-

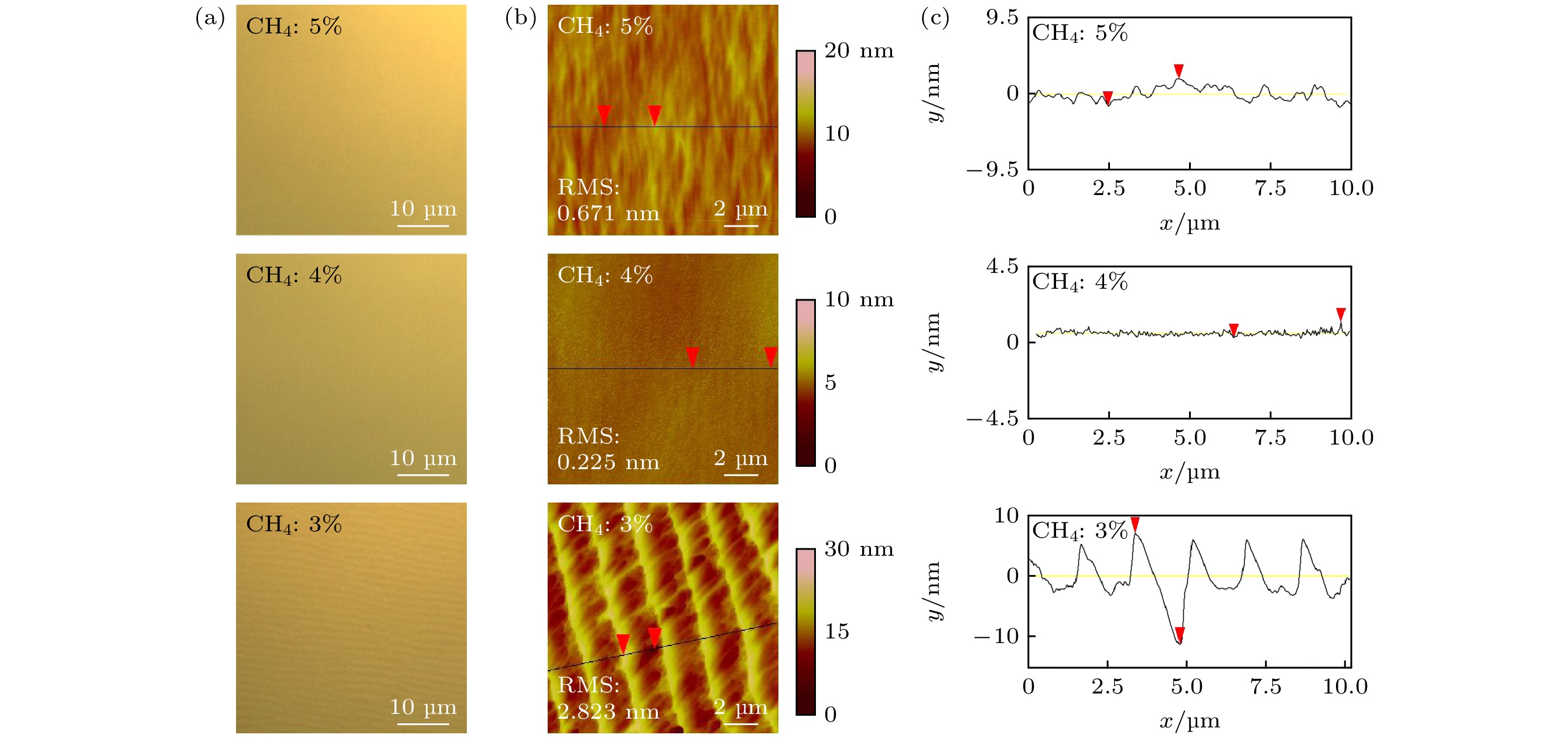

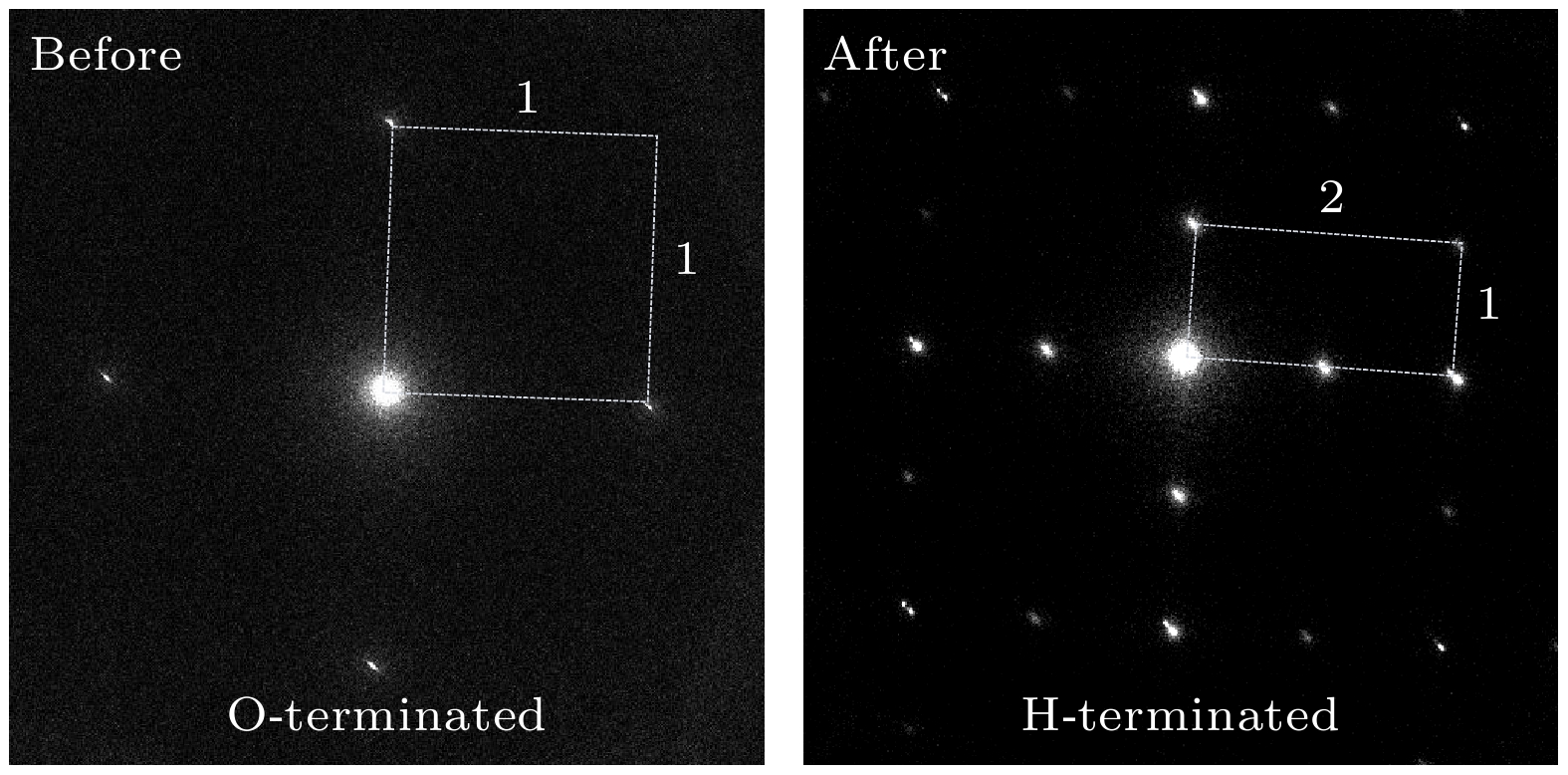

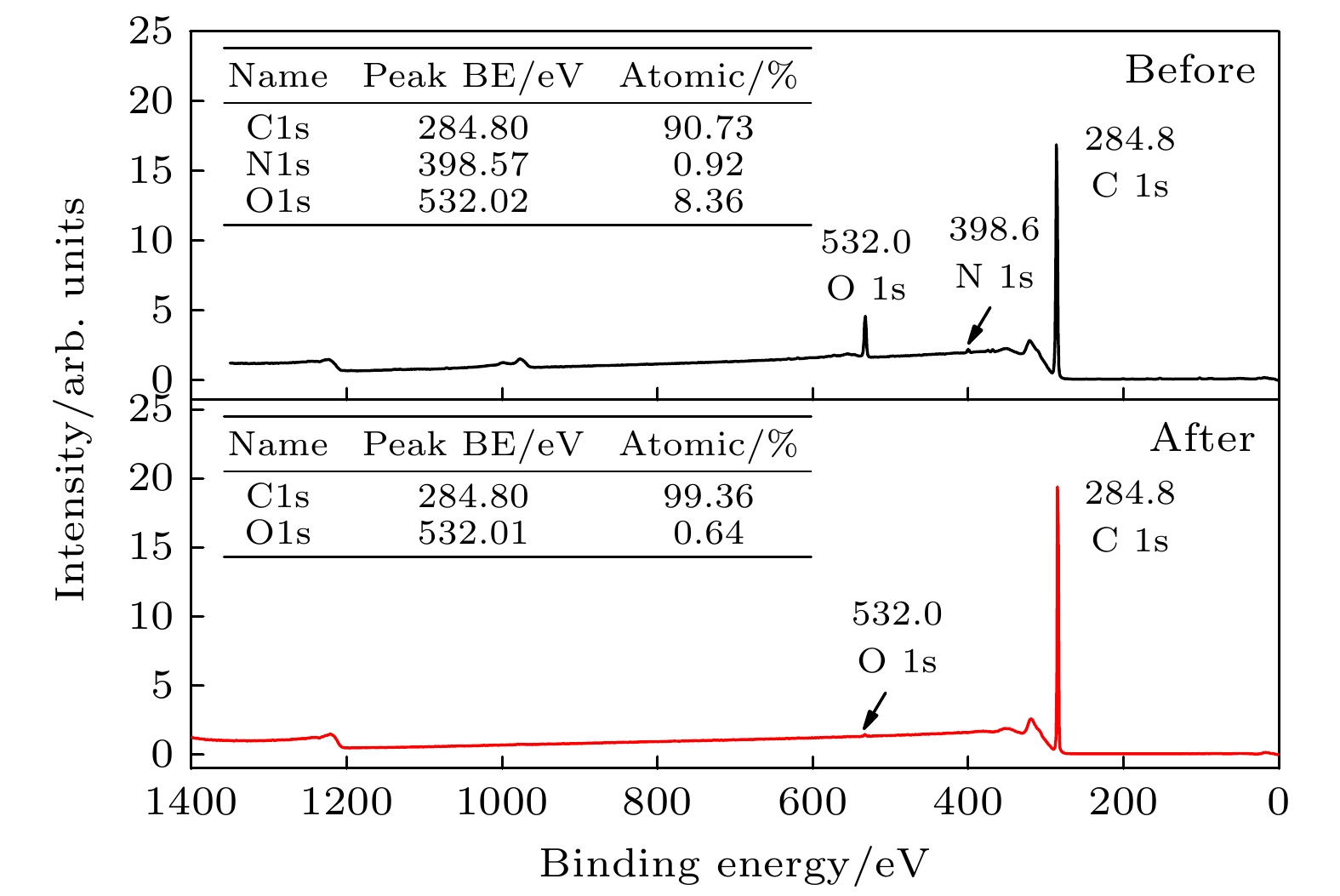

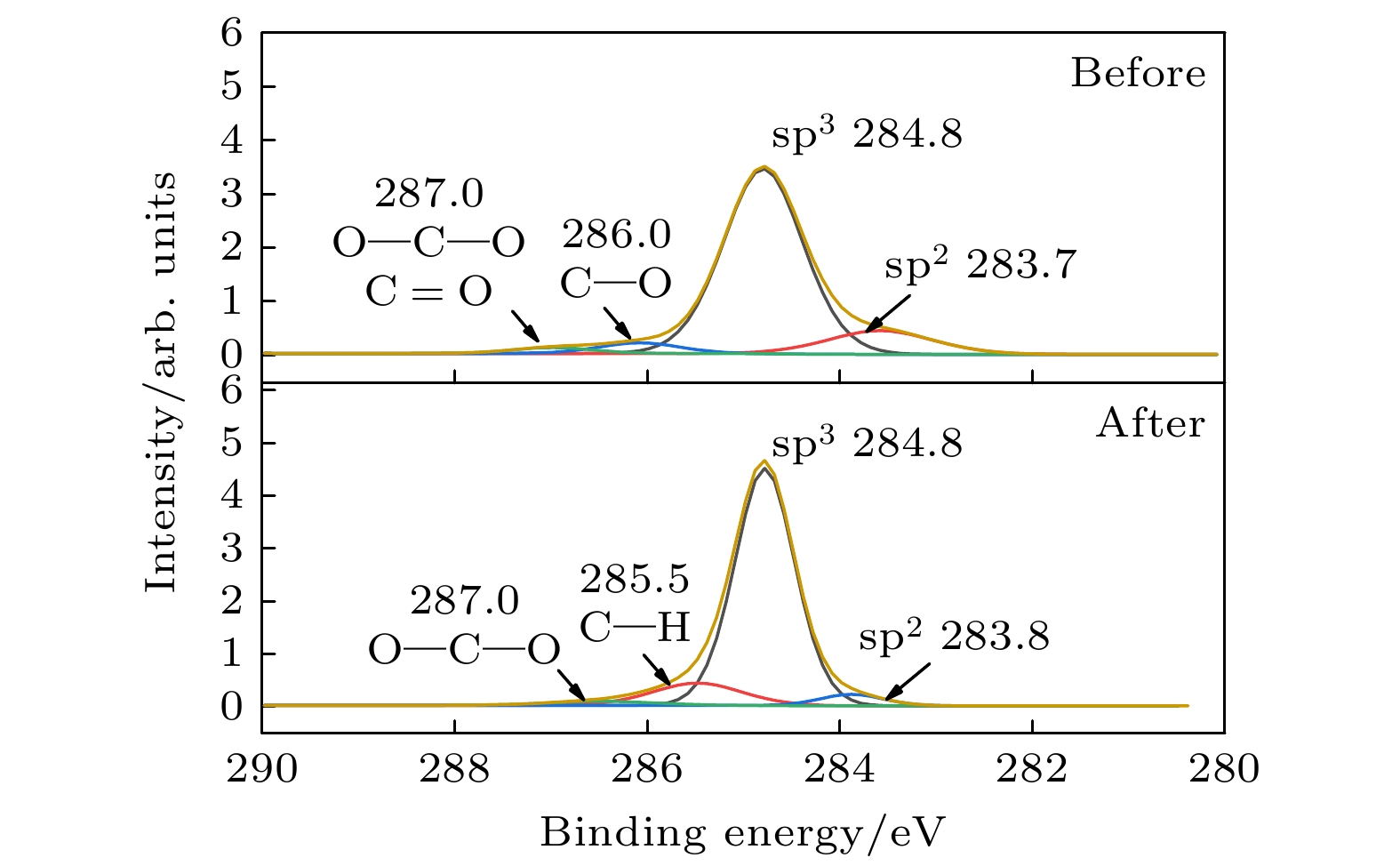

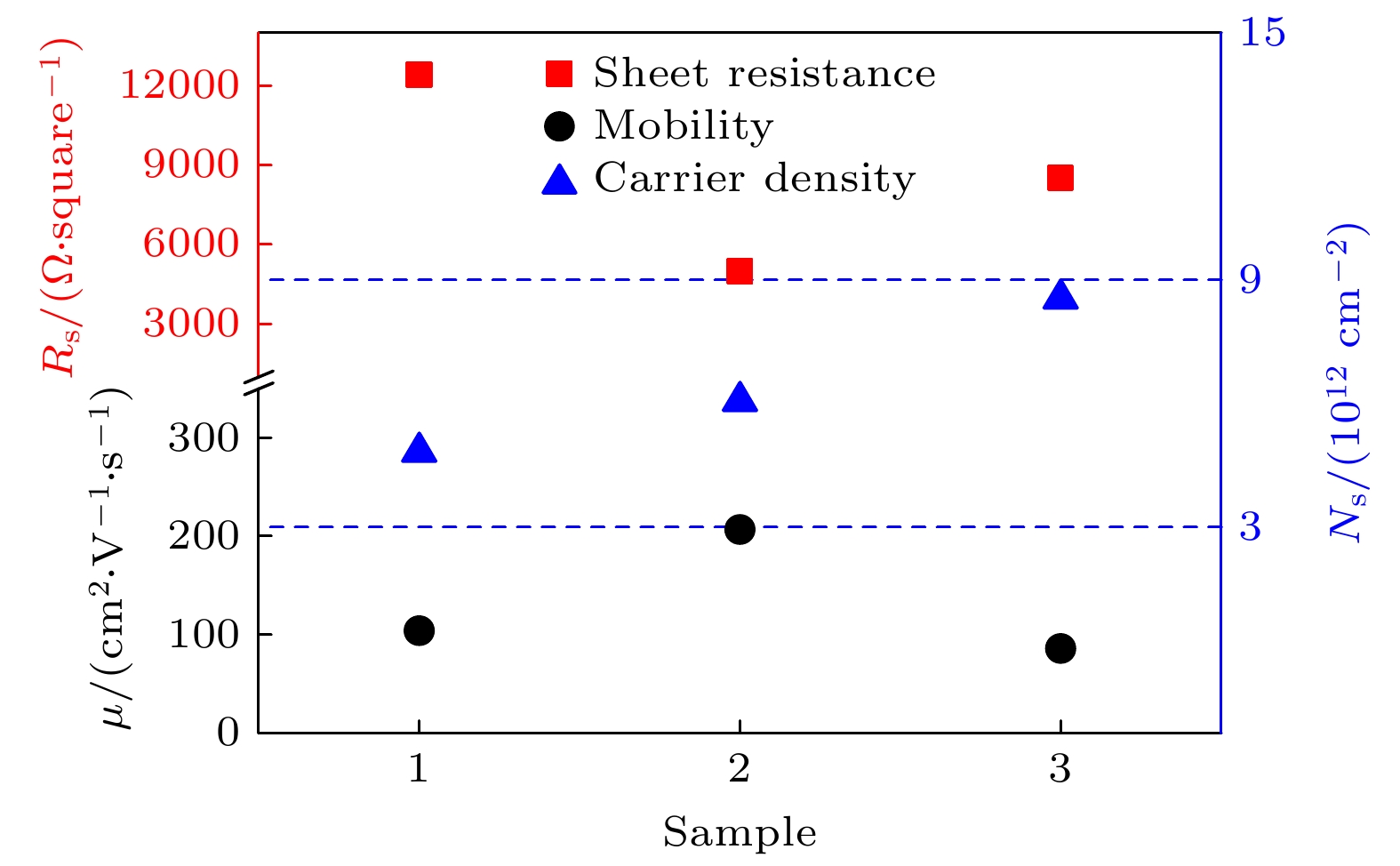

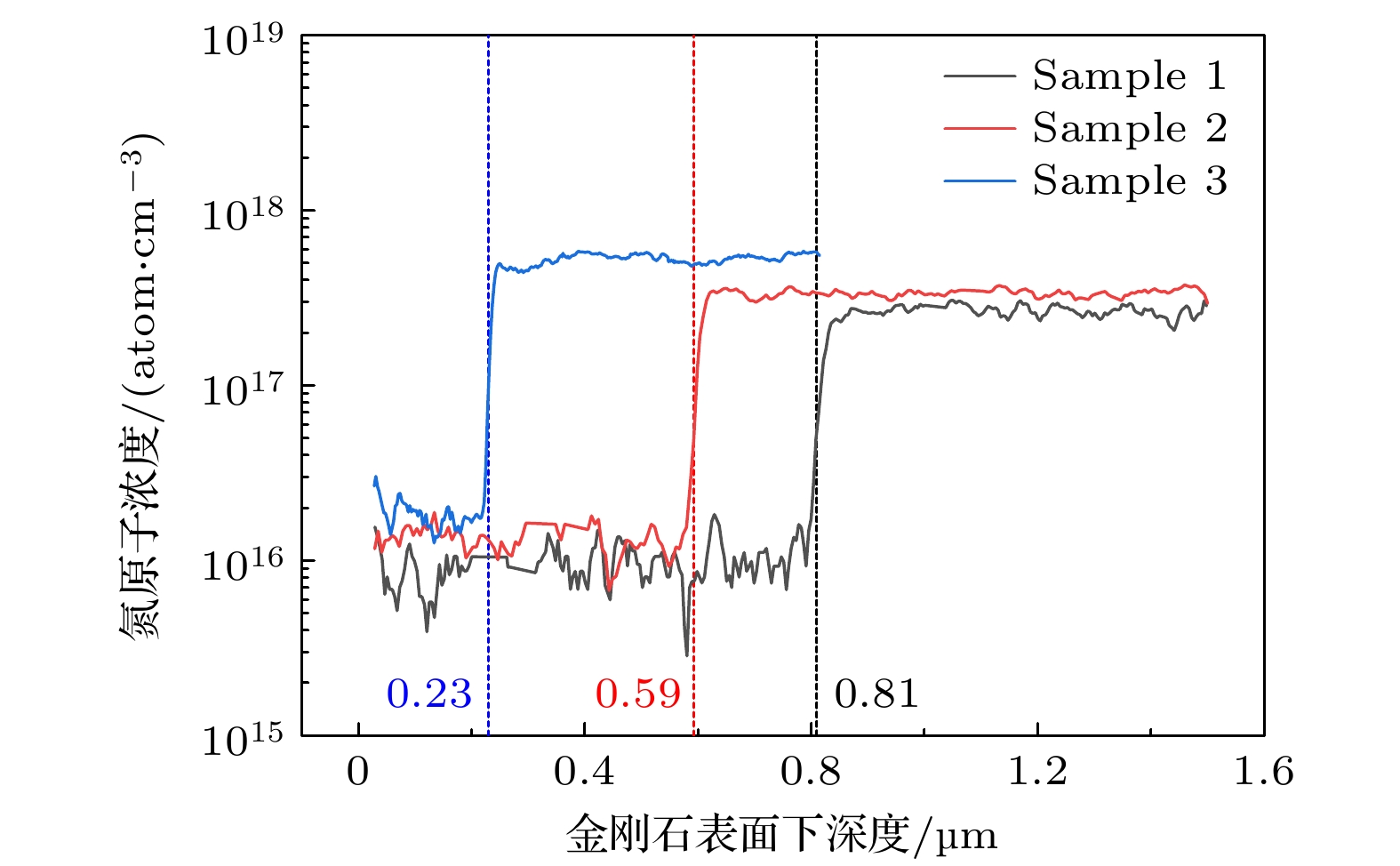

氢终端金刚石的导电性问题是目前限制其在器件领域应用的关键因素. 传统的氢终端金刚石制备工艺由于金刚石中含有杂质元素以及表面的加工损伤的存在, 限制了氢终端金刚石的电特性. 在金刚石衬底上直接外延一层高纯、表面平整的氢终端金刚石薄膜成为一种可行方案, 但该方案仍存在薄膜质量表征困难, 表面粗糙度较大等问题. 本文采用微波等离子体化学气相沉积(CVD)技术, 在含氮CVD金刚石衬底上外延一层亚微米级厚度金刚石薄膜, 并研究分析了不同甲烷浓度对金刚石薄膜生长以及导电性能的影响. 测试结果显示: 金刚石薄膜生长厚度为230—810 nm, 且外延层氮浓度含量低于1×1016 atom/cm3, 不同的甲烷浓度生长时, 金刚石外延层表面出现了三种生长模式, 这主要与金刚石的生长和刻蚀作用相关. 经过短时间生长后的金刚石薄膜表面为氢终端(2×1: H)结构, 而氧、氮元素在其中的占比极低, 这使得生长后的金刚石薄膜具有P型导电特性. 霍尔测试结果显示, 甲烷浓度为4%条件下生长的氢终端金刚石薄膜导电性最好, 其方块电阻为4981 Ω/square, 空穴迁移率为207 cm2/(V·s), 有效地提升了氢终端金刚石电特性, 为推进大功率金刚石器件发展应用起到支撑作用.The conductivity of hydrogen-terminated diamond is a limiting factor in its application in field-effect transistor devices. The traditional preparation process hinders the improvement of the electrical properties of hydrogen-terminated diamond due to impurity elements in the diamond bulk and surface damage caused by processing near the diamond surface. To overcome this, researchers have explored the epitaxial growth of a high-purity and flat-surfaced diamond thin film on a diamond substrate. However, this approach still faces challenges in film characterization and achieving high surface smoothness. In this study, microwave plasma chemical vapor deposition technology is used to epitaxially grow a sub-micron thick diamond film on a nitrogen-doping chemical vapor deposition diamond substrate of 10 mm × 10 mm × 0.5 mm in size. The influence of methane concentration on the growth and conductivity of diamond film is investigated. The test results reveal that the growth thickness of the diamond film ranges from 230 to 810 nm, and the nitrogen concentration in the epitaxial layer is lower than 1×1016 atom/cm3. Three growth modes are observed for the homoepitaxial growth of the diamond thin film under different methane concentrations. A methane concentration of 4% enables two-dimensional planar growth of diamond, resulting in a smooth and flat surface with a roughness of 0.225 nm (10 μm×10 μm). The formation of different surface morphologies is attributed to the growing process and etching process of diamond. Surface low-energy electron diffraction testing indicates that the surface of the diamond film undergoes a structural transition from oxygen terminal (1×1: O) to hydrogen terminal (2×1: H) when grown for a short period of time. X-ray photoelectron spectroscopy analysis reveals an extremely low ratio of oxygen element to nitrogen element, giving the grown diamond film P-type conductivity characteristics. The Hall test results demonstrate that the hydrogen-terminated diamond film grown with a methane concentration of 4% exhibits the highest conductivity, with a square resistance of 4981 Ω/square and a hole mobility of 207 cm2/(V·s). This enhanced conductivity can be attributed to the lower defect density observed under these specific conditions. The findings of this study effectively improve the electrical properties of hydrogen-terminated diamond, and contribute to the development and practical application of high-power diamond devices.

[1] 王艳丰, 王宏兴 2020 人工晶体学报 49 2139

Google Scholar

Google Scholar

Wang Y F, Wang H X 2020 J. Synth. Cryst. 49 2139

Google Scholar

Google Scholar

[2] Zhang C M, Zheng Y B, Jiang Z G, Lü X Y, Hou X, Hu S A, Liu J W 2010 Chin. Phys. Lett. 27 088103

Google Scholar

Google Scholar

[3] 房超, 贾晓鹏, 颜丙敏, 陈宁, 李亚东, 陈良超, 郭龙锁, 马红安 2015 64 228101

Google Scholar

Google Scholar

Fang C, Jia X P, Yan B M, Chen N, Li Y D, Chen L C, Guo L S, Ma H A 2015 Acta Phys. Sin. 64 228101

Google Scholar

Google Scholar

[4] 邢雨菲, 任泽阳, 张金风, 苏凯, 丁森川, 何琦, 张进成, 张春福, 郝跃 2022 71 088102

Google Scholar

Google Scholar

Xing Y F, Ren Z Y, Zhang J F, Su K, Ding S C, He Q, Zhang J C, Zhang C F, Hao Y 2022 Acta Phys. Sin. 71 088102

Google Scholar

Google Scholar

[5] Crawford K G, Maini I, Macdonald D A, Moran D A J 2021 Prog. Surf. Sci. 96 100613

Google Scholar

Google Scholar

[6] Okushi H, Watanabe H, Ri S 2022 J. Cryst. Growth 237 1269

[7] Sung G R, Hiroaki Y B, Sadanori Y, Hideyuki W, Daisuke T, Hideyo O 2002 J. Cryst. Growth 235 300

Google Scholar

Google Scholar

[8] Achard J, Silva F, Tallaire A, Bonnin X, A Gicquel 2007 J. Phys. D: Appl. Phys. 40 6175

[9] Tallaire A, Achard J, Silva F, Sussmann R S, Gicquel A 2005 Diamond Relat. Mater. 14 249

Google Scholar

Google Scholar

[10] Hirama K, Takayanagi H, Yamauchi S, Yang J H, Kawarada H, Umezawa H 2008 Appl. Phys. Lett. 92 480

[11] Kubovi M, Kasu M, Kageshima H, Maeda F 2010 Diamond Relat. Mater. 19 889

Google Scholar

Google Scholar

[12] Sato H, Kasu M 2012 Diamond Relat. Mater. 24 99

Google Scholar

Google Scholar

[13] 刘聪, 汪建华, 翁俊 2015 64 028101

Google Scholar

Google Scholar

Liu C, Wang J H, Weng J 2015 Acta Phys. Sin. 64 028101

Google Scholar

Google Scholar

[14] Bushuev E V, Yurov V Y, Bolshakov A P, Ralchenko V G, Khomich A A, Antonova I A, Ashkinazi E E, Shershulin V A, Pashinin V P, Konov V I 2017 Diamond Relat. Mater. 72 61

Google Scholar

Google Scholar

[15] 耿传文, 夏禹豪, 赵洪阳, 付秋明, 马志斌 2018 67 248101

Google Scholar

Google Scholar

Geng C W, Xia Y H, Zhao H Y, Fu Q M, Ma Z B 2018 Acta Phys. Sin. 67 248101

Google Scholar

Google Scholar

[16] Shu G Y, Ralchenko V G, Bolshakov A P, Zavedeev E V, Khomich A A, Pivovarov P A, Ashkinazi E E, Konov V I, Dai B, Han J C, Zhu J Q 2020 CrystEngComm 22 2138

Google Scholar

Google Scholar

[17] 张金风, 徐佳敏, 任泽阳, 何琦, 许晟瑞, 张春福, 张进成, 郝跃 2020 69 028101

Google Scholar

Google Scholar

Zhang J F, Xu J M, Ren Z Y, He Q, Xu S R, Zhang C F, Zhang J C, Hao Y 2020 Acta Phys. Sin. 69 028101

Google Scholar

Google Scholar

[18] Ren Z Y, Liu J, Su K, Zhang J F, Zhang J C, Xu S R, Hao Y 2019 Chin. Phys. B 28 128103

Google Scholar

Google Scholar

[19] Liu K, Zhang S, Liu B, Xu M, Zhu J 2020 Carbon 169 440

Google Scholar

Google Scholar

[20] Sear M J, Schenk A K, Anton T, Alastair S, Pakes C I 2018 Phys. Status. Solidi A 215 18002831

[21] Attrash M, Kuntumalla M K, Michaelson S, Hoffman A 2020 J. Phys. Chem. C 124 5657

[22] Alba G, Eon D, Villar M P, Chicot G, Letellier J, Pernot J, Araujo D 2020 Surfaces 3 61

Google Scholar

Google Scholar

[23] 任泽阳, 张金风, 张进成, 许晟瑞, 张春福, 全汝岱, 郝跃 2017 66 208101

Google Scholar

Google Scholar

Ren Z Y, Zhang J F, Zhang J C, Xu S R, Zhang C F, Quan R D, Hao Y 2017 Acta Phys. Sin. 66 208101

Google Scholar

Google Scholar

[24] 任泽阳 2019 博士学位论文(西安: 西安电子科技大学)

Ren Z Y 2019 Ph. D. Disserertation (Xi’an: Xi’an University of Electronic Science and technology

[25] Liu J L, Zheng Y T, Lin L Z, Zhao Y, Chen L X, Wei J J, Guo J C, Feng Z H, Li C M 2018 J. Mater. Sci. 53 13030

Google Scholar

Google Scholar

[26] Liu J L, Yu H S, Si W T, Ju P Z, Xiao H Y, Xiao L W, Jun J C, Liang X Y, Hai T, Li C M 2020 Diamond Relat. Mater. 104 107750

Google Scholar

Google Scholar

-

表 1 MPCVD外延生长金刚石薄膜的实验参数

Table 1. Experimental parameters for MPCVD epitaxial growth of diamond thin films.

样品1 样品2 样品3 输出功率/W 3500 3500 3500 温度/ºC 860 860 860 H2流量/sccm 190 192 194 CH4浓度/% 5 4 3 -

[1] 王艳丰, 王宏兴 2020 人工晶体学报 49 2139

Google Scholar

Google Scholar

Wang Y F, Wang H X 2020 J. Synth. Cryst. 49 2139

Google Scholar

Google Scholar

[2] Zhang C M, Zheng Y B, Jiang Z G, Lü X Y, Hou X, Hu S A, Liu J W 2010 Chin. Phys. Lett. 27 088103

Google Scholar

Google Scholar

[3] 房超, 贾晓鹏, 颜丙敏, 陈宁, 李亚东, 陈良超, 郭龙锁, 马红安 2015 64 228101

Google Scholar

Google Scholar

Fang C, Jia X P, Yan B M, Chen N, Li Y D, Chen L C, Guo L S, Ma H A 2015 Acta Phys. Sin. 64 228101

Google Scholar

Google Scholar

[4] 邢雨菲, 任泽阳, 张金风, 苏凯, 丁森川, 何琦, 张进成, 张春福, 郝跃 2022 71 088102

Google Scholar

Google Scholar

Xing Y F, Ren Z Y, Zhang J F, Su K, Ding S C, He Q, Zhang J C, Zhang C F, Hao Y 2022 Acta Phys. Sin. 71 088102

Google Scholar

Google Scholar

[5] Crawford K G, Maini I, Macdonald D A, Moran D A J 2021 Prog. Surf. Sci. 96 100613

Google Scholar

Google Scholar

[6] Okushi H, Watanabe H, Ri S 2022 J. Cryst. Growth 237 1269

[7] Sung G R, Hiroaki Y B, Sadanori Y, Hideyuki W, Daisuke T, Hideyo O 2002 J. Cryst. Growth 235 300

Google Scholar

Google Scholar

[8] Achard J, Silva F, Tallaire A, Bonnin X, A Gicquel 2007 J. Phys. D: Appl. Phys. 40 6175

[9] Tallaire A, Achard J, Silva F, Sussmann R S, Gicquel A 2005 Diamond Relat. Mater. 14 249

Google Scholar

Google Scholar

[10] Hirama K, Takayanagi H, Yamauchi S, Yang J H, Kawarada H, Umezawa H 2008 Appl. Phys. Lett. 92 480

[11] Kubovi M, Kasu M, Kageshima H, Maeda F 2010 Diamond Relat. Mater. 19 889

Google Scholar

Google Scholar

[12] Sato H, Kasu M 2012 Diamond Relat. Mater. 24 99

Google Scholar

Google Scholar

[13] 刘聪, 汪建华, 翁俊 2015 64 028101

Google Scholar

Google Scholar

Liu C, Wang J H, Weng J 2015 Acta Phys. Sin. 64 028101

Google Scholar

Google Scholar

[14] Bushuev E V, Yurov V Y, Bolshakov A P, Ralchenko V G, Khomich A A, Antonova I A, Ashkinazi E E, Shershulin V A, Pashinin V P, Konov V I 2017 Diamond Relat. Mater. 72 61

Google Scholar

Google Scholar

[15] 耿传文, 夏禹豪, 赵洪阳, 付秋明, 马志斌 2018 67 248101

Google Scholar

Google Scholar

Geng C W, Xia Y H, Zhao H Y, Fu Q M, Ma Z B 2018 Acta Phys. Sin. 67 248101

Google Scholar

Google Scholar

[16] Shu G Y, Ralchenko V G, Bolshakov A P, Zavedeev E V, Khomich A A, Pivovarov P A, Ashkinazi E E, Konov V I, Dai B, Han J C, Zhu J Q 2020 CrystEngComm 22 2138

Google Scholar

Google Scholar

[17] 张金风, 徐佳敏, 任泽阳, 何琦, 许晟瑞, 张春福, 张进成, 郝跃 2020 69 028101

Google Scholar

Google Scholar

Zhang J F, Xu J M, Ren Z Y, He Q, Xu S R, Zhang C F, Zhang J C, Hao Y 2020 Acta Phys. Sin. 69 028101

Google Scholar

Google Scholar

[18] Ren Z Y, Liu J, Su K, Zhang J F, Zhang J C, Xu S R, Hao Y 2019 Chin. Phys. B 28 128103

Google Scholar

Google Scholar

[19] Liu K, Zhang S, Liu B, Xu M, Zhu J 2020 Carbon 169 440

Google Scholar

Google Scholar

[20] Sear M J, Schenk A K, Anton T, Alastair S, Pakes C I 2018 Phys. Status. Solidi A 215 18002831

[21] Attrash M, Kuntumalla M K, Michaelson S, Hoffman A 2020 J. Phys. Chem. C 124 5657

[22] Alba G, Eon D, Villar M P, Chicot G, Letellier J, Pernot J, Araujo D 2020 Surfaces 3 61

Google Scholar

Google Scholar

[23] 任泽阳, 张金风, 张进成, 许晟瑞, 张春福, 全汝岱, 郝跃 2017 66 208101

Google Scholar

Google Scholar

Ren Z Y, Zhang J F, Zhang J C, Xu S R, Zhang C F, Quan R D, Hao Y 2017 Acta Phys. Sin. 66 208101

Google Scholar

Google Scholar

[24] 任泽阳 2019 博士学位论文(西安: 西安电子科技大学)

Ren Z Y 2019 Ph. D. Disserertation (Xi’an: Xi’an University of Electronic Science and technology

[25] Liu J L, Zheng Y T, Lin L Z, Zhao Y, Chen L X, Wei J J, Guo J C, Feng Z H, Li C M 2018 J. Mater. Sci. 53 13030

Google Scholar

Google Scholar

[26] Liu J L, Yu H S, Si W T, Ju P Z, Xiao H Y, Xiao L W, Jun J C, Liang X Y, Hai T, Li C M 2020 Diamond Relat. Mater. 104 107750

Google Scholar

Google Scholar

计量

- 文章访问数: 4493

- PDF下载量: 331

- 被引次数: 0

下载:

下载: