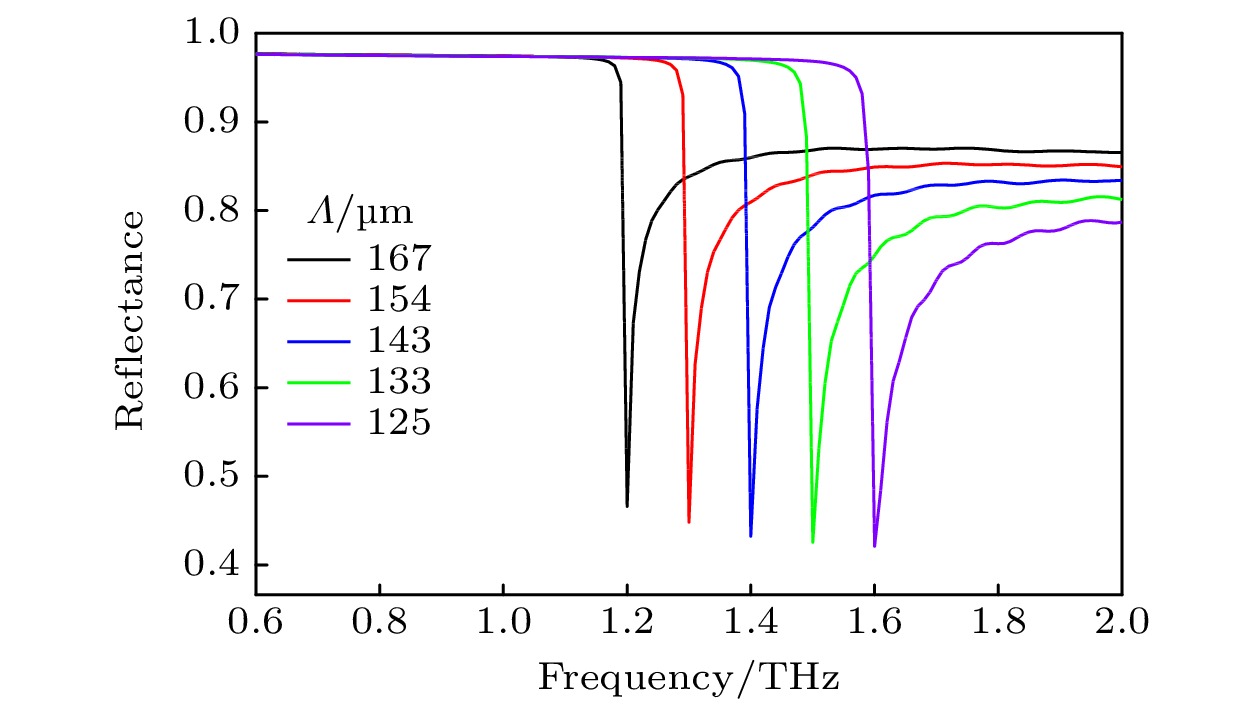

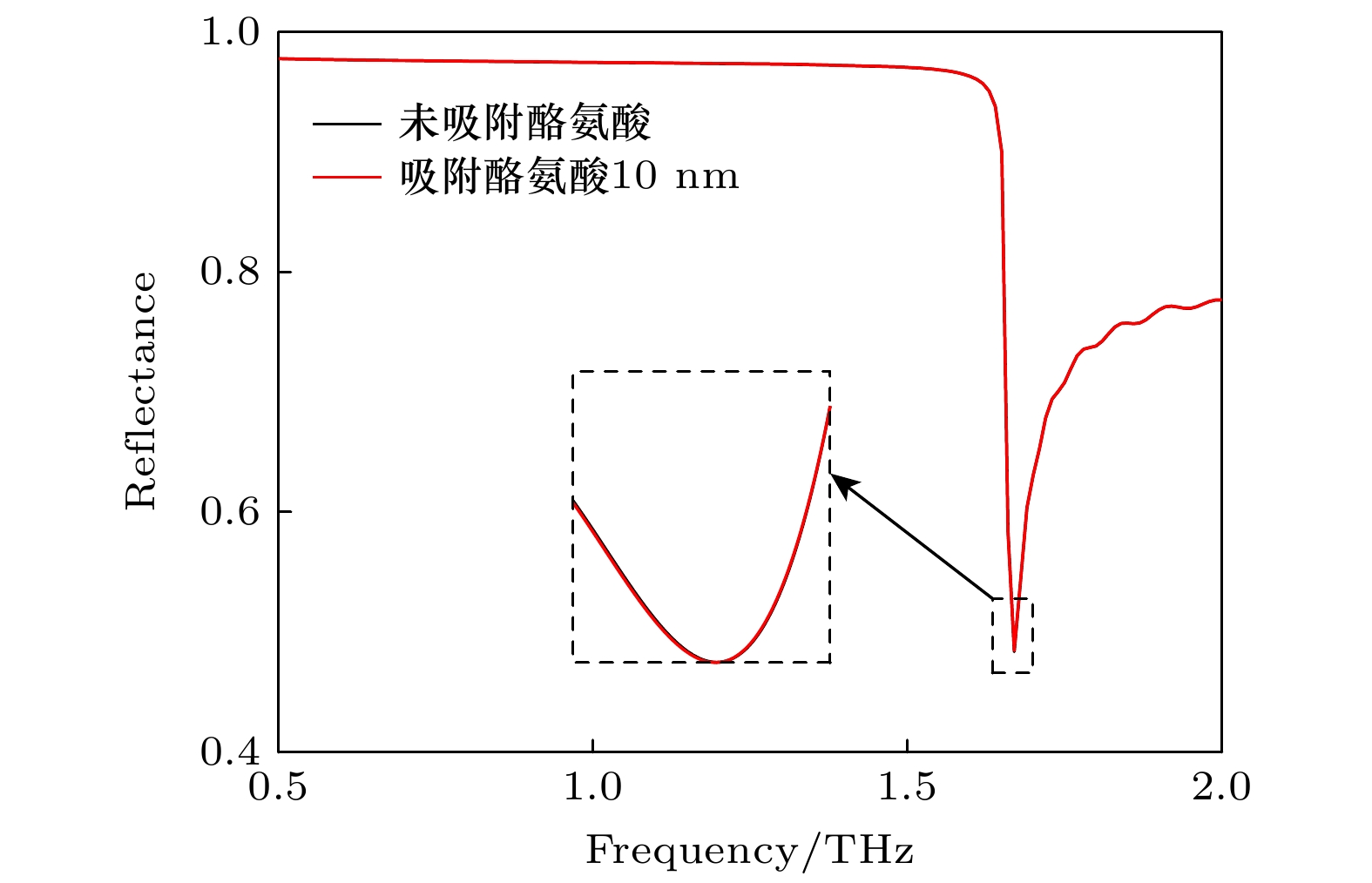

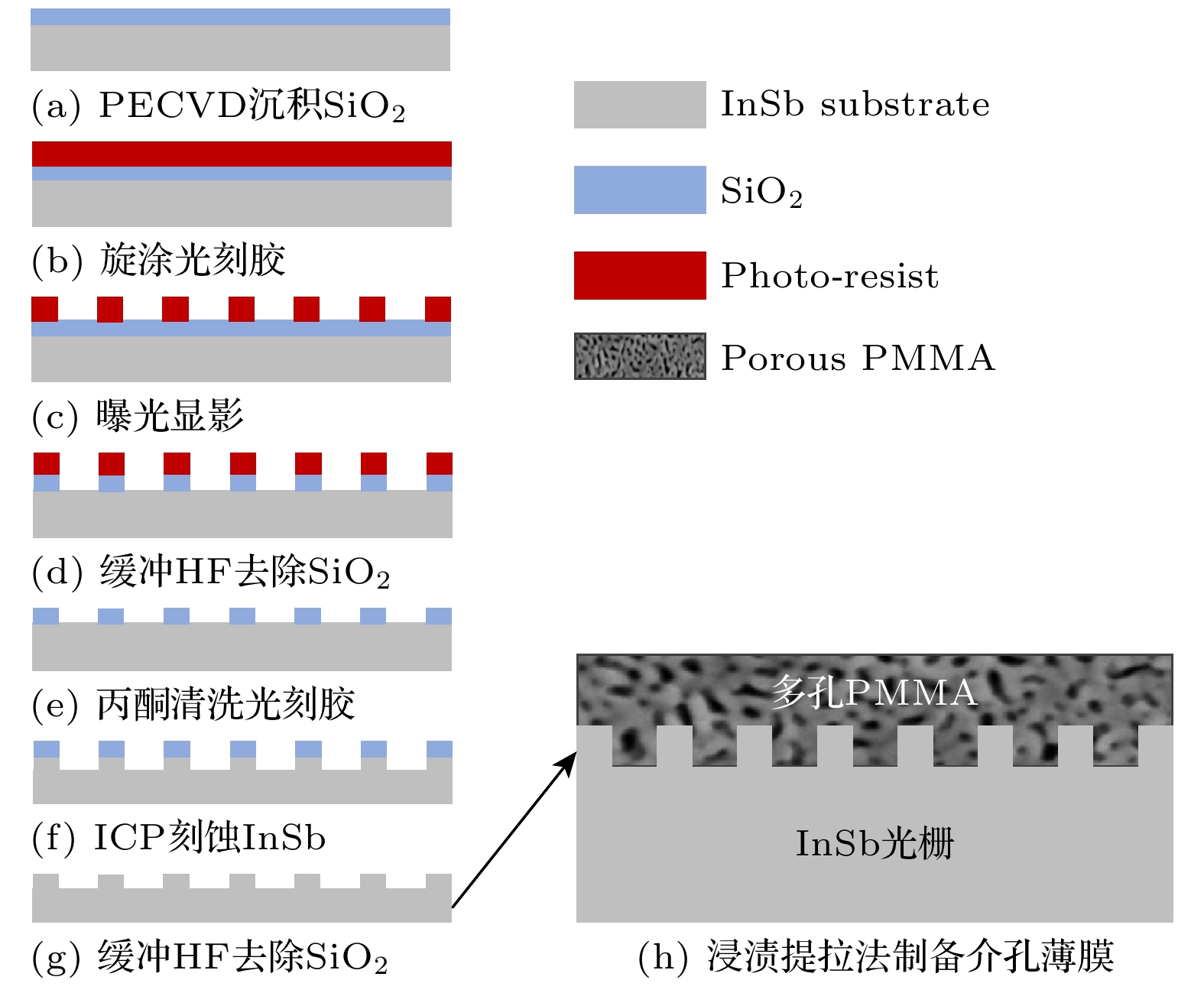

仿真设计了一种光栅耦合型太赫兹(THz)表面等离激元(SPP)共振生化传感结构, 该结构通过在锑化铟(InSb)基底表面刻蚀亚毫米光栅形成. 基于波矢匹配方程的仿真结果表明, 当TM偏振的THz平行波束以30°入射角照射到光栅区间时, 光栅的–1和+1级THz衍射波束能够分别激励传播方向相反的低频SPP和高频SPP. 由于采用商业THz时域谱装置可以准确测量低频SPP, 本文系统地分析了低频SPP的共振和传感特性对光栅结构参数的依赖关系. 仿真结果表明: InSb光栅耦合的THz-SPP共振传感芯片的折射率灵敏度随光栅周期的增大而减小; 当光栅周期为120 μm、入射角为30°时, 折射率灵敏度为1.05 THz/RIU, 在此条件下, 传感芯片不能对生物分子单分子吸附层作出可探测的响应, 究其原因是, 低频SPP的消逝场穿透深度远大于生物分子尺寸, 致使两者相互作用不足. 为了探测生物分子, 仿真分析了多孔薄膜覆盖InSb光栅的增敏方法. 多孔薄膜具有分子富集作用, 能够将THz表面波与生物靶标的相互作用从单分子尺度扩展至整个薄膜厚度, 从而提高传感器的生物检测灵敏度. 以酪氨酸吸附为例的仿真结果表明, 当InSb光栅表面覆盖厚度为120 μm、孔隙率为0.4的多孔聚甲基丙烯酸甲酯(PMMA)薄膜后, 其吸附灵敏度为0.39 THz/单位体积分数.

-

关键词:

- 太赫兹表面等离激元共振 /

- InSb光栅 /

- 生化传感 /

- 多孔材料

A grating-coupled terahertz (THz) surface plasmon polariton (SPP) resonant biochemical sensing structure is designed with simulation, which can be easily prepared by etching a submillimeter grating on the surface of indium antimonide (InSb) substrate. The simulation results based on the phase matching equation show that when the TM-polarized broadband terahertz collimated beam is incident on the InSb grating at a 30° angle, the low-frequency SPP and high-frequency SPP with opposite propagation directions can be simultaneously excited by the –1st and +1st order diffraction beams of the grating, respectively. Since the low-frequency SPP is easy to accurately measure with a commercial THz time-domain spectroscopy devices, the dependence of the resonance characteristics and sensing characteristics of low-frequency SPP on the grating structure parameters is systematically simulated in this paper. The simulation results show that the refractive-index sensitivity of the InSb grating-coupled THz-SPP resonant sensor chip decreases with the increase of the grating period, and is 1.05 THz/RIU at a grating period of 120 μm and an incident angle of 30°. Under these conditions, the sensor chip cannot make a detectable response to the monolayer adsorption of biomolecules, because the evanescent field penetration depth of the low-frequency SPP is much greater than the biomolecular size, resulting in insufficient field-biomolecular interaction at the surface. In order to detect biomolecules, a sensitivity enhancement method based on porous thin films is proposed and analyzed with simulation. The porous films enable not only to enrich biomolecules, but also to extend the interaction between THz-SPP and biomolecules from the molecular size to the entire film thickness, thereby improving the sensitivity of the sensor to biomolecular adsorption. Taking tyrosine adsorption as an example, the simulation results show that when the InSb grating is covered with a porous polymethyl methacrylate (PMMA) film with a thickness of 120 μm and a porosity of 0.4, the sensor sensitivity to tyrosine adsorption is 0.39 THz/unit volume fraction.-

Keywords:

- terahertz surface plasmon resonance /

- InSb grating /

- biochemical sensing /

- porous materials

[1] 张喆, 柳倩, 祁志美 2013 62 060703

Google Scholar

Google Scholar

Zhang Z, Liu Q, Qi Z M 2013 Acta Phys. Sin. 62 060703

Google Scholar

Google Scholar

[2] Zhang C L, Liu Z W, Cai C, Yang Z H, Qi Z M 2022 Opt. Lett. 47 4155

Google Scholar

Google Scholar

[3] Anker J N, Hall W P, Lyandres O, Shah N C, Zhao J, Van Duyne R P 2008 Nat. Mater. 7 442

Google Scholar

Google Scholar

[4] 刘濮鲲, 黄铁军 2020 红外与毫米波学报 39 169

Google Scholar

Google Scholar

Liu P K, Huang T J 2020 J. Infrared Millim. Waves 39 169

Google Scholar

Google Scholar

[5] Pendry J B, Martín-Moreno L, Garcia-Vidal F J 2004 Science 305 847

Google Scholar

Google Scholar

[6] Hibbins A P, Evans B R, Sambles J R 2005 Science 308 670

Google Scholar

Google Scholar

[7] Williams C R, Andrews S R, Maier S A, Fernández-Domínguez A I, Martín-Moreno L, García-Vidal F J 2008 Nat. Photonics 2 175

Google Scholar

Google Scholar

[8] Ng B H, Wu J F, Hanham S M, Fernández-Domínguez A I, Klein N, Liew Y F, Breese M B H, Hong M H, Maier S A 2013 Adv. Opt. Mater. 1 543

Google Scholar

Google Scholar

[9] Ng B H, Hanham S M, Wu J F, Fernández-Domínguez A I, Klein N, Liew Y F, Breese M B H, Hong M H, Maier S A 2014 ACS Photonics 1 1059

Google Scholar

Google Scholar

[10] Shen X P, Cui T J 2014 Laser Photonics Rev. 8 137

Google Scholar

Google Scholar

[11] Chochol J, Postava K, Čada M, Vanwolleghem M, Halagačka L, Lampin J F, Pištora J 2016 AIP Adv. 6 115021

Google Scholar

Google Scholar

[12] Marschall N, Fischer B, Queisser H J 1971 Phy. Rev. Lett. 27 95

Google Scholar

Google Scholar

[13] Cheng B H, Ye Y S, Lan Y C, Tsai D P 2017 Sci. Rep. 7 6443

Google Scholar

Google Scholar

[14] Chochol J, Postava K, Cada M, Pistora J 2017 Sci. Rep. 7 13117

Google Scholar

Google Scholar

[15] Isaac T H, Barnes W L, Hendry E 2008 Appl. Phys. Lett. 93 241115

Google Scholar

Google Scholar

[16] Madelung O 1991 Semiconductors: Group IV Elements and III-V Compounds (Berlin, Heidelberg: Springer) p147

[17] Shibayama J, Shimizu K, Yamauchi J, Nakano H 2016 J. Lightwave Technol. 34 2518

Google Scholar

Google Scholar

[18] Tao H, Chieffo L R, Brenckle M A, Siebert S M, Liu M K, Strikwerda A C, Fan K B, Kaplan D L, Zhang X, Averitt R D, Omenetto F C 2011 Adv. Mater. 23 3197

Google Scholar

Google Scholar

[19] Wang Y, Cui Z J, Zhu D Y, Wang X M, Chen S G, Nie P C 2019 Opt. Express 27 14133

Google Scholar

Google Scholar

[20] Nie P C, Zhu D Y, Cui Z J, Qu F F, Lin L, Wang Y 2020 Sens. Actuator B-Chem. 307 127642

Google Scholar

Google Scholar

[21] 向星诚, 马海贝, 王磊, 田达, 张伟, 张彩虹, 吴敬波, 范克斌, 金飚兵, 陈健, 吴培亨 2023 72 128701

Google Scholar

Google Scholar

Xiang X, Ma H, Wang L, Tian D, Zhang W, Zhang C, Wu J, Fan K, Jin B, Chen J, Wu P 2023 Acta Phys. Sin. 72 128701

Google Scholar

Google Scholar

[22] 岳伟伟, 王卫宁, 赵国忠, 张存林, 闫海涛 2005 54 3094

Google Scholar

Google Scholar

Yue W W, Wang W N, Zhao G Z, Zhang C L, Yan H T 2005 Acta Phys. Sin. 54 3094

Google Scholar

Google Scholar

[23] 王国阳, 白志晨, 王佳慧, 苏波, 张存林 2021 光谱学与光谱分析 41 1678

Google Scholar

Google Scholar

Wang G Y, Bai Z C, Wang J H, Su B, Zhang C L 2021 Spectrosc. Spectral Anal. 41 1678

Google Scholar

Google Scholar

-

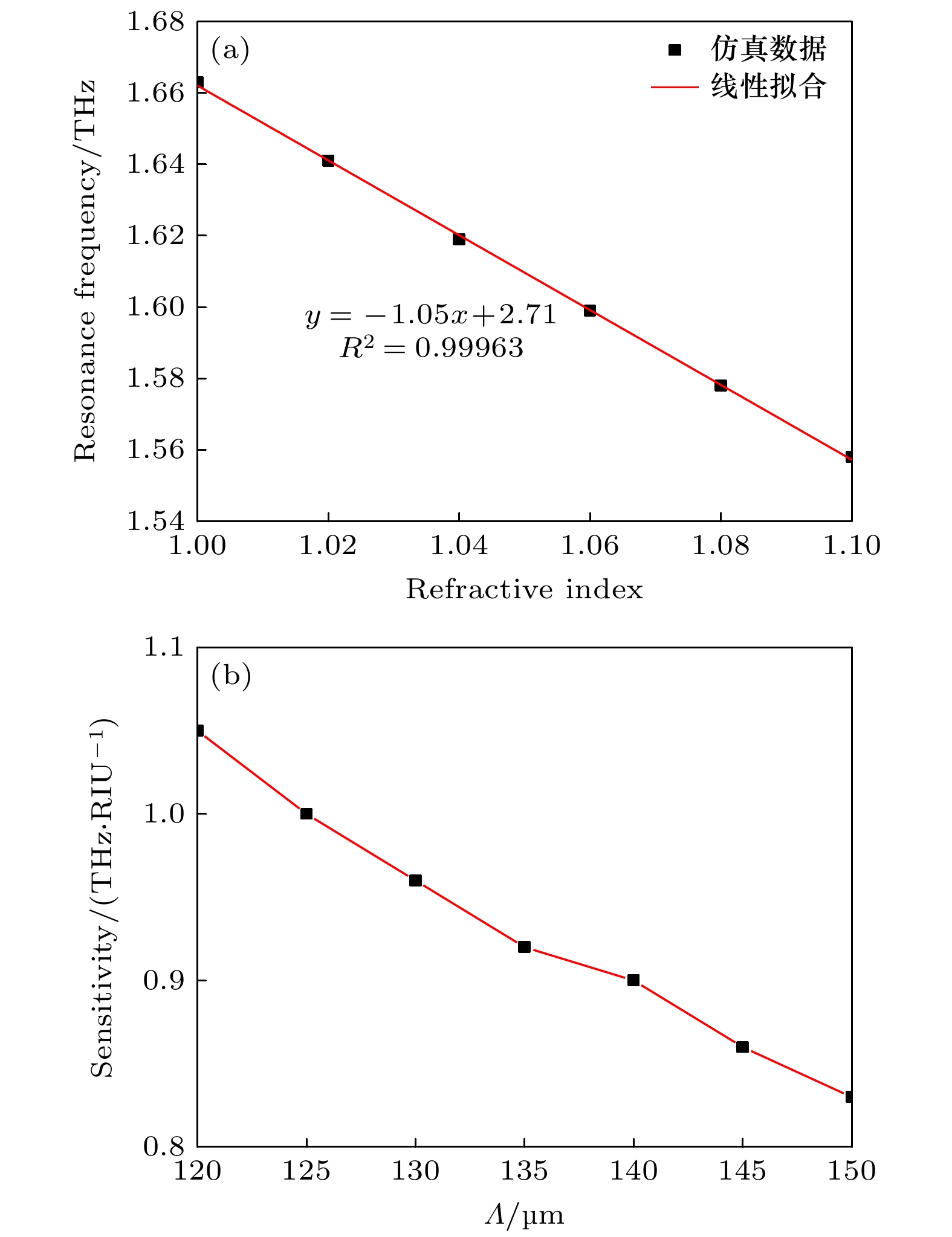

图 6 (a) 光栅周期为120 μm时共振频率随介质折射率的变化, 及线性拟合得到的折射率灵敏度; (b) 折射率灵敏度随光栅周期的变化

Fig. 6. 6. (a) Resonance frequency variation curve with medium refractive index when the grating period is 120 μm, and the refractive index sensitivity obtained by linear fitting; (b) variation curve of refractive index sensitivity with grating period.

图 10 在厚度h = 25 μm情况下的仿真结果 (a) 折射率灵敏度随多孔PMMA孔隙率P的变化; (b) 介质层平均电场模随多孔PMMA孔隙率P的变化; (c) 不同孔隙率下的场分布示意图; (d) 不同孔隙率下介质层与多孔PMMA层界面处的电场强度; 其中图(b), (c), (d)均为介质层折射率$ {n}_{{\mathrm{d}}}=1 $的结果

Fig. 10. Simulation results in the case of h = 25 μm: (a) Variation curve of refractive index sensitivity with porosity P of porous PMMA; (b) variation curve of average electric field mode of dielectric layer with porosity P of porous PMMA; (c) schematic diagram of field distribution under different porosity; (d) the electric field intensity curve at the interface between the dielectric layer and the porous PMMA layer under different porosity. Note: panels (b), (c), (d) are the results under the condition that the refractive index of the dielectric layer $ {n}_{{\mathrm{d}}}=1 $.

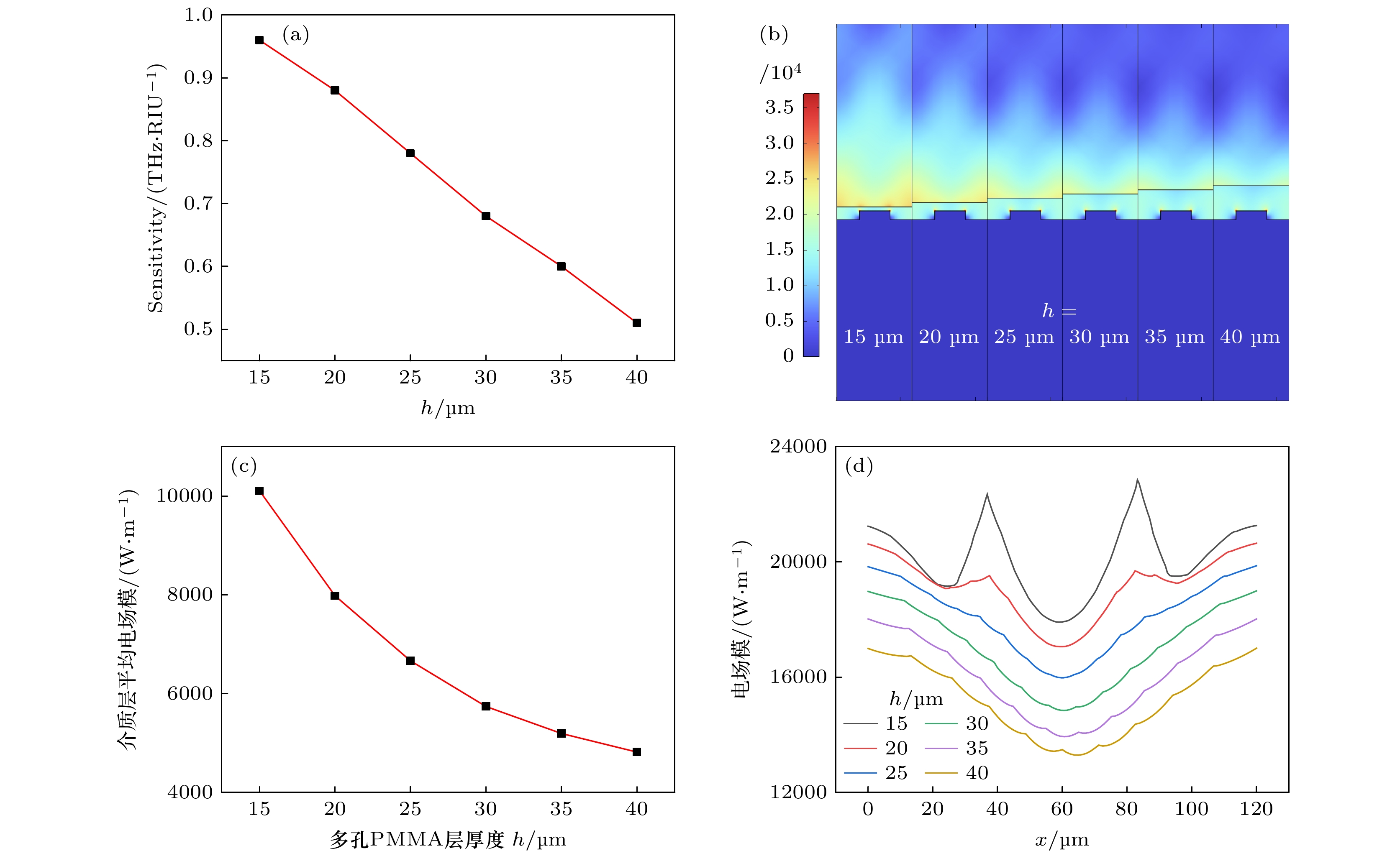

图 11 在孔隙率P = 0.4情况下的仿真结果 (a) 折射率灵敏度随多孔PMMA厚度h的变化; (b) 介质层平均电场模随多孔PMMA厚度h的变化; (c) 不同厚度下的场分布示意图; (d) 不同厚度下介质层与多孔PMMA层界面处的电场强度曲线; 其中图(b), (c), (d)均为介质层折射率$ {n}_{{\mathrm{d}}}=1 $的结果

Fig. 11. Simulation results in the case of P = 0.4: (a) Variation curve of refractive index sensitivity with porous PMMA thickness h; (b) variation curve of average electric field mode of dielectric layer with thickness h of porous PMMA; (c) schematic diagram of field distribution under different thickness; (d) the electric field intensity curves at the interface between the dielectric layer and the porous PMMA layer under different thickness. Note: panels (b), (c), (d) are the results of the refractive index of the dielectric layer $ {n}_{{\mathrm{d}}}=1 $.

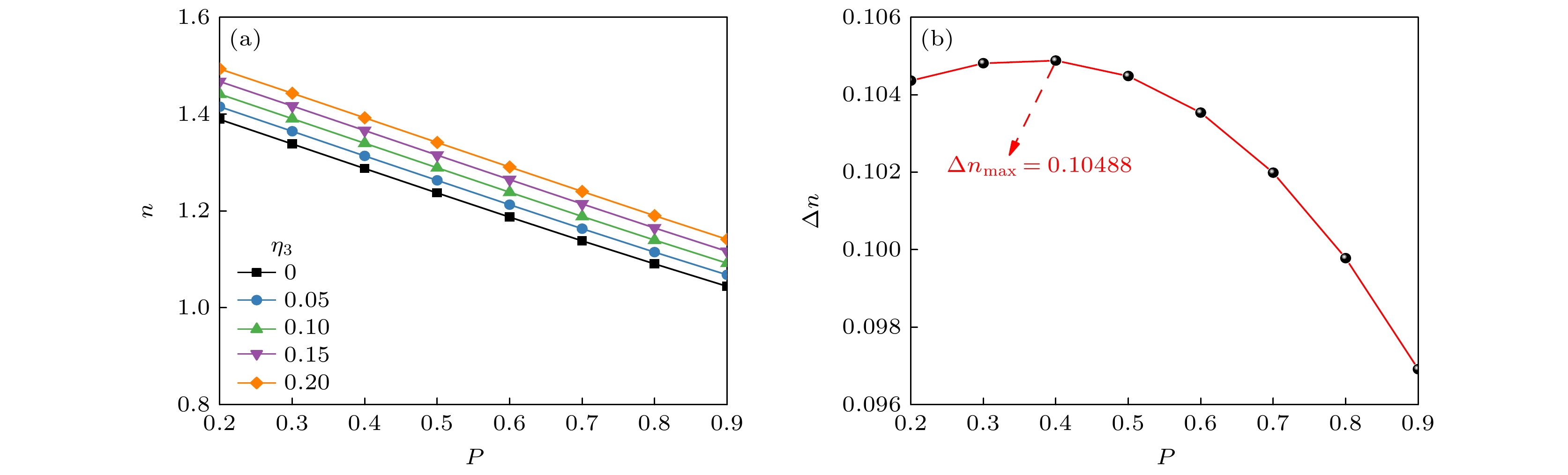

图 12 (a) 不同孔隙率下多孔PMMA吸附酪氨酸体积分数$ {\eta }_{3}= $0, 0.05, 0.10, 0.15, 0.20时的等效折射率n; (b) $ {\eta }_{3} $由0变为0.2时, 不同孔隙率多孔PMMA的等效折射率变化量$ \Delta n $

Fig. 12. (a) Equivalent refractive index n when the volume fraction of tyrosine adsorbed by porous PMMA $ {\eta }_{3} $ is 0, 0.05, 0.10, 0.15 and 0.20 under different porosity; (b) the change of equivalent refractive index $ \Delta n $ of porous PMMA with different porosity when $ {\eta }_{3} $ changing from 0 to 0.2.

图 13 在孔隙率P = 0.4条件下的仿真结果 (a) 覆盖厚度为40 μm的多孔PMMA, 传感器吸附不同体积分数酪氨酸的反射光谱; (b) 覆盖厚度为40 μm的多孔PMMA, 传感器吸附不同体积分数酪氨酸的共振频率变化曲线, 及线性拟合得到的吸附灵敏度; (c) 覆盖厚度为120 μm的多孔PMMA, 传感器吸附不同体积分数酪氨酸的反射光谱; (d) 覆盖20—240 μm厚度的多孔PMMA, 传感器吸附灵敏度变化曲线

Fig. 13. Simulation results in the case of porosity P = 0.4: (a) The reflection spectra of the sensor after adsorption of tyrosine with different volume fractions when the thickness of the covered porous PMMA is 40 μm; (b) the resonance frequency curve of the sensor after adsorption of tyrosine with different volume fractions and the adsorption sensitivity obtained by linear fitting when the thickness of the covered porous PMMA is 40 μm; (c) the reflection spectra of the sensor after adsorption of tyrosine with different volume fractions when the thickness of the covered porous PMMA is 40 μm; (d) variation curves of sensor adsorption sensitivity when the thickness of covered porous PMMA is 20–240 μm.

-

[1] 张喆, 柳倩, 祁志美 2013 62 060703

Google Scholar

Google Scholar

Zhang Z, Liu Q, Qi Z M 2013 Acta Phys. Sin. 62 060703

Google Scholar

Google Scholar

[2] Zhang C L, Liu Z W, Cai C, Yang Z H, Qi Z M 2022 Opt. Lett. 47 4155

Google Scholar

Google Scholar

[3] Anker J N, Hall W P, Lyandres O, Shah N C, Zhao J, Van Duyne R P 2008 Nat. Mater. 7 442

Google Scholar

Google Scholar

[4] 刘濮鲲, 黄铁军 2020 红外与毫米波学报 39 169

Google Scholar

Google Scholar

Liu P K, Huang T J 2020 J. Infrared Millim. Waves 39 169

Google Scholar

Google Scholar

[5] Pendry J B, Martín-Moreno L, Garcia-Vidal F J 2004 Science 305 847

Google Scholar

Google Scholar

[6] Hibbins A P, Evans B R, Sambles J R 2005 Science 308 670

Google Scholar

Google Scholar

[7] Williams C R, Andrews S R, Maier S A, Fernández-Domínguez A I, Martín-Moreno L, García-Vidal F J 2008 Nat. Photonics 2 175

Google Scholar

Google Scholar

[8] Ng B H, Wu J F, Hanham S M, Fernández-Domínguez A I, Klein N, Liew Y F, Breese M B H, Hong M H, Maier S A 2013 Adv. Opt. Mater. 1 543

Google Scholar

Google Scholar

[9] Ng B H, Hanham S M, Wu J F, Fernández-Domínguez A I, Klein N, Liew Y F, Breese M B H, Hong M H, Maier S A 2014 ACS Photonics 1 1059

Google Scholar

Google Scholar

[10] Shen X P, Cui T J 2014 Laser Photonics Rev. 8 137

Google Scholar

Google Scholar

[11] Chochol J, Postava K, Čada M, Vanwolleghem M, Halagačka L, Lampin J F, Pištora J 2016 AIP Adv. 6 115021

Google Scholar

Google Scholar

[12] Marschall N, Fischer B, Queisser H J 1971 Phy. Rev. Lett. 27 95

Google Scholar

Google Scholar

[13] Cheng B H, Ye Y S, Lan Y C, Tsai D P 2017 Sci. Rep. 7 6443

Google Scholar

Google Scholar

[14] Chochol J, Postava K, Cada M, Pistora J 2017 Sci. Rep. 7 13117

Google Scholar

Google Scholar

[15] Isaac T H, Barnes W L, Hendry E 2008 Appl. Phys. Lett. 93 241115

Google Scholar

Google Scholar

[16] Madelung O 1991 Semiconductors: Group IV Elements and III-V Compounds (Berlin, Heidelberg: Springer) p147

[17] Shibayama J, Shimizu K, Yamauchi J, Nakano H 2016 J. Lightwave Technol. 34 2518

Google Scholar

Google Scholar

[18] Tao H, Chieffo L R, Brenckle M A, Siebert S M, Liu M K, Strikwerda A C, Fan K B, Kaplan D L, Zhang X, Averitt R D, Omenetto F C 2011 Adv. Mater. 23 3197

Google Scholar

Google Scholar

[19] Wang Y, Cui Z J, Zhu D Y, Wang X M, Chen S G, Nie P C 2019 Opt. Express 27 14133

Google Scholar

Google Scholar

[20] Nie P C, Zhu D Y, Cui Z J, Qu F F, Lin L, Wang Y 2020 Sens. Actuator B-Chem. 307 127642

Google Scholar

Google Scholar

[21] 向星诚, 马海贝, 王磊, 田达, 张伟, 张彩虹, 吴敬波, 范克斌, 金飚兵, 陈健, 吴培亨 2023 72 128701

Google Scholar

Google Scholar

Xiang X, Ma H, Wang L, Tian D, Zhang W, Zhang C, Wu J, Fan K, Jin B, Chen J, Wu P 2023 Acta Phys. Sin. 72 128701

Google Scholar

Google Scholar

[22] 岳伟伟, 王卫宁, 赵国忠, 张存林, 闫海涛 2005 54 3094

Google Scholar

Google Scholar

Yue W W, Wang W N, Zhao G Z, Zhang C L, Yan H T 2005 Acta Phys. Sin. 54 3094

Google Scholar

Google Scholar

[23] 王国阳, 白志晨, 王佳慧, 苏波, 张存林 2021 光谱学与光谱分析 41 1678

Google Scholar

Google Scholar

Wang G Y, Bai Z C, Wang J H, Su B, Zhang C L 2021 Spectrosc. Spectral Anal. 41 1678

Google Scholar

Google Scholar

计量

- 文章访问数: 4036

- PDF下载量: 75

- 被引次数: 0

下载:

下载: