-

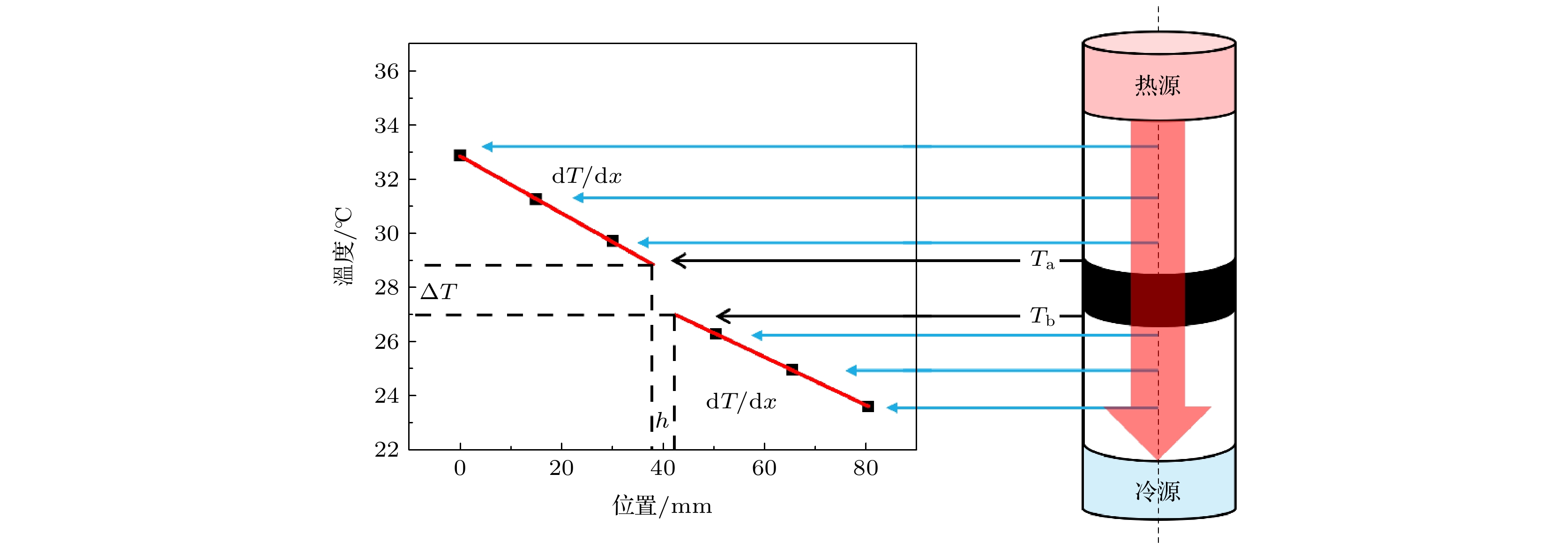

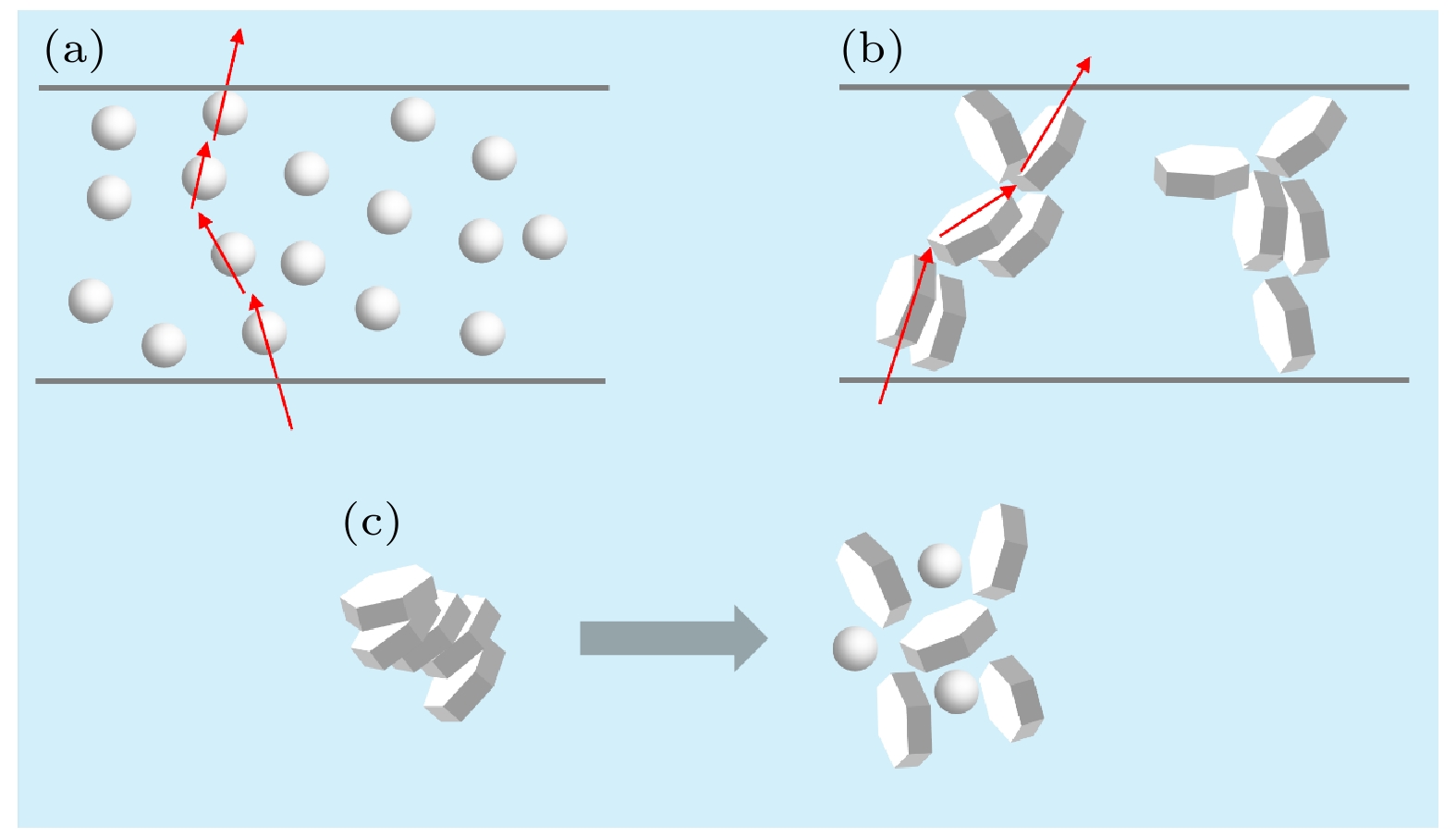

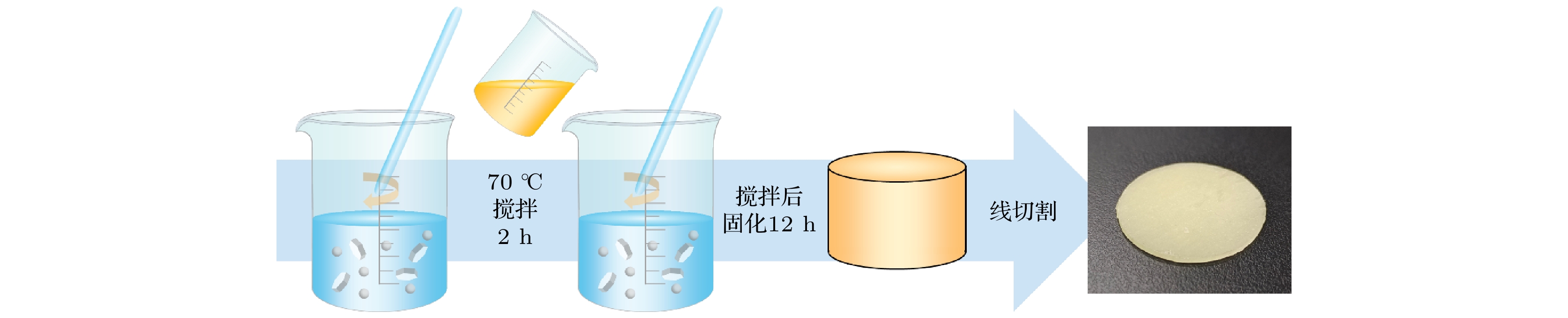

添加高导热填料的有机聚合物是最常用的一种热界面材料. 其中一种提升热导率的方式是采用不同形貌填料复合添加, 结合各种填料的优点, 取长补短. 然而, 由于有效介质理论的局限性, 以及热逾渗理论的滞后研究, 对于不同形貌填料的协同机制依旧缺乏探索. 为了剔除不同材料的耦合影响, 本文采用不同形貌的同种氧化铝作为填料, 分别制备了添加氧化铝球、氧化铝片以及球/片1∶1混合的环氧树脂复合材料. 通过稳态法测量样品的热导率, 发现球/片1∶1混合样品热导率得到显著提升. 结合热逾渗理论, 以及对填料微观分析的观测, 发现片状和球状填料复合添加的协同作用对热逾渗网络有促进作用.Polymers incorporated with high thermal conductivity fillers have numerous applications in thermal interface materials. Plenty of efforts have been made to improve the thermal conductivity of polymer composite. A possible method is to choose fillers with different morphologies, which can combine the advantages of various fillers. However, owing to the limitations of the effective medium theory as well as lack of researches of thermal percolation, there is still little understanding of the synergistic mechanism of fillers with different morphologies. In order to avoid the coupling effect of different materials, this work uses the same kind of Al2O3 but with different morphologies to prepare different kinds of epoxy composites incorporated with spherical Al2O3, plate-like Al2O3 and fillers mixed of 1∶1 ratio. The thermal conductivity of each sample is measured by the steady state method. With the fitting of the thermal percolation theory, the synergistic effect of plate-like fillers and that of spherical fillers are verified to promote the formation of thermal percolation network. In addition, by observing the microscopic distribution of fillers, we try to explain the mechanism of this synergistic effect.

-

Keywords:

- thermal conductivity /

- thermal percolation /

- thermal conductive polymers /

- epoxy composites

[1] Li S, Zheng Q, Lü Y, Liu X, Wang X, Huang P Y, Cahill D G, Lü B 2018 Science 361 579

Google Scholar

Google Scholar

[2] Xu X F, Chen J, Zhou J, Li B W 2018 Adv. Mater. 30 1705544

Google Scholar

Google Scholar

[3] Tian F, Ren Z F 2019 Angew. Chem. Int. Ed. 58 5824

Google Scholar

Google Scholar

[4] Chen J, Huang X Y, Zhu Y K, Jiang P K 2017 Adv. Funct. Mater. 27 1604754

Google Scholar

Google Scholar

[5] Lin M Y, Li Y H, Xu K, Ou Y H, Su L F, Feng X, Li J, Qi H S, Liu D 2019 Compos. Sci. Technol. 175 85

Google Scholar

Google Scholar

[6] Li X X, Yan Y P, Dong L, Guo J, Aiyiti A, Xu X F, Li B W 2017 J. Phys. D: Appl. Phys. 50 104002

Google Scholar

Google Scholar

[7] Wang L M, Liu Y C, Zhang Z M, Wang B R, Qiu J J, Hui D, Wang S 2017 Compos. B. Eng. 122 145

Google Scholar

Google Scholar

[8] Choy C L 1977 Polymer 18 984

Google Scholar

Google Scholar

[9] Henry A 2014 Annu. Rev. Heat Transf. 17 485

Google Scholar

Google Scholar

[10] Feng H, Tang N, An M, Guo R L, Ma D K, Yu X X, Zang J F, Yang N 2019 J. Phys. Chem. C 123 31003

Google Scholar

Google Scholar

[11] Zhang C, Huang R J, Wang Y G, Wu Z X, Guo S B, Zhang H, Li J, Huang C J, Wang W, Li L F 2018 J. Mater. Chem. A 6 20663

Google Scholar

Google Scholar

[12] Zhang T, Sun J J, Ren L L, Yao Y M, Wang M M, Zeng X L, Sun R, Xu J B, Wong C P 2019 Compos. Part A Appl. Sci. Manuf. 121 92

Google Scholar

Google Scholar

[13] Lu C H, Chiang S W, Du H, Li J, Gan L, Zhang X, Chu X D, Yao Y W, Li B H, Kang F Y 2017 Polymer 115 52

Google Scholar

Google Scholar

[14] Deng S C, Yuan J L, Lin Y L, Yu X X, Ma D K, Huang Y W, Ji R C, Zhang G Z, Yang N 2021 Nano Energy 82 105749

Google Scholar

Google Scholar

[15] Zhang W B, Zhang Z X, Yang J H, Huang T, Zhang N, Zheng X T, Wang Y, Zhou Z W 2015 Carbon 90 242

Google Scholar

Google Scholar

[16] Li Z L, Ju D D, Han L J, Dong L S 2017 Thermochim. Acta. 652 9

Google Scholar

Google Scholar

[17] McCue J P 1973 Coord. Chem. Rev. 10 265

Google Scholar

Google Scholar

[18] Bruggeman D A G 1935 Ann. Phys. 416 636

Google Scholar

Google Scholar

[19] Wang Y W, Weng G J, Meguid S A, Hamouda A M 2014 J. Appl. Phys. 115 193706

Google Scholar

Google Scholar

[20] Kim G H, Lee D, Shanker A, Shao L, Kwon M S, Gidley D, Kim J, Pipe K P 2015 Nat. Mater. 14 295

Google Scholar

Google Scholar

[21] Coleman J N, Khan U, Blau W J, Gun’ko Y K 2006 Carbon 44 1624

Google Scholar

Google Scholar

[22] Zheng R, Gao J, Wang J, Feng S P, Ohtani H, Wang J, Chen G 2012 Nano Lett. 12 188

Google Scholar

Google Scholar

[23] Shi B, Dong L, Li M Q, Liu B, Kim K, Xu X F, Zhou J, Liu J 2018 Appl. Phys. Lett. 113 041902

Google Scholar

Google Scholar

[24] 潘东楷, 宗志成, 杨诺 2022 71 086302

Google Scholar

Google Scholar

Pan D K, Zong Z C, Yang N 2022 Acta Phys. Sin. 71 086302

Google Scholar

Google Scholar

[25] Kempers R, Kolodner P, Lyons A, Robinson A J 2009 Rev. Sci. Instrum. 80 095111

Google Scholar

Google Scholar

[26] Prasher R S, Simmons C, Solbrekken G L 2000 ASME 2000 International Mechanical Engineering Congress and Exposition Orlando, Florida, USA, November 5–10, 2000 p461

[27] Wu Y M, Ye K, Liu Z D, Wang M J, Chee K W, Lin C T, Jiang N, Yu J 2018 J. Mater. Chem. C 6 6494

Google Scholar

Google Scholar

[28] Chen X K, Hu X Y, Jia P, Xie Z X, Liu J 2021 Int. J. Mech. Sci. 206 106576

Google Scholar

Google Scholar

[29] Liu C Q, Chen C, Yu W, Chen M, Zhou D Y, Xie H Q 2020 Int. J. Therm. Sci. 152 106293

Google Scholar

Google Scholar

[30] Mehra N, Mu L W, Ji T, Yang X T, Kong J, Gu J W, Zhu J H 2018 Appl. Mater. Today 12 92

Google Scholar

Google Scholar

[31] Fang Z N, Li M, Wang S K, Gu Y Z, Li Y X, Zhang Z G 2019 Int. J. Heat Mass Transfer 137 1103

Google Scholar

Google Scholar

[32] Eucken A 1940 Forsch. Ingenieurwes. A 11 6

Google Scholar

Google Scholar

[33] Chen H Y, Ginzburg V V, Yang J, Yang Y F, Liu W, Huang Y, Du L B, Chen B 2016 Prog. Polym. Sci. 59 41

Google Scholar

Google Scholar

[34] Fuller J J, Marotta E E 2001 J. Therm. Heat Transfer 15 228

Google Scholar

Google Scholar

[35] Hill R F, Supancic P H 2005 J. Am. Ceram. Soc. 87 1831

Google Scholar

Google Scholar

[36] Zhang G Q, Xia Y P, Wang H, Tao Y, Tao G L, Tu S T, Wu H P 2009 J. Compos. Mater. 44 963

Google Scholar

Google Scholar

-

图 6 氧化铝/环氧树脂复合材料的SEM照片 (a) 球形氧化铝分散性; (b) 球形氧化铝的接触; (c) 片状氧化铝的导热通路; (d) 片状氧化铝的接触; (e) 1∶1混合添加的导热通路; (f) 1∶1混合添加的整体分散性

Fig. 6. SEM images of Al2O3/epoxy composites: (a) The dispersion of spherical Al2O3; (b) the mutual contact of spherical Al2O3; (c) the thermal conductive pathway of plate-like Al2O3; (d) the mutual contact of plate-like Al2O3; (e) the thermal conductive pathway of fillers mixed of 1∶1 ratio; (f) the dispersion of Al2O3 of fillers mixed of 1∶1 ratio.

-

[1] Li S, Zheng Q, Lü Y, Liu X, Wang X, Huang P Y, Cahill D G, Lü B 2018 Science 361 579

Google Scholar

Google Scholar

[2] Xu X F, Chen J, Zhou J, Li B W 2018 Adv. Mater. 30 1705544

Google Scholar

Google Scholar

[3] Tian F, Ren Z F 2019 Angew. Chem. Int. Ed. 58 5824

Google Scholar

Google Scholar

[4] Chen J, Huang X Y, Zhu Y K, Jiang P K 2017 Adv. Funct. Mater. 27 1604754

Google Scholar

Google Scholar

[5] Lin M Y, Li Y H, Xu K, Ou Y H, Su L F, Feng X, Li J, Qi H S, Liu D 2019 Compos. Sci. Technol. 175 85

Google Scholar

Google Scholar

[6] Li X X, Yan Y P, Dong L, Guo J, Aiyiti A, Xu X F, Li B W 2017 J. Phys. D: Appl. Phys. 50 104002

Google Scholar

Google Scholar

[7] Wang L M, Liu Y C, Zhang Z M, Wang B R, Qiu J J, Hui D, Wang S 2017 Compos. B. Eng. 122 145

Google Scholar

Google Scholar

[8] Choy C L 1977 Polymer 18 984

Google Scholar

Google Scholar

[9] Henry A 2014 Annu. Rev. Heat Transf. 17 485

Google Scholar

Google Scholar

[10] Feng H, Tang N, An M, Guo R L, Ma D K, Yu X X, Zang J F, Yang N 2019 J. Phys. Chem. C 123 31003

Google Scholar

Google Scholar

[11] Zhang C, Huang R J, Wang Y G, Wu Z X, Guo S B, Zhang H, Li J, Huang C J, Wang W, Li L F 2018 J. Mater. Chem. A 6 20663

Google Scholar

Google Scholar

[12] Zhang T, Sun J J, Ren L L, Yao Y M, Wang M M, Zeng X L, Sun R, Xu J B, Wong C P 2019 Compos. Part A Appl. Sci. Manuf. 121 92

Google Scholar

Google Scholar

[13] Lu C H, Chiang S W, Du H, Li J, Gan L, Zhang X, Chu X D, Yao Y W, Li B H, Kang F Y 2017 Polymer 115 52

Google Scholar

Google Scholar

[14] Deng S C, Yuan J L, Lin Y L, Yu X X, Ma D K, Huang Y W, Ji R C, Zhang G Z, Yang N 2021 Nano Energy 82 105749

Google Scholar

Google Scholar

[15] Zhang W B, Zhang Z X, Yang J H, Huang T, Zhang N, Zheng X T, Wang Y, Zhou Z W 2015 Carbon 90 242

Google Scholar

Google Scholar

[16] Li Z L, Ju D D, Han L J, Dong L S 2017 Thermochim. Acta. 652 9

Google Scholar

Google Scholar

[17] McCue J P 1973 Coord. Chem. Rev. 10 265

Google Scholar

Google Scholar

[18] Bruggeman D A G 1935 Ann. Phys. 416 636

Google Scholar

Google Scholar

[19] Wang Y W, Weng G J, Meguid S A, Hamouda A M 2014 J. Appl. Phys. 115 193706

Google Scholar

Google Scholar

[20] Kim G H, Lee D, Shanker A, Shao L, Kwon M S, Gidley D, Kim J, Pipe K P 2015 Nat. Mater. 14 295

Google Scholar

Google Scholar

[21] Coleman J N, Khan U, Blau W J, Gun’ko Y K 2006 Carbon 44 1624

Google Scholar

Google Scholar

[22] Zheng R, Gao J, Wang J, Feng S P, Ohtani H, Wang J, Chen G 2012 Nano Lett. 12 188

Google Scholar

Google Scholar

[23] Shi B, Dong L, Li M Q, Liu B, Kim K, Xu X F, Zhou J, Liu J 2018 Appl. Phys. Lett. 113 041902

Google Scholar

Google Scholar

[24] 潘东楷, 宗志成, 杨诺 2022 71 086302

Google Scholar

Google Scholar

Pan D K, Zong Z C, Yang N 2022 Acta Phys. Sin. 71 086302

Google Scholar

Google Scholar

[25] Kempers R, Kolodner P, Lyons A, Robinson A J 2009 Rev. Sci. Instrum. 80 095111

Google Scholar

Google Scholar

[26] Prasher R S, Simmons C, Solbrekken G L 2000 ASME 2000 International Mechanical Engineering Congress and Exposition Orlando, Florida, USA, November 5–10, 2000 p461

[27] Wu Y M, Ye K, Liu Z D, Wang M J, Chee K W, Lin C T, Jiang N, Yu J 2018 J. Mater. Chem. C 6 6494

Google Scholar

Google Scholar

[28] Chen X K, Hu X Y, Jia P, Xie Z X, Liu J 2021 Int. J. Mech. Sci. 206 106576

Google Scholar

Google Scholar

[29] Liu C Q, Chen C, Yu W, Chen M, Zhou D Y, Xie H Q 2020 Int. J. Therm. Sci. 152 106293

Google Scholar

Google Scholar

[30] Mehra N, Mu L W, Ji T, Yang X T, Kong J, Gu J W, Zhu J H 2018 Appl. Mater. Today 12 92

Google Scholar

Google Scholar

[31] Fang Z N, Li M, Wang S K, Gu Y Z, Li Y X, Zhang Z G 2019 Int. J. Heat Mass Transfer 137 1103

Google Scholar

Google Scholar

[32] Eucken A 1940 Forsch. Ingenieurwes. A 11 6

Google Scholar

Google Scholar

[33] Chen H Y, Ginzburg V V, Yang J, Yang Y F, Liu W, Huang Y, Du L B, Chen B 2016 Prog. Polym. Sci. 59 41

Google Scholar

Google Scholar

[34] Fuller J J, Marotta E E 2001 J. Therm. Heat Transfer 15 228

Google Scholar

Google Scholar

[35] Hill R F, Supancic P H 2005 J. Am. Ceram. Soc. 87 1831

Google Scholar

Google Scholar

[36] Zhang G Q, Xia Y P, Wang H, Tao Y, Tao G L, Tu S T, Wu H P 2009 J. Compos. Mater. 44 963

Google Scholar

Google Scholar

计量

- 文章访问数: 6484

- PDF下载量: 127

- 被引次数: 0

下载:

下载: