-

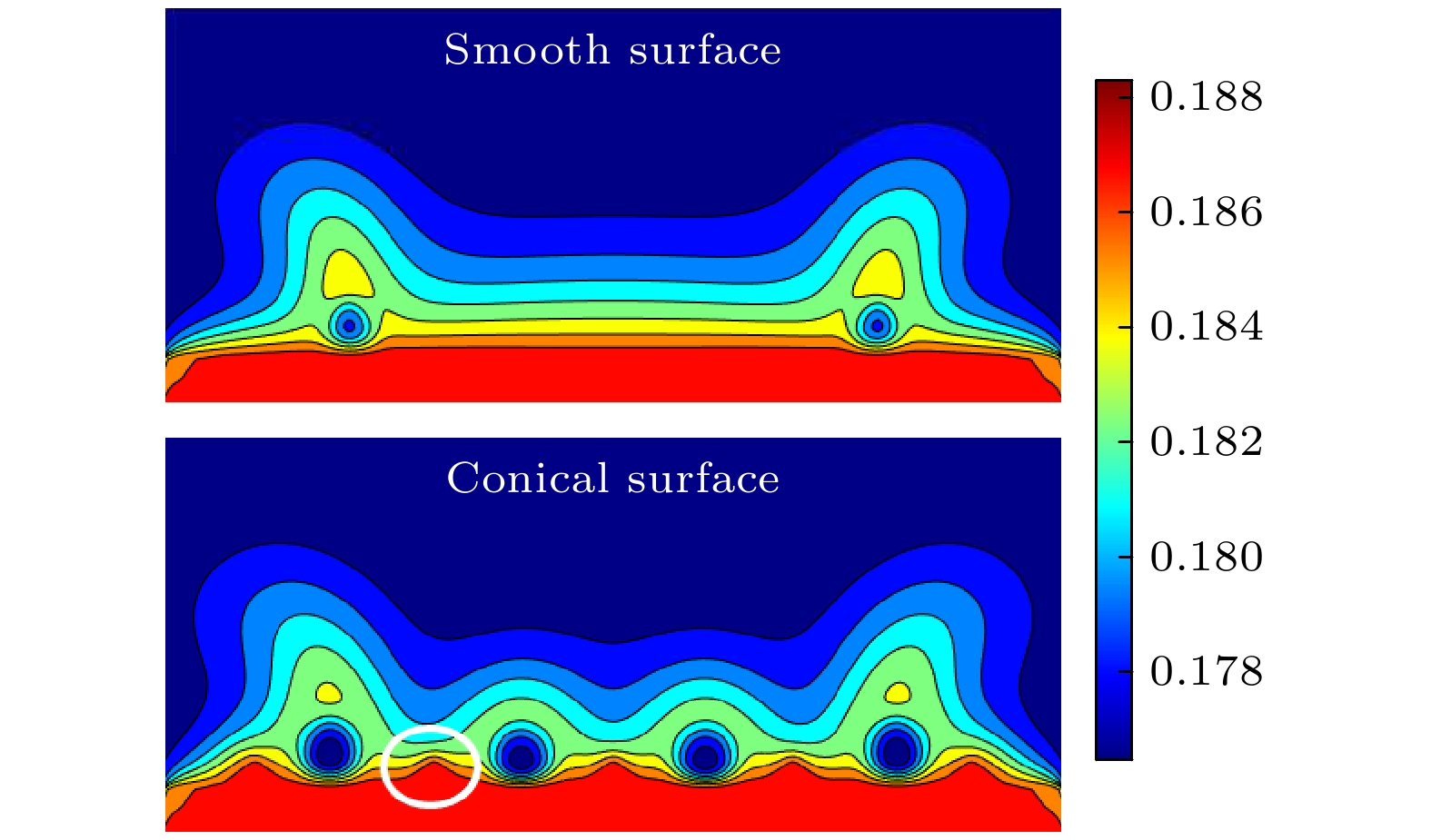

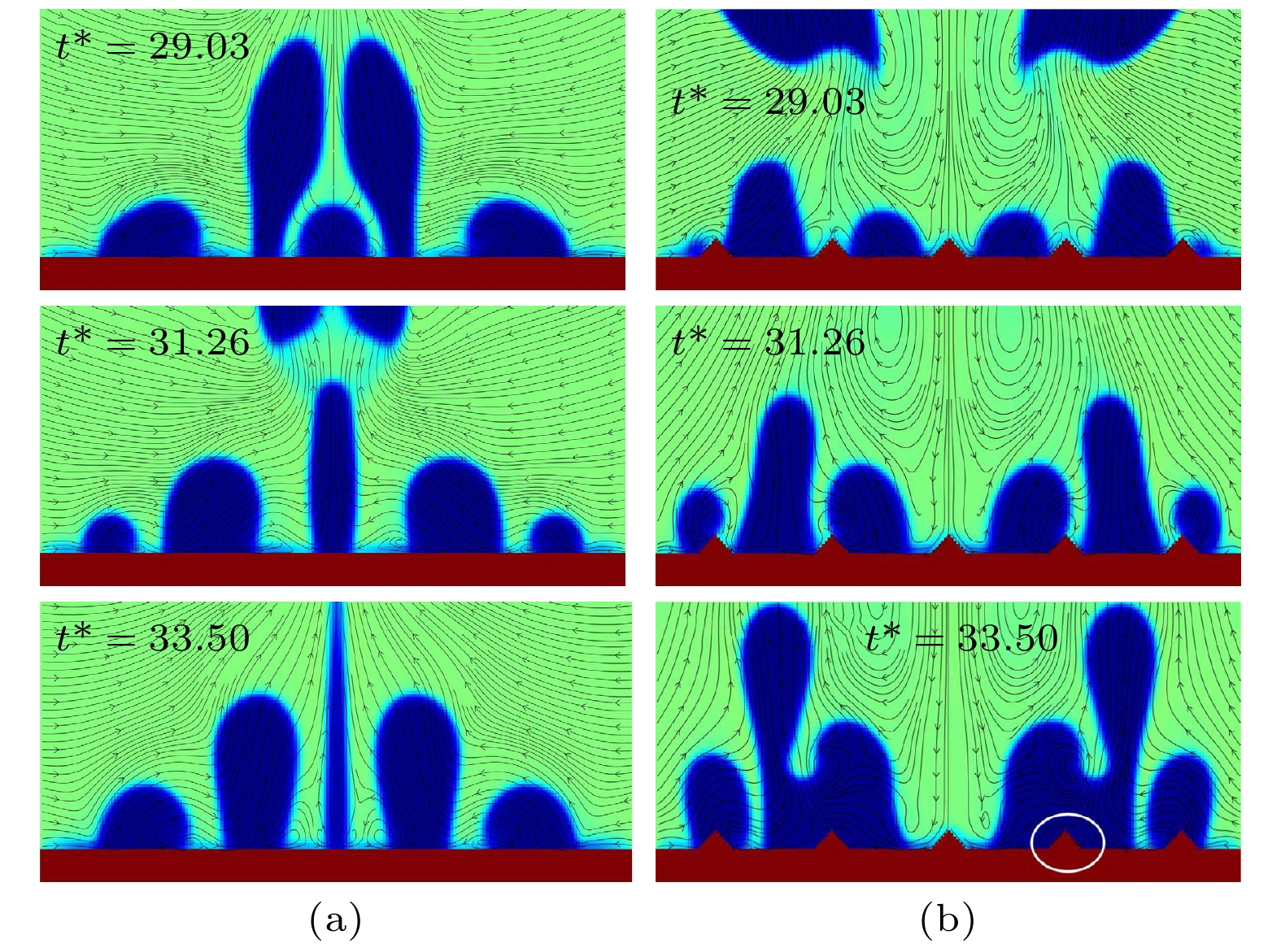

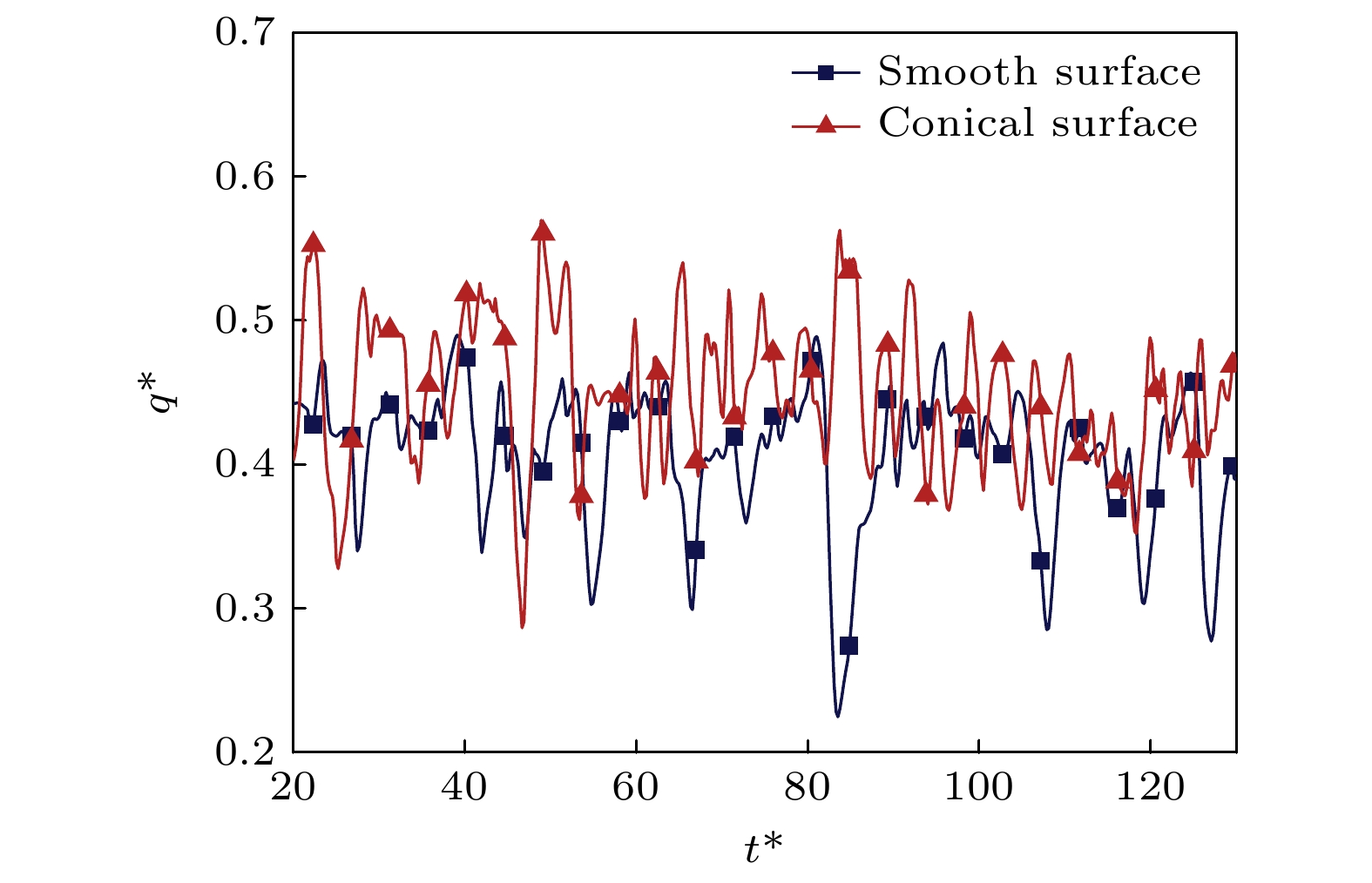

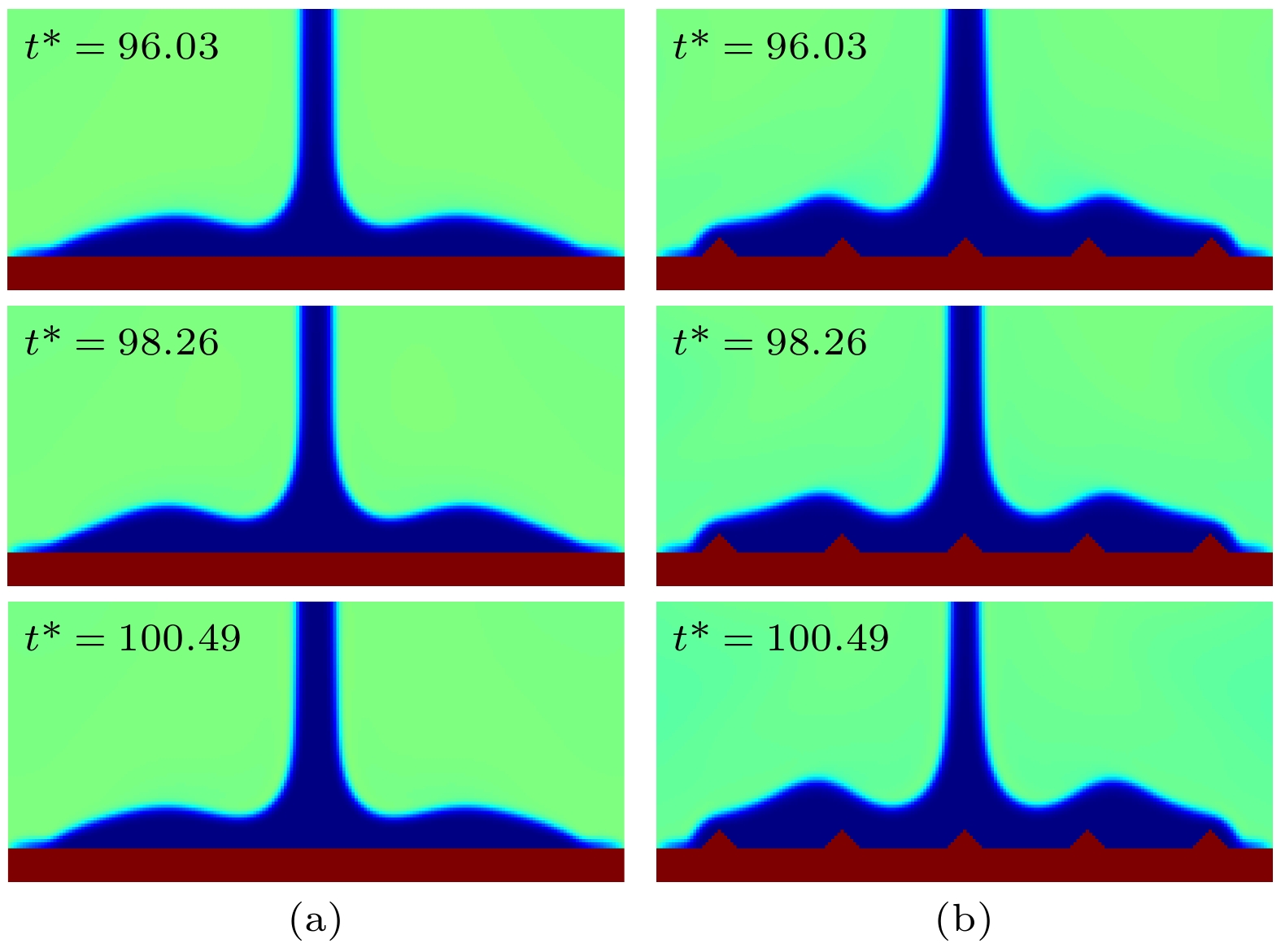

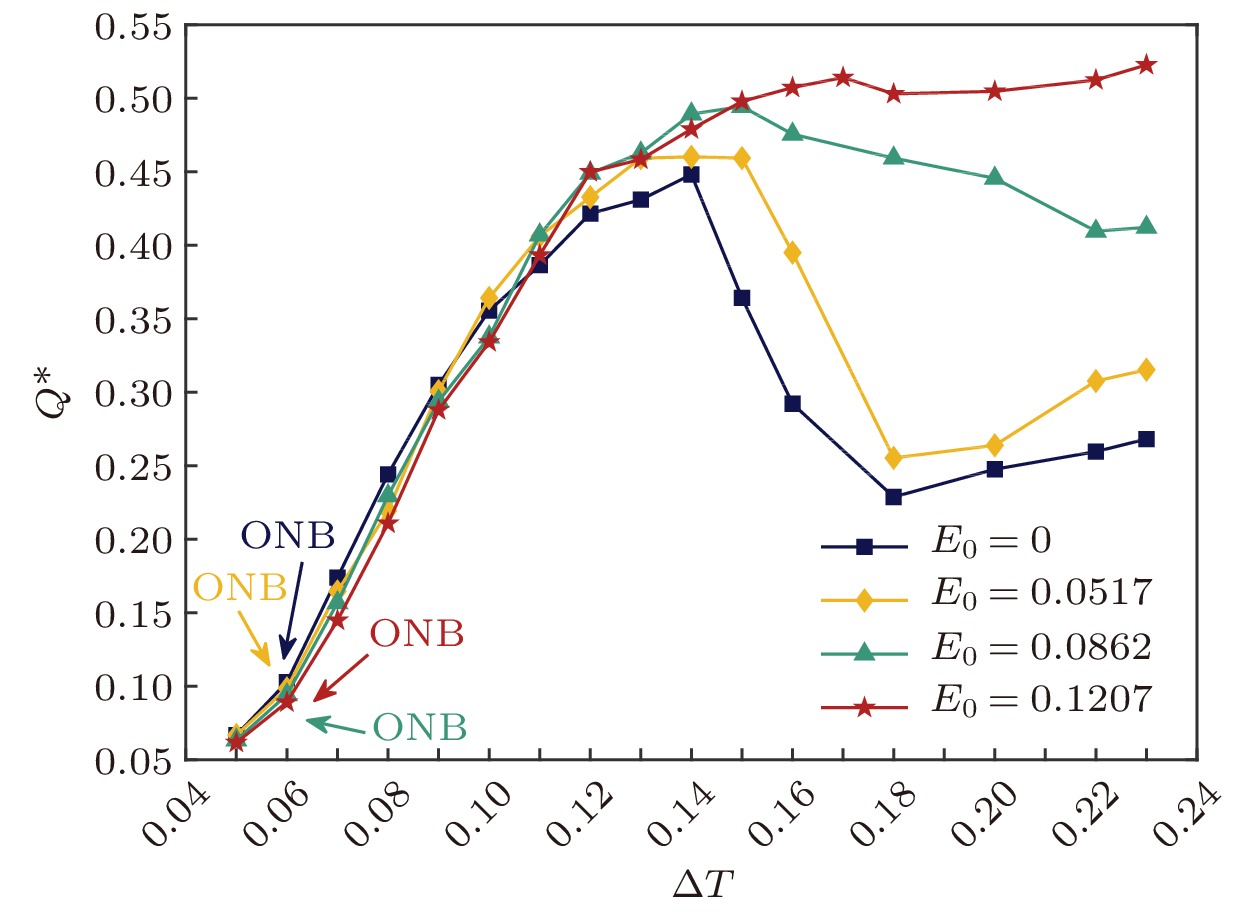

采用耦合电场模型的相变格子Boltzmann模型, 数值研究了电场作用下锥翅结构表面的饱和池沸腾换热. 为了定量分析电场对锥翅结构表面沸腾换热影响的机理, 首先在无电场作用下对比调查了平滑表面和锥翅表面的沸腾换热现象. 发现锥翅结构在核态沸腾阶段有更多的成核点, 沸腾换热性能增强, 临界热流密度(critical heat flux, CHF)提高. 而在过渡沸腾阶段以及膜态沸腾阶段, 由于锥翅结构增加了锥翅表面流体的流动阻力, 阻碍了气液交换, 换热性能低于平滑表面. 基于以上发现, 通过对锥翅表面池沸腾过程施加电场, 进一步强化了锥翅表面沸腾换热. 结果表明, 在起始核态沸腾阶段, 电场的存在稍微延后了气泡开始成核时间, 气泡尺寸减小, 沸腾轻微被抑制; 充分核态沸腾阶段, 由于电场力的作用以及电场与锥翅结构协同表现出的尖端效应, 阻止了加热表面干斑的扩散和蔓延, 促进沸腾换热; 过渡沸腾以及膜态沸腾阶段, 尖端效应更加明显, 逐渐增大的电场强度使沸腾在更高过热度下处于核态沸腾状态, 沸腾换热性能大幅度提高, 且CHF逐渐提高.

-

关键词:

- 锥翅结构 /

- 电场 /

- 格子Boltzmann方法 /

- 池沸腾

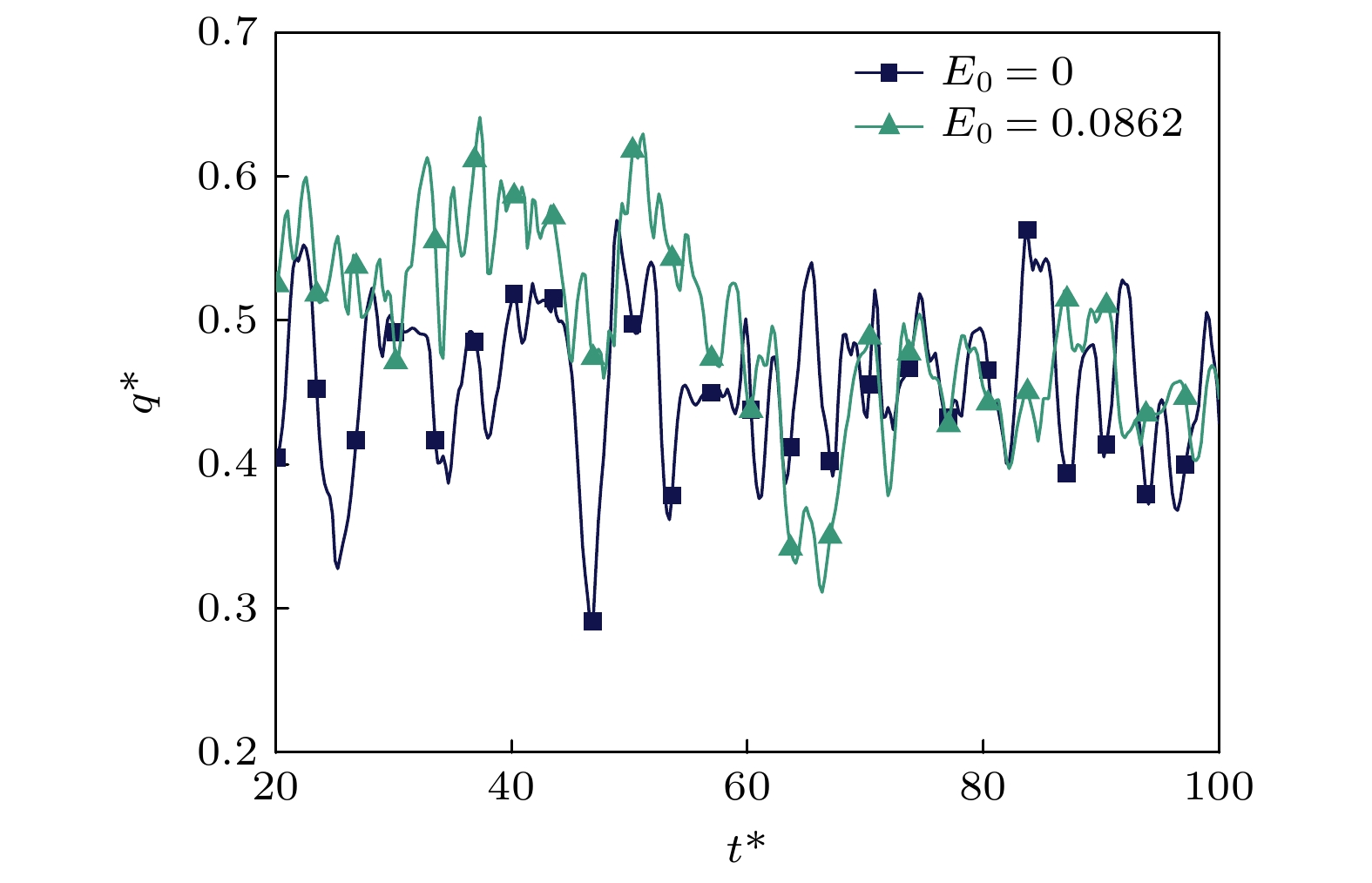

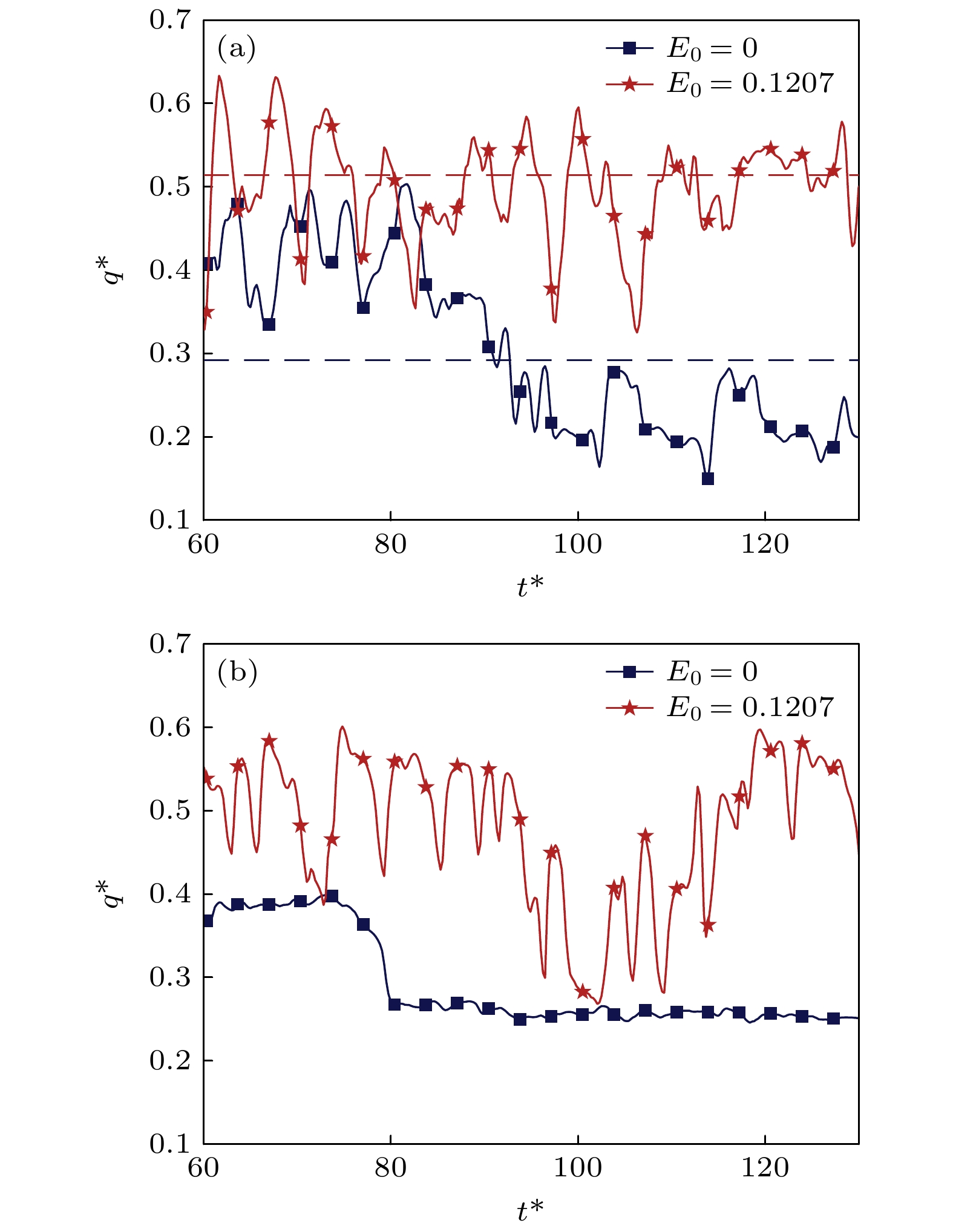

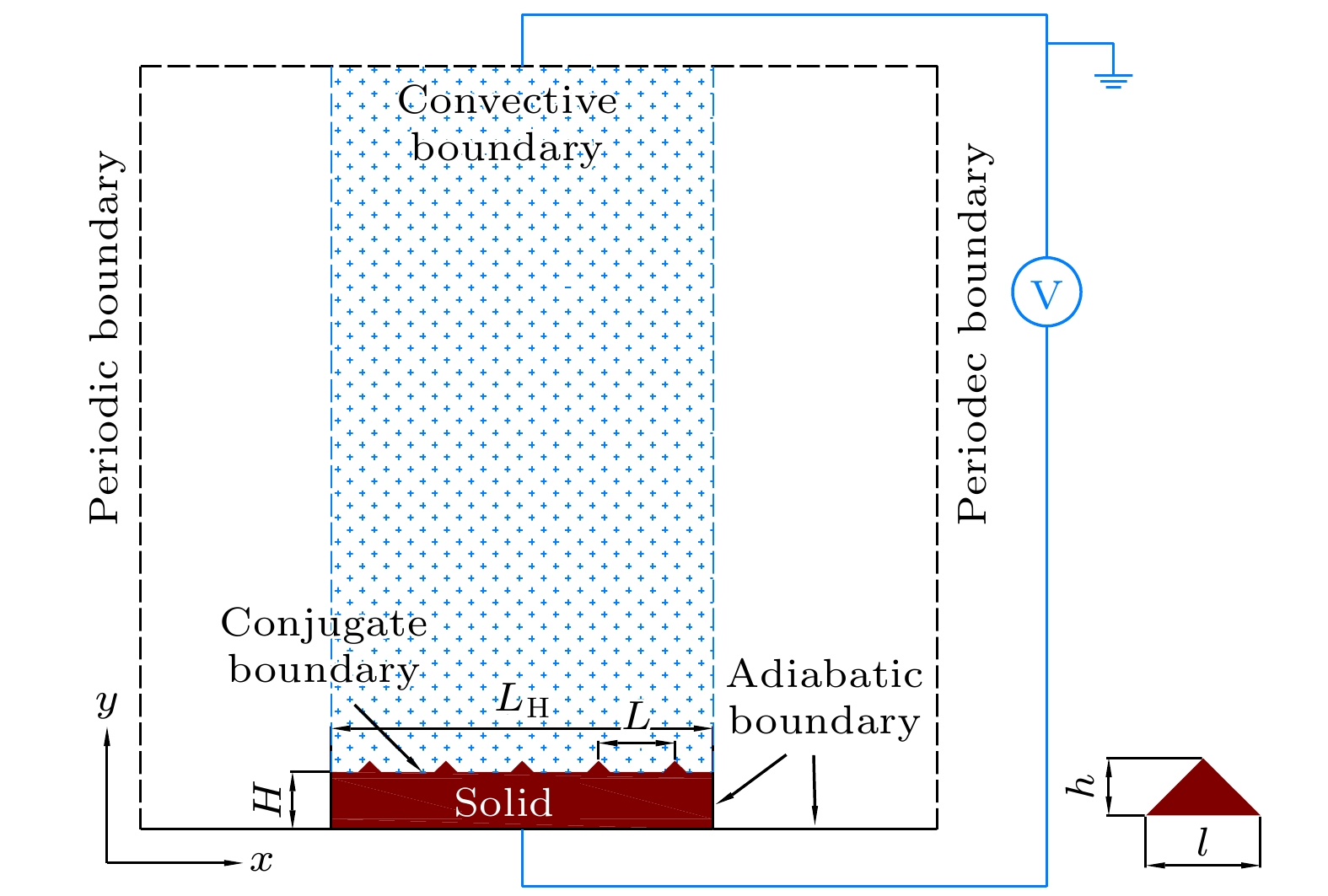

The saturated pool boiling heat transfer on a conical structure surface under the action of an electric field is numerically investigated by using the lattice Boltzmann (LB) model coupled with an electric field model. A comparison study of boiling heat transfer phenomenon smooth surface and conical surface without the action of an electric field is first conducted in order to quantitatively analyze the mechanism of the electric field effect on boiling heat transfer on the conical structure surface. It is discovered that the conical structure has more active nucleation sites during the nucleate boiling regime, improving the boiling heat transfer efficiency and enhancing the critical heat flux (CHF). However, in the transition boiling stage and film boiling stage, the conical structure increases the flow resistance of the fluid on the fin surface, hindering heat transfer between the vapor and liquid and producing lower heat transfer performance than smooth surface. Based on the aforementioned findings, the boiling heat transmission on the conical structure surface is enhanced by applying an electric field. Numerical results indicate that the effect of the electric field on the boiling heat transfer performance on the conical structure surface is related to the boiling regime. In the earlier stage of the nucleation boiling regime, when an electric field is present, the onset time of bubble nucleation is slightly delayed, bubble size decreases a little, and boiling is slightly suppressed. However, the combination effect of electric field and conical structure, especially the tip effect, prevents the spread and diffusion of dry areas on the heating surface, thereby enhancing boiling heat transfer in the fully developed nucleate boiling stage. The tip effect grows more evidently in the transition boiling regime and film boiling regime, and increasing electric field intensity causes boiling to continue in the nucleate boiling regime at a higher superheat level. As a result, boiling heat transfer performance is greatly improved, and CHF steadily rises.-

Keywords:

- conical structure /

- electric field /

- lattice Boltzmann method /

- pool boiling

[1] Zaidi S 2015 Chem. Eng. Res. Des. 98 44

Google Scholar

Google Scholar

[2] Massih A R, Persson S 1992 J. Nucl. Mater. 188 323

Google Scholar

Google Scholar

[3] Mohammed H I, Giddings D, Walker G S 2019 Int. J. Heat Mass Transfer 130 710

Google Scholar

Google Scholar

[4] Nikolayev V S, Chatain D, Garrabos Y, Beysens D 2006 Phys. Rev. Lett. 97 184503

Google Scholar

Google Scholar

[5] Li W, Dai R K, Zeng M, Wang Q W 2020 Renew. Sust. Energ. Rev. 130 109926

Google Scholar

Google Scholar

[6] Tian Z, Etedali S, Afrand M, Abdollahi A, Goodarzi M 2019 Powder Technol. 356 391

Google Scholar

Google Scholar

[7] Wei J J, Honda H 2003 Int. J. Heat Mass Transfer 46 4059

Google Scholar

Google Scholar

[8] Li Q, Zhao J H, Sun X Z, Liu B 2022 Appl. Therm. Eng. 215 118924

Google Scholar

Google Scholar

[9] Kong X, Zhang Y H, Wei J J 2018 Exp. Therm. Fluid Sci. 91 9

Google Scholar

Google Scholar

[10] Kim S H, Lee C G, Kang J Y, Moriyama K, Kim M H, Park H S 2015 Int. J. Heat Mass Transfer 91 1140

Google Scholar

Google Scholar

[11] Elkholy A, Swift J, Kempers R 2023 Appl. Therm. Eng 219 119665

Google Scholar

Google Scholar

[12] Clubb L 1916 UK Patent 100796 [1916-07-09

[13] Dong W, Li R Y, Yu H L, Yan Y Y 2006 Exp. Therm. Fluid Sci. 30 579

Google Scholar

Google Scholar

[14] Gao M, Cheng P, Quan X J 2013 Int. J. Heat Mass Transfer 67 984

Google Scholar

Google Scholar

[15] Hristov Y, Zhao D, Kenning D B R, Sefiane K, Karayiannis T G 2009 Heat Mass Transfer 45 999

Google Scholar

Google Scholar

[16] Garivalis A I, Manfredini G, Saccone G, Di Marco P, Kossolapov A, Bucci M 2021 NPJ Microgravity 7(1) 37

Google Scholar

Google Scholar

[17] Quan X J, Gao M, Cheng P, Li J S 2015 Int. J. Heat Mass Transfer 85 595

Google Scholar

Google Scholar

[18] Liu B, Garivalis A I, Cao Z, Zhang Y, Wei J 2022 Int. J. Heat Mass Transfer 183 122154

Google Scholar

Google Scholar

[19] Liu X, Chai Z H, Shi B C 2019 Phys. Fluids 31 092103

Google Scholar

Google Scholar

[20] Liu X, Chai Z H, Shi B C 2021 Commun. Comput. Phys. 30 1346

Google Scholar

Google Scholar

[21] Feng Y, Li H, Guo K, Lei X, Zhao J 2019 Int. J. Heat Mass Transfer 135 885

Google Scholar

Google Scholar

[22] Li W X, Li Q, Chang H Z, Yu Y, Tang S 2022 Phys. Fluids 34 123327

Google Scholar

Google Scholar

[23] Lou Q, Wang H Y, Li L 2023 Phys. Fluids 35 123327

Google Scholar

Google Scholar

[24] Ezzatneshan E, Salehi A, Vaseghnia H 2023 Int. J. Therm. Sci 184 107913

Google Scholar

Google Scholar

[25] Gong S, Cheng P 2012 Int. J. Heat Mass Transfer 55 4923

Google Scholar

Google Scholar

[26] Guo Z L, Zheng C G, Shi B C 2011 Phys. Rev. E 83 036707

Google Scholar

Google Scholar

[27] Chai Z H, Zhao T S 2012 Phys. Rev. E 86 016705

Google Scholar

Google Scholar

[28] Panofsky W, Phillips M, Jauch J M 1956 Am. J. Phys. 24 416

[29] He X Y, Ning L 2000 Comput. Phys. Commun. 129 158

Google Scholar

Google Scholar

[30] Chai Z H, Shi B C 2008 Appl. Math. Model. 32 2050

Google Scholar

Google Scholar

[31] Chai Z H, Liang H, Du R, Shi B C 2019 SIAM J. Sci. Comput. 41 B746

Google Scholar

Google Scholar

[32] Wang L, Wei Z C, Li T F, Chai Z H, Shi B C 2021 Appl. Math. Model. 95 361

Google Scholar

Google Scholar

[33] Wang H Y, Lou Q, Liu G J, Li L 2022 Int. J. Therm. Sci. 178 107554

Google Scholar

Google Scholar

[34] Lou Q, Guo Z L, Shi B C 2013 Phys. Rev. E 87 063301

Google Scholar

Google Scholar

[35] Ladd A J C 1994 J. Fluid Mech. 271 285

Google Scholar

Google Scholar

[36] Li L, Chen C, Mei R, Mei M, Klausner J 2014 Phys. Rev. E 89 043308

Google Scholar

Google Scholar

[37] Gong S, Cheng P 2017 Int. Commun. Heat Mass Transfer 87 61

Google Scholar

Google Scholar

[38] Li Q, Yu Y, Luo K H 2019 Phys. Rev. E 100 053313

Google Scholar

Google Scholar

[39] Sadasivan P, Unal C, Nelson R 1995 J. Heat Transfer 117 558

Google Scholar

Google Scholar

[40] 柴立和, 彭晓峰, 王补宣 1999 原子能科学技术 33 533

Chai L H, Peng X F, Wang B X 1999 Atomic Energy Sci. Techno. 33 533

[41] Berghmans J 1976 Int. J. Heat Mass Transfer 19 791

Google Scholar

Google Scholar

[42] Johnson R 1968 AIAA J. 6 8

-

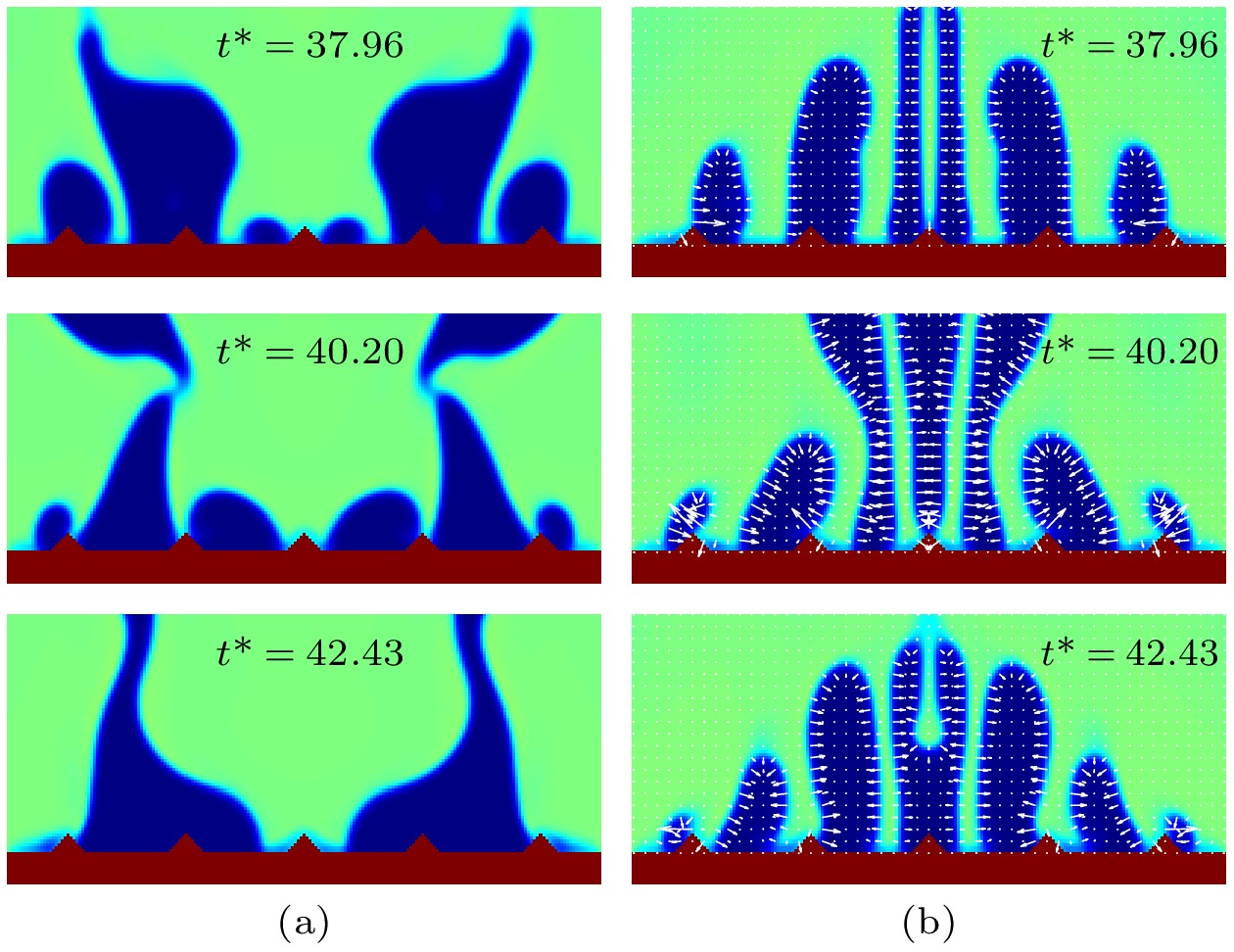

图 10 $ T_{\rm{b}}=0.96 T_{\rm{c}} $时, 不同电场强度下锥翅表面的沸腾过程 (a) E0 = 0; (b) E0 = 0.0517; (c) E0 = 0.0862; (d) E0 = 0.1207

Fig. 10. Snapshots of boiling processes on the conical surface at $ T_{\rm{b}}=0.96 T_{\rm{c}} $ under different electric field intensities: (a) E0 = 0; (b) E0 = 0.0517; (c) E0 = 0.0862; (d) E0 = 0.1207

表 1 格子单位与物理单位转换

Table 1. The unit conversion from lattice unit to physical unit.

符号 格子单位 物理单位 转换因子 $ \rho_{\rm{l}} $ 5.426 570.02 $ {\rm{kg/m^3}} $ 106.16 $ {\rm{kg/m^3}} $ $ \rho_{\rm{v}} $ 0.8113 86.13 $ {\rm{kg/m^3}} $ 106.16 $ {\rm{kg/m^3}} $ $ l_0 $ 16 $ 4.72\times 10^{-6}\;{\rm{m}} $ $ 2.95\times 10^{-7}\;{\rm{m}} $ $ u_0 $ 0.0358 38.56 $ {\rm{m/s}} $ 1077.09 $ {\rm{m/s}} $ $ t_0 $ 447.8 $ 1.224\times 10^{-7}\;{\rm{s}} $ $ 2.734\times 10^{-10}\;{\rm{s}} $ $ \nu $ 0.06 $ 0.19\times 10^{-4}\;{\rm{m^2/s}} $ $ 3.18\times 10^{-4}\;{\rm{m^2/s}} $ $ T_{\rm{c}} $ 0.1961 647.2 $ {\rm{K}} $ 3300.36 $ {\rm{K}} $ $ p_{\rm{c}} $ 0.1784 $ 0.221\times 10^{8}\;{\rm{Pa}} $ $ 1.24\times 10^{8}\;{\rm{Pa}} $ $ c_{\rm{vl}} $ 4.0 1405.9 $ {\rm{J/(kg\cdot K)}} $ 351.48 $ {\rm{J/(kg\cdot K)}} $ $ h_{\rm{fg}} $ 0.624 $ 0.726\times 10^{6}\;{\rm{J/kg}} $ $ 1.16\times 10^{6}\;{\rm{J/kg}} $ $ \lambda_{\rm{s}} $ 32.556 390.67 $ {\rm{W/(m\cdot K)}} $ 12.0 $ {\rm{W/(m\cdot K)}} $ $ q_0 $ 0.01269 $ 1.69\times 10^{9}\;{\rm{J/(m^2\cdot s)}} $ $ 1.33\times 10^{11}\;{\rm{J/(m^2\cdot s)}} $ $ \varepsilon_0\varepsilon_{\rm{l}} $ 2.236 $ 1.98\times 10^{-11}\;{\rm{F/m}} $ $ 8.85\times 10^{-12}\;{\rm{F/m}} $ $ \varepsilon_0\varepsilon_{\rm{v}} $ 1 $ 8.85\times 10^{-12}\;{\rm{F/m}} $ $ 8.85\times 10^{-12}\;{\rm{F/m}} $ $ V $ 1 1096.96 $ {\rm{V}} $ 1096.96 $ {\rm{V}} $ -

[1] Zaidi S 2015 Chem. Eng. Res. Des. 98 44

Google Scholar

Google Scholar

[2] Massih A R, Persson S 1992 J. Nucl. Mater. 188 323

Google Scholar

Google Scholar

[3] Mohammed H I, Giddings D, Walker G S 2019 Int. J. Heat Mass Transfer 130 710

Google Scholar

Google Scholar

[4] Nikolayev V S, Chatain D, Garrabos Y, Beysens D 2006 Phys. Rev. Lett. 97 184503

Google Scholar

Google Scholar

[5] Li W, Dai R K, Zeng M, Wang Q W 2020 Renew. Sust. Energ. Rev. 130 109926

Google Scholar

Google Scholar

[6] Tian Z, Etedali S, Afrand M, Abdollahi A, Goodarzi M 2019 Powder Technol. 356 391

Google Scholar

Google Scholar

[7] Wei J J, Honda H 2003 Int. J. Heat Mass Transfer 46 4059

Google Scholar

Google Scholar

[8] Li Q, Zhao J H, Sun X Z, Liu B 2022 Appl. Therm. Eng. 215 118924

Google Scholar

Google Scholar

[9] Kong X, Zhang Y H, Wei J J 2018 Exp. Therm. Fluid Sci. 91 9

Google Scholar

Google Scholar

[10] Kim S H, Lee C G, Kang J Y, Moriyama K, Kim M H, Park H S 2015 Int. J. Heat Mass Transfer 91 1140

Google Scholar

Google Scholar

[11] Elkholy A, Swift J, Kempers R 2023 Appl. Therm. Eng 219 119665

Google Scholar

Google Scholar

[12] Clubb L 1916 UK Patent 100796 [1916-07-09

[13] Dong W, Li R Y, Yu H L, Yan Y Y 2006 Exp. Therm. Fluid Sci. 30 579

Google Scholar

Google Scholar

[14] Gao M, Cheng P, Quan X J 2013 Int. J. Heat Mass Transfer 67 984

Google Scholar

Google Scholar

[15] Hristov Y, Zhao D, Kenning D B R, Sefiane K, Karayiannis T G 2009 Heat Mass Transfer 45 999

Google Scholar

Google Scholar

[16] Garivalis A I, Manfredini G, Saccone G, Di Marco P, Kossolapov A, Bucci M 2021 NPJ Microgravity 7(1) 37

Google Scholar

Google Scholar

[17] Quan X J, Gao M, Cheng P, Li J S 2015 Int. J. Heat Mass Transfer 85 595

Google Scholar

Google Scholar

[18] Liu B, Garivalis A I, Cao Z, Zhang Y, Wei J 2022 Int. J. Heat Mass Transfer 183 122154

Google Scholar

Google Scholar

[19] Liu X, Chai Z H, Shi B C 2019 Phys. Fluids 31 092103

Google Scholar

Google Scholar

[20] Liu X, Chai Z H, Shi B C 2021 Commun. Comput. Phys. 30 1346

Google Scholar

Google Scholar

[21] Feng Y, Li H, Guo K, Lei X, Zhao J 2019 Int. J. Heat Mass Transfer 135 885

Google Scholar

Google Scholar

[22] Li W X, Li Q, Chang H Z, Yu Y, Tang S 2022 Phys. Fluids 34 123327

Google Scholar

Google Scholar

[23] Lou Q, Wang H Y, Li L 2023 Phys. Fluids 35 123327

Google Scholar

Google Scholar

[24] Ezzatneshan E, Salehi A, Vaseghnia H 2023 Int. J. Therm. Sci 184 107913

Google Scholar

Google Scholar

[25] Gong S, Cheng P 2012 Int. J. Heat Mass Transfer 55 4923

Google Scholar

Google Scholar

[26] Guo Z L, Zheng C G, Shi B C 2011 Phys. Rev. E 83 036707

Google Scholar

Google Scholar

[27] Chai Z H, Zhao T S 2012 Phys. Rev. E 86 016705

Google Scholar

Google Scholar

[28] Panofsky W, Phillips M, Jauch J M 1956 Am. J. Phys. 24 416

[29] He X Y, Ning L 2000 Comput. Phys. Commun. 129 158

Google Scholar

Google Scholar

[30] Chai Z H, Shi B C 2008 Appl. Math. Model. 32 2050

Google Scholar

Google Scholar

[31] Chai Z H, Liang H, Du R, Shi B C 2019 SIAM J. Sci. Comput. 41 B746

Google Scholar

Google Scholar

[32] Wang L, Wei Z C, Li T F, Chai Z H, Shi B C 2021 Appl. Math. Model. 95 361

Google Scholar

Google Scholar

[33] Wang H Y, Lou Q, Liu G J, Li L 2022 Int. J. Therm. Sci. 178 107554

Google Scholar

Google Scholar

[34] Lou Q, Guo Z L, Shi B C 2013 Phys. Rev. E 87 063301

Google Scholar

Google Scholar

[35] Ladd A J C 1994 J. Fluid Mech. 271 285

Google Scholar

Google Scholar

[36] Li L, Chen C, Mei R, Mei M, Klausner J 2014 Phys. Rev. E 89 043308

Google Scholar

Google Scholar

[37] Gong S, Cheng P 2017 Int. Commun. Heat Mass Transfer 87 61

Google Scholar

Google Scholar

[38] Li Q, Yu Y, Luo K H 2019 Phys. Rev. E 100 053313

Google Scholar

Google Scholar

[39] Sadasivan P, Unal C, Nelson R 1995 J. Heat Transfer 117 558

Google Scholar

Google Scholar

[40] 柴立和, 彭晓峰, 王补宣 1999 原子能科学技术 33 533

Chai L H, Peng X F, Wang B X 1999 Atomic Energy Sci. Techno. 33 533

[41] Berghmans J 1976 Int. J. Heat Mass Transfer 19 791

Google Scholar

Google Scholar

[42] Johnson R 1968 AIAA J. 6 8

计量

- 文章访问数: 5111

- PDF下载量: 216

- 被引次数: 0

下载:

下载: