-

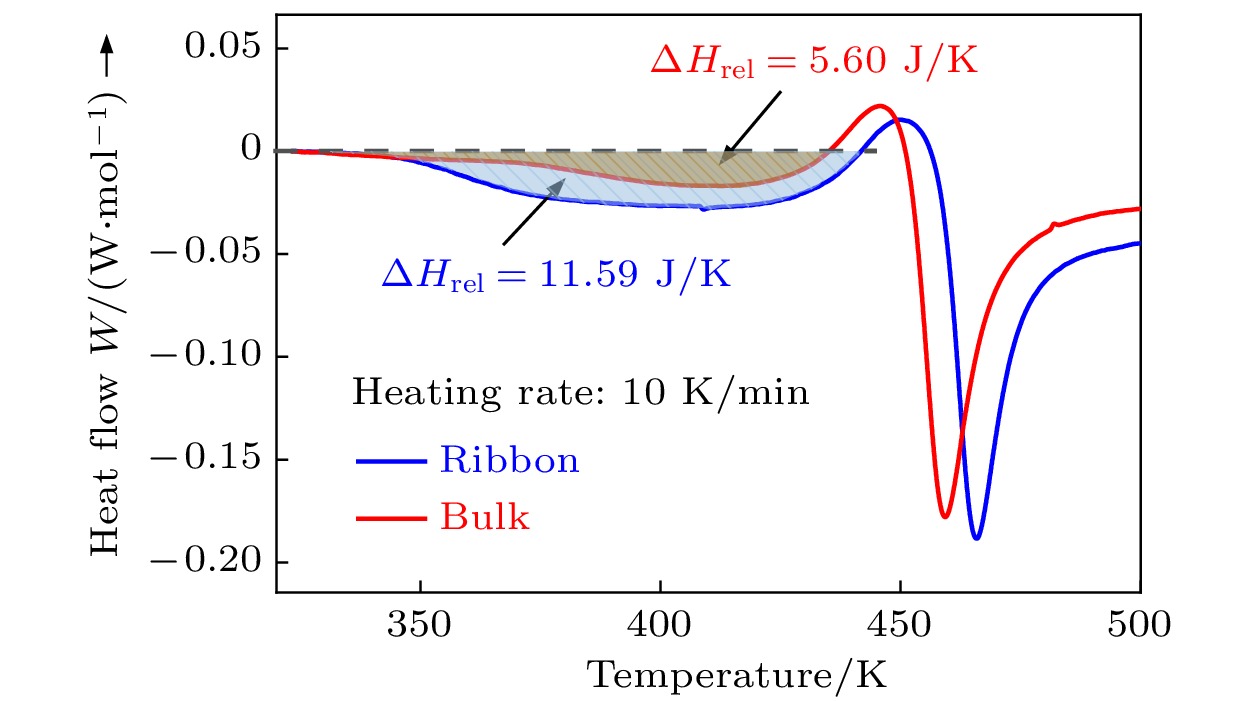

β弛豫行为及应力弛豫是探索非晶合金微观结构非均匀性的重要切入口. β弛豫行为及应力弛豫与非晶合金扩散、玻璃转变行为以及塑性变形等密切相关, 探究它们之间关联有重要科学意义. 本文以典型的La基非晶合金作为研究载体, 系统地探究了通过不同冷却速率所得块体样品与条带样品的β弛豫特征及应力弛豫行为. 结果表明, 冷却速率是控制玻璃体系能量状态, 进而影响其物理力学性能的重要参数. 冷却速率越大, 低温内耗更大, 对应β弛豫激活能更小, β弛豫行为在温度谱中展宽更大, 表明高冷却速率导致原子移动性更大, 微观尺度结构非均匀程度更高. 基于应力弛豫测量与分析, 发现高冷却速率变形特征时间减小, 归一化应力衰减幅度更大, 在外加力场作用下更易变形, 变形单元更易激活以容纳结构形变. 本研究为进一步厘清非晶合金β弛豫、变形及微观结构非均匀性之间关联提供了思路.The dynamic relaxation process and stress relaxation process are two important processes which can reflect the microstructures of materials, for they are closely related to the diffusions, the glass transition phenomena and the microstructural heterogeneities. It is of great significance to explore the relationship among them. In the current research, the β-relaxation characteristics and stress relaxation behaviors of bulk and ribbon samples obtained by different cooling rates are systematically investigated by taking the typical La-based amorphous alloys as model systems. The experimental results demonstrate that the cooling rate is an important parameter for controlling the energy state of the glass system, which further affects its physical and mechanical properties. Based on the dynamical mechanical spectra, the larger the cooling rate, the greater the low-temperature internal friction is and the smaller the beta relaxation activation energy according to Arrhenius calculations, and the greater the broadening of the beta relaxation behavior in the temperature spectra, suggesting that the higher cooling rate leads to greater atomic mobility and a high degree of heterogeneity in the microstructure. Thermodynamic analysis is conducted to study the slow process of thermal activation and the fast process driven by stress. At low temperature, the activation volume of the strip sample is larger than that of the bulk sample, and the activation volume values of the two samples are almost the same, as the cooling rate only affect the β relaxation stage, but exert little effect on the α relaxation, which is consistent with the conclusion that the stress relaxation behavior and β relaxation behavior are related to the structural non-uniformity of the amorphous alloy. The stress relaxation tests show that the characteristic time of deformation decreases at higher cooling rate, the normalized stress decay is larger, it is easier to deform under an applied force field, and the deformation unit is more likely to activate to accommodate structural deformation. The correlation between stress relaxation and β relaxation of amorphous alloy is further confirmed, and the proportion of liquid-like region is proportional to the relaxation mode spectrum, which also shows that β relaxation and stress relaxation are consistent. Finally, by calculating relaxation enthalpy

$ \Delta {H}_{{\mathrm{r}}{\mathrm{e}}{\mathrm{l}}} $ , the variation of microstructure heterogeneity with cooling rate is experimentally verified. The research sheds new light on further clarifying the relationship among β relaxation, deformation and microstructural heterogeneity of the amorphous alloy.-

Keywords:

- amorphous alloy /

- β relaxation behavior /

- cooling rate /

- stress relaxation /

- microstructural heterogeneity

[1] Angell C A 1996 Curr. Opin. Solid State Mater. Sci. 1 578

Google Scholar

Google Scholar

[2] Greer A L 1995 Science 267 1947

Google Scholar

Google Scholar

[3] Chang C, Zhang H P, Zhao R, Li F C, Luo P, Li M Z, Bai H Y 2022 Nat. Mater. 21 1240

Google Scholar

Google Scholar

[4] Qiao J C, Wang Q, Pelletier J M, Kato H, Casalini R, Crespo D, Pineda E, Yao Y, Yang Y 2019 Prog. Mater. Sci. 104 250

[5] Wang Q, Liu J J, Ye Y F, Liu T T, Wang S, Liu C T, Lu J, Yang Y 2017 Mater. Today 20 293

Google Scholar

Google Scholar

[6] Wang Q, Shang Y H, Yang Y 2023 Mater. Futures 2 017501

Google Scholar

Google Scholar

[7] Wang W H 2019 Prog. Mater. Sci. 106 100561

Google Scholar

Google Scholar

[8] 乔吉超, 张浪渟, 童钰, 吕国建, 郝奇, 陶凯 2022 力学进展 52 117

Google Scholar

Google Scholar

Qiao J C, Zhang L T, Tong Y, Lyu G J, Hao Q, Tao K 2022 Adv. Mech. 52 117

Google Scholar

Google Scholar

[9] Wang X D, Ruta B, Xiong L H, Zhang D W, Chushkin Y, Sheng H W, Lou H B, Cao Q P, Jiang J Z 2015 Acta Mater. 99 290

Google Scholar

Google Scholar

[10] 胡丽娜, 张春芝, 岳远征, 边秀房 2010 科学通报 55 115

Hu L N, Zhang C Z, Yue Y Z, Bian X F 2010 Sci. Bull. 55 115

[11] Capaccioli S, Paluch M, Prevosto D, Wang L M, Ngai K L 2012 J. Phys. Chem. Lett. 3 735

Google Scholar

Google Scholar

[12] Ngai K L, Wang Z, Gao X Q, Yu H B, Wang W H 2013 J. Chem. Phys. 139 014502

Google Scholar

Google Scholar

[13] Wang W H 2011 J. Appl. Phys. 110 053521

Google Scholar

Google Scholar

[14] Yu H B, Wang W H, Bai H Y, Wu Y, Chen M V 2010 Phys. Rev. B 81 220201

Google Scholar

Google Scholar

[15] Yu H B, Wang W H, Bai H Y, Samwer K 2014 Nat. Sci. Rev. 1 429

Google Scholar

Google Scholar

[16] Li N, Xu X N, Zheng Z Z, Liu L 2014 Acta Mater. 65 400

Google Scholar

Google Scholar

[17] Yu H B, Samwer K, Wu Y, Wang W H 2012 Phys. Rev. Lett. 109 095508

Google Scholar

Google Scholar

[18] Yu H B, Wang W H, Samwer K 2013 Mater. Today 16 183

Google Scholar

Google Scholar

[19] Ashby M F, Greer A L 2006 Scr. Mater. 54 321

Google Scholar

Google Scholar

[20] Dyre J C 2006 Rev. Mod. Phys. 78 953

Google Scholar

Google Scholar

[21] Ediger M D, Harrowell P 2012 J. Chem. Phys. 137 080901

Google Scholar

Google Scholar

[22] Goldstein M 2011 J. Non-Cryst. Solids 357 249

Google Scholar

Google Scholar

[23] Hu L, Yue Y 2009 J. Phys. Chem. C 113 15001

Google Scholar

Google Scholar

[24] Wang W H, Dong C, Shek C H 2004 Mater. Sci. Eng. , R 44 45

Google Scholar

Google Scholar

[25] 汪卫华 2013 物理学进展 33 177

Wang W H 2013 Prog. Phys. 33 177

[26] Zhao L Z, Wang W H, Bai H Y 2014 J. Non-Cryst. Solids 405 207

Google Scholar

Google Scholar

[27] Ma Z J, Guo Y C, Li Y, Lugee T, Gao P H, Yang Z, Zeng X R 2015 J. Alloys Compd. 648 18

Google Scholar

Google Scholar

[28] Wang B, Shang B S, Gao X Q, Wang W H, Bai H Y, Pan M X, Guan P F 2016 J. Phys. Chem. Lett. 7 4945

Google Scholar

Google Scholar

[29] Zhang L T, Duan Y J, Wang Y J, Yang Y, Qiao J C 2023 Sci. China-Technol. Sci. 66 173

Google Scholar

Google Scholar

[30] Jiao W, Sun B A, Wen P, Bai H Y, Kong Q P, Wang W H 2013 Appl. Phys. Lett. 103 101903

Google Scholar

Google Scholar

[31] Ke H B, Zhang P, Sun B A, Zhang P G, Liu T W, Chen P H, Wu M, Huang H G 2019 J. Alloys Compd. 788 391

Google Scholar

Google Scholar

[32] Milkus R, Zaccone A 2017 Phys. Rev. E 95 023001

Google Scholar

Google Scholar

[33] Qiao J C, Wang Y J, Pelletier J M, Keer L M, Fine M E, Yao Y 2015 Acta Mater. 98 43

Google Scholar

Google Scholar

[34] Qiao J C, Wang Y J, Zhao L Z, Dai L H, Crespo D, Pelletier J M, Keer L M, Yao Y 2016 Phys. Rev. B 94 104203

Google Scholar

Google Scholar

[35] Liang S Y, Zhang L T, Wang B, Wang Y J, Pineda E, Qiao J C 2024 Intermetallics 164 108115

Google Scholar

Google Scholar

[36] Luo P, Li M X, Jiang H Y, Wen P, Bai H Y, Wang W H 2017 J. Appl. Phys. 121 135104

Google Scholar

Google Scholar

[37] Luo P, Wen P, Bai H Y, Ruta B, Wang W H 2017 Phys. Rev. Lett. 118 225901

Google Scholar

Google Scholar

[38] Jiao W, Wen P, Peng H L, Bai H Y, Sun B A, Wang W H 2013 Appl. Phys. Lett. 102 101903

Google Scholar

Google Scholar

[39] Wang Z, Sun B A, Bai H Y, Wang W H 2014 Nat. Commun. 5 5823

Google Scholar

Google Scholar

[40] 汪卫华 2014 中国科学: 物理学 力学 天文学 44 396

Google Scholar

Google Scholar

Wang W H, 2014 Sci. Sin. Phys. Mech. Astr. 44 396

Google Scholar

Google Scholar

[41] Li R, Pang S, Ma C L, Zhang T 2007 Acta Mater. 55 3719

Google Scholar

Google Scholar

[42] Lin X H, Johnson W L 1995 J. Appl. Phys. 78 6514

Google Scholar

Google Scholar

[43] Perez J 1990 Solid State Ionics 39 69

Google Scholar

Google Scholar

[44] Perez J, Etienne S, Tatibouät J 1990 Phys. Status Solidi A 121 129

Google Scholar

Google Scholar

[45] Qiao J C, Pelletier J M 2014 J. Mater. Sci. Technol. 30 523

Google Scholar

Google Scholar

[46] Wang Q, Pelletier J M, Blandin J J, Suery M 2005 J. Non-Cryst. Solids 351 2224

Google Scholar

Google Scholar

[47] Perez J 2018 Physics and Mechanics of Amorphous Polymers (London: Routledge) pp117–119

[48] Rinaldi R, Gaertner R, Chazeau L, Gauthier C 2011 Int. J. Non-Linear Mech. 46 496

Google Scholar

Google Scholar

[49] Evenson Z, Naleway S E, Wei S, Gross O, Kruzic J J, Gallino I, Possart W, Stommel M, Busch R 2014 Phys. Rev. B 89 174204

Google Scholar

Google Scholar

[50] Wang B, Gao X Q, Qiao J C 2024 Rare Met. Mater. Eng. 53 70

Google Scholar

Google Scholar

[51] 孟绍怡, 郝奇, 吕国建, 乔吉超 2023 72 076101

Google Scholar

Google Scholar

Meng S Y, Hao Q, Lyu G J, Qiao J C 2023 Acta Phys. Sin. 72 076101

Google Scholar

Google Scholar

[52] Kawamura Y, Shibata T, Inoue A, Masumoto T 1999 Mater. Trans., JIM 40 335

Google Scholar

Google Scholar

[53] Rösner P, Samwer K, Lunkenheimer P 2004 Europhys. Lett. 68 226

Google Scholar

Google Scholar

[54] Zhang P, Maldonis J J, Liu Z, Schroers J, Voyles P M 2018 Nat. Commun. 9 1129

Google Scholar

Google Scholar

[55] Polk D E, Turnbull D 1972 Acta Metall. 20 493

Google Scholar

Google Scholar

[56] Spaepen F 1977 Acta Metall. 25 407

Google Scholar

Google Scholar

[57] Heggen M, Spaepen F, Feuerbacher M 2004 J. Appl. Phys. 97 033506

[58] Fan Y, Iwashita T, Egami T 2014 Nat. Commun. 5 5083

Google Scholar

Google Scholar

[59] Fan Y, Iwashita T, Egami T 2015 Phys. Rev. Lett. 115 045501

Google Scholar

Google Scholar

[60] Duan Y J, Zhang L T, Qiao J C, Wang Y J, Yang Y, Wada T, Kato H, Pelletier J M, Pineda E, Crespo D 2022 Phys. Rev. Lett. 129 175501

Google Scholar

Google Scholar

[61] Mayr S G 2006 Phys. Rev. Lett. 97 195501

Google Scholar

Google Scholar

[62] Wagner H, Bedorf D, Küchemann S, Schwabe M, Zhang B, Arnold W, Samwer K 2011 Nat. Mater. 10 439

Google Scholar

Google Scholar

[63] Chen H S 1980 Rep. Prog. Phys. 43 353

Google Scholar

Google Scholar

[64] Zhang L T, Wang Y J, Yang Y, Qiao J C 2023 Sci. China Phys. Mech. 66 286111

Google Scholar

Google Scholar

[65] Afonin G V, Mitrofanov Y P, Kobelev N P, da Silva Pinto M W, Wilde G, Khonik V A 2019 Scr. Mater. 166 6

Google Scholar

Google Scholar

-

图 1 (a) (La0.6Ce0.4)65Al10Co25非晶合金内耗随温度演化(升温速率为2 K/min, 加载频率为1 Hz); (b) (La0.6Ce0.4)65Al10Co25非晶合金损耗模量随温度演化, 实线为准点缺陷公式拟合β弛豫结果

Fig. 1. (a) Temperature dependence of the internal friction for (La0.6Ce0.4)65Al10Co25 amorphous alloy (heating rate: 2 K/min, driving frequency: 1 Hz); (b) temperature dependence of the loss modulus $ {E}'' $ for (La0.6Ce0.4)65Al10Co25 amorphous alloy. The solid line is the β relaxation result fitted by QPD theory.

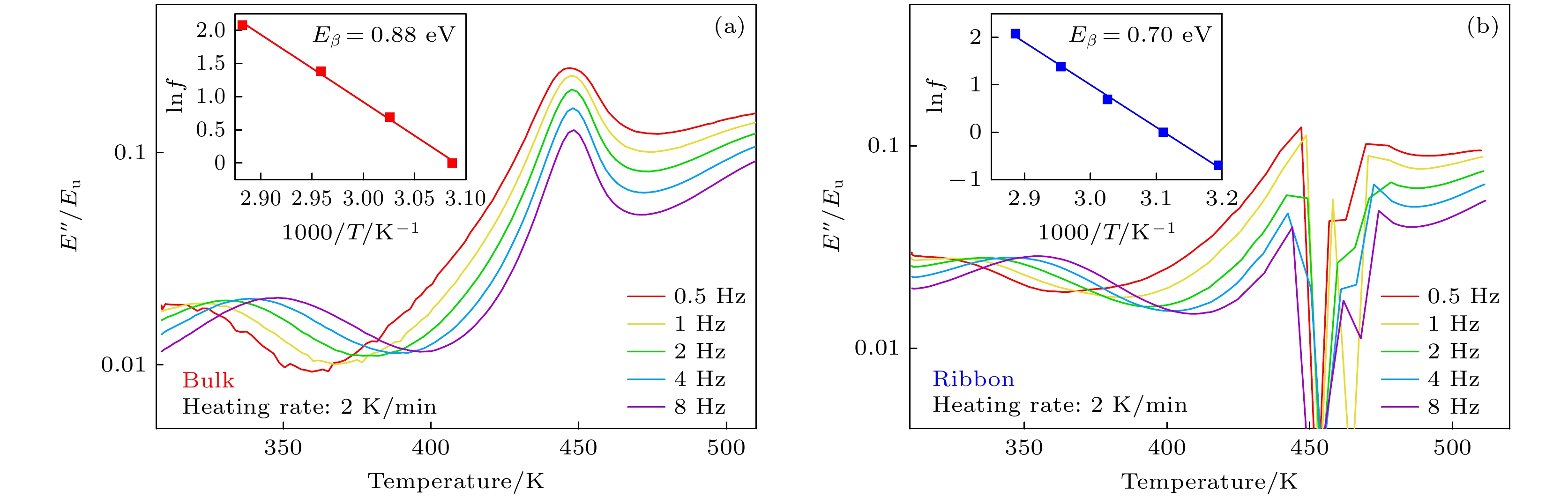

图 2 (La0.6Ce0.4)65Al10Co25非晶合金不同加载频率归一化损耗模量$ {E''}/{E}_{{\mathrm{u}}} $随温度演化 (a)块体样品; (b) 条带样品; 升温速率为2 K/min; 插图为β弛豫峰温与加载频率关系, 实线为Arrhenius方程拟合

Fig. 2. Temperature dependence of the normalized loss modulus ${E''}/{E}_{{\mathrm{u}}} $ for (La0.6Ce0.4)65Al10Co25 amorphous alloy with different frequency: (a) Bulk; (b) ribbon. Inset shows the frequency versus peak temperature of the β relaxation, the solid line is the Arrhenius equation fit.

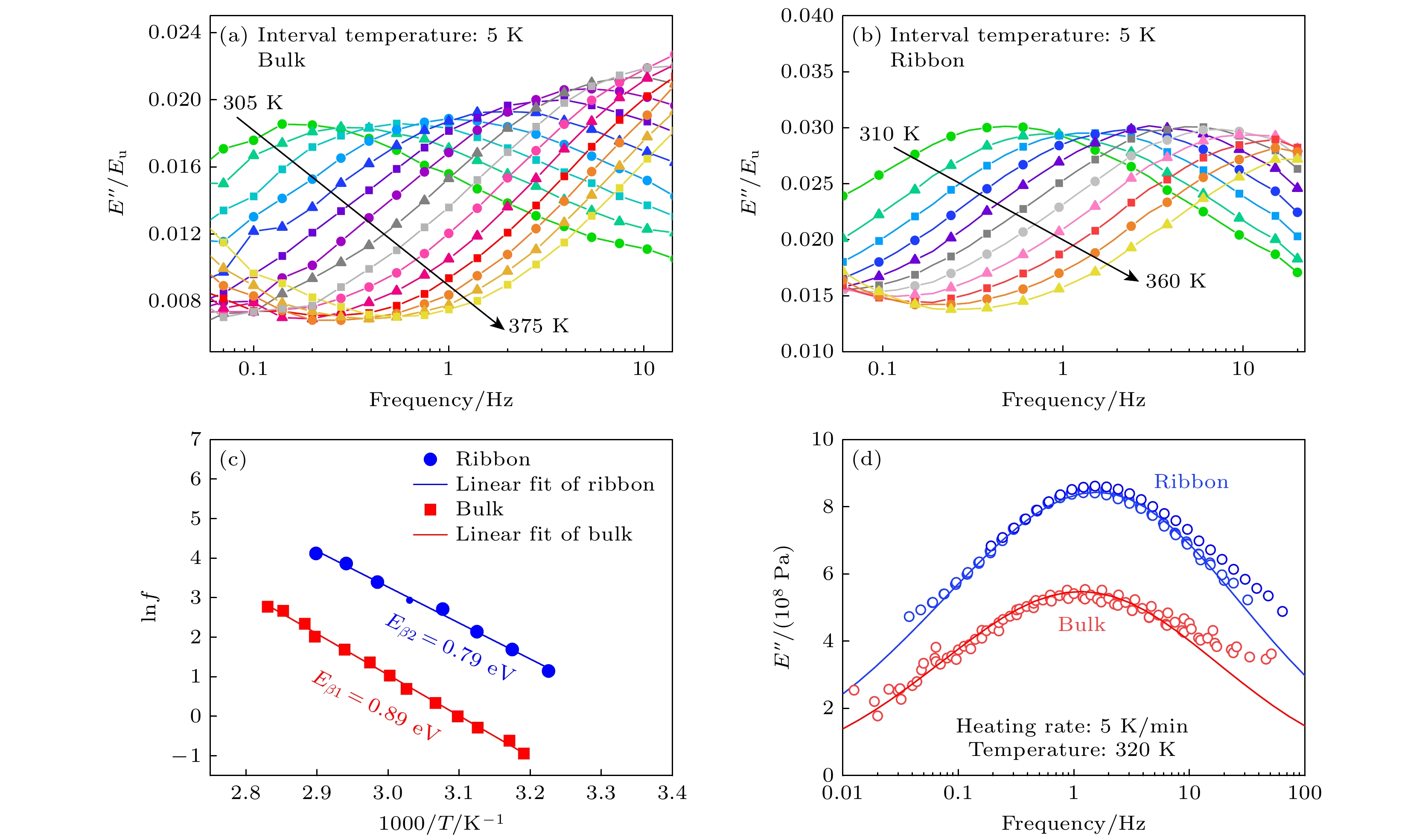

图 3 (a) 不同温度下(La0.6Ce0.4)65Al10Co25非晶合金块体样品归一化损耗模量$ {E''}/{E}_{{\mathrm{u}}} $随加载频率演化[51]; (b) 不同温度下(La0.6Ce0.4)65Al10Co25非晶合金条带样品归一化损耗模量$ {E''}/{E}_{{\mathrm{u}}} $随加载频率演化; (c) (La0.6Ce0.4)65Al10Co25非晶合金块体样品和条带样品等温扫频条件β弛豫峰温和频率的关系, 实线为Arrhenius方程拟合; (d) (La0.6Ce0.4)65Al10Co25非晶合金块体样品和条带样品的损耗模量在320 K参考温度下主曲线(实线为(1)式拟合结果)

Fig. 3. (a) Frequency dependence of the normalized loss modulus ${E''}/{E}_{{\mathrm{u}}} $ for (La0.6Ce0.4)65Al10Co25 amorphous alloy with different temperature (bulk); (b) frequency dependence of the normalized loss modulus ${E''}/{E}_{{\mathrm{u}}} $ for (La0.6Ce0.4)65Al10Co25 amorphous alloy with different temperature (ribbon); (c) the frequency versus peak temperature of the β relaxation with different states (bulk and ribbon), the solid line is the Arrhenius equation fit; (d) main curve of loss modulus for amorphous alloy with different states (bulk sample and ribbon sample) at 320 K (solid line is fitting result of Eq. (1)).

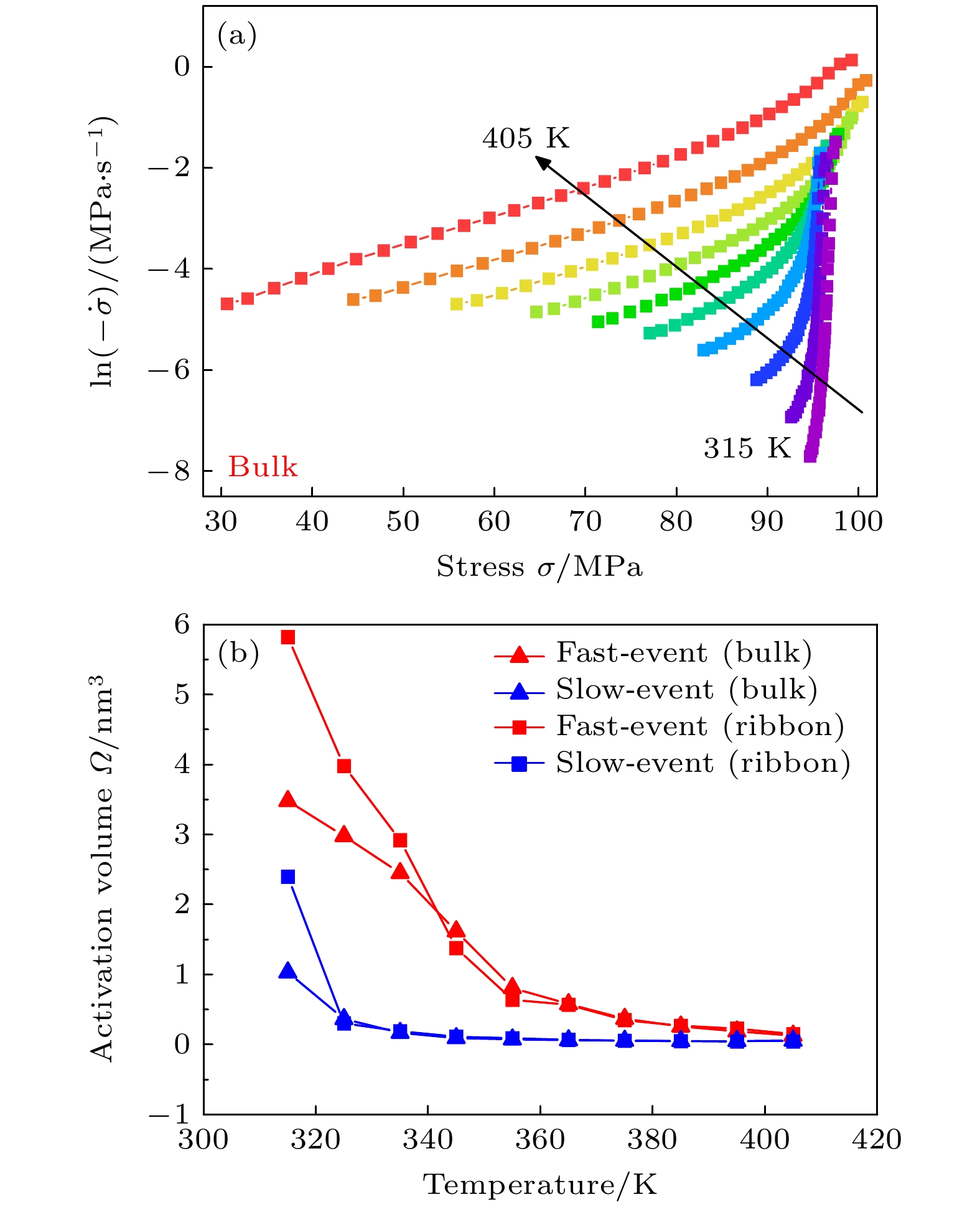

图 4 (La0.6Ce0.4)65Al10Co25非晶合金在310—425 K 的应力弛豫曲线(实线为KWW 方程拟合结果) (a) 块体样品; (b) 条带样品; (c) 370 K下块体样品及条带样品应力弛豫曲线; (d) (La0.6Ce0.4)65Al10Co25非晶合金应力弛豫过程中特征弛豫时间$ {\tau }_{{\mathrm{c}}} $对数随温度演化

Fig. 4. Stress relaxation curve of (La0.6Ce0.4)65Al10Co25 amorphous alloy from 310 K to 425 K (solid line is the fitting results based on KWW equation): (a) Bulk; (b) ribbon; (c) stress relaxation curves of 370 K for bulk and ribbon; (d) temperature dependence of the logarithm of characteristic relaxation time $ {\tau }_{{\mathrm{c}}} $ in stress relaxation process for (La0.6Ce0.4)65Al10Co25 amorphous alloy.

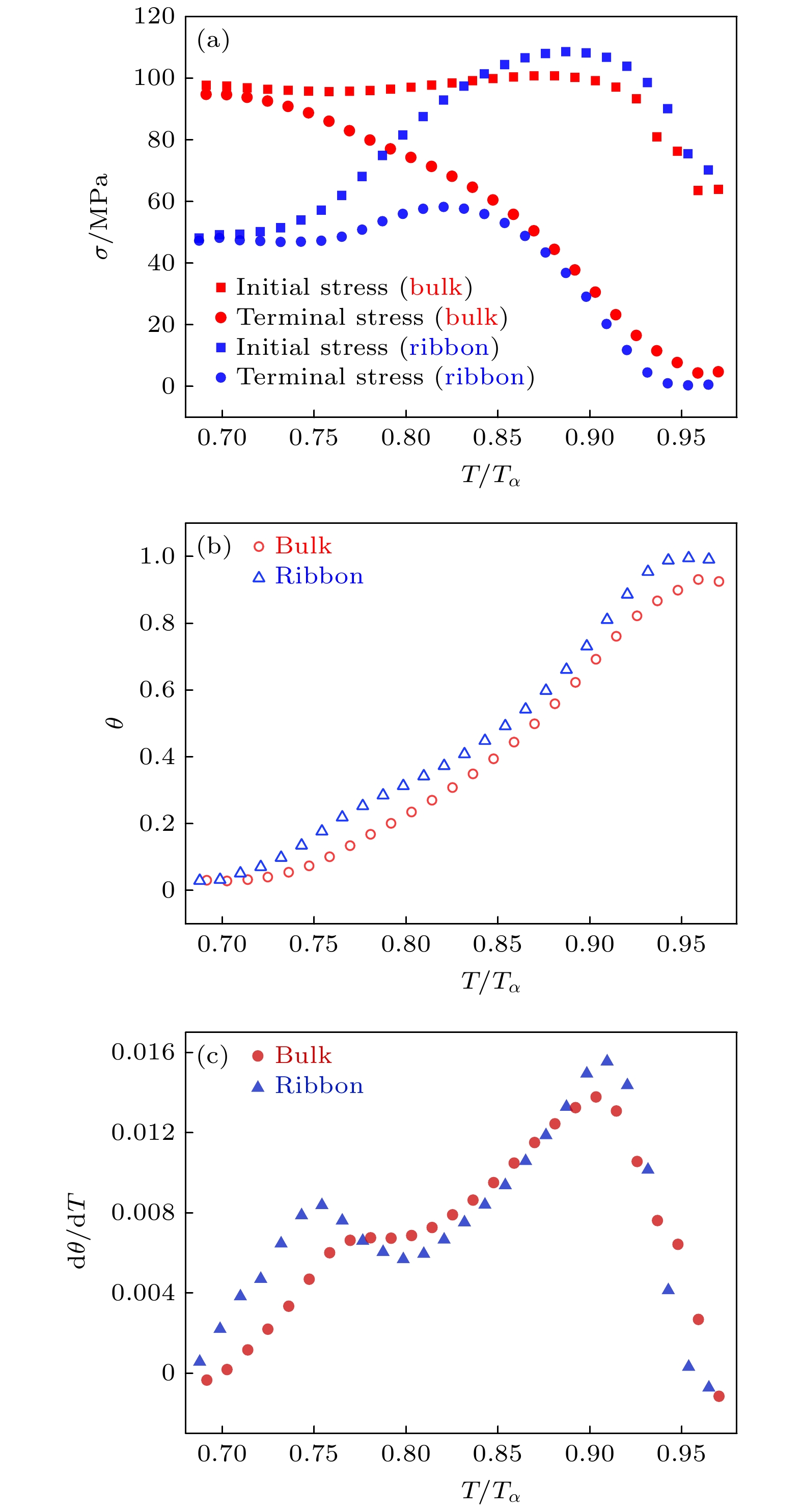

图 6 (a) (La0.6Ce0.4)65Al10Co25非晶合金不同温度下应力弛豫曲线初始应力和最终应力演化; (b) $ \theta $随温度演化; (c) $ {\mathrm{d}}\theta /{\mathrm{d}}T $随温度演化

Fig. 6. (a) Initial stress and terminal stress evolution of stress relaxation curves for (La0.6Ce0.4)65Al10Co25 amorphous alloy at different temperatures; (b) temperature dependence of the $ \theta $ for bulk and ribbon samples; (c) temperature dependence of the $ {\mathrm{d}}\theta /{\mathrm{d}}T $ for bulk and ribbon samples.

-

[1] Angell C A 1996 Curr. Opin. Solid State Mater. Sci. 1 578

Google Scholar

Google Scholar

[2] Greer A L 1995 Science 267 1947

Google Scholar

Google Scholar

[3] Chang C, Zhang H P, Zhao R, Li F C, Luo P, Li M Z, Bai H Y 2022 Nat. Mater. 21 1240

Google Scholar

Google Scholar

[4] Qiao J C, Wang Q, Pelletier J M, Kato H, Casalini R, Crespo D, Pineda E, Yao Y, Yang Y 2019 Prog. Mater. Sci. 104 250

[5] Wang Q, Liu J J, Ye Y F, Liu T T, Wang S, Liu C T, Lu J, Yang Y 2017 Mater. Today 20 293

Google Scholar

Google Scholar

[6] Wang Q, Shang Y H, Yang Y 2023 Mater. Futures 2 017501

Google Scholar

Google Scholar

[7] Wang W H 2019 Prog. Mater. Sci. 106 100561

Google Scholar

Google Scholar

[8] 乔吉超, 张浪渟, 童钰, 吕国建, 郝奇, 陶凯 2022 力学进展 52 117

Google Scholar

Google Scholar

Qiao J C, Zhang L T, Tong Y, Lyu G J, Hao Q, Tao K 2022 Adv. Mech. 52 117

Google Scholar

Google Scholar

[9] Wang X D, Ruta B, Xiong L H, Zhang D W, Chushkin Y, Sheng H W, Lou H B, Cao Q P, Jiang J Z 2015 Acta Mater. 99 290

Google Scholar

Google Scholar

[10] 胡丽娜, 张春芝, 岳远征, 边秀房 2010 科学通报 55 115

Hu L N, Zhang C Z, Yue Y Z, Bian X F 2010 Sci. Bull. 55 115

[11] Capaccioli S, Paluch M, Prevosto D, Wang L M, Ngai K L 2012 J. Phys. Chem. Lett. 3 735

Google Scholar

Google Scholar

[12] Ngai K L, Wang Z, Gao X Q, Yu H B, Wang W H 2013 J. Chem. Phys. 139 014502

Google Scholar

Google Scholar

[13] Wang W H 2011 J. Appl. Phys. 110 053521

Google Scholar

Google Scholar

[14] Yu H B, Wang W H, Bai H Y, Wu Y, Chen M V 2010 Phys. Rev. B 81 220201

Google Scholar

Google Scholar

[15] Yu H B, Wang W H, Bai H Y, Samwer K 2014 Nat. Sci. Rev. 1 429

Google Scholar

Google Scholar

[16] Li N, Xu X N, Zheng Z Z, Liu L 2014 Acta Mater. 65 400

Google Scholar

Google Scholar

[17] Yu H B, Samwer K, Wu Y, Wang W H 2012 Phys. Rev. Lett. 109 095508

Google Scholar

Google Scholar

[18] Yu H B, Wang W H, Samwer K 2013 Mater. Today 16 183

Google Scholar

Google Scholar

[19] Ashby M F, Greer A L 2006 Scr. Mater. 54 321

Google Scholar

Google Scholar

[20] Dyre J C 2006 Rev. Mod. Phys. 78 953

Google Scholar

Google Scholar

[21] Ediger M D, Harrowell P 2012 J. Chem. Phys. 137 080901

Google Scholar

Google Scholar

[22] Goldstein M 2011 J. Non-Cryst. Solids 357 249

Google Scholar

Google Scholar

[23] Hu L, Yue Y 2009 J. Phys. Chem. C 113 15001

Google Scholar

Google Scholar

[24] Wang W H, Dong C, Shek C H 2004 Mater. Sci. Eng. , R 44 45

Google Scholar

Google Scholar

[25] 汪卫华 2013 物理学进展 33 177

Wang W H 2013 Prog. Phys. 33 177

[26] Zhao L Z, Wang W H, Bai H Y 2014 J. Non-Cryst. Solids 405 207

Google Scholar

Google Scholar

[27] Ma Z J, Guo Y C, Li Y, Lugee T, Gao P H, Yang Z, Zeng X R 2015 J. Alloys Compd. 648 18

Google Scholar

Google Scholar

[28] Wang B, Shang B S, Gao X Q, Wang W H, Bai H Y, Pan M X, Guan P F 2016 J. Phys. Chem. Lett. 7 4945

Google Scholar

Google Scholar

[29] Zhang L T, Duan Y J, Wang Y J, Yang Y, Qiao J C 2023 Sci. China-Technol. Sci. 66 173

Google Scholar

Google Scholar

[30] Jiao W, Sun B A, Wen P, Bai H Y, Kong Q P, Wang W H 2013 Appl. Phys. Lett. 103 101903

Google Scholar

Google Scholar

[31] Ke H B, Zhang P, Sun B A, Zhang P G, Liu T W, Chen P H, Wu M, Huang H G 2019 J. Alloys Compd. 788 391

Google Scholar

Google Scholar

[32] Milkus R, Zaccone A 2017 Phys. Rev. E 95 023001

Google Scholar

Google Scholar

[33] Qiao J C, Wang Y J, Pelletier J M, Keer L M, Fine M E, Yao Y 2015 Acta Mater. 98 43

Google Scholar

Google Scholar

[34] Qiao J C, Wang Y J, Zhao L Z, Dai L H, Crespo D, Pelletier J M, Keer L M, Yao Y 2016 Phys. Rev. B 94 104203

Google Scholar

Google Scholar

[35] Liang S Y, Zhang L T, Wang B, Wang Y J, Pineda E, Qiao J C 2024 Intermetallics 164 108115

Google Scholar

Google Scholar

[36] Luo P, Li M X, Jiang H Y, Wen P, Bai H Y, Wang W H 2017 J. Appl. Phys. 121 135104

Google Scholar

Google Scholar

[37] Luo P, Wen P, Bai H Y, Ruta B, Wang W H 2017 Phys. Rev. Lett. 118 225901

Google Scholar

Google Scholar

[38] Jiao W, Wen P, Peng H L, Bai H Y, Sun B A, Wang W H 2013 Appl. Phys. Lett. 102 101903

Google Scholar

Google Scholar

[39] Wang Z, Sun B A, Bai H Y, Wang W H 2014 Nat. Commun. 5 5823

Google Scholar

Google Scholar

[40] 汪卫华 2014 中国科学: 物理学 力学 天文学 44 396

Google Scholar

Google Scholar

Wang W H, 2014 Sci. Sin. Phys. Mech. Astr. 44 396

Google Scholar

Google Scholar

[41] Li R, Pang S, Ma C L, Zhang T 2007 Acta Mater. 55 3719

Google Scholar

Google Scholar

[42] Lin X H, Johnson W L 1995 J. Appl. Phys. 78 6514

Google Scholar

Google Scholar

[43] Perez J 1990 Solid State Ionics 39 69

Google Scholar

Google Scholar

[44] Perez J, Etienne S, Tatibouät J 1990 Phys. Status Solidi A 121 129

Google Scholar

Google Scholar

[45] Qiao J C, Pelletier J M 2014 J. Mater. Sci. Technol. 30 523

Google Scholar

Google Scholar

[46] Wang Q, Pelletier J M, Blandin J J, Suery M 2005 J. Non-Cryst. Solids 351 2224

Google Scholar

Google Scholar

[47] Perez J 2018 Physics and Mechanics of Amorphous Polymers (London: Routledge) pp117–119

[48] Rinaldi R, Gaertner R, Chazeau L, Gauthier C 2011 Int. J. Non-Linear Mech. 46 496

Google Scholar

Google Scholar

[49] Evenson Z, Naleway S E, Wei S, Gross O, Kruzic J J, Gallino I, Possart W, Stommel M, Busch R 2014 Phys. Rev. B 89 174204

Google Scholar

Google Scholar

[50] Wang B, Gao X Q, Qiao J C 2024 Rare Met. Mater. Eng. 53 70

Google Scholar

Google Scholar

[51] 孟绍怡, 郝奇, 吕国建, 乔吉超 2023 72 076101

Google Scholar

Google Scholar

Meng S Y, Hao Q, Lyu G J, Qiao J C 2023 Acta Phys. Sin. 72 076101

Google Scholar

Google Scholar

[52] Kawamura Y, Shibata T, Inoue A, Masumoto T 1999 Mater. Trans., JIM 40 335

Google Scholar

Google Scholar

[53] Rösner P, Samwer K, Lunkenheimer P 2004 Europhys. Lett. 68 226

Google Scholar

Google Scholar

[54] Zhang P, Maldonis J J, Liu Z, Schroers J, Voyles P M 2018 Nat. Commun. 9 1129

Google Scholar

Google Scholar

[55] Polk D E, Turnbull D 1972 Acta Metall. 20 493

Google Scholar

Google Scholar

[56] Spaepen F 1977 Acta Metall. 25 407

Google Scholar

Google Scholar

[57] Heggen M, Spaepen F, Feuerbacher M 2004 J. Appl. Phys. 97 033506

[58] Fan Y, Iwashita T, Egami T 2014 Nat. Commun. 5 5083

Google Scholar

Google Scholar

[59] Fan Y, Iwashita T, Egami T 2015 Phys. Rev. Lett. 115 045501

Google Scholar

Google Scholar

[60] Duan Y J, Zhang L T, Qiao J C, Wang Y J, Yang Y, Wada T, Kato H, Pelletier J M, Pineda E, Crespo D 2022 Phys. Rev. Lett. 129 175501

Google Scholar

Google Scholar

[61] Mayr S G 2006 Phys. Rev. Lett. 97 195501

Google Scholar

Google Scholar

[62] Wagner H, Bedorf D, Küchemann S, Schwabe M, Zhang B, Arnold W, Samwer K 2011 Nat. Mater. 10 439

Google Scholar

Google Scholar

[63] Chen H S 1980 Rep. Prog. Phys. 43 353

Google Scholar

Google Scholar

[64] Zhang L T, Wang Y J, Yang Y, Qiao J C 2023 Sci. China Phys. Mech. 66 286111

Google Scholar

Google Scholar

[65] Afonin G V, Mitrofanov Y P, Kobelev N P, da Silva Pinto M W, Wilde G, Khonik V A 2019 Scr. Mater. 166 6

Google Scholar

Google Scholar

计量

- 文章访问数: 4550

- PDF下载量: 109

- 被引次数: 0

下载:

下载: