-

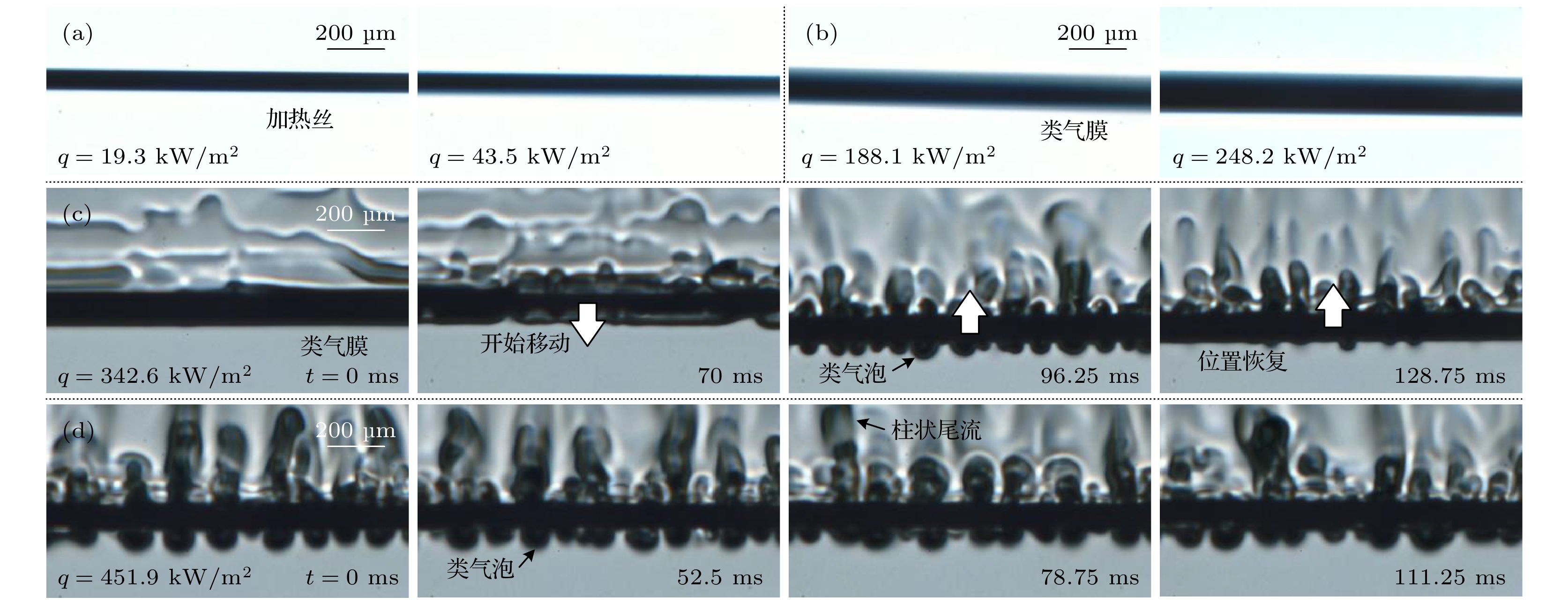

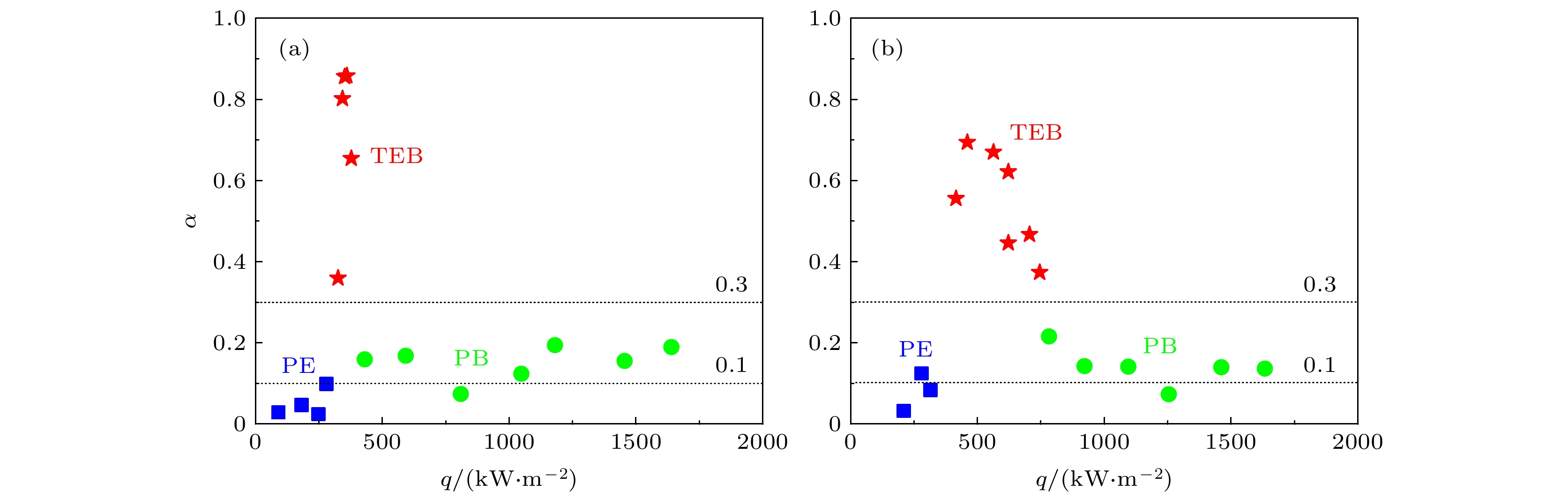

亚临界沸腾包括界面蒸发和气泡动力学诱导的传热, 但超临界传热是否存在类界面蒸发和类气泡传热以及两者间的转换缺少直接的实验证据. 本文进行了超临界CO2液池传热的实验研究, 压力和液池温度分别为8—10 MPa和15 ℃. 作为加热元件和感温元件, 22 mm长和70 μm直径的镍铬丝水平放置在液池中, 光纤探针垂直放置, 其顶端高于镍铬丝200 μm. 发现随热流密度或壁面过热度的持续增大, 依次发生自然对流、类界面蒸发、类蒸发-沸腾转换、类沸腾4种传热模式. 本文重点关注类界面蒸发和类沸腾传热以及两者间的转换. 在类界面蒸发模式下, 传热系数随壁面过热度增大略有下降, 光纤输出小幅/高频信号, 不存在主频, 多尺度熵大, 表征随机信号波动. 在类蒸发-沸腾转换模式下, 光纤输出大幅/低频周期信号, 存在明显主频, 多尺度熵小, 代表有序的周期性脉动传热. 在以类气泡为特征的类沸腾模式下, 光纤信号波动幅度介于类蒸发和转换模式之间, 主频不明显, 多尺度熵也介于类蒸发和转换模式之间. 研究获得了超临界类沸腾直接的实验证据, 加深了对超临界传热机理的理解, 为后续理论研究和工程应用提供了基础.Subcritical boiling includes interfacial evaporation and heat transfer induced by bubble dynamics. However, for supercritical heat transfer, direct experimental evidence of the existence of pseudo-evaporation and pseudo-boiling heat transfer, as well as the conversion between them is lacking. In this work, the experimental study of supercritical carbon dioxide pool heat transfer is conducted. The pressure and temperature of the cell are 8–10 MPa and 15 ℃, respectively. As heating element and temperature sensing element, a nickel-chromium alloy wire with a length of 22 mm and diameter of 70 μm is placed horizontally in the high-pressure cell. The fiber optic probe is placed vertically, with its tip 200 μm above the wire. Four heat transfer modes, i.e. natural convection, pseudo-evaporation, transition of evaporation and boiling, and pseudo-boiling, are found to occur sequentially with the increase of heat flux density or wall superheat. Natural convection occurs when the wall temperature is below the pseudo-critical temperature. This work focuses on pseudo-evaporation and pseudo-boiling heat transfer and the transition between them. In the pseudo-evaporation mode, the heat transfer coefficient decreases slightly with wall superheat increasing. The fiber outputs a high frequency signal with small amplitude, and there is no dominant frequency. The multiscale entropy is large, characterizing random signal fluctuations. In the transition of evaporation and boiling mode, the fiber outputs a large-amplitude/low-frequency periodic signal with a significant dominant frequency and small multiscale entropy, representing an ordered periodic pulsating heat transfer. In the pseudo-boiling mode characterized by bubble-like structure, the fiber signal fluctuation amplitude and multiscale entropy are between the counterparts of the first two modes i.e. natural convection mode and pseudo-evaporation mode. The dominant frequency is not obvious. The multiscale entropies in the specific case are calculated under different key parameters, such as dimensionality, time scale factor, and length of origin data. Optimal parameters are selected based on the best separation of heat transfer modes. Finally, pseudo-boiling can be distinguished from pseudo-evaporation by multiscale entropy of 0.9, and from transition of evaporation and boiling by multiscale entropy of 0.5. In this work, direct experimental evidence of supercritical-like boiling is obtained, which deepens the understanding of the supercritical heat transfer mechanism and provides a basis for theoretical studies and engineering applications in future.

-

Keywords:

- supercritical fluid /

- pseudo boiling /

- fiber optic /

- multiscale entropy

[1] Saeed M, Kim M H 2022 Energy 239 121868

Google Scholar

Google Scholar

[2] Zhang Z, Zhou R, Ge X, Zhang J, Wu X 2020 Energy 190 116411

Google Scholar

Google Scholar

[3] Bian X Y, Xuan W, Rui W, Cai J W, Hua T, Shu G Q 2022 Energy 256 124691

Google Scholar

Google Scholar

[4] Cengel Y, Boles M 2005 Thermodynamics: An Engineering Approach (5th Ed.) (SI Units) (New York: McGraw-Hill) p119

[5] Huang D, Wu Z, Sunden B, Li W 2016 Appl. Energ. 162 494

Google Scholar

Google Scholar

[6] Simeoni G, Bryk T, Gorelli F, Krisch M, Ruocco G, Santoro M, Scopigno T 2010 Nat. Phys. 6 503

Google Scholar

Google Scholar

[7] Gorelli F A, Bryk T, Krisch M, Ruocco G, Santoro M, Scopigno T 2013 Sci. Rep. 3 1203

Google Scholar

Google Scholar

[8] Ha M Y, Yoon T J, Tlusty T, Jho Y, Lee W B 2018 J. Phys. Chem. Lett. 9 1734

Google Scholar

Google Scholar

[9] Kandlikar S G 1999 Handbook of Phase Change: Boiling and Condensation (1st Ed. ) (Routledge) p63

[10] Nasuti F, Pizzarelli M 2021 J. Supercrit. Fluid 168 105066

Google Scholar

Google Scholar

[11] Knapp K K, Sabersky R H 1966 Int. J. Heat Mass Transf. 9 41

Google Scholar

Google Scholar

[12] Knapp K K 1965 Ph. D. Dissertation (California: California Institute of Technology)

[13] Hahne E, Neumann R 1981 Wärme-und Stoffübertragung 15 171

[14] Rousselet Y, Warrier G R, Dhir V K 2013 J. Heat Trans. 135 022501

Google Scholar

Google Scholar

[15] Holman J, Rea S, Howard C 1965 Int. J. Heat Mass Transf. 8 1095

Google Scholar

Google Scholar

[16] Sakurai K, Ko H S, Okamoto K, Madarame H 2001 International Conference on Nuclear Engineering, France, April 8–12, 2001 INIS-FR-759

[17] Du X, Zhu X J, Yu X, Wu F Y, Qiu Q G 2022 Nucl. Eng. Des. 386 111574

Google Scholar

Google Scholar

[18] Zhu B G, Xu J L, Yan C S, Xie J 2020 Int. J. Heat Mass Transf. 148 119080

Google Scholar

Google Scholar

[19] 张海松, 朱鑫杰, 朱兵国, 徐进良, 刘欢 2020 69 064401

Google Scholar

Google Scholar

Zhang H S, Zhu X J, Zhu B G, Xu J L, Liu H 2020 Acta Phys. Sin. 69 064401

Google Scholar

Google Scholar

[20] Maxim F, Contescu C, Boillat P, Niceno B, Karalis K, Testino A, Ludwig C 2019 Nat. Commun. 10 1

Google Scholar

Google Scholar

[21] 程洁, 郭亚军, 王腾, 桂淼, 刘朝辉, 随志强 2019 化工学报 70 1375

Cheng J, Guo Y J, Wang T, Gui M, Liu C H, Sui Z Q 2019 Ciesc Journal 70 1375

[22] 潘艳芝, 郑永建, 王栋, 安维峥, 牛棚满 2020 工程热 41 2756

Pan Y Z, Zheng Y J, Wang D, An W Z, Niu P M 2020 J. Engineering Thermophysics 41 2756

[23] 冷洁, 胡雪音, 田瑞峰 2020 核动力工程 41 74

Leng J, Hu X Y, Tian R F 2020 Nuclear Power Engineering 41 74

[24] 翟路生, 金宁德 2016 65 010501

Google Scholar

Google Scholar

Zhai L S, Jin N D 2016 Acta Phys. Sin. 65 010501

Google Scholar

Google Scholar

[25] 马敏, 郭鑫, 于洁 2022 仪器仪表学报 43 110

Ma M, Guo X, Yu J 2022 Chin. J. Sci. Instrum. 43 110

[26] 刘若琳, 孔明, 曹鸣, 王道档, 单良 2022 光电子·激光 33 840

Liu R L, Kong M, Cao M, Wang D D, Shan L 2022 J. Optoelectro. Laser 33 840

[27] 谭万尧, 刘晓晶, 吴德操, 罗彬彬, 赵明富, 郭裕丰, 龙俊宇, 张颖 2022 光学学报 42 52

Tan W Y, Liu X J, Wu D C, Luo B B, Zhao M F, Guo Y F, Long J Y, Zhang Y 2022 Acta Opt. Sin. 42 52

[28] Avdeev M V, Konovalov A N, Bagratashvili V N, Popov V K, Tsypina S I, Sokolova M, Ke J, Poliakoff M 2004 Phys. Chem. Chem. Phys. 6 1258

Google Scholar

Google Scholar

[29] Holman J P 2012 Experimental Methods for Engineers (New York: McGraw Hill) pp64–65

[30] Barney R, Nourgaliev R, McCallen R, Delplanque J P 2021 Int. J. Heat Mass Transf. 178 121572

Google Scholar

Google Scholar

[31] Liu H D, Liu W, Yan P G, Chen D Q, Dong K J, Qin J, Liu H Z 2022 Int. J. Heat Mass Transf. 196 123248

Google Scholar

Google Scholar

[32] Xu J L, Shen S, Gan Y H, Li Y X, Zhang W, Su Q C 2005 J. Micromech Microeng 15 1344

Google Scholar

Google Scholar

[33] Taylor G I 1950 Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences 201 192

[34] Shannon C E 1948 Bell Sys. Tec. J. 27 379

Google Scholar

Google Scholar

[35] Pincus S M 1991 Pro. Nat. Academy Sci. 88 2297

Google Scholar

Google Scholar

[36] Richman J S, Moorman J R 2000 Am. J. Physiol-Heart C 278 H2039

Google Scholar

Google Scholar

[37] 杨大为, 赵永东, 冯辅周, 江鹏程, 丁闯 2018 兵工学报 39 1683

Google Scholar

Google Scholar

Yang D W, Zhao Y D, Feng F Z, Jiang P C, Ding C 2018 Acta Armamentarii 39 1683

Google Scholar

Google Scholar

[38] Haryadi B, Liou J J, Wei H C, Xiao M X, Wu H T, Sun C K 2018 Comput. Meth. Prog. Bio. 166 115

Google Scholar

Google Scholar

[39] Silva L E V, Duque J J, Felipe J C, Murta L O, Humeau-Heurtier A 2018 Signal Process. 147 224

Google Scholar

Google Scholar

[40] Li Y B, Wang X Z, Liu Z B, Liang X H, Si S B 2018 IEEE Access 6 66723

Google Scholar

Google Scholar

-

图 1 SCF池式传热实验系统 (a) 实验台照片; (b) 实验台原理图 (1-真空泵, 2-阀门, 3-CO2气瓶, 4-增压泵, 5-减压阀, 6-压力变送器, 7-光环行器, 8-分光器, 9-激光光源, 10-光电转换电路, 11-光纤探针, 12-高压釜, 13-LED光源, 14-冷却铜管, 15-加热丝, 16-可视窗, 17-高速相机, 18-热电偶, 19-恒温槽, 20-PID控制器, 21-直流电源, 22-标准电阻, 23-同步器, 24-高速数采仪); (c) 光纤探针封装结构

Fig. 1. Experiment system of SCF pool heat transfer: (a) The photo of experiment system; (b) schematic diagram of the experimental system (1-vacuum pump, 2-valve, 3-CO2 cylinder, 4-piston pump, 5-reducing valve, 6-pressure transmitter, 7-optical circulator, 8-splitter, 9-laser light source, 10-optical conversion circuit, 11-fiber optic probe, 12-high pressure vessel, 13-LED light source, 14-circulating pipe, 15-heating wire, 16-viewable window, 17-high-speed camera, 18-thermocouple, 19-thermostat, 20-PID controller, 21-DC power source, 22-standard resistor, 23-synchronizer, 24-high-speed data acquisition); (c) fiber optic probe package structure.

图 3 不同压力下的传热曲线和传热模式分区 (a), (b) P分别为7.955—8.048 MPa和9.928—10.035 MPa时热流密度与过热度关系; (c), (d) P分别为7.955—8.048 MPa和9.928—10.035 MPa时传热系数与过热度关系

Fig. 3. Q-ΔTw and h-ΔTw curves and heat transfer modes under different pressure: (a), (b) Heat flux density versus superheat for P = 7.955–8.048 MPa and 9.928–10.035 MPa, respectively; (c), (d) heat transfer coefficient versus superheat for P = 7.955– 8.048 MPa and 9.928–10.035 MPa, respectively.

-

[1] Saeed M, Kim M H 2022 Energy 239 121868

Google Scholar

Google Scholar

[2] Zhang Z, Zhou R, Ge X, Zhang J, Wu X 2020 Energy 190 116411

Google Scholar

Google Scholar

[3] Bian X Y, Xuan W, Rui W, Cai J W, Hua T, Shu G Q 2022 Energy 256 124691

Google Scholar

Google Scholar

[4] Cengel Y, Boles M 2005 Thermodynamics: An Engineering Approach (5th Ed.) (SI Units) (New York: McGraw-Hill) p119

[5] Huang D, Wu Z, Sunden B, Li W 2016 Appl. Energ. 162 494

Google Scholar

Google Scholar

[6] Simeoni G, Bryk T, Gorelli F, Krisch M, Ruocco G, Santoro M, Scopigno T 2010 Nat. Phys. 6 503

Google Scholar

Google Scholar

[7] Gorelli F A, Bryk T, Krisch M, Ruocco G, Santoro M, Scopigno T 2013 Sci. Rep. 3 1203

Google Scholar

Google Scholar

[8] Ha M Y, Yoon T J, Tlusty T, Jho Y, Lee W B 2018 J. Phys. Chem. Lett. 9 1734

Google Scholar

Google Scholar

[9] Kandlikar S G 1999 Handbook of Phase Change: Boiling and Condensation (1st Ed. ) (Routledge) p63

[10] Nasuti F, Pizzarelli M 2021 J. Supercrit. Fluid 168 105066

Google Scholar

Google Scholar

[11] Knapp K K, Sabersky R H 1966 Int. J. Heat Mass Transf. 9 41

Google Scholar

Google Scholar

[12] Knapp K K 1965 Ph. D. Dissertation (California: California Institute of Technology)

[13] Hahne E, Neumann R 1981 Wärme-und Stoffübertragung 15 171

[14] Rousselet Y, Warrier G R, Dhir V K 2013 J. Heat Trans. 135 022501

Google Scholar

Google Scholar

[15] Holman J, Rea S, Howard C 1965 Int. J. Heat Mass Transf. 8 1095

Google Scholar

Google Scholar

[16] Sakurai K, Ko H S, Okamoto K, Madarame H 2001 International Conference on Nuclear Engineering, France, April 8–12, 2001 INIS-FR-759

[17] Du X, Zhu X J, Yu X, Wu F Y, Qiu Q G 2022 Nucl. Eng. Des. 386 111574

Google Scholar

Google Scholar

[18] Zhu B G, Xu J L, Yan C S, Xie J 2020 Int. J. Heat Mass Transf. 148 119080

Google Scholar

Google Scholar

[19] 张海松, 朱鑫杰, 朱兵国, 徐进良, 刘欢 2020 69 064401

Google Scholar

Google Scholar

Zhang H S, Zhu X J, Zhu B G, Xu J L, Liu H 2020 Acta Phys. Sin. 69 064401

Google Scholar

Google Scholar

[20] Maxim F, Contescu C, Boillat P, Niceno B, Karalis K, Testino A, Ludwig C 2019 Nat. Commun. 10 1

Google Scholar

Google Scholar

[21] 程洁, 郭亚军, 王腾, 桂淼, 刘朝辉, 随志强 2019 化工学报 70 1375

Cheng J, Guo Y J, Wang T, Gui M, Liu C H, Sui Z Q 2019 Ciesc Journal 70 1375

[22] 潘艳芝, 郑永建, 王栋, 安维峥, 牛棚满 2020 工程热 41 2756

Pan Y Z, Zheng Y J, Wang D, An W Z, Niu P M 2020 J. Engineering Thermophysics 41 2756

[23] 冷洁, 胡雪音, 田瑞峰 2020 核动力工程 41 74

Leng J, Hu X Y, Tian R F 2020 Nuclear Power Engineering 41 74

[24] 翟路生, 金宁德 2016 65 010501

Google Scholar

Google Scholar

Zhai L S, Jin N D 2016 Acta Phys. Sin. 65 010501

Google Scholar

Google Scholar

[25] 马敏, 郭鑫, 于洁 2022 仪器仪表学报 43 110

Ma M, Guo X, Yu J 2022 Chin. J. Sci. Instrum. 43 110

[26] 刘若琳, 孔明, 曹鸣, 王道档, 单良 2022 光电子·激光 33 840

Liu R L, Kong M, Cao M, Wang D D, Shan L 2022 J. Optoelectro. Laser 33 840

[27] 谭万尧, 刘晓晶, 吴德操, 罗彬彬, 赵明富, 郭裕丰, 龙俊宇, 张颖 2022 光学学报 42 52

Tan W Y, Liu X J, Wu D C, Luo B B, Zhao M F, Guo Y F, Long J Y, Zhang Y 2022 Acta Opt. Sin. 42 52

[28] Avdeev M V, Konovalov A N, Bagratashvili V N, Popov V K, Tsypina S I, Sokolova M, Ke J, Poliakoff M 2004 Phys. Chem. Chem. Phys. 6 1258

Google Scholar

Google Scholar

[29] Holman J P 2012 Experimental Methods for Engineers (New York: McGraw Hill) pp64–65

[30] Barney R, Nourgaliev R, McCallen R, Delplanque J P 2021 Int. J. Heat Mass Transf. 178 121572

Google Scholar

Google Scholar

[31] Liu H D, Liu W, Yan P G, Chen D Q, Dong K J, Qin J, Liu H Z 2022 Int. J. Heat Mass Transf. 196 123248

Google Scholar

Google Scholar

[32] Xu J L, Shen S, Gan Y H, Li Y X, Zhang W, Su Q C 2005 J. Micromech Microeng 15 1344

Google Scholar

Google Scholar

[33] Taylor G I 1950 Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences 201 192

[34] Shannon C E 1948 Bell Sys. Tec. J. 27 379

Google Scholar

Google Scholar

[35] Pincus S M 1991 Pro. Nat. Academy Sci. 88 2297

Google Scholar

Google Scholar

[36] Richman J S, Moorman J R 2000 Am. J. Physiol-Heart C 278 H2039

Google Scholar

Google Scholar

[37] 杨大为, 赵永东, 冯辅周, 江鹏程, 丁闯 2018 兵工学报 39 1683

Google Scholar

Google Scholar

Yang D W, Zhao Y D, Feng F Z, Jiang P C, Ding C 2018 Acta Armamentarii 39 1683

Google Scholar

Google Scholar

[38] Haryadi B, Liou J J, Wei H C, Xiao M X, Wu H T, Sun C K 2018 Comput. Meth. Prog. Bio. 166 115

Google Scholar

Google Scholar

[39] Silva L E V, Duque J J, Felipe J C, Murta L O, Humeau-Heurtier A 2018 Signal Process. 147 224

Google Scholar

Google Scholar

[40] Li Y B, Wang X Z, Liu Z B, Liang X H, Si S B 2018 IEEE Access 6 66723

Google Scholar

Google Scholar

计量

- 文章访问数: 6796

- PDF下载量: 81

- 被引次数: 0

下载:

下载: