-

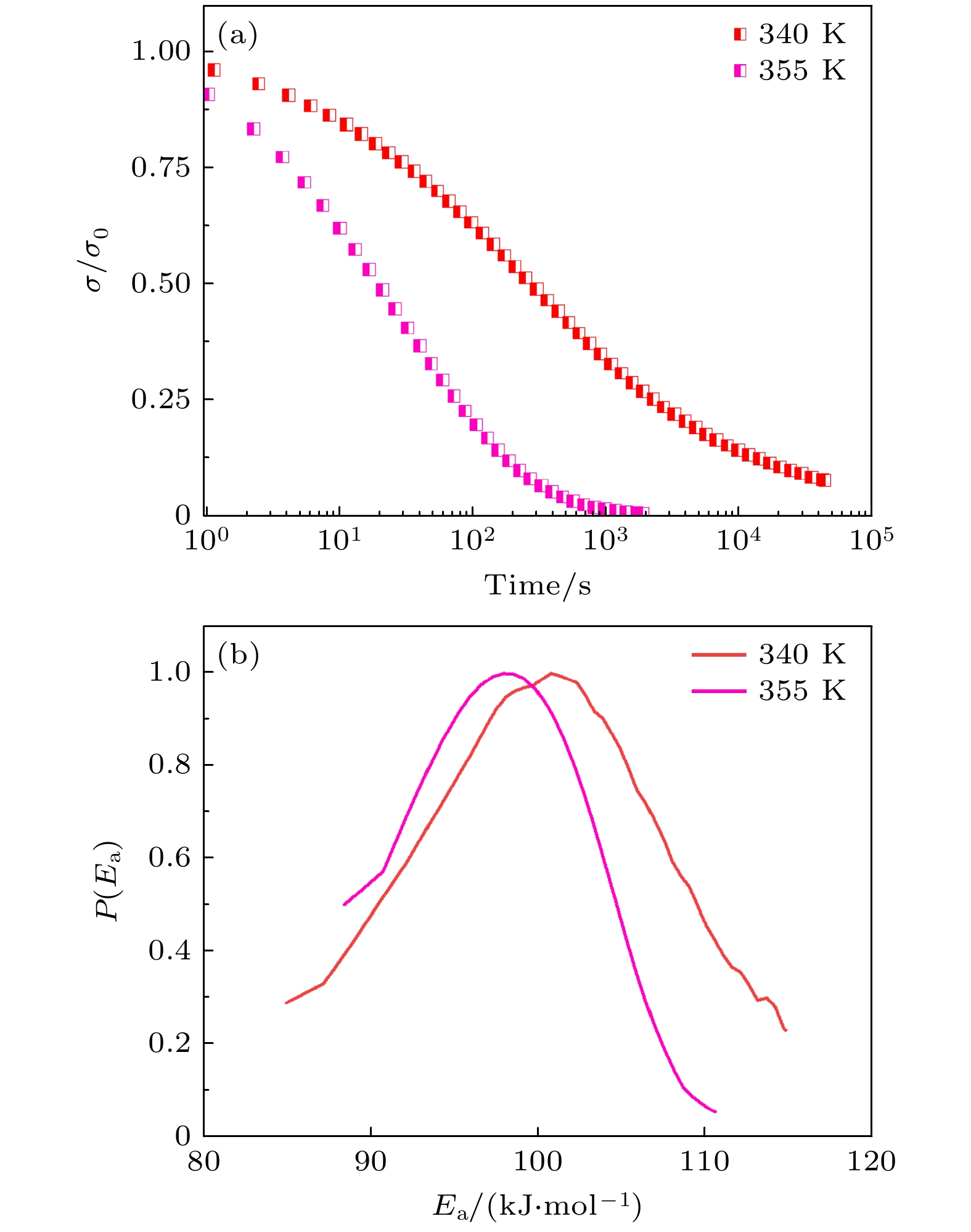

研究了非晶态聚苯乙烯材料应力松弛行为与其固有微观结构非均匀性之间的关联, 从基本Maxwell黏弹性模型出发, 到三参量扩展指数方程, 讨论了变形单元特征时间的分布本质及聚合物应力松弛过程中的链段效应. 结果表明, 非晶态聚苯乙烯应力松弛行为呈现典型非指数特征, 单一特征时间的指数衰减形式与有限特征时间的有限谱方法均无法合理描述聚苯乙烯应力松弛行为, 这是由于非晶态聚合物微观结构非均匀性所导致的特征时间谱连续分布. 此外, 本文进一步探究了物理老化导致的应力松弛行为变化, 老化导致体系向更稳定能量状态迁移, 变形单元难以激活, 因而导致应力松弛过程慢化, 特征时间延长.The relationship between stress relaxation behavior and inherent microstructural heterogeneity in amorphous polystyrene materials is studied in this work. Starting from the basic Maxwell viscoelastic model and extending to the three-parameter stretched exponential equation, the nature of the distribution of characteristic timescales and the segmental effects during polymer stress relaxation are discussed. The results indicate that the stress relaxation behavior of amorphous polymers exhibits non-exponential characteristics. Neither a single characteristic time with exponential decay nor a finite spectrum method with finite characteristic time can adequately describe the stress relaxation behavior of polystyrene due to the continuous distribution of characteristic timescales resulting from microstructural heterogeneity in amorphous polymers. In addition, the changes in stress relaxation behavior caused by physical aging are explored. Aging leads to a transition of the system towards a more stable energy state, making it difficult to activate the relaxation of the individual units, thus slowing down the stress relaxation process and increasing the characteristic time.

-

Keywords:

- polystyrene /

- stress relaxation behavior /

- viscoelastic deformation /

- microstructural heterogeneity

[1] Ozerin A N, Golubev E K, Ivanchev S S, Aulov V A, Kechek’yan A S, Kurkin T S, Ivan’kova E M, Adonin N Y 2022 Polym. Sci. Ser. A 64 73

Google Scholar

Google Scholar

[2] Müller M, Abetz V 2021 Chem. Rev. 121 14189

Google Scholar

Google Scholar

[3] Li Y, Tang S, Abberton B C, Kröger M, Burkhart C, Jiang B, Papakonstantopoulos G J, Poldneff M, Liu W K 2012 Polymer 53 5935

Google Scholar

Google Scholar

[4] Boland C S, Khan U, Ryan G, Barwich S, Charifou R, Harvey A, Backes C, Li Z, Ferreira M S, Möbius M E, Young R J, Coleman J N 2016 Science 354 1257

Google Scholar

Google Scholar

[5] 金日光, 华幼卿 2000 高分子物理 (第二版) (北京: 化学工业出版社)

Jin R G, Hua Y Q 2000 Polymer Physics (2nd Ed.) (Beijing: Chemical Industry Press

[6] Hou J X, Svaneborg C, Everaers R, Grest G S 2010 Phys. Rev. Lett. 105 068301

Google Scholar

Google Scholar

[7] Spathis G, Kontou E 2012 Compos. Sci. Technol. 72 959

Google Scholar

Google Scholar

[8] Huang J S, Gibson L J 1991 J. Mater. Sci. 26 637

Google Scholar

Google Scholar

[9] Papanicolaou G C, Zaoutsos S P 2019 Creep and Fatigue in Polymer Matrix Composites (Woodhead Publishing) pp3–59

[10] Di Marzio E A, Kasianowicz J J 2003 J. Chem. Phys. 119 6378

Google Scholar

Google Scholar

[11] Auhl R, Everaers R, Grest G S, Kremer K, Plimpton S J 2003 J. Chem. Phys. 119 12718

Google Scholar

Google Scholar

[12] Kreer T, Metzger S, Müller M, Binder K, Baschnagel J 2004 J. Chem. Phys. 120 4012

Google Scholar

Google Scholar

[13] Chui C, Boyce M C 1999 Macromolecules 32 3795

Google Scholar

Google Scholar

[14] Perez J 1998 Physics and Mechanics of Amorphous Polymers (CRC Press

[15] Ediger M D 2000 Annu. Rev. Phys. Chem. 51 99

Google Scholar

Google Scholar

[16] Wang X Y, Xu W S, Zhang H, Douglas J F 2019 J. Chem. Phys. 151 184503

Google Scholar

Google Scholar

[17] Dmowski W, Iwashita T, Chuang C P, Almer J, Egami T 2010 Phys. Rev. Lett. 105 205502

Google Scholar

Google Scholar

[18] Hu Y, Guan P, Li M, Liu C, Yang Y, Bai H, Wang W 2016 Phys. Rev. B 93 214202

Google Scholar

Google Scholar

[19] Smith G D, Borodin O, Paul W 2002 J. Chem. Phys. 117 10350

Google Scholar

Google Scholar

[20] Jin W, Boyd R H 2002 Polymer 43 503

Google Scholar

Google Scholar

[21] Borodin O, Smith G D, Bandyopadhyaya R, Byutner O 2003 Macromolecules 36 7873

Google Scholar

Google Scholar

[22] Smith G D, Paul W, Monkenbusch M, Richter D 2001 J. Chem. Phys. 114 4285

Google Scholar

Google Scholar

[23] Gebremichael Y, Schrøder T B, Starr F W, Glotzer S C 2001 Phys. Rev. E 64 051503

Google Scholar

Google Scholar

[24] Bennemann C, Donati C, Baschnagel J, Glotzer S C 1999 Nature 399 246

Google Scholar

Google Scholar

[25] Etienne S, David L 2007 Philos. Mag. 87 417

Google Scholar

Google Scholar

[26] Lunkenheimer P, Wehn R, Schneider U, Loidl A 2005 Phys. Rev. Lett. 95 055702

Google Scholar

Google Scholar

[27] Bruns M, Hassani M, Varnik F, Hassanpour A, Divinski S, Wilde G 2021 Phys. Rev. Res. 3 013234

Google Scholar

Google Scholar

[28] Pan J, Ivanov Y P, Zhou W H, Li Y, Greer A L 2020 Nature 578 559

Google Scholar

Google Scholar

[29] Pan J, Wang Y X, Guo Q, Zhang D, Greer A L, Li Y 2018 Nat. Commun. 9 560

Google Scholar

Google Scholar

[30] Wunsch J R 2014 Polystyrene-Synthesis, Production and Applications (New York: Nova Science Publishers, Inc.

[31] 张智枢, 顾欣, 杨云云, 蔡绪福 2017 工程科学与技术 49 232

Google Scholar

Google Scholar

Zhang Z S, Gu X, Yang Y Y, Cai X F 2017 Adv. Eng. Sci. 49 232

Google Scholar

Google Scholar

[32] 郝奇, 乔吉超 2022 力学学报 54 3058

Google Scholar

Google Scholar

Hao Q, Qiao J C 2022 Chin. J. Theo. Appl. Mech. 54 3058

Google Scholar

Google Scholar

[33] Taub A, Spaepen F 1981 J. Mater. Sci. 16 3087

Google Scholar

Google Scholar

[34] Qiao J C, Wang Y J, Zhao L Z, et al. 2016 Phys. Rev. B 94 104203

Google Scholar

Google Scholar

[35] Duan Y J, Zhang L T, Qiao J C, et al. 2022 Phys. Rev. Lett. 129 175501

Google Scholar

Google Scholar

[36] Wagner H, Bedorf D, Küchemann S, Schwabe M, Zhang B, Arnold W, Samwer K 2011 Nat. Mater 10 439

Google Scholar

Google Scholar

[37] 黄蓓蓓, 郝奇, 吕国建, 乔吉超 2023 72 136101

Google Scholar

Google Scholar

Huang B B, Hao Q, Lyu G J, Qiao J C 2023 Acta Phys. Sin. 72 136101

Google Scholar

Google Scholar

[38] Gibbs M R J, Evetts J E, Leake J A 1983 J. Mater. Sci. 18 278

Google Scholar

Google Scholar

[39] Jiao W, Wen P, Peng H L, Bai H Y, Sun B A, Wang W H 2013 Appl. Phys. Lett. 102 101903

Google Scholar

Google Scholar

[40] Lu Z, Shang B, Sun Y, Zhu Z, Guan P, Wang W, Bai H 2016 J. Chem. Phys. 144 144501

Google Scholar

Google Scholar

[41] 汪卫华 2013 物理学进展 33 177

Wang W H 2013 Prog. Phys. 33 177

[42] 王峥, 汪卫华 2017 66 176103

Google Scholar

Google Scholar

Wang Z, Wang W H 2017 Acta Phys. Sin. 66 176103

Google Scholar

Google Scholar

[43] Zhao Y, Shang B, Zhang B, Tong X, Ke H, Bai H, Wang W H 2022 Sci. Adv. 8 eabn3623

Google Scholar

Google Scholar

[44] Casalini R, Roland C M 2009 Phys. Rev. Lett. 102 035701

Google Scholar

Google Scholar

-

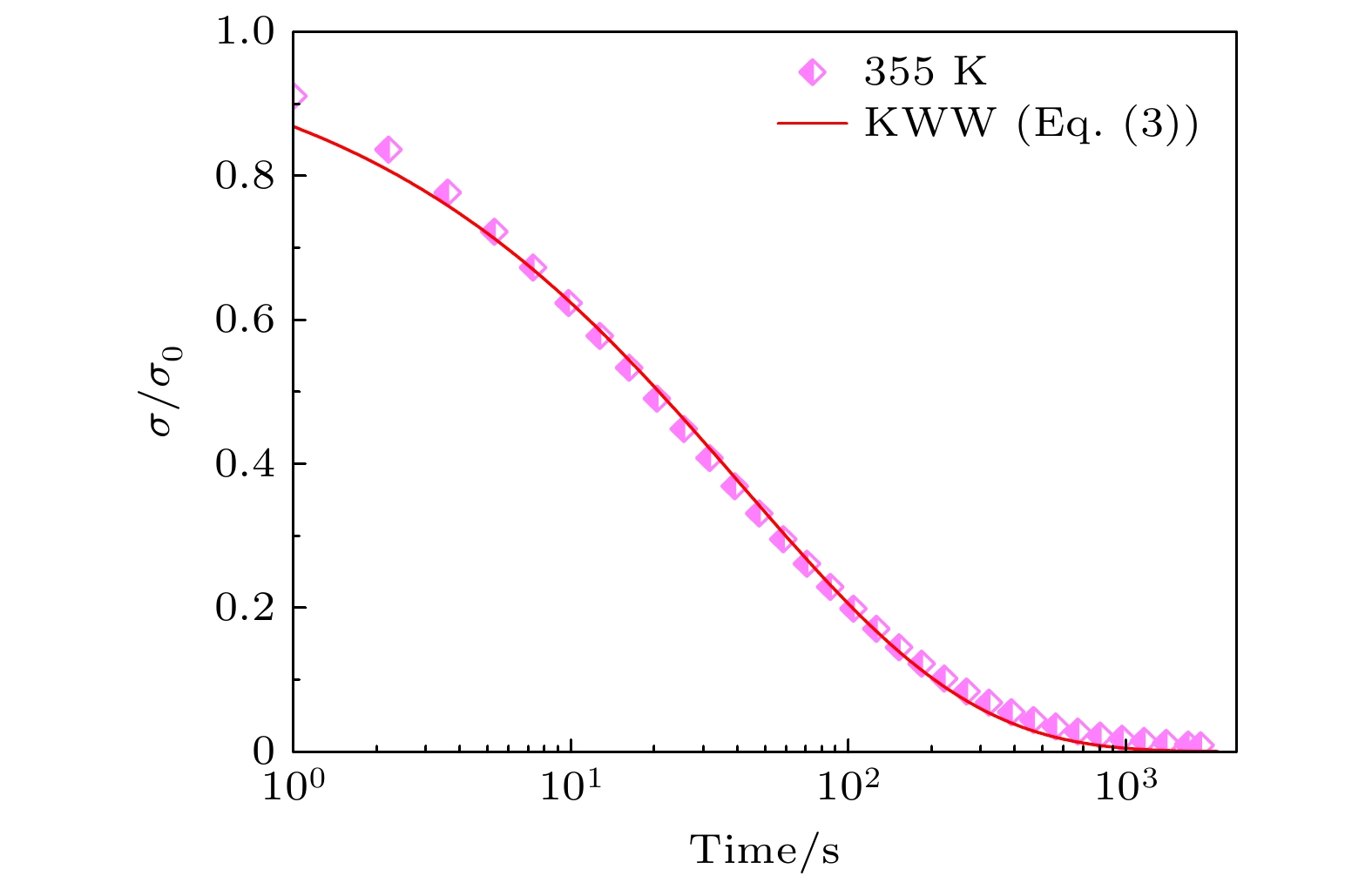

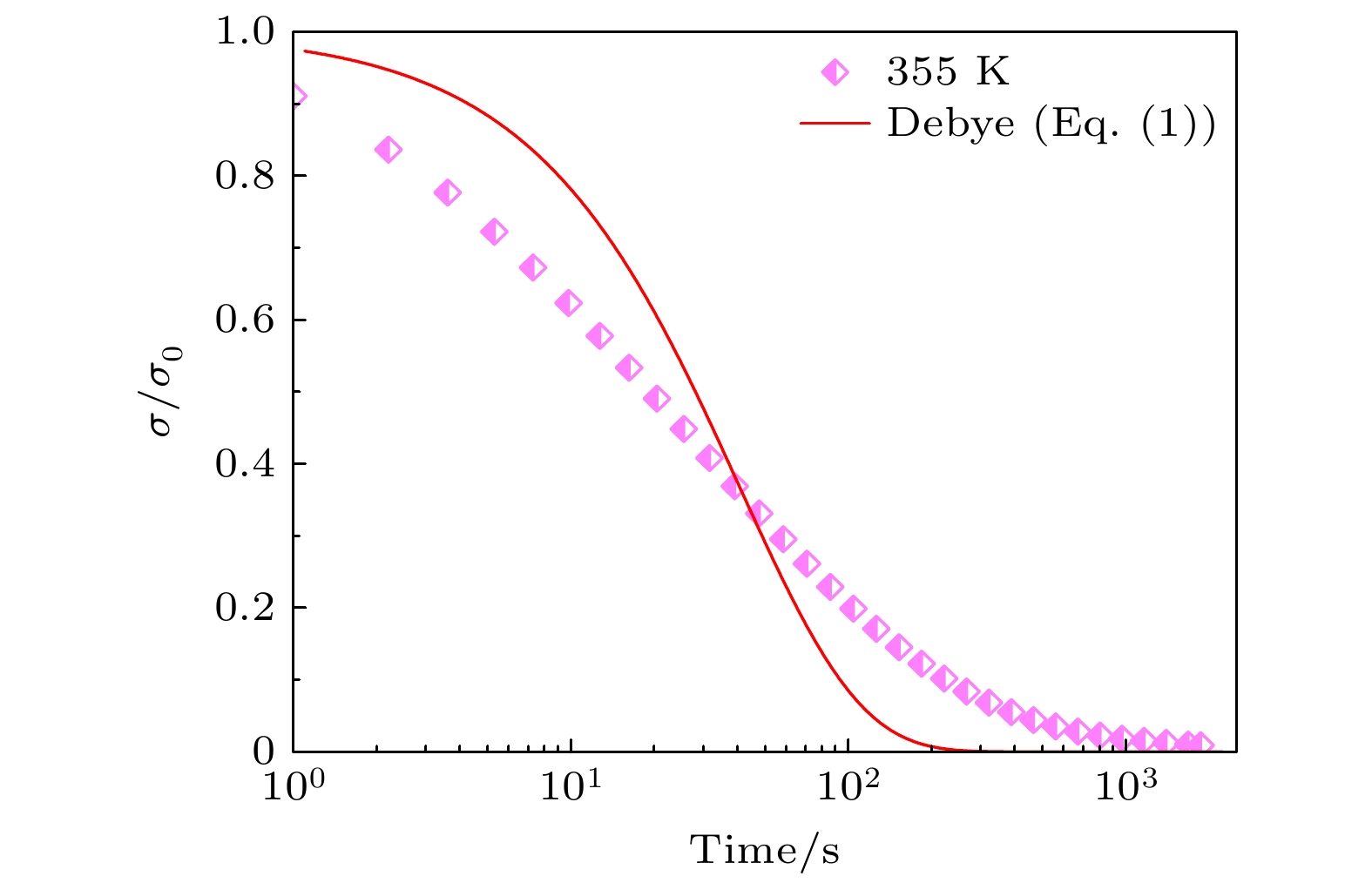

图 1 聚苯乙烯在给定应变0.4%条件下的应力松弛响应. 测试温度为355 K, 加载前保温30 min以使测试环境温度稳定; 红色实线为Maxwell模型 ((1)式)拟合曲线

Fig. 1. Stress response of PS at a given strain of 0.4%. The test temperature is 355 K, and the temperature is kept for 30 min before loading to stabilize the ambient temperature in an equilibrium state. The red solid curve is the least fitting using the Maxwell model (Eq. (1)).

图 8 不同老化时间条件下(15, 30, 60, 90, 120 min)聚苯乙烯应力松弛曲线, 测试温度为350 K, 红色实线为三参数扩展指数方程((6)式)拟合结果

Fig. 8. Stress relaxation curves of polystyrene after annealing for different time (15, 30, 60, 90, 120 min). The red solid curves represent the fitting results of the three-parameter extended exponential equation (Eq. (6)).

-

[1] Ozerin A N, Golubev E K, Ivanchev S S, Aulov V A, Kechek’yan A S, Kurkin T S, Ivan’kova E M, Adonin N Y 2022 Polym. Sci. Ser. A 64 73

Google Scholar

Google Scholar

[2] Müller M, Abetz V 2021 Chem. Rev. 121 14189

Google Scholar

Google Scholar

[3] Li Y, Tang S, Abberton B C, Kröger M, Burkhart C, Jiang B, Papakonstantopoulos G J, Poldneff M, Liu W K 2012 Polymer 53 5935

Google Scholar

Google Scholar

[4] Boland C S, Khan U, Ryan G, Barwich S, Charifou R, Harvey A, Backes C, Li Z, Ferreira M S, Möbius M E, Young R J, Coleman J N 2016 Science 354 1257

Google Scholar

Google Scholar

[5] 金日光, 华幼卿 2000 高分子物理 (第二版) (北京: 化学工业出版社)

Jin R G, Hua Y Q 2000 Polymer Physics (2nd Ed.) (Beijing: Chemical Industry Press

[6] Hou J X, Svaneborg C, Everaers R, Grest G S 2010 Phys. Rev. Lett. 105 068301

Google Scholar

Google Scholar

[7] Spathis G, Kontou E 2012 Compos. Sci. Technol. 72 959

Google Scholar

Google Scholar

[8] Huang J S, Gibson L J 1991 J. Mater. Sci. 26 637

Google Scholar

Google Scholar

[9] Papanicolaou G C, Zaoutsos S P 2019 Creep and Fatigue in Polymer Matrix Composites (Woodhead Publishing) pp3–59

[10] Di Marzio E A, Kasianowicz J J 2003 J. Chem. Phys. 119 6378

Google Scholar

Google Scholar

[11] Auhl R, Everaers R, Grest G S, Kremer K, Plimpton S J 2003 J. Chem. Phys. 119 12718

Google Scholar

Google Scholar

[12] Kreer T, Metzger S, Müller M, Binder K, Baschnagel J 2004 J. Chem. Phys. 120 4012

Google Scholar

Google Scholar

[13] Chui C, Boyce M C 1999 Macromolecules 32 3795

Google Scholar

Google Scholar

[14] Perez J 1998 Physics and Mechanics of Amorphous Polymers (CRC Press

[15] Ediger M D 2000 Annu. Rev. Phys. Chem. 51 99

Google Scholar

Google Scholar

[16] Wang X Y, Xu W S, Zhang H, Douglas J F 2019 J. Chem. Phys. 151 184503

Google Scholar

Google Scholar

[17] Dmowski W, Iwashita T, Chuang C P, Almer J, Egami T 2010 Phys. Rev. Lett. 105 205502

Google Scholar

Google Scholar

[18] Hu Y, Guan P, Li M, Liu C, Yang Y, Bai H, Wang W 2016 Phys. Rev. B 93 214202

Google Scholar

Google Scholar

[19] Smith G D, Borodin O, Paul W 2002 J. Chem. Phys. 117 10350

Google Scholar

Google Scholar

[20] Jin W, Boyd R H 2002 Polymer 43 503

Google Scholar

Google Scholar

[21] Borodin O, Smith G D, Bandyopadhyaya R, Byutner O 2003 Macromolecules 36 7873

Google Scholar

Google Scholar

[22] Smith G D, Paul W, Monkenbusch M, Richter D 2001 J. Chem. Phys. 114 4285

Google Scholar

Google Scholar

[23] Gebremichael Y, Schrøder T B, Starr F W, Glotzer S C 2001 Phys. Rev. E 64 051503

Google Scholar

Google Scholar

[24] Bennemann C, Donati C, Baschnagel J, Glotzer S C 1999 Nature 399 246

Google Scholar

Google Scholar

[25] Etienne S, David L 2007 Philos. Mag. 87 417

Google Scholar

Google Scholar

[26] Lunkenheimer P, Wehn R, Schneider U, Loidl A 2005 Phys. Rev. Lett. 95 055702

Google Scholar

Google Scholar

[27] Bruns M, Hassani M, Varnik F, Hassanpour A, Divinski S, Wilde G 2021 Phys. Rev. Res. 3 013234

Google Scholar

Google Scholar

[28] Pan J, Ivanov Y P, Zhou W H, Li Y, Greer A L 2020 Nature 578 559

Google Scholar

Google Scholar

[29] Pan J, Wang Y X, Guo Q, Zhang D, Greer A L, Li Y 2018 Nat. Commun. 9 560

Google Scholar

Google Scholar

[30] Wunsch J R 2014 Polystyrene-Synthesis, Production and Applications (New York: Nova Science Publishers, Inc.

[31] 张智枢, 顾欣, 杨云云, 蔡绪福 2017 工程科学与技术 49 232

Google Scholar

Google Scholar

Zhang Z S, Gu X, Yang Y Y, Cai X F 2017 Adv. Eng. Sci. 49 232

Google Scholar

Google Scholar

[32] 郝奇, 乔吉超 2022 力学学报 54 3058

Google Scholar

Google Scholar

Hao Q, Qiao J C 2022 Chin. J. Theo. Appl. Mech. 54 3058

Google Scholar

Google Scholar

[33] Taub A, Spaepen F 1981 J. Mater. Sci. 16 3087

Google Scholar

Google Scholar

[34] Qiao J C, Wang Y J, Zhao L Z, et al. 2016 Phys. Rev. B 94 104203

Google Scholar

Google Scholar

[35] Duan Y J, Zhang L T, Qiao J C, et al. 2022 Phys. Rev. Lett. 129 175501

Google Scholar

Google Scholar

[36] Wagner H, Bedorf D, Küchemann S, Schwabe M, Zhang B, Arnold W, Samwer K 2011 Nat. Mater 10 439

Google Scholar

Google Scholar

[37] 黄蓓蓓, 郝奇, 吕国建, 乔吉超 2023 72 136101

Google Scholar

Google Scholar

Huang B B, Hao Q, Lyu G J, Qiao J C 2023 Acta Phys. Sin. 72 136101

Google Scholar

Google Scholar

[38] Gibbs M R J, Evetts J E, Leake J A 1983 J. Mater. Sci. 18 278

Google Scholar

Google Scholar

[39] Jiao W, Wen P, Peng H L, Bai H Y, Sun B A, Wang W H 2013 Appl. Phys. Lett. 102 101903

Google Scholar

Google Scholar

[40] Lu Z, Shang B, Sun Y, Zhu Z, Guan P, Wang W, Bai H 2016 J. Chem. Phys. 144 144501

Google Scholar

Google Scholar

[41] 汪卫华 2013 物理学进展 33 177

Wang W H 2013 Prog. Phys. 33 177

[42] 王峥, 汪卫华 2017 66 176103

Google Scholar

Google Scholar

Wang Z, Wang W H 2017 Acta Phys. Sin. 66 176103

Google Scholar

Google Scholar

[43] Zhao Y, Shang B, Zhang B, Tong X, Ke H, Bai H, Wang W H 2022 Sci. Adv. 8 eabn3623

Google Scholar

Google Scholar

[44] Casalini R, Roland C M 2009 Phys. Rev. Lett. 102 035701

Google Scholar

Google Scholar

计量

- 文章访问数: 5873

- PDF下载量: 98

- 被引次数: 0

下载:

下载: