-

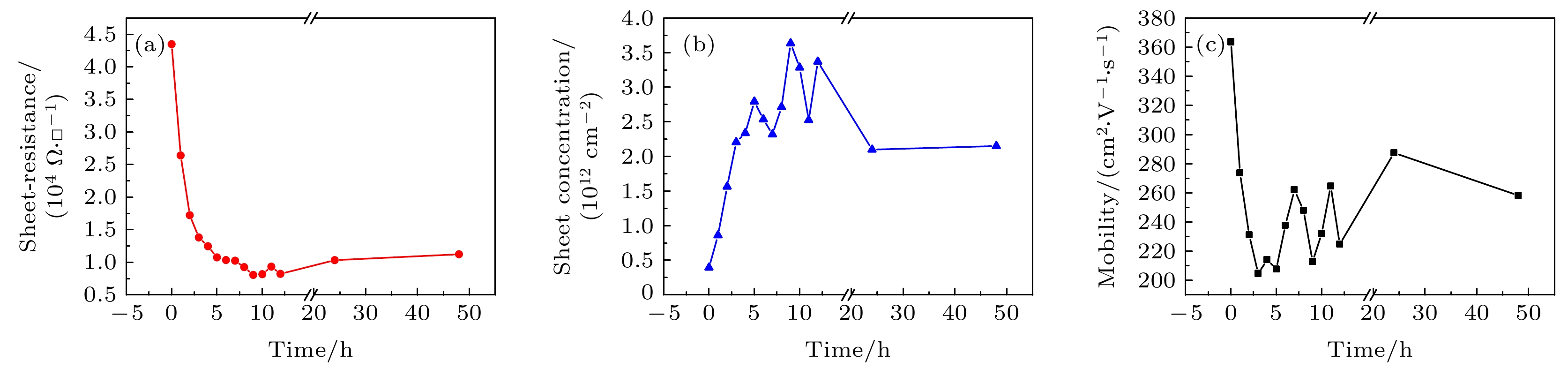

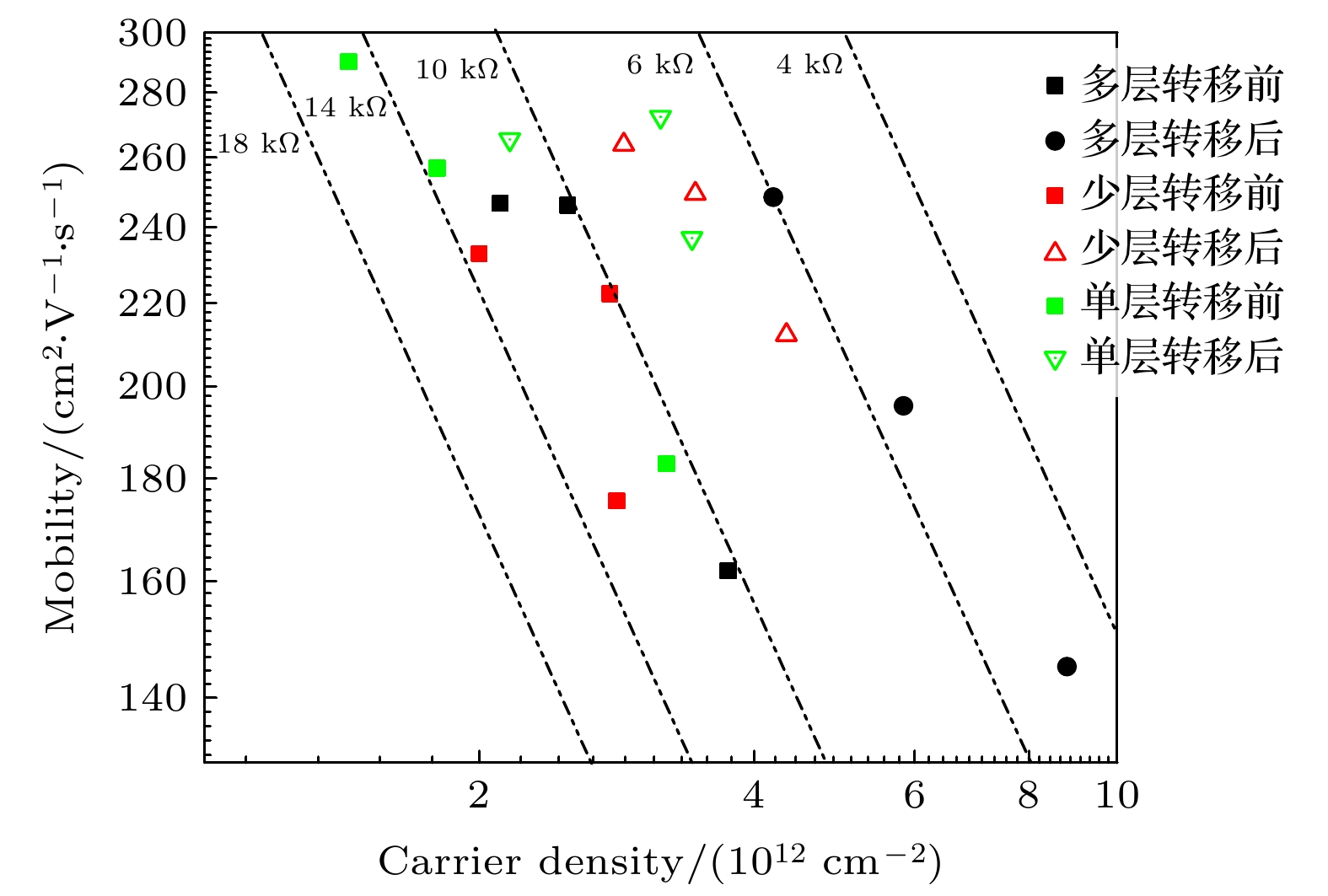

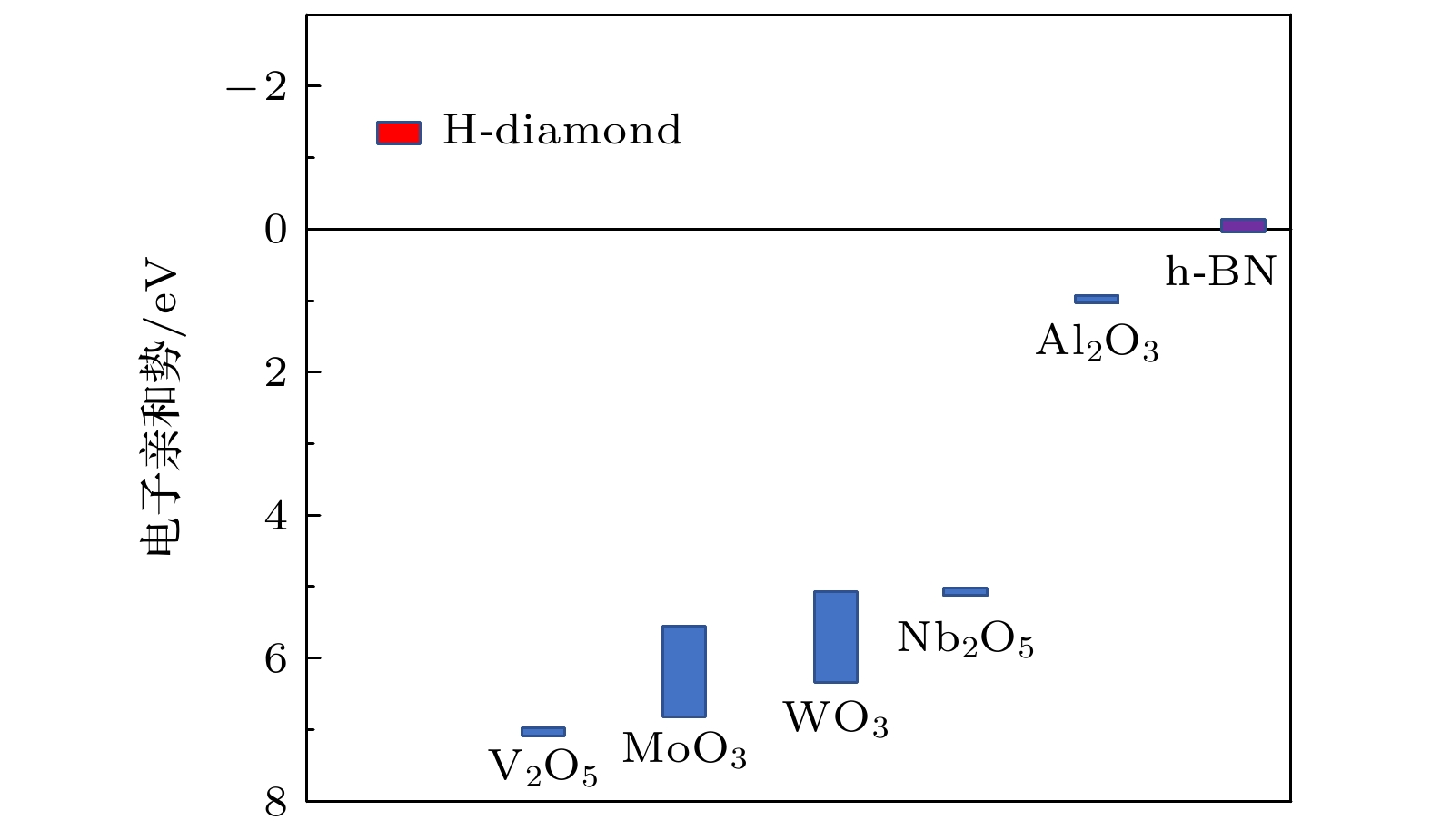

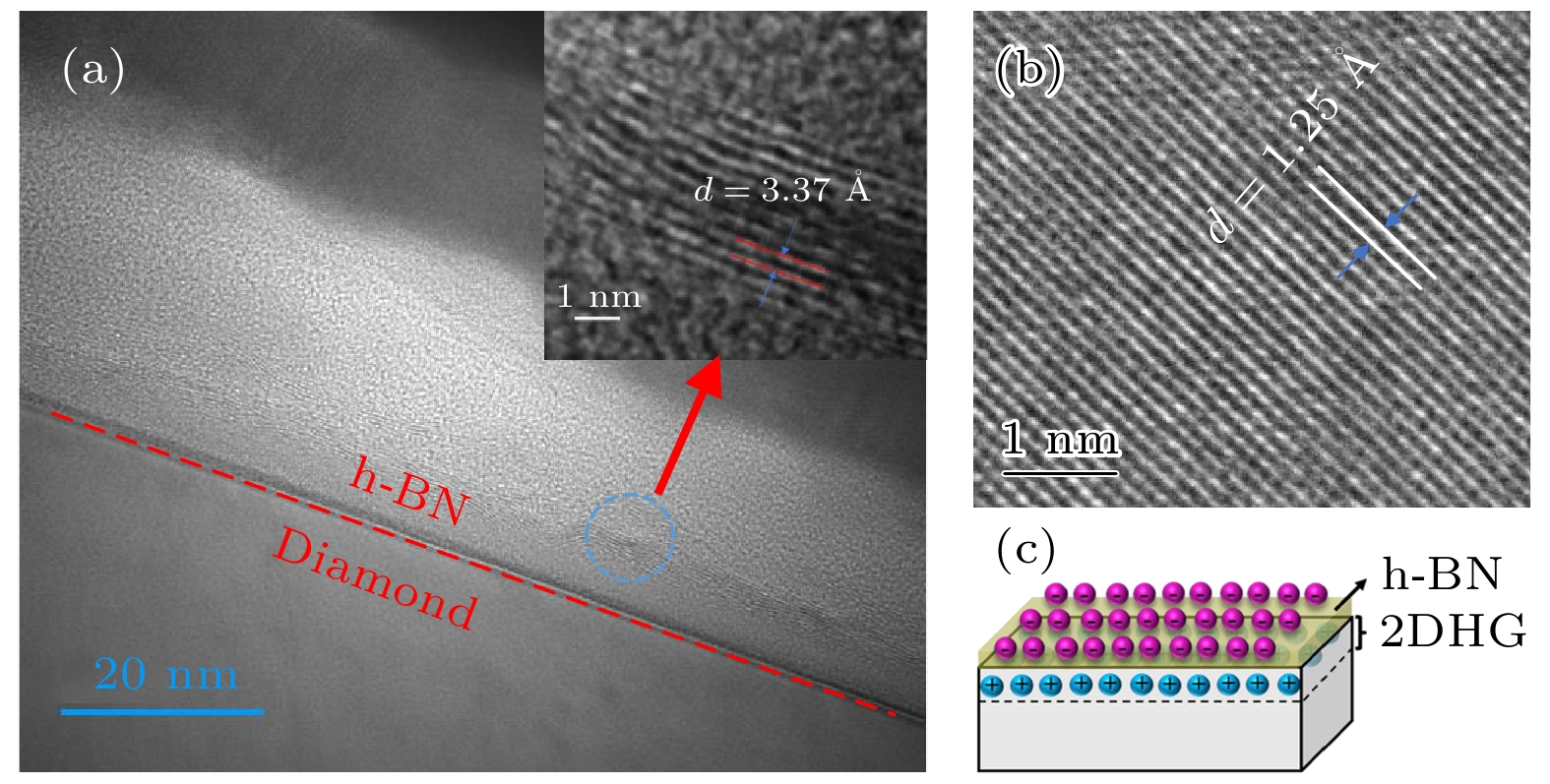

基于h-BN钝化的氢终端金刚石表面导电沟道表现出高的空穴迁移率, 但是当前h-BN钝化金刚石主要采用机械剥离的方法, 无法实现大尺寸导电沟道, 难以满足实际的应用要求. 本文系统地开展了经典转移h-BN对氢终端金刚石表面导电沟道的载流子输运影响研究. 通过微波化学气相沉积外延生长高质量单晶金刚石, 并通过表面氢化处理得到氢终端金刚石. 通过湿法转移不同层数h-BN制备出h-BN/H-diamond异质结, 系统地研究了沟道载流子输运特征. 研究结果表明, h-BN转移后沟道导电性能明显增强, 且随着h-BN厚度的增加, 沟道导电性增强效果趋于稳定. 多层h-BN的转移可使氢终端金刚石表面载流子密度提升近2倍, 方阻降低到之前的50%. 当前的结果显示h-BN/H-diamond异质结可能存在转移掺杂效果, 使得载流子密度显著提升. 伴随载流子密度的增加, h-BN钝化的金刚石表面沟道迁移率保持稳定, h-BN在金刚石表面吸附, 使得原本在氢终端表面的负电荷向h-BN表面移动, 作用距离加大, 减弱了氢终端金刚石导电沟道中空穴和介质层负电荷的耦合作用, 使其迁移率保持稳定.Conductive channel on the surface of hydrogen terminated diamond with two-dimensional h-BN passivation exhibits high hole mobility. However, the current h-BN passivated diamond mainly uses the method of mechanical peeling, which cannot achieve a large-size conductive channel and is difficult to meet the actual application requirements. In this study, the effect of classical transfer h-BN on the conductive channel on the surface of hydrogen terminated diamond is studied. High-quality single crystal diamond is epitaxially grown by microwave chemical vapor deposition (MPCVD) and the hydrogen terminated diamond is obtained by surface hydrogenation treatment. H-BN/H-diamond heterojunctions with different layers of h-BN are prepared by wetting transfer, and the characteristics of channel carrier transport are systematically studied. The results show that the channel conductivity is significantly enhanced after h-BN transfer, and with the increase of h-BN thickness, the enhancement effect of channel conductivity tends to be stable. The transfer of multilayer h-BN can increase the carrier density on the surface of hydrogen terminated diamond by nearly 2 times, and the square resistance is reduced to 50%. The current results show that the h-BN/H-diamond heterojunction may have a transfer doping effect, resulting in a significant increase in carrier density. With the increase of the channel carrier density, the channel mobility on the surface of the h-BN passivated diamond remains stable. The H-BN absorbs on the surface of the diamond, so that the negative charge originally on the surface of the hydrogen termination moves to the surface of h-BN, and the distance of action increases, weakening the coupling of the negative charge of the hole with the negative charge of the dielectric layer in the conductive channel of the hydrogen terminated diamond, which makes the mobility stable.

-

Keywords:

- hydrogen terminated diamond /

- heterostructure /

- h-BN /

- wetting transfer

[1] Stenger I, Pinault Thaury M A, Kociniewski T, Lusson A, Chikoidze E, Jomard F, Dumont Y, Chevallier J, Barjon J 2013 J. Appl. Phys. 114 073711

Google Scholar

Google Scholar

[2] 李成明, 任飞桐, 邵思武, 牟恋希, 张钦睿, 何健, 郑宇亭, 刘金龙, 魏俊俊, 陈良贤, 吕反修 2022 人工晶体学报 51 759

Google Scholar

Google Scholar

Li C M, Ren F T, Shao S W, Mou L X, Zhang Q R, He J, Zheng Y T, Liu J L, Wei J J, Chen L X, Lü F X 2022 J. Synth. Cryst. 51 759

Google Scholar

Google Scholar

[3] 姜荣超, 雷雨, 李超群, 刘谷成, 周晓丹 2008 金刚石与磨料磨具工程 20 42

Google Scholar

Google Scholar

Jiang R C, Li C Q, Liu G C, Zhou X D 2008 Diamond Abras. Eng. 20 42

Google Scholar

Google Scholar

[4] Kubovic M, Kasu M, Kageshima H, Maeda F 2010 Diamond Relat. Mater. 19 889

Google Scholar

Google Scholar

[5] Geis M W, Fedynyshyn T H, Plaut M E, Wade T C, Wuorio C H, Vitale S A, Varghese J O, Grotjohn T A, Nemanich R J, Hollis M A 2018 Diamond Relat. Mater. 84 86

Google Scholar

Google Scholar

[6] Saha N C, Takahashi K, Imamura M, Kasu M 2020 J. Appl. Phys. 128 135702

Google Scholar

Google Scholar

[7] Sato H, Kasu M 2012 Diamond Relat. Mater. 24 99

Google Scholar

Google Scholar

[8] Daicho A, Saito T, Kurihara S, Hiraiwa A, Kawarada H 2014 J. Appl. Phys. 115 223711

Google Scholar

Google Scholar

[9] Geis M W, Varghese J O, Hollis M A, Nemanich R J, Zhang X, Turner G W, Warnock S M, Vitale S A, Osadchy T, Zhang B 2020 Diamond Relat. Mater. 106 107819

Google Scholar

Google Scholar

[10] Russell S A O, Cao L, Qi D, Tallaire A, Crawford K G, Wee A T S, Moran D A 2013 Appl. Phys. Lett. 103 202112

Google Scholar

Google Scholar

[11] Tordjman M, Saguy C, Bolker A, Kalish R 2014 Adv. Mater. 1 1300155

Google Scholar

Google Scholar

[12] Verona C, Ciccognani W, Colangeli S, Limiti E, Marco Marinelli G, Verona R 2016 J. Appl. Phys. 120 025104

Google Scholar

Google Scholar

[13] Tordjman M, Weinfeld K, Kalish R 2017 Appl. Phys. Lett. 111 111601

Google Scholar

Google Scholar

[14] Kevin G, Crawford, Liang C, Dongchen Q, Alexandre T, Limiti E, Verona C, Andrew T S W, David A J M 2016 Appl. Phys. Lett. 108 042103

Google Scholar

Google Scholar

[15] Hussain J, Abbasi H N, Wang W, Wang Y F, Wang H X 2020 AIP Adv. 10 035327

Google Scholar

Google Scholar

[16] 邢雨菲, 任泽阳, 张金风, 苏凯, 丁森川, 何琦, 张进成, 张春福, 郝跃 2022 71 088102

Google Scholar

Google Scholar

Xing Y F, Ren Z Y, Zhang J F, Su K, Ding S C, He Q, Zhang J C, Zhang C F, Hao Y 2022 Acta Phys. Sin. 71 088102

Google Scholar

Google Scholar

[17] Ren Z, Zhang J, Zhang J, Zhang C, Chen D, Quan R, Yang J, Lin Z, Hao Y 2017 AIP Adv. 7 125302

Google Scholar

Google Scholar

[18] Imura, M, Banal R G, Liao M, Liu J, Aizawa T, Tanaka A 2017 J. Appl. Phys. 121 025702

Google Scholar

Google Scholar

[19] Liu J L, Zheng Y T, Lin L Z, Zhao Y, Chen L X, Wei J J 2018 J. Mater. Sci. 53 13030

Google Scholar

Google Scholar

[20] Liu J L, Yu H, Shao S W, Tu J P, Zhu X H, Yuan X L, Wei J J, Chen L X, Ye H T, Li C M 2020 Diamond Relat. Mater. 104 107750

Google Scholar

Google Scholar

[21] Sasama Y, Komatsu K, Moriyama S, Imura M, Takahide Y 2018 APL Mater. 6 111105

Google Scholar

Google Scholar

[22] Sasama Y, Kageura T, Imura M, Watanabe K, Taniguchi T, Uchihashi T, Takahide Y 2022 Nat. Eletronics 5 37

[23] Su J, Li Y, Li X, Yao P, Tang W 2014 Diamond Relat. Mater. 42 28

Google Scholar

Google Scholar

[24] 安康, 刘金龙, 林亮珍, 张博弈, 赵云, 郭彦召, Tomasz O, 陈良贤, 魏俊俊, 李成明 2018 表面技术 47 11

An K, Liu J L, Lin L Z, Zhang B Y, Zhao Y, Guo Y Z, Tomasz O, Chen L X, Wei J J, Li C M 2018 Surf. Technol. 47 11

[25] Lindblom J 2005 Am. Mineral 90 428

Google Scholar

Google Scholar

[26] Crawford, Kevin G, Tallaire, Alexandre X, Macdonald, David A, Dongchen M, David A J 2018 Diamond Relat. Mater. 84 48

Google Scholar

Google Scholar

[27] Geis M W, Varghese J O, Vardi A, Kedzierski J, Zhang B 2021 Diamond Relat. Mater. 118 108518

Google Scholar

Google Scholar

[28] Tang S, Liu H, Tian Y, Chen D, Zhou J 2021 Spectrochim. Acta, Part A 262 120092

Google Scholar

Google Scholar

[29] Xing K, Xiang Y, Jiang, M, Creedon, D L, Qi D C 2020 Appl. Surf. Sci. 509 144890

Google Scholar

Google Scholar

[30] Verona C, Arciprete F, Foffi M, Limiti E, Marinelli M, Placidi E 2018 Appl. Phys. Lett. 112 180602

Google Scholar

Google Scholar

[31] Ogawa S, Yamada T, Kadowaki R, Taniguchi T, Abukawa T, Takakuwa Y 2019 J. Appl. Phys. 125 144303

Google Scholar

Google Scholar

[32] Mirabedini P S, Debnath B, Neupane M R, Greaney P A, Ivanov T G 2020 Appl. Phys. Lett. 117 121901

Google Scholar

Google Scholar

[33] Gorbachev R V, Riaz I, Nair R, Jalil R, Britnell L, Belle B D, Hill E W, Novoselov K S, Watanabe K, Taniguchi T, Geim A K, Blake P 2011 Small 7 465

Google Scholar

Google Scholar

[34] Verona C, Ciccognani W, Colangeli S, Limiti E, Marinelli M, Verona R G 2016 J. Appl. Phy. 120 025104

[35] Li Y, Zhang J, Liu G, Ren Z, Zhang J, Hao Y 2018 Phys. Status Solidi RRL. 12 1700401

Google Scholar

Google Scholar

-

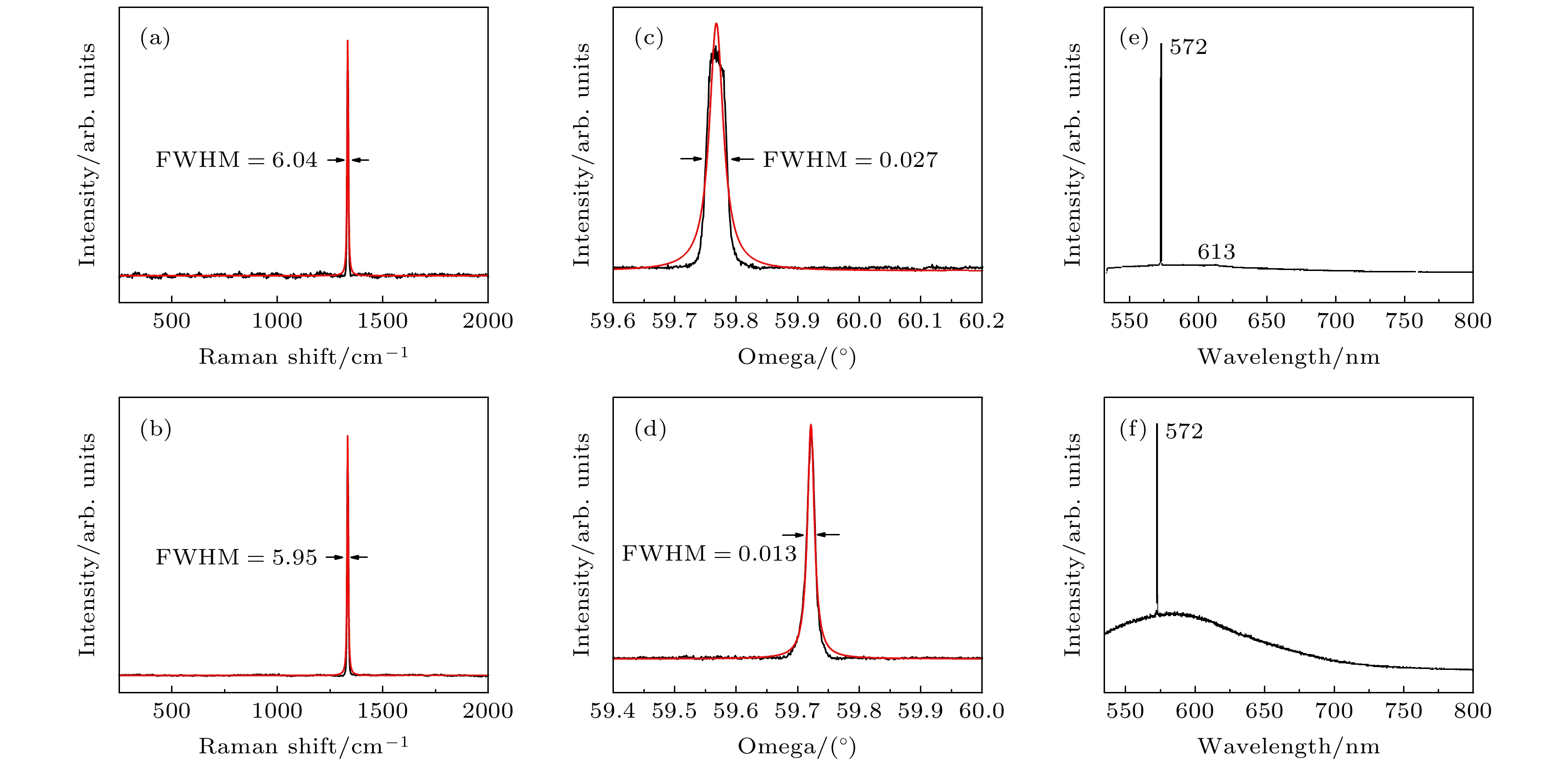

图 1 (a) 生长前衬底拉曼光谱图; (b) 生长后外延层拉曼光谱图; (c) 生长前衬底摇摆曲线; (d) 生长后外延层摇摆曲线; (e) 生长前衬底PL光谱; (f) 生长后外延层PL光谱

Fig. 1. (a) Raman spectra of the substrate before growth; (b) raman spectra of the epitaxial layer after growth; (c) rocking curve of pre-growth substrate; (d) rocking curve of postgrowth epitaxial layer; (e) PL spectra of pre-growth substrate; (f) PL spectra of postgrowth epitaxial layer.

表 1 生长、氢化预处理、表面氢化工艺参数

Table 1. Growth, cleaning, and hydrogenation parameters.

工艺参数 温度/℃ 功率/W 腔压/kPa 甲烷流量/% 氧气流量/% 生长 800—850 3800—3900 17—20 5 0.3 氢化预处理 800 1500—2000 10—12 — — 表面氢化 700—750 1400—1600 3—5 — — 表 2 多层h-BN转移前后(100)氢终端金刚石的电学性能(YW-0为PMMA空白对照试验; YW-1, YW-2, YW-3为多层h-BN转移前后的结果)

Table 2. Electrical properties of hydrogen terminated diamond before and after multilayer h-BN transfer (YW-0 is a PMMA blank control test; YW-1, YW-2, YW-3 are multilayer Results before and after h-BN transfer).

编号 方阻

/(103 Ω·□–1)迁移率

/(cm2·V–1·s–1)载流子密度

/(1012 cm–2)YW-0 转移前 10.8 203.9 2.84 转移后 10.6 198.5 2.96 YW-1 转移前 12.0 246.6 2.11 转移后 5.98 248.4 4.20 YW-2 转移前 10.1 246.0 2.50 转移后 5.48 195.6 5.83 YW-3 转移前 10.2 161.9 3.75 转移后 4.88 145.1 8.81 -

[1] Stenger I, Pinault Thaury M A, Kociniewski T, Lusson A, Chikoidze E, Jomard F, Dumont Y, Chevallier J, Barjon J 2013 J. Appl. Phys. 114 073711

Google Scholar

Google Scholar

[2] 李成明, 任飞桐, 邵思武, 牟恋希, 张钦睿, 何健, 郑宇亭, 刘金龙, 魏俊俊, 陈良贤, 吕反修 2022 人工晶体学报 51 759

Google Scholar

Google Scholar

Li C M, Ren F T, Shao S W, Mou L X, Zhang Q R, He J, Zheng Y T, Liu J L, Wei J J, Chen L X, Lü F X 2022 J. Synth. Cryst. 51 759

Google Scholar

Google Scholar

[3] 姜荣超, 雷雨, 李超群, 刘谷成, 周晓丹 2008 金刚石与磨料磨具工程 20 42

Google Scholar

Google Scholar

Jiang R C, Li C Q, Liu G C, Zhou X D 2008 Diamond Abras. Eng. 20 42

Google Scholar

Google Scholar

[4] Kubovic M, Kasu M, Kageshima H, Maeda F 2010 Diamond Relat. Mater. 19 889

Google Scholar

Google Scholar

[5] Geis M W, Fedynyshyn T H, Plaut M E, Wade T C, Wuorio C H, Vitale S A, Varghese J O, Grotjohn T A, Nemanich R J, Hollis M A 2018 Diamond Relat. Mater. 84 86

Google Scholar

Google Scholar

[6] Saha N C, Takahashi K, Imamura M, Kasu M 2020 J. Appl. Phys. 128 135702

Google Scholar

Google Scholar

[7] Sato H, Kasu M 2012 Diamond Relat. Mater. 24 99

Google Scholar

Google Scholar

[8] Daicho A, Saito T, Kurihara S, Hiraiwa A, Kawarada H 2014 J. Appl. Phys. 115 223711

Google Scholar

Google Scholar

[9] Geis M W, Varghese J O, Hollis M A, Nemanich R J, Zhang X, Turner G W, Warnock S M, Vitale S A, Osadchy T, Zhang B 2020 Diamond Relat. Mater. 106 107819

Google Scholar

Google Scholar

[10] Russell S A O, Cao L, Qi D, Tallaire A, Crawford K G, Wee A T S, Moran D A 2013 Appl. Phys. Lett. 103 202112

Google Scholar

Google Scholar

[11] Tordjman M, Saguy C, Bolker A, Kalish R 2014 Adv. Mater. 1 1300155

Google Scholar

Google Scholar

[12] Verona C, Ciccognani W, Colangeli S, Limiti E, Marco Marinelli G, Verona R 2016 J. Appl. Phys. 120 025104

Google Scholar

Google Scholar

[13] Tordjman M, Weinfeld K, Kalish R 2017 Appl. Phys. Lett. 111 111601

Google Scholar

Google Scholar

[14] Kevin G, Crawford, Liang C, Dongchen Q, Alexandre T, Limiti E, Verona C, Andrew T S W, David A J M 2016 Appl. Phys. Lett. 108 042103

Google Scholar

Google Scholar

[15] Hussain J, Abbasi H N, Wang W, Wang Y F, Wang H X 2020 AIP Adv. 10 035327

Google Scholar

Google Scholar

[16] 邢雨菲, 任泽阳, 张金风, 苏凯, 丁森川, 何琦, 张进成, 张春福, 郝跃 2022 71 088102

Google Scholar

Google Scholar

Xing Y F, Ren Z Y, Zhang J F, Su K, Ding S C, He Q, Zhang J C, Zhang C F, Hao Y 2022 Acta Phys. Sin. 71 088102

Google Scholar

Google Scholar

[17] Ren Z, Zhang J, Zhang J, Zhang C, Chen D, Quan R, Yang J, Lin Z, Hao Y 2017 AIP Adv. 7 125302

Google Scholar

Google Scholar

[18] Imura, M, Banal R G, Liao M, Liu J, Aizawa T, Tanaka A 2017 J. Appl. Phys. 121 025702

Google Scholar

Google Scholar

[19] Liu J L, Zheng Y T, Lin L Z, Zhao Y, Chen L X, Wei J J 2018 J. Mater. Sci. 53 13030

Google Scholar

Google Scholar

[20] Liu J L, Yu H, Shao S W, Tu J P, Zhu X H, Yuan X L, Wei J J, Chen L X, Ye H T, Li C M 2020 Diamond Relat. Mater. 104 107750

Google Scholar

Google Scholar

[21] Sasama Y, Komatsu K, Moriyama S, Imura M, Takahide Y 2018 APL Mater. 6 111105

Google Scholar

Google Scholar

[22] Sasama Y, Kageura T, Imura M, Watanabe K, Taniguchi T, Uchihashi T, Takahide Y 2022 Nat. Eletronics 5 37

[23] Su J, Li Y, Li X, Yao P, Tang W 2014 Diamond Relat. Mater. 42 28

Google Scholar

Google Scholar

[24] 安康, 刘金龙, 林亮珍, 张博弈, 赵云, 郭彦召, Tomasz O, 陈良贤, 魏俊俊, 李成明 2018 表面技术 47 11

An K, Liu J L, Lin L Z, Zhang B Y, Zhao Y, Guo Y Z, Tomasz O, Chen L X, Wei J J, Li C M 2018 Surf. Technol. 47 11

[25] Lindblom J 2005 Am. Mineral 90 428

Google Scholar

Google Scholar

[26] Crawford, Kevin G, Tallaire, Alexandre X, Macdonald, David A, Dongchen M, David A J 2018 Diamond Relat. Mater. 84 48

Google Scholar

Google Scholar

[27] Geis M W, Varghese J O, Vardi A, Kedzierski J, Zhang B 2021 Diamond Relat. Mater. 118 108518

Google Scholar

Google Scholar

[28] Tang S, Liu H, Tian Y, Chen D, Zhou J 2021 Spectrochim. Acta, Part A 262 120092

Google Scholar

Google Scholar

[29] Xing K, Xiang Y, Jiang, M, Creedon, D L, Qi D C 2020 Appl. Surf. Sci. 509 144890

Google Scholar

Google Scholar

[30] Verona C, Arciprete F, Foffi M, Limiti E, Marinelli M, Placidi E 2018 Appl. Phys. Lett. 112 180602

Google Scholar

Google Scholar

[31] Ogawa S, Yamada T, Kadowaki R, Taniguchi T, Abukawa T, Takakuwa Y 2019 J. Appl. Phys. 125 144303

Google Scholar

Google Scholar

[32] Mirabedini P S, Debnath B, Neupane M R, Greaney P A, Ivanov T G 2020 Appl. Phys. Lett. 117 121901

Google Scholar

Google Scholar

[33] Gorbachev R V, Riaz I, Nair R, Jalil R, Britnell L, Belle B D, Hill E W, Novoselov K S, Watanabe K, Taniguchi T, Geim A K, Blake P 2011 Small 7 465

Google Scholar

Google Scholar

[34] Verona C, Ciccognani W, Colangeli S, Limiti E, Marinelli M, Verona R G 2016 J. Appl. Phy. 120 025104

[35] Li Y, Zhang J, Liu G, Ren Z, Zhang J, Hao Y 2018 Phys. Status Solidi RRL. 12 1700401

Google Scholar

Google Scholar

计量

- 文章访问数: 8504

- PDF下载量: 259

- 被引次数: 0

下载:

下载: