-

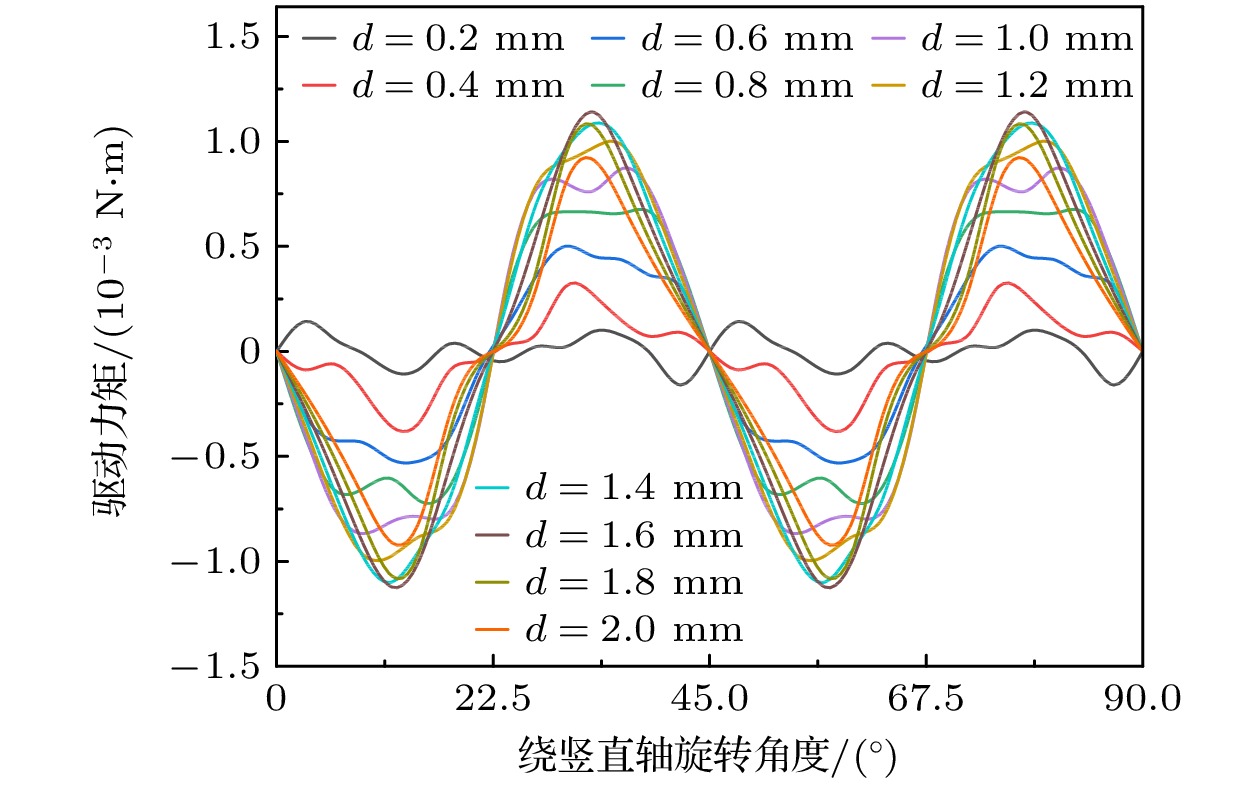

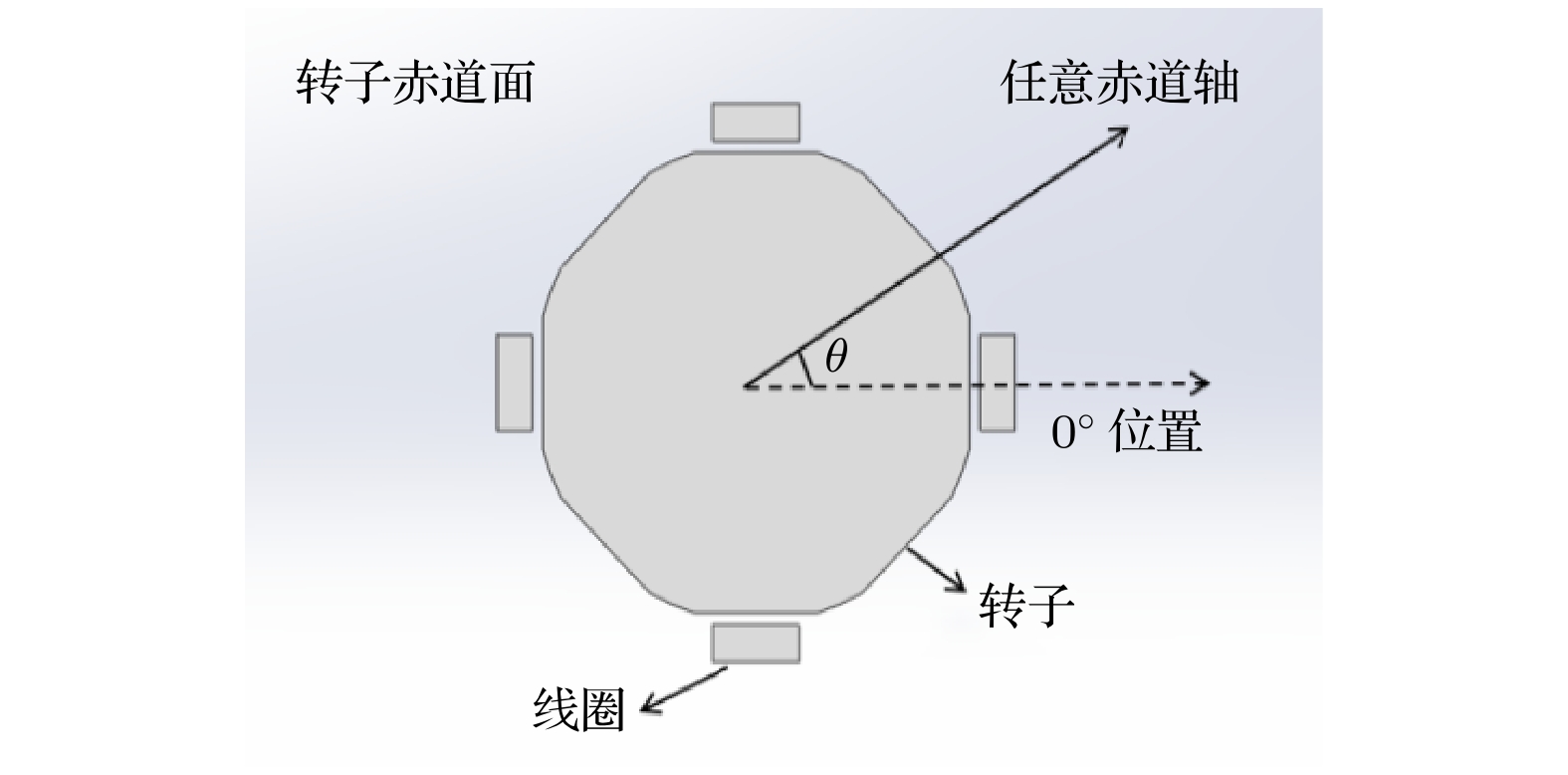

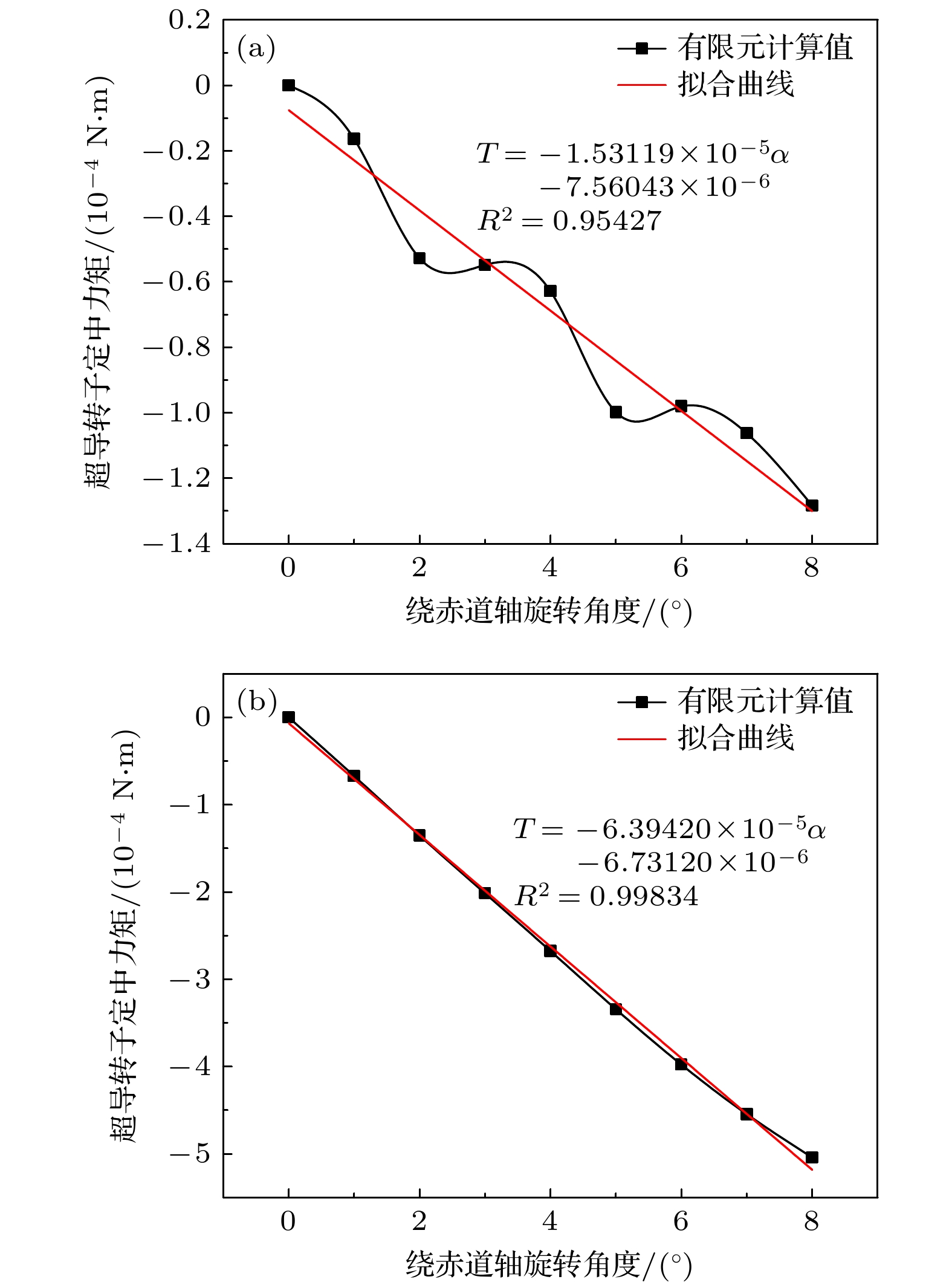

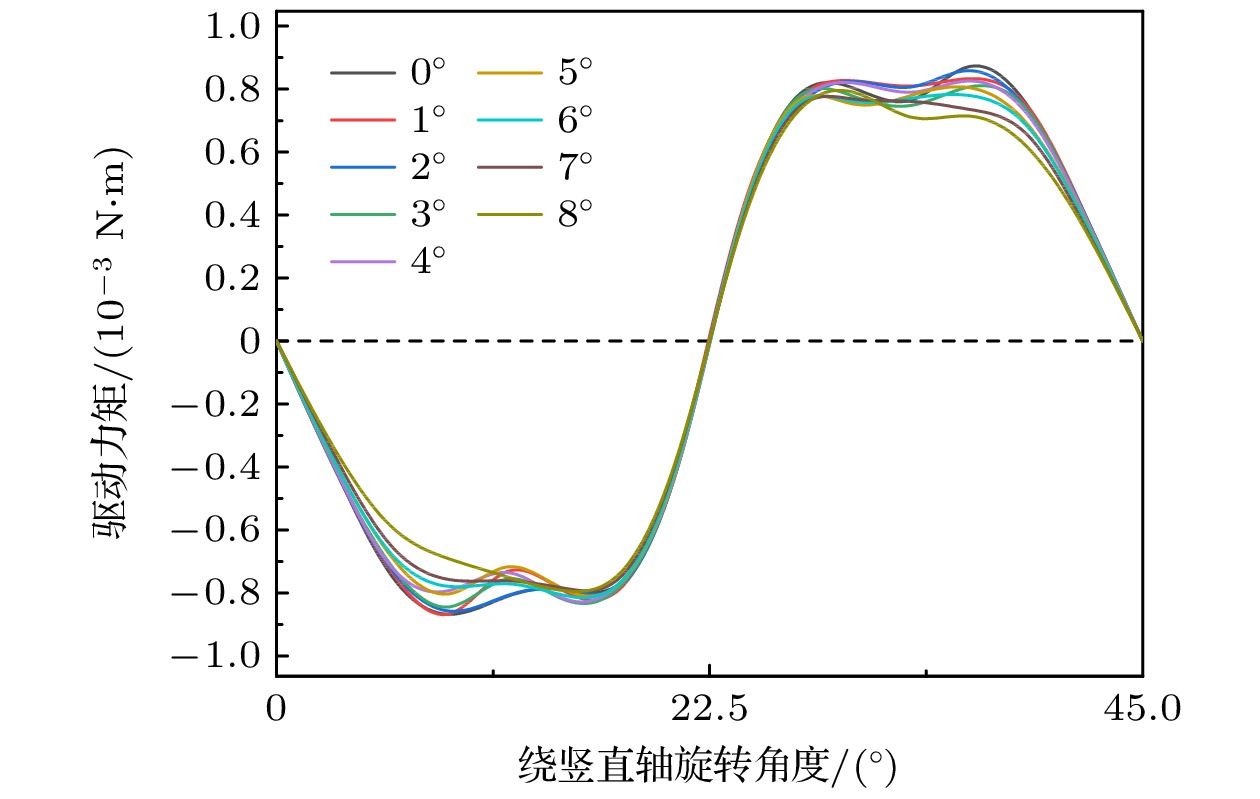

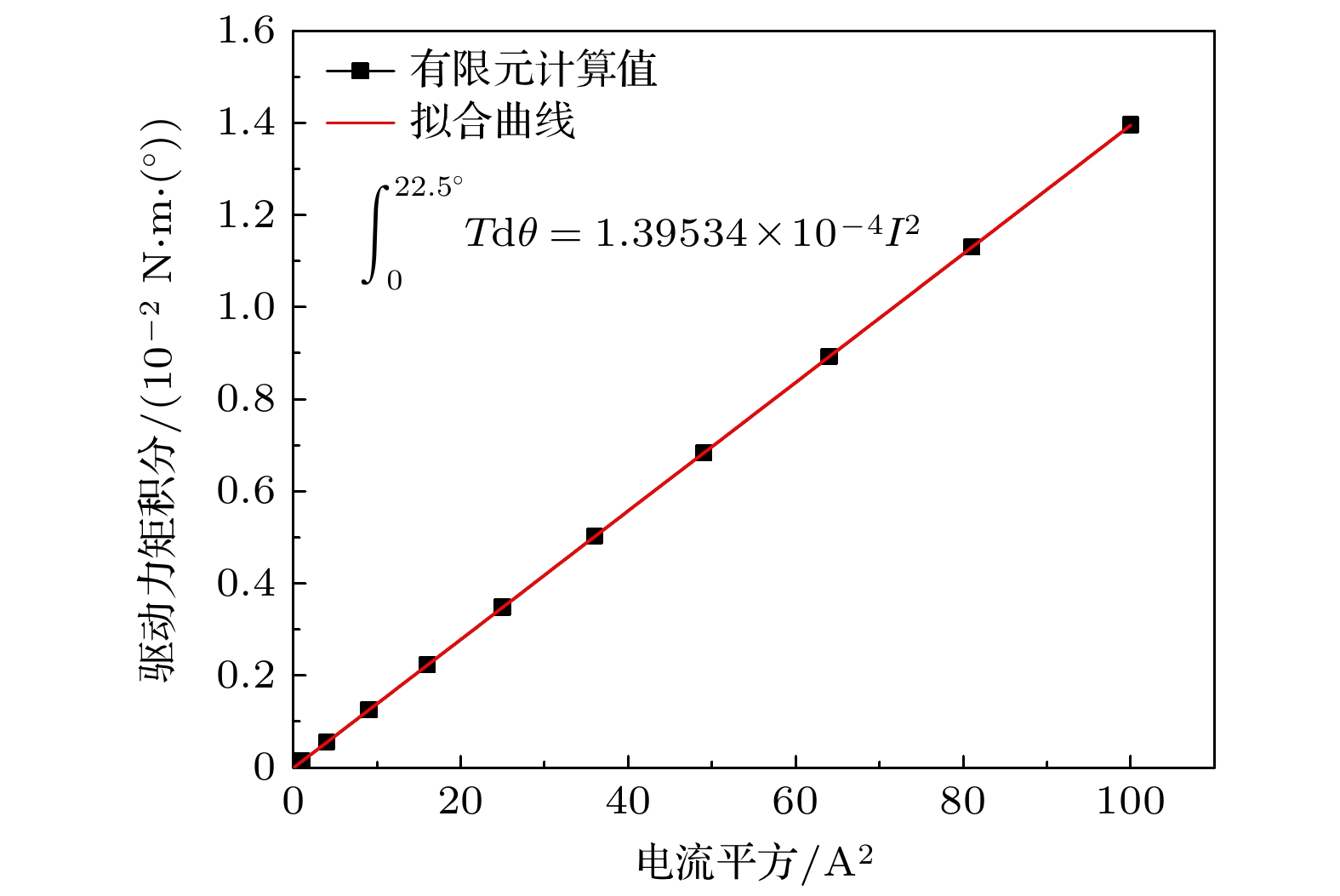

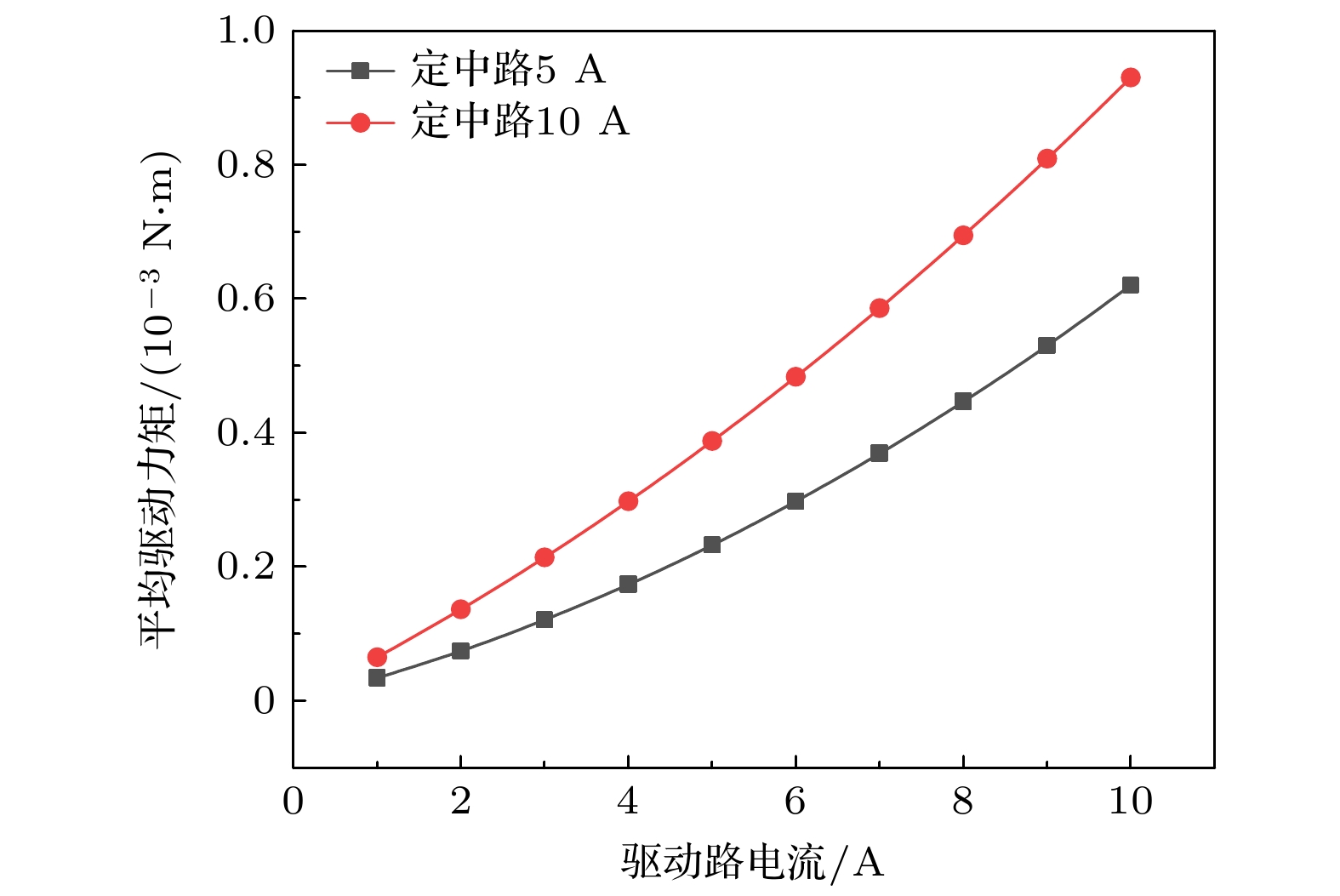

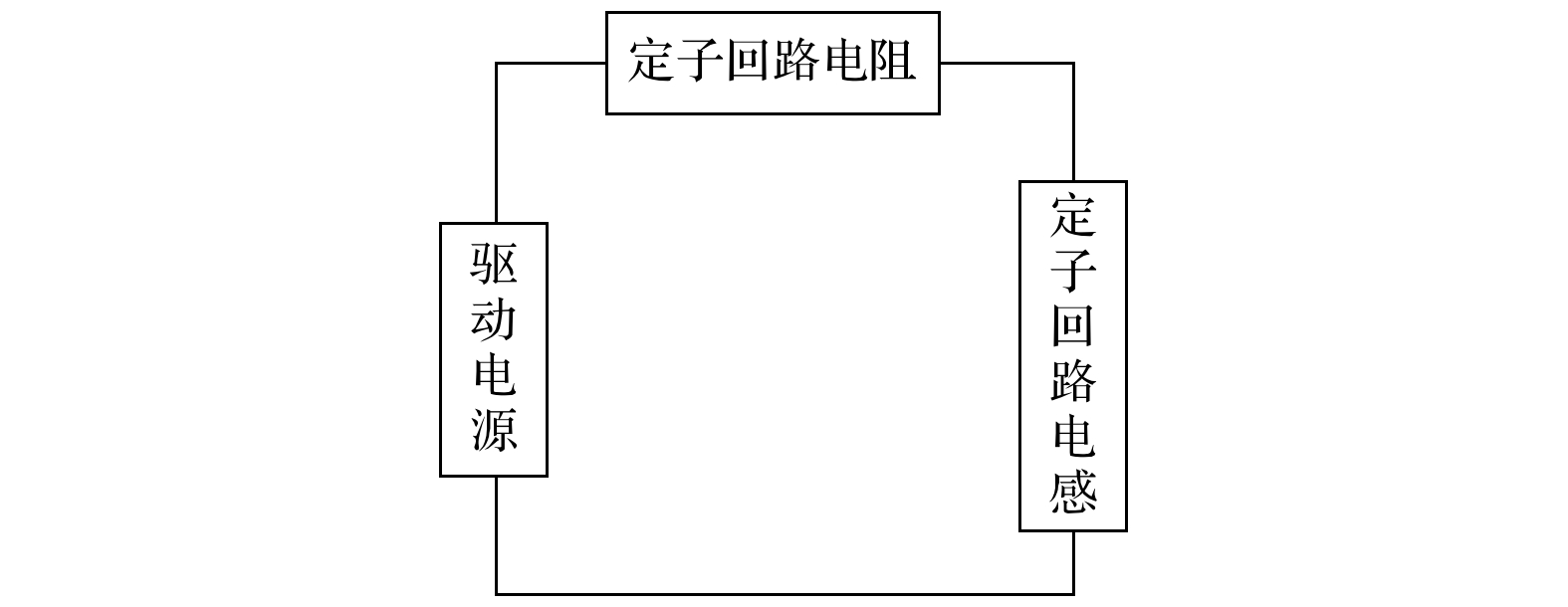

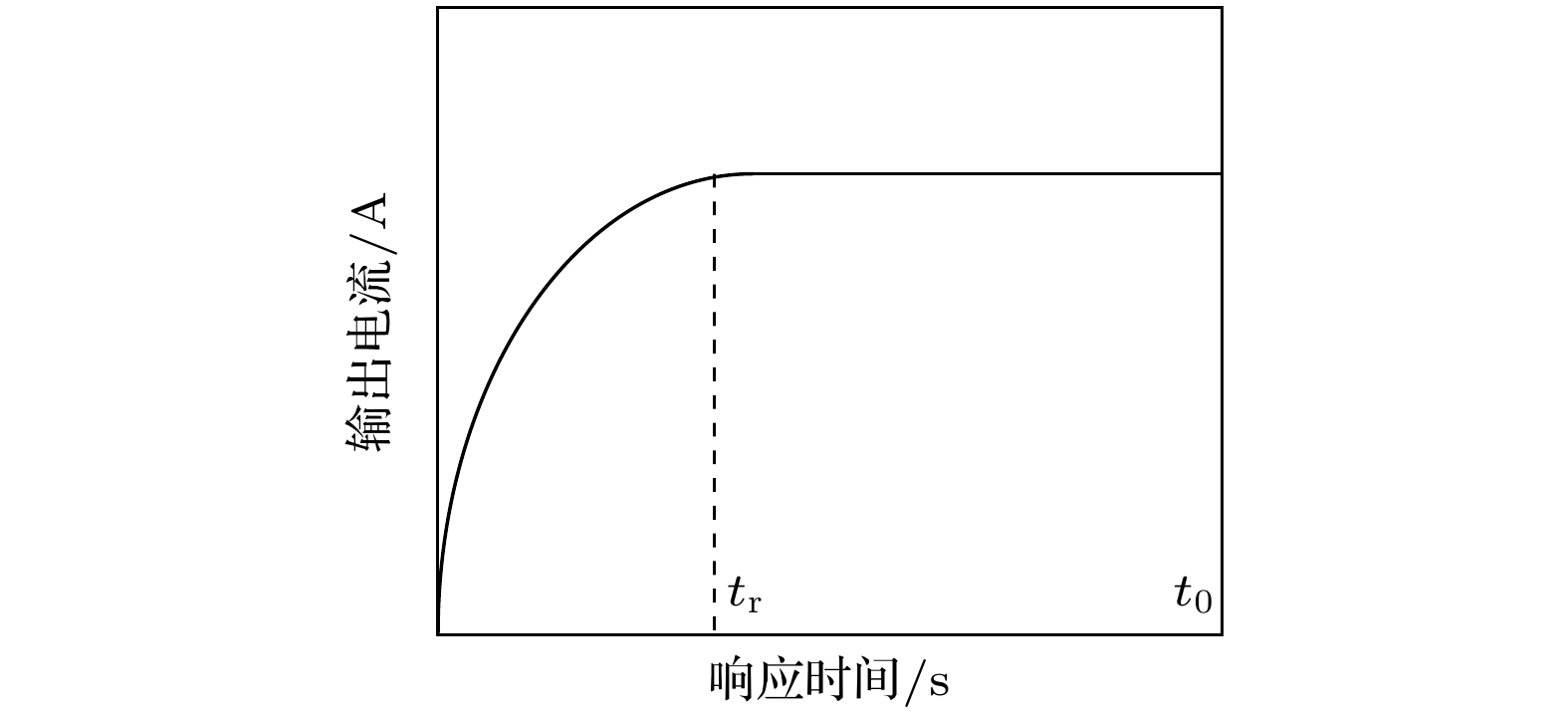

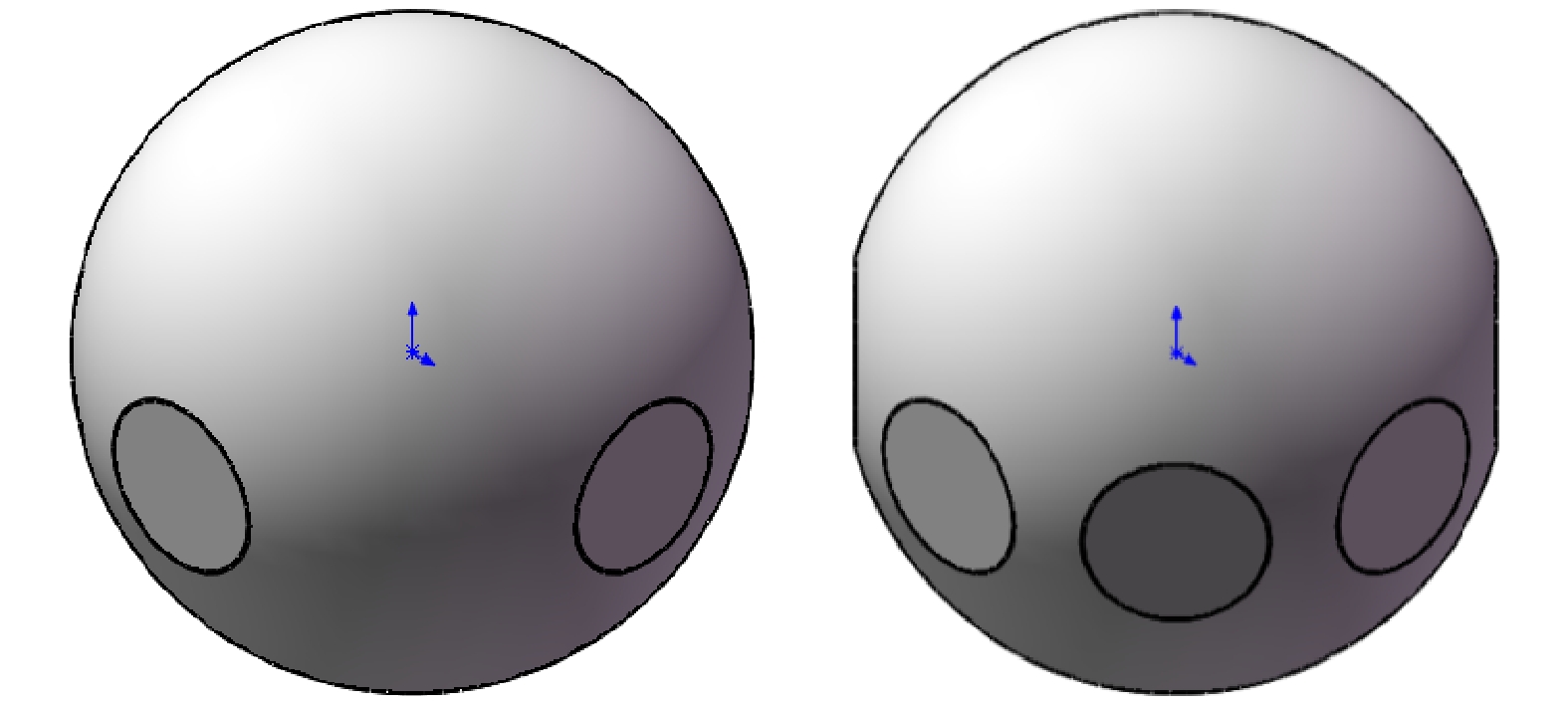

高速旋转的超导转子可制作高精度惯性器件, 对载体的角位置或角速度进行测量, 超导转子的质量偏心和球面误差是影响测量精度的主要误差源. 超导转子结构越复杂, 其制作和装配过程造成的质量偏心和球面误差就越大, 则其测量角速度的精度越低. 基于此, 本文设计了一种结构简单的超导转子驱动电磁结构, 并通过有限元方法研究了定子对超导转子产生的转矩, 分析了定子对超导转子的定中和加转效果. 基于对超导转子转矩的研究结果, 提出了一种定中和驱动一体化的超导转子驱动方法, 即通过定子线圈同时实现定中和驱动功能, 并设计了对应的定子控制时序. 最后分析了所提驱动方法驱动过程的力矩分布, 并结合定子系统的响应特性对驱动效果进行了定量分析, 计算了不同条件下超导转子加速到50 Hz需要的时间. 结果表明, 所设计的驱动电磁结构及提出的定中驱动一体化的驱动方法可以对超导转子定中和驱动, 研究结果为进一步优化超导转子结构, 及超导转子的驱动方法提供参考.The high-speed rotating superconducting rotor can be used as a high-precision inertial device to measure the angular position or angular velocity of the carrier. The mass eccentricity and spherical error of the superconducting rotor are the main error sources that affect the measurement accuracy. The more complex the structure of the superconducting rotor, the greater the mass eccentricity and spherical error caused by its production and assembly process are, and the lower the accuracy of its measurement of angular velocity. Based on this, in this work, an electromagnetic drive structure with a simple rotor structure is designed. And the torque generated by the stator on the superconducting rotor is studied through finite element method (FEM). The effects of the stator on vertical alignment and acceleration of the superconducting rotor are analyzed. Based on the research results of the superconducting rotor torque, a superconducting rotor drive method with integrated driving and vertical alignment is proposed, which achieves the driving and vertical alignment functions simultaneously through the stator coil, and corresponding stator control timing is designed. Finally, the torque distribution in the driving process of the proposed driving method is analyzed, and the driving effect is quantitatively analyzed based on the response characteristics of the stator system. The time for the superconducting rotor to be accelerated to 50 Hz under different conditions is calculated. The results show that the designed driving electromagnetic structure and the proposed integrated driving method of vertical alignment and driving can be used for vertical aligning and driving the superconducting rotor. The research results provide a reference for further optimizing the superconducting rotor structure and driving methods of superconducting rotors.

-

Keywords:

- superconducting rotor /

- Meissner effect /

- integrated driving and alignment /

- electromagnetic drive

[1] 汤继强, 赵琳, 罗俊艳 2004 弹箭与制导学报 24 136

Google Scholar

Google Scholar

Tang J Q, Zhao L, Luo J Y 2004 J. Projectiles Rockets Missiles Guidance 24 136

Google Scholar

Google Scholar

[2] 胡新宁, 赵尚武, 王厚生, 王晖, 王秋良 2008 稀有金属材料与工程 37 436

Google Scholar

Google Scholar

Hu X N, Zhao S W, Wang H S, Wang H, Wang Q L 2008 Rare Met. Mater. Eng. 37 436

Google Scholar

Google Scholar

[3] 胡新宁, 王厚生, 王晖, 王秋良 2010 光学精密工程 18 169

Hu X N, Wang H S, Wang H, Wang Q L 2010 Opt. Precis. Eng. 18 169

[4] 江磊, 钟智勇, 仪德英, 张怀武 2014 仪器仪表学报 29 1115

Google Scholar

Google Scholar

Jiang L, Zhong Z Y, Yi D Y, Zhang H W 2014 Chin. J. Sci. Instrum. 29 1115

Google Scholar

Google Scholar

[5] 韩玉龙, 向楠 2017 高新技术企业 05 16

Google Scholar

Google Scholar

Han Y L, Xiang N 2017 Chin. High-Tech Enterprise 05 16

Google Scholar

Google Scholar

[6] 崔春艳, 胡新宁, 程军胜, 王晖, 王秋良 2014 64 018403

Google Scholar

Google Scholar

Cui C Y, Hu X N, Chen J S, Wang H, Wang Q L 2014 Acta Phys. Sin. 64 018403

Google Scholar

Google Scholar

[7] Hu X N, Wang Q L, Cui C Y 2010 IEEE Trans. Appl. Supercond. 20 892

Google Scholar

Google Scholar

[8] Wang H, Hu X N, Cui C Y, Wang L, Wang Q L 2018 IEEE Trans. Appl. Supercond. 28 5207905

Google Scholar

Google Scholar

[9] Schoch K F, Darrel B 1967 Proceedings of the 1966 Cryogenic Engineering Conference Colorado, America, 1967 June 13–15, p657

[10] 汤继强 2005 博士学位论文(哈尔滨: 哈尔滨工程大学)

Tang J Q 2005 Ph. D. Dissertation (Harbin: Harbin Engineering University

[11] Harding T H, Lawson D W 1968 AIAA J. 6 305

Google Scholar

Google Scholar

[12] Schoch K F, Darrel B 1967 Adv. Cryog. Eng. 12 657

[13] Hu X N, Cui C Y, Wang H, Liu J H, Wang H S, Wang H, Dai Y M, Li Y, Cheng J S, Li L K, Feng Z K, Yan L G 2015 IEEE Trans. Appl. Supercond. 25 5201705

Google Scholar

Google Scholar

[14] Cui C Y, Li L K, Hu X N, Wang H, Wang Q L 2015 Proceedings of 2015 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices, Shanghai, November 20–23, 2015 p439

[15] Shang M X, Dai Y M, Wang Q L, Yu Y J, Zhao B Z, Kim K, Oh S 2006 IEEE Trans. Appl. Supercond. 16 1481

Google Scholar

Google Scholar

[16] Hu X N, Wang Q L, Wang H S, Cui C Y, Liu J H 2012 IEEE Trans. Appl. Supercond. 22 3600904

Google Scholar

Google Scholar

[17] Buchhold T A 1961 Cryogenics 1 203

Google Scholar

Google Scholar

[18] 赵尚武, 胡新宁, 崔春燕, 王秋良 2008 稀有金属材料与工程 37 217

Google Scholar

Google Scholar

Zhao S W, Hu X N, Cui C Y, Wang Q L 2008 Rare Met. Mater. Eng. 37 217

Google Scholar

Google Scholar

[19] 刘延柱 1979 静电陀螺仪动力学(北京: 清华大学出版社)第21—23页)

Liu Y Z 1979 Electrostatic Gyroscope Dynamics (Beijing: Tsinghua University Press) pp21–23

[20] Cui C Y, Wang Q L, Zhao S W, Hu X N 2010 IEEE Trans. Appl. Supercond. 20 1763

Google Scholar

Google Scholar

[21] 王生春, 张兢 2001 电路原理 (重庆: 重庆大学出版社) 第109—124页

Wang S C, Zhang J 2001 Circuit Principle (Chongqing: Chongqing University Press) pp109–124

-

-

[1] 汤继强, 赵琳, 罗俊艳 2004 弹箭与制导学报 24 136

Google Scholar

Google Scholar

Tang J Q, Zhao L, Luo J Y 2004 J. Projectiles Rockets Missiles Guidance 24 136

Google Scholar

Google Scholar

[2] 胡新宁, 赵尚武, 王厚生, 王晖, 王秋良 2008 稀有金属材料与工程 37 436

Google Scholar

Google Scholar

Hu X N, Zhao S W, Wang H S, Wang H, Wang Q L 2008 Rare Met. Mater. Eng. 37 436

Google Scholar

Google Scholar

[3] 胡新宁, 王厚生, 王晖, 王秋良 2010 光学精密工程 18 169

Hu X N, Wang H S, Wang H, Wang Q L 2010 Opt. Precis. Eng. 18 169

[4] 江磊, 钟智勇, 仪德英, 张怀武 2014 仪器仪表学报 29 1115

Google Scholar

Google Scholar

Jiang L, Zhong Z Y, Yi D Y, Zhang H W 2014 Chin. J. Sci. Instrum. 29 1115

Google Scholar

Google Scholar

[5] 韩玉龙, 向楠 2017 高新技术企业 05 16

Google Scholar

Google Scholar

Han Y L, Xiang N 2017 Chin. High-Tech Enterprise 05 16

Google Scholar

Google Scholar

[6] 崔春艳, 胡新宁, 程军胜, 王晖, 王秋良 2014 64 018403

Google Scholar

Google Scholar

Cui C Y, Hu X N, Chen J S, Wang H, Wang Q L 2014 Acta Phys. Sin. 64 018403

Google Scholar

Google Scholar

[7] Hu X N, Wang Q L, Cui C Y 2010 IEEE Trans. Appl. Supercond. 20 892

Google Scholar

Google Scholar

[8] Wang H, Hu X N, Cui C Y, Wang L, Wang Q L 2018 IEEE Trans. Appl. Supercond. 28 5207905

Google Scholar

Google Scholar

[9] Schoch K F, Darrel B 1967 Proceedings of the 1966 Cryogenic Engineering Conference Colorado, America, 1967 June 13–15, p657

[10] 汤继强 2005 博士学位论文(哈尔滨: 哈尔滨工程大学)

Tang J Q 2005 Ph. D. Dissertation (Harbin: Harbin Engineering University

[11] Harding T H, Lawson D W 1968 AIAA J. 6 305

Google Scholar

Google Scholar

[12] Schoch K F, Darrel B 1967 Adv. Cryog. Eng. 12 657

[13] Hu X N, Cui C Y, Wang H, Liu J H, Wang H S, Wang H, Dai Y M, Li Y, Cheng J S, Li L K, Feng Z K, Yan L G 2015 IEEE Trans. Appl. Supercond. 25 5201705

Google Scholar

Google Scholar

[14] Cui C Y, Li L K, Hu X N, Wang H, Wang Q L 2015 Proceedings of 2015 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices, Shanghai, November 20–23, 2015 p439

[15] Shang M X, Dai Y M, Wang Q L, Yu Y J, Zhao B Z, Kim K, Oh S 2006 IEEE Trans. Appl. Supercond. 16 1481

Google Scholar

Google Scholar

[16] Hu X N, Wang Q L, Wang H S, Cui C Y, Liu J H 2012 IEEE Trans. Appl. Supercond. 22 3600904

Google Scholar

Google Scholar

[17] Buchhold T A 1961 Cryogenics 1 203

Google Scholar

Google Scholar

[18] 赵尚武, 胡新宁, 崔春燕, 王秋良 2008 稀有金属材料与工程 37 217

Google Scholar

Google Scholar

Zhao S W, Hu X N, Cui C Y, Wang Q L 2008 Rare Met. Mater. Eng. 37 217

Google Scholar

Google Scholar

[19] 刘延柱 1979 静电陀螺仪动力学(北京: 清华大学出版社)第21—23页)

Liu Y Z 1979 Electrostatic Gyroscope Dynamics (Beijing: Tsinghua University Press) pp21–23

[20] Cui C Y, Wang Q L, Zhao S W, Hu X N 2010 IEEE Trans. Appl. Supercond. 20 1763

Google Scholar

Google Scholar

[21] 王生春, 张兢 2001 电路原理 (重庆: 重庆大学出版社) 第109—124页

Wang S C, Zhang J 2001 Circuit Principle (Chongqing: Chongqing University Press) pp109–124

计量

- 文章访问数: 3404

- PDF下载量: 63

- 被引次数: 0

下载:

下载: