-

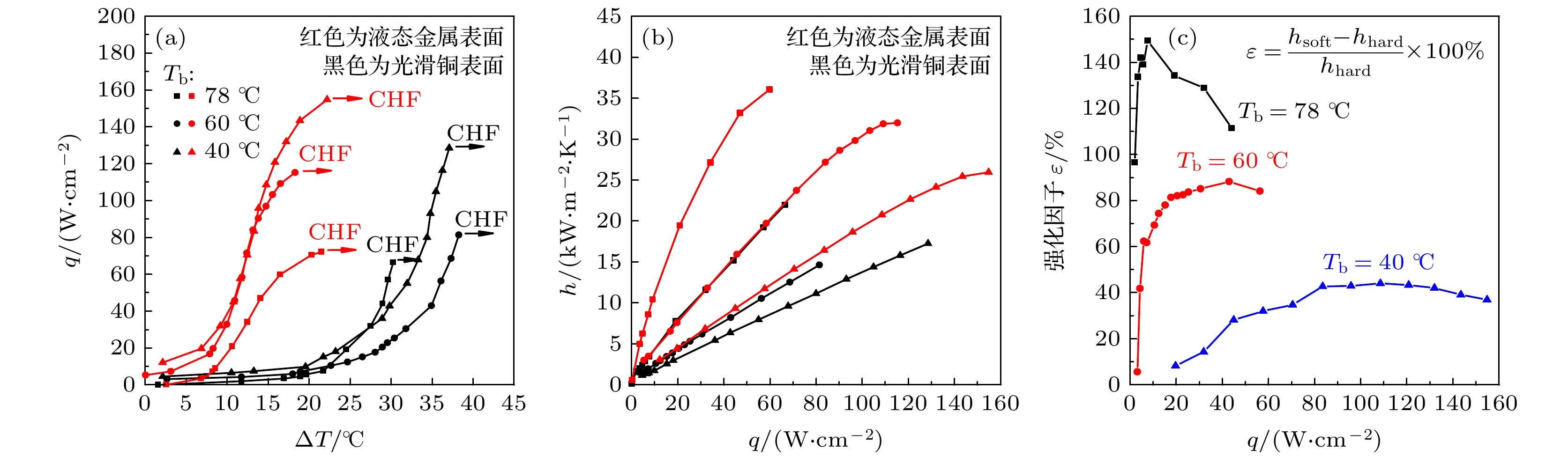

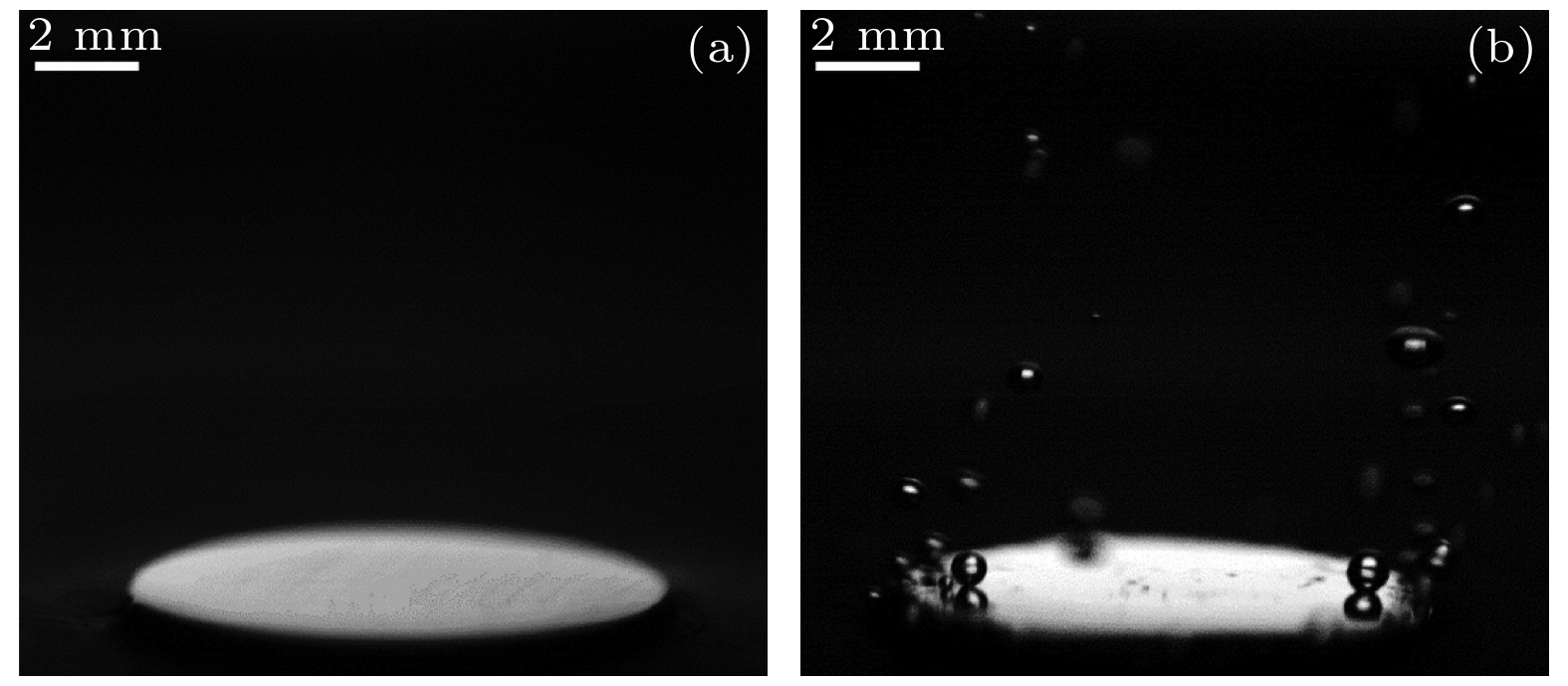

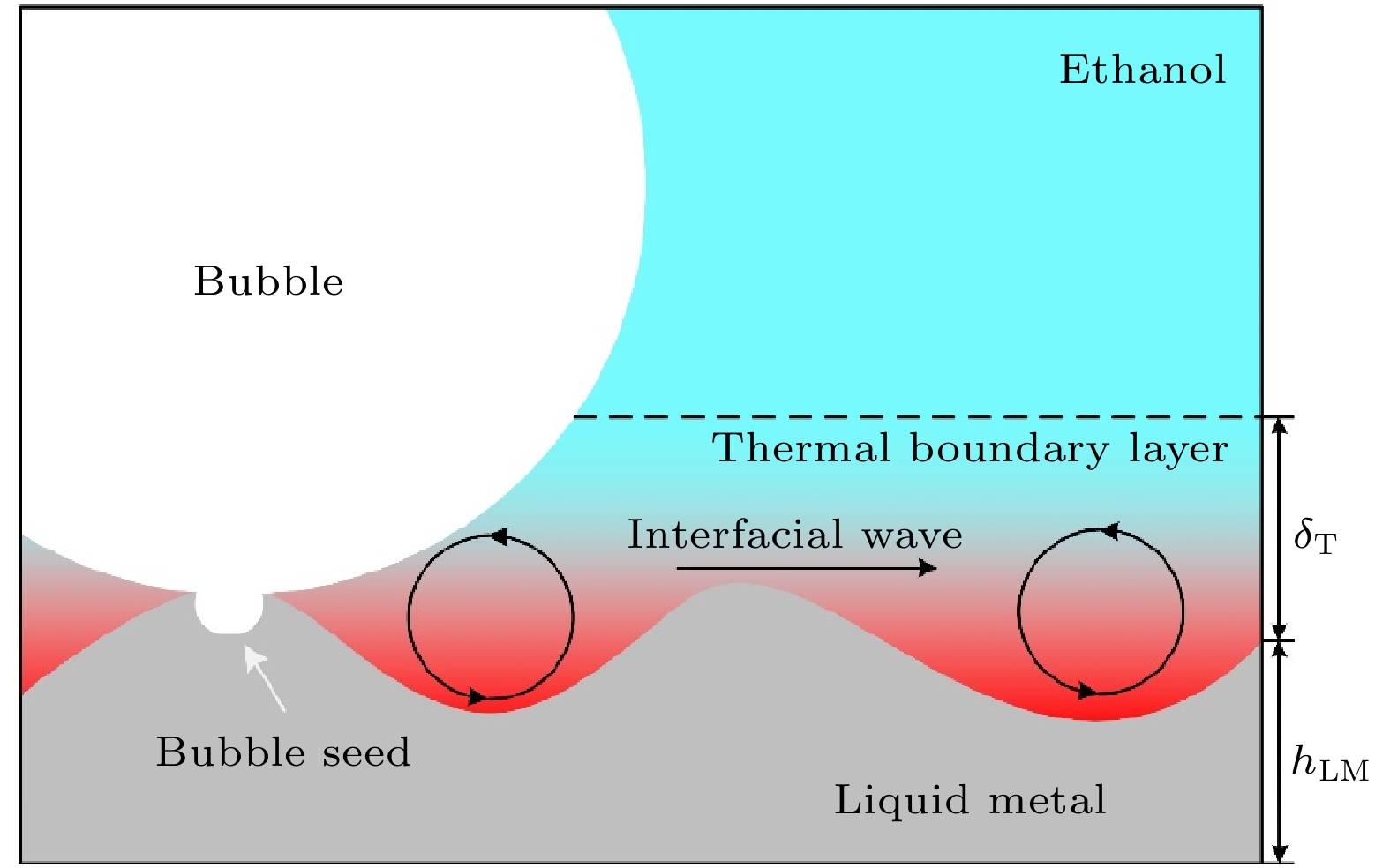

池沸腾是一种高效的传热方式, 目前主要通过刚性固体表面改性强化沸腾传热. 本文以乙醇为工质, 实验研究了光滑铜表面和液态金属软表面池沸腾传热. 发现液态金属软表面可有效降低沸腾起始点(ONB)壁面过热度, 饱和沸腾时, ONB壁面过热度从光滑铜表面的约18 ℃降低到软表面的约6 ℃, 沸腾传热系数最大提高了149%. 与光滑铜表面相比, 液态金属软表面增加了汽泡核化穴数量, 减小了汽泡尺寸, 提高了汽泡脱离频率. 观察到软表面弹性毛细波和汽泡射流现象. 弹性毛细波增强了壁面热边界层热质传递. 发现汽泡脱离过程中, 汽泡尾部在液态金属薄层内形成残余核化穴, 残余核化穴快速长大, 与上升的大汽泡聚合, 形成汽泡射流现象. 弹性毛细波及汽泡射流解释了液态金属软表面强化池沸腾传热的机理.Pool boiling is a high-efficient energy transfer method through the gas-liquid phase transition. It has the characteristics of small heat transfer temperature difference and high heat flux density. The current enhancement of boiling heat transfer is realized mainly through modifying the solid heating surface. So far, there has been no report on the study of pool boiling heat transfer on soft surfaces. Therefore, in this work the pool boiling heat transfer performances of ethanol on the copper surface and soft liquid metal surface are investigated experimentally. The experimental results indicate that soft surface can effectively reduce the wall superheat corresponding to the onset of boiling (ONB). In saturation boiling, the superheat of the wall surface at ONB is reduced by nearly 12 ℃, while the heat transfer coefficient is improved by 149%. It is found that soft surface enhances pool boiling heat transfer performance significantly by increasing nucleate site density, reducing the bubble departure diameter, and increasing bubble departure frequency. Unlike the copper surface, the soft surface deforms elastically under the action of the vertical component of surface tension γlvsinθ at the three-phase contact line of the vapor bubble. From the perspective of surface energy analysis, the difference in surface energy ΔELM between before and after bubble departure on soft liquid metal surface is smaller than in smooth surface ΔECS. The potential barrier of the soft surface is smaller than of the copper surface, and the buoyancy required for bubble separation is small, and the bubble is easy to separate. Elastocapillary wave and bubble jet phenomenon on the soft surface are observed particularly, which are generated on liquid metal under the action of elastic restoring force. The fluctuation of elastocapillary wave contributes to the enhancement of heat and mass transfer in thermal boundary layer and the generation of residual nucleation site. The residual bubble grows up rapidly and coalesces with the rising large bubble, forming bubble jet phenomenon. Elastocapillary wave and bubble jet contribute to the enhancement of pool boiling heat transfer on soft liquid metal surface.

-

Keywords:

- liquid metal /

- soft surface /

- pool boiling /

- elastocapillary wave

[1] 曹泷, 杨辉, 吴学红, 周振华 2020 微纳电子技术 57 982

Cao S, Yang H, Wu X H, Zhou Z H 2020 Micronanoelectronic Technology 57 982

[2] Mori S, Utaka Y 2017 Int. J. Heat Mass Transfer 108 2534

Google Scholar

Google Scholar

[3] Kong X, Zhang Y, Wei J 2018 Exp. Therm. Fluid Sci. 91 9

Google Scholar

Google Scholar

[4] Liang G, Mudawar I 2019 Int. J. Heat Mass Transfer 128 892

Google Scholar

Google Scholar

[5] Gregorcic P, Zupancic M, Golobic I 2018 Sci. Rep. 8 7461

Google Scholar

Google Scholar

[6] 余雄江, 袁金斗, 王彦博, 徐进良 2018 化工进展 37 3751

Yu X J, Yuan J D, WangY B, Xu J L 2018 Chem. Ind. Eng. Prog. 37 3751

[7] Lu M C, Huang C H, Huang C T, Chen Y C 2015 Int. J. Therm. Sci. 91 133

Google Scholar

Google Scholar

[8] Xu Z G, Zhao C Y 2016 Appl. Therm. Eng. 100 68

Google Scholar

Google Scholar

[9] Ryohachi, Shimada, Jun, Komai, Yoichi, Hirono, Satoshi 1991 Exp. Therm. Fluid Sci.

[10] Xu J, Ji X, Zhang W, Liu G 2008 Int. J. Multiphase Flow 34 1008

Google Scholar

Google Scholar

[11] Jaikumar A, Kandlikar S G 2017 Sci. Rep. 7 15691

Google Scholar

Google Scholar

[12] 郑晓欢, 纪献兵, 王野, 徐进良, 黄彦平, 李勇 2017 核动力工程 038 179

Zheng X H, Ji X B, Wang Y, Xu J L, Huang Y P, Li Y 2017 Nuclear Power Engineering 038 179

[13] An S, Kim D Y, Lee J G, Jo H S, Kim M W, Al-Deyab S S, Choi J, Yoon S S 2016 Int. J. Heat Mass Transfer 98 124

Google Scholar

Google Scholar

[14] Surtaev A, Kuznetsov D, Serdyukov V, Pavlenko A, Kalita V, Komlev D, Ivannikov A, Radyuk A 2018 Appl. Therm. Eng. 133 532

Google Scholar

Google Scholar

[15] Son H H, Seo G H, Jeong U, Shin D Y, Kim S J 2017 Int. J. Heat Mass Transfer 113 115

Google Scholar

Google Scholar

[16] Rishi A M, Kandlikar S G, Gupta A 2019 Int. J. Heat Mass Transfer 132 462

Google Scholar

Google Scholar

[17] Mao L, Zhou W, Hu X, He Y, Zhang G, Zhang L, Fu R 2020 Int. J. Therm. Sci. 147 106154

Google Scholar

Google Scholar

[18] Yim K, Lee J, Naccarato B, Kim K J 2019 Int. J. Heat Mass Transfer 133 352

Google Scholar

Google Scholar

[19] Lee Y C, Hossain Bhuiya M M, Kim K J 2010 Int. J. Heat Mass Transfer 53 4274

Google Scholar

Google Scholar

[20] Ramaswamy C, Joshi Y, Nakayama W, Johnson W B 2002 Int. J. Heat Mass Transfer 45 4761

Google Scholar

Google Scholar

[21] Park S J, Weon B M, Lee J S, Lee J, Kim J, Je J H 2014 Nat. Commun. 5 4369

Google Scholar

Google Scholar

[22] Desai P R, Wang Y, Sachar H S, Jing H, Sinha S, Das S 2019 Matter 1 1262

Google Scholar

Google Scholar

[23] Lopes M C, Bonaccurso E 2012 Soft Matter 8 7875

Google Scholar

Google Scholar

[24] Sokuler M, Auernhammer G K, Roth M, Liu C, Bonacurrso E, Butt H J 2010 Langmuir 26 1544

Google Scholar

Google Scholar

[25] Narhe R, Anand S, Rykaczewski K, Medici M-G, González-Viñas W, Varanasi K K, Beysens D 2015 Langmuir 31 5353

Google Scholar

Google Scholar

[26] Petit J, Bonaccurso E 2014 Langmuir 30 1160

Google Scholar

Google Scholar

[27] Carré A, Shanahan M E R 2001 Langmuir 17 2982

Google Scholar

Google Scholar

[28] Shanahan M E R, Carre A 1995 Langmuir 11 1396

Google Scholar

Google Scholar

[29] Weisensee P B, Tian J, Miljkovic N, King W P 2016 Sci. Rep. 6 30328

Google Scholar

Google Scholar

[30] Mangili S, Antonini C, Marengo M, Amirfazli A 2012 Soft Matter 8 10045

Google Scholar

Google Scholar

[31] Young T 1805 Philos. Trans. R. Soc. London 95 65

Google Scholar

Google Scholar

[32] Yu Y S 2012 Appl. Math. Mech. 33 1095

Google Scholar

Google Scholar

[33] Weijs J H, Andreotti B, Snoeijer J H 2013 Soft Matter 9 8494

Google Scholar

Google Scholar

[34] Rykaczewski K, Phadnis A 2018 Nanoscale Microscale Thermophys. Eng. 22 230

Google Scholar

Google Scholar

[35] 杨小虎, 刘静 2018 科技导报 36 54

Yang X H, Liu J 2018 Science & Technology Review 36 54

[36] Jaikumar A, Kandlikar S G 2015 Int. J. Heat Mass Tranfer 88 652

Google Scholar

Google Scholar

[37] Liu T, Sen P, Kim C J 2012 J. Microelectromech. Syst. 21 443

Google Scholar

Google Scholar

[38] Dickey M D 2014 ACS Appl. Mater Interfaces 6 18369

Google Scholar

Google Scholar

[39] Xu Q, Oudalov N, Guo Q, Jaeger H M, Brown E 2012 Phys. Fluids 24 063101

Google Scholar

Google Scholar

[40] Shanahan M E R, Carré A 2002 Colloids Surf., A 206 115

Google Scholar

Google Scholar

[41] Jacob A R, Parekh D P, Dickey M D, Hsiao L C 2019 Langmuir 35 11774

Google Scholar

Google Scholar

[42] 林瑞泰 1988 沸腾换热 (北京: 科学出版社) 第112页

Lin R T 1988 Boiling Heat Transfer (Beijing: Science Press) (in Chinese) p112

[43] Tien C J 1962 Int. J. Heat Mass Transfer 5 533

Google Scholar

Google Scholar

-

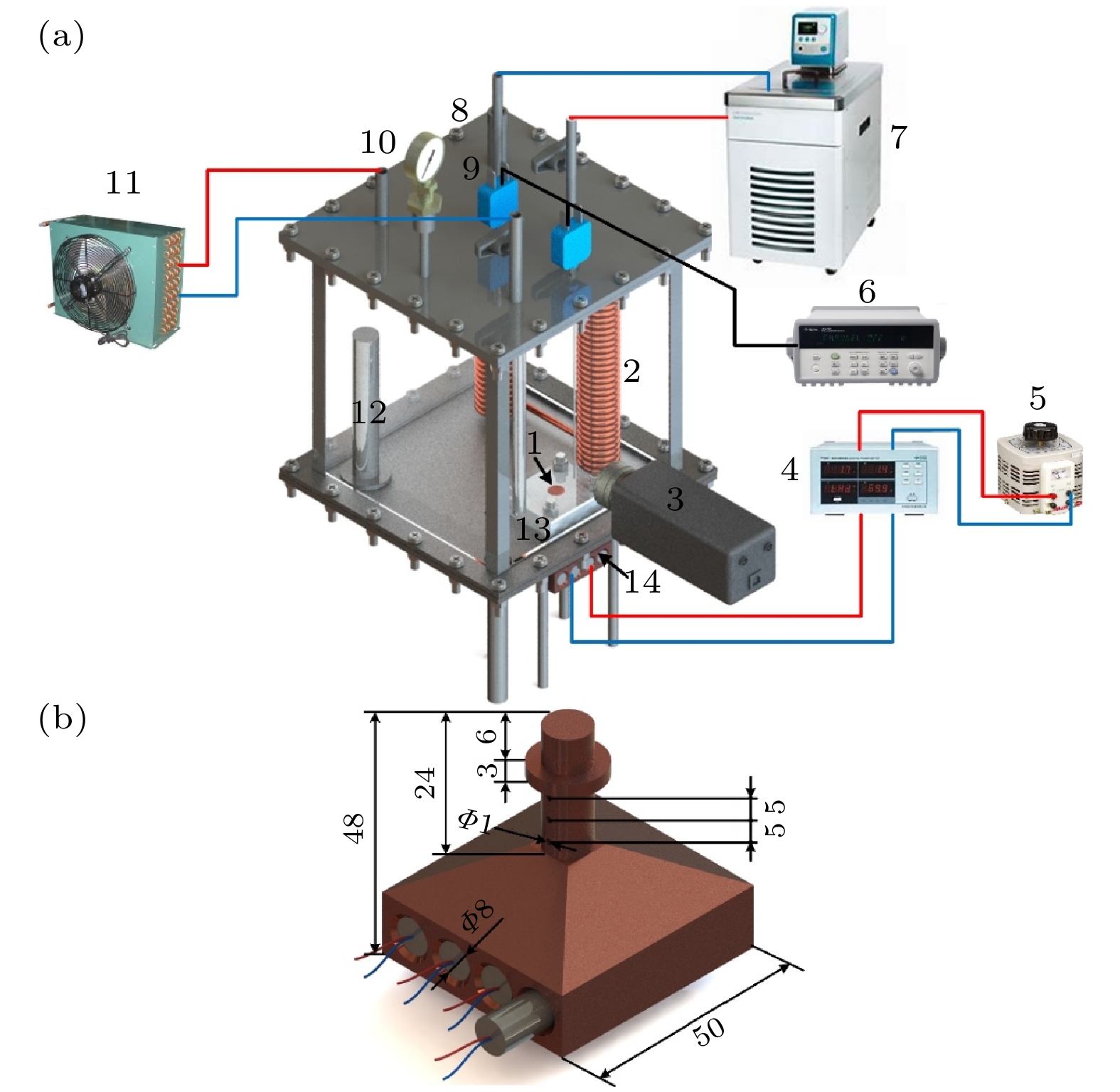

图 1 (a)池沸腾实验装置. 1: Ga67In20.5Sn12.5; 2: 冷凝盘管; 3: 高速相机; 4: 功率计; 5: 调压器; 6: Agilent 34970A; 7: 恒温水箱; 8: 充液口; 9: K型热电偶; 10: 压力表; 11: 风冷冷凝器; 12: 辅助加热器; 13: 聚四氟乙烯; 14: 紫铜块. (b)紫铜块尺寸(所有尺寸均以mm为单位)

Fig. 1. (a) Pool boiling experiment setup. 1: Ga67In20.5Sn12.5; 2: coiled-tube; 3: high-speed camera; 4: power meter; 5: voltage transformer; 6: Agilent 34970A; 7: constant temperature water bath; 8: filling port; 9: K thermocouple; 10: pressure gauge; 11: air-cooled condenser; 12: auxiliary heater; 13: teflon; 14: copper block. (b) Copper block size (all dimensions are in mm).

表 1 乙醇的物性参数(20 ℃, 101.325 kPa)

Table 1. Physical parameters of ethanol (20 ℃, 101.325 kPa).

Ts/℃ ρ/(kg·m–3) hfg/(kJ·kg–1) cpl/(kJ·kg–1·K–1) λ/(W·m–1·K–1) ν/(10-6m2·s–1) μ/(10-3Pa·s) σ/(10-3N·m–1) Pr 液体 78.23 789.42 — 2.40 0.16 1.507 1.19 22.3 17.39 蒸汽 1.65 849.63 1.72 0.02 6.061 0.010 — 0.861 表 2 液态金属Galinstan (Ga67In20.5Sn12.5)与水物性参数对比(20 ℃, 101.325 kPa)

Table 2. Physical properties of liquid metal Galinstan (Ga67In20.5Sn12.5) and water at 20 ℃ and 101.325 kPa.

流体 ρ/(kg·m–3) Tm/℃ Ts/℃ hfg/(kJ·kg–1) cpl/(J·kg–1·K–1) λ/(W·m–1·K–1) μ/(10-3Pa·s) σ/(10-3N·m–1) Pr 水 998 0 100 2256.47 4184 0.6 1.002 72.8 7.008 Galinstan 6440 10.5 > 1300 24.00 366 16.5 2.400 533.0 0.053 -

[1] 曹泷, 杨辉, 吴学红, 周振华 2020 微纳电子技术 57 982

Cao S, Yang H, Wu X H, Zhou Z H 2020 Micronanoelectronic Technology 57 982

[2] Mori S, Utaka Y 2017 Int. J. Heat Mass Transfer 108 2534

Google Scholar

Google Scholar

[3] Kong X, Zhang Y, Wei J 2018 Exp. Therm. Fluid Sci. 91 9

Google Scholar

Google Scholar

[4] Liang G, Mudawar I 2019 Int. J. Heat Mass Transfer 128 892

Google Scholar

Google Scholar

[5] Gregorcic P, Zupancic M, Golobic I 2018 Sci. Rep. 8 7461

Google Scholar

Google Scholar

[6] 余雄江, 袁金斗, 王彦博, 徐进良 2018 化工进展 37 3751

Yu X J, Yuan J D, WangY B, Xu J L 2018 Chem. Ind. Eng. Prog. 37 3751

[7] Lu M C, Huang C H, Huang C T, Chen Y C 2015 Int. J. Therm. Sci. 91 133

Google Scholar

Google Scholar

[8] Xu Z G, Zhao C Y 2016 Appl. Therm. Eng. 100 68

Google Scholar

Google Scholar

[9] Ryohachi, Shimada, Jun, Komai, Yoichi, Hirono, Satoshi 1991 Exp. Therm. Fluid Sci.

[10] Xu J, Ji X, Zhang W, Liu G 2008 Int. J. Multiphase Flow 34 1008

Google Scholar

Google Scholar

[11] Jaikumar A, Kandlikar S G 2017 Sci. Rep. 7 15691

Google Scholar

Google Scholar

[12] 郑晓欢, 纪献兵, 王野, 徐进良, 黄彦平, 李勇 2017 核动力工程 038 179

Zheng X H, Ji X B, Wang Y, Xu J L, Huang Y P, Li Y 2017 Nuclear Power Engineering 038 179

[13] An S, Kim D Y, Lee J G, Jo H S, Kim M W, Al-Deyab S S, Choi J, Yoon S S 2016 Int. J. Heat Mass Transfer 98 124

Google Scholar

Google Scholar

[14] Surtaev A, Kuznetsov D, Serdyukov V, Pavlenko A, Kalita V, Komlev D, Ivannikov A, Radyuk A 2018 Appl. Therm. Eng. 133 532

Google Scholar

Google Scholar

[15] Son H H, Seo G H, Jeong U, Shin D Y, Kim S J 2017 Int. J. Heat Mass Transfer 113 115

Google Scholar

Google Scholar

[16] Rishi A M, Kandlikar S G, Gupta A 2019 Int. J. Heat Mass Transfer 132 462

Google Scholar

Google Scholar

[17] Mao L, Zhou W, Hu X, He Y, Zhang G, Zhang L, Fu R 2020 Int. J. Therm. Sci. 147 106154

Google Scholar

Google Scholar

[18] Yim K, Lee J, Naccarato B, Kim K J 2019 Int. J. Heat Mass Transfer 133 352

Google Scholar

Google Scholar

[19] Lee Y C, Hossain Bhuiya M M, Kim K J 2010 Int. J. Heat Mass Transfer 53 4274

Google Scholar

Google Scholar

[20] Ramaswamy C, Joshi Y, Nakayama W, Johnson W B 2002 Int. J. Heat Mass Transfer 45 4761

Google Scholar

Google Scholar

[21] Park S J, Weon B M, Lee J S, Lee J, Kim J, Je J H 2014 Nat. Commun. 5 4369

Google Scholar

Google Scholar

[22] Desai P R, Wang Y, Sachar H S, Jing H, Sinha S, Das S 2019 Matter 1 1262

Google Scholar

Google Scholar

[23] Lopes M C, Bonaccurso E 2012 Soft Matter 8 7875

Google Scholar

Google Scholar

[24] Sokuler M, Auernhammer G K, Roth M, Liu C, Bonacurrso E, Butt H J 2010 Langmuir 26 1544

Google Scholar

Google Scholar

[25] Narhe R, Anand S, Rykaczewski K, Medici M-G, González-Viñas W, Varanasi K K, Beysens D 2015 Langmuir 31 5353

Google Scholar

Google Scholar

[26] Petit J, Bonaccurso E 2014 Langmuir 30 1160

Google Scholar

Google Scholar

[27] Carré A, Shanahan M E R 2001 Langmuir 17 2982

Google Scholar

Google Scholar

[28] Shanahan M E R, Carre A 1995 Langmuir 11 1396

Google Scholar

Google Scholar

[29] Weisensee P B, Tian J, Miljkovic N, King W P 2016 Sci. Rep. 6 30328

Google Scholar

Google Scholar

[30] Mangili S, Antonini C, Marengo M, Amirfazli A 2012 Soft Matter 8 10045

Google Scholar

Google Scholar

[31] Young T 1805 Philos. Trans. R. Soc. London 95 65

Google Scholar

Google Scholar

[32] Yu Y S 2012 Appl. Math. Mech. 33 1095

Google Scholar

Google Scholar

[33] Weijs J H, Andreotti B, Snoeijer J H 2013 Soft Matter 9 8494

Google Scholar

Google Scholar

[34] Rykaczewski K, Phadnis A 2018 Nanoscale Microscale Thermophys. Eng. 22 230

Google Scholar

Google Scholar

[35] 杨小虎, 刘静 2018 科技导报 36 54

Yang X H, Liu J 2018 Science & Technology Review 36 54

[36] Jaikumar A, Kandlikar S G 2015 Int. J. Heat Mass Tranfer 88 652

Google Scholar

Google Scholar

[37] Liu T, Sen P, Kim C J 2012 J. Microelectromech. Syst. 21 443

Google Scholar

Google Scholar

[38] Dickey M D 2014 ACS Appl. Mater Interfaces 6 18369

Google Scholar

Google Scholar

[39] Xu Q, Oudalov N, Guo Q, Jaeger H M, Brown E 2012 Phys. Fluids 24 063101

Google Scholar

Google Scholar

[40] Shanahan M E R, Carré A 2002 Colloids Surf., A 206 115

Google Scholar

Google Scholar

[41] Jacob A R, Parekh D P, Dickey M D, Hsiao L C 2019 Langmuir 35 11774

Google Scholar

Google Scholar

[42] 林瑞泰 1988 沸腾换热 (北京: 科学出版社) 第112页

Lin R T 1988 Boiling Heat Transfer (Beijing: Science Press) (in Chinese) p112

[43] Tien C J 1962 Int. J. Heat Mass Transfer 5 533

Google Scholar

Google Scholar

计量

- 文章访问数: 12112

- PDF下载量: 163

- 被引次数: 0

下载:

下载: