-

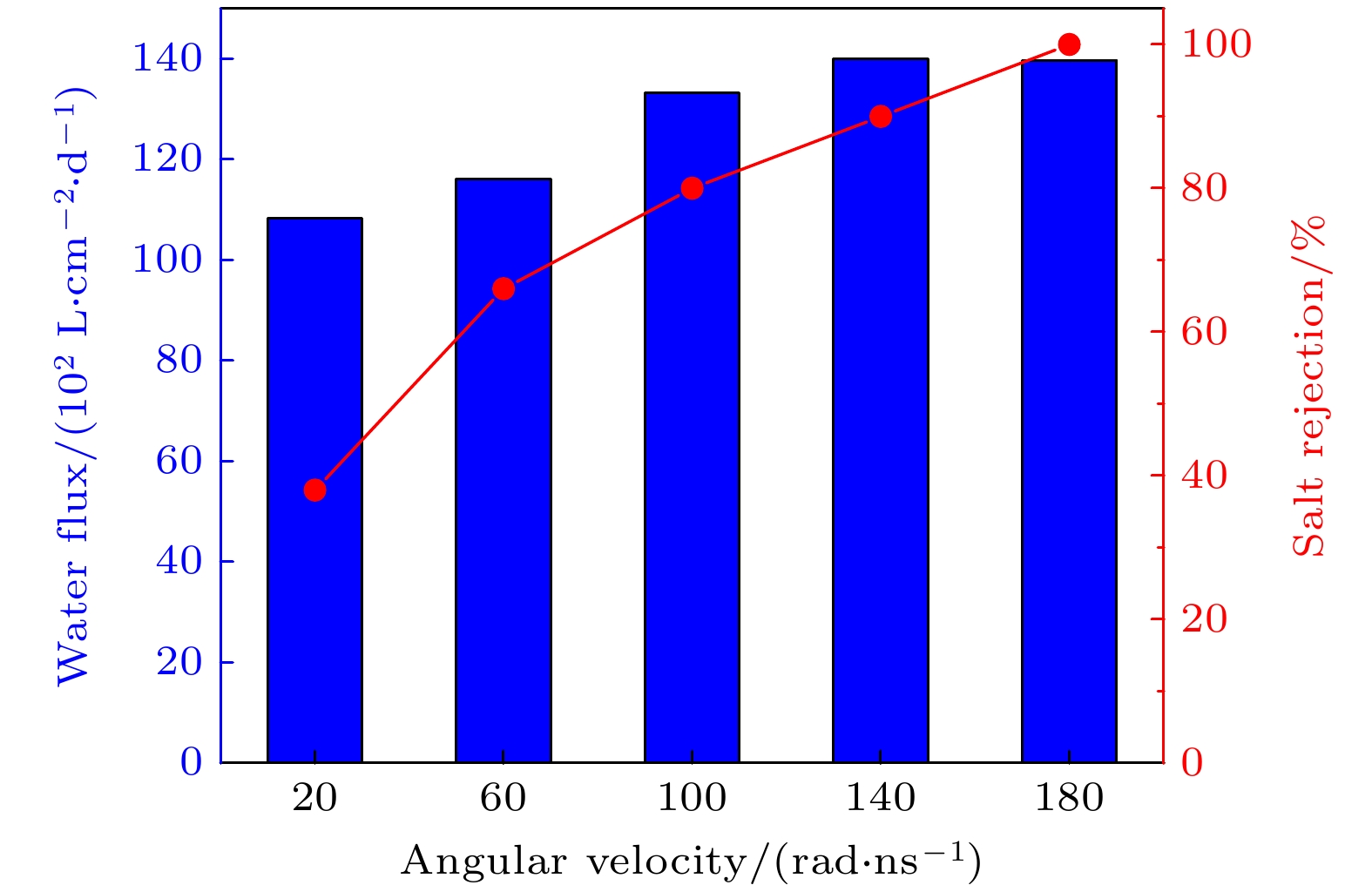

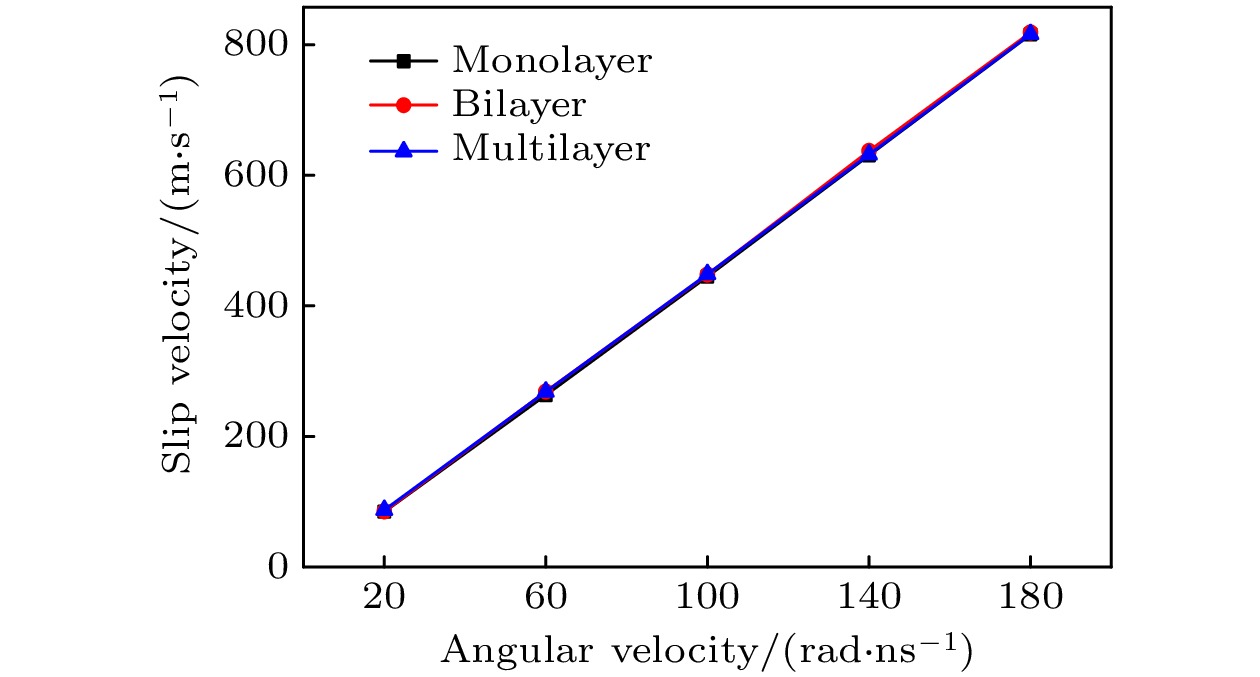

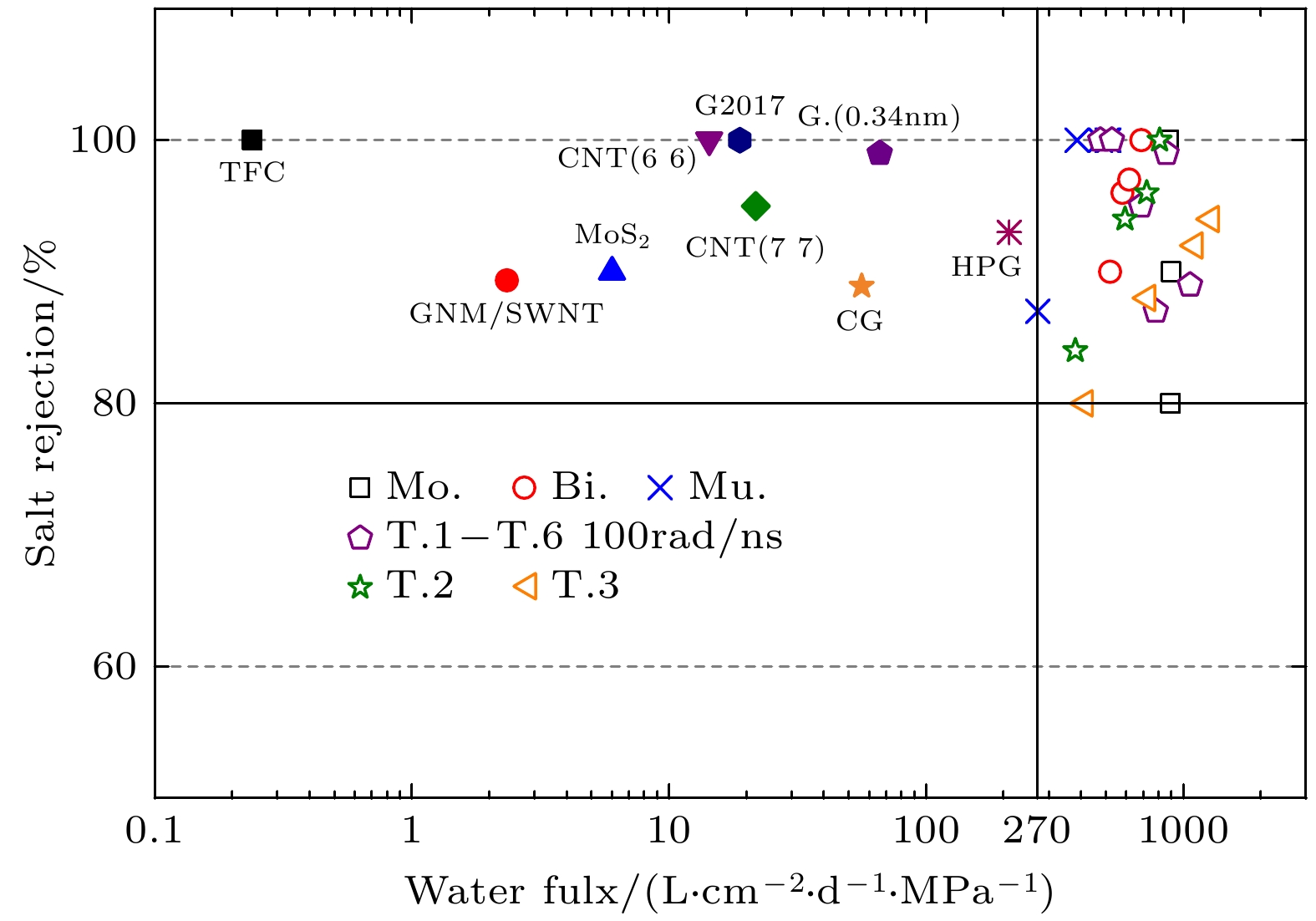

时间维度选择性反渗透原理虽然克服了反渗透膜微孔尺寸的限制, 一定程度上突破了渗透性和选择性之间的平衡, 但多层反渗透膜时间维度的滤盐机理尚未明晰. 本文采用分子动力学方法, 揭示了多孔石墨烯反渗透膜的厚度和剪切速度对盐水反渗透特性的影响规律. 结果表明, 随着多孔石墨烯反渗透膜旋转速度的增加, 离子截留率增加而水通量先增加后降低; 反渗透膜厚度的增加会提高离子截留率, 但阻碍了水通量的上升. 本文创新性地对三层石墨烯反渗透膜上的纳米孔结构进行了设计研究, 发现梯度孔结构在保证高选择性的同时提高了渗透性; 供给端最内层纳米孔径的变化对水通量的影响最为显著, 水通量随该孔径的增加而快速上升. 研究结果进一步阐明并验证了时间维度反渗透滤盐机理, 利用梯度孔的设计提升了相同膜厚度情况下的水通量, 为大尺度滤盐设备的设计研发提供了理论基础.Reverse osmosis (RO) technology is currently the most progressive, energy-saving and efficient membrane separation technology . Meanwhile, graphene becomes a promising candidate for fabricating the RO membranes in water desalination due to its high salt rejection and water flux. The concept of “temporal selectivity” is first proposed in our previous work in terms of the time difference between the penetration time of an ion passing through the pore and the tangential slipping time for the ion sliding across the pore. Nevertheless, the temporal selectivity mechanism of multilayered graphene membrane remains ambiguous. In this paper, the RO process of saltwater through porous graphene column RO membrane is studied by using molecular dynamics (MD) simulations method, and the effects of rotating angular velocity and the thickness of RO membrane on desalination performance of seawater are considered first. The MD results show that the salt rejection increases with the rotation speed of porous membrane increasing while the water flux initially increases and then decreases . Meanwhile, the interfacial slip velocity increases linearly with angular velocity increasing. On the other hand, the increasing thickness of porous graphene membrane can enhance the selectivity and reduce the permeability of water molecules. As expected, the tri-layered porous graphene RO membrane can achieve high salt rejection at low interfacial slip velocity. In order to ensure high selectivity and energy conservation and efficient, the pore structure of the porous graphene RO membrane is optimized. The results show that the optimized nanopores can increase the water flux significantly, whereas the salt rejection is not changed appreciably. It is found that the pore size of the innermost layer membrane near the feed region has the most significant effect on the water flux. The water flux increases sharply with the increase of pore diameter and the salt rejection remains totally higher than 80%. Moreover, the RO membrane with a special Type 3 structure exhibits excellent performance in seawater desalination, specifically, the ultrahigh water flux reaches 20029 L·cm–2·d–1 and the super salt rejection arrives at 94%. The research results further clarify and verify the mechanism of the temporal selectivity in RO process, and improve the water flux under the condition of the same membrane thickness by designing gradient hole. The findings can conduce to the in-depth theoretical understanding of porous graphene-based membranes and designing and developing the large-scale seawater desalination devices and water filtration equipment.

-

Keywords:

- reverse osmosis /

- porous graphene /

- temporal selectivity /

- interfacial slip velocity /

- molecular dynamics

[1] Homaeigohar S, Elbahri M 2017 NPG Asia Mater. 9 e427

Google Scholar

Google Scholar

[2] Boretti A, Al-Zubaidy S, Vaclavikova M, Al-Abri M, Castelletto S, Mikhalovsky S 2018 NPJ Clean Water 5 1

Google Scholar

Google Scholar

[3] Amy G, Ghaffour N, Li Z Y, Francis L, Linares R V, Missimer T, Lattemann S 2017 Desalination 401 16

Google Scholar

Google Scholar

[4] Liu G P, Jin W Q, Xu N P 2015 Chem. Soc. Rev. 44 5016

Google Scholar

Google Scholar

[5] Sun C Z, Liu M, Bai B F 2019 Carbon 153 481

Google Scholar

Google Scholar

[6] Seo D H, Pineda S, Woo Y C, Xie M, Murdock A T, Ang E Y M, Jiao Y L, Park M J, Lim S I, Lawn M, Borghi F F, Han Z J, Gray S, Millar G, Du A J, Shon H K, Ng T Y, Ostrikov K K 2018 Nat. Commun. 9 683

Google Scholar

Google Scholar

[7] Choi K, Droudian A, Wyss R M, Schlichting K P, Park H G 2018 Sci. Adv. 4 eaau0476

Google Scholar

Google Scholar

[8] Hong S, Constans C, Surmani M M V, Seow Y C, Guevara C J A, Garaj S 2017 Nano Lett. 17 728

Google Scholar

Google Scholar

[9] You Y, Sahajwalla V, Yoshimura M, Joshi R K 2016 Nanoscale 8 117

Google Scholar

Google Scholar

[10] Mi B X 2019 Science 364 1033

Google Scholar

Google Scholar

[11] Abraham J, Vasu K S, Williams C D, Gopinadhan K, Su Y, Cherian C T, Dix J, Prestat E, Haigh S J, Grigorieva I V, Carbone P, Geim A K, Nair R R 2017 Nat. Nanotechnol. 12 546

Google Scholar

Google Scholar

[12] Zhang M C, Guan K C, Ji Y F, Liu G P, Jin W Q, Xu N P 2019 Nat. Commun. 10 1253

Google Scholar

Google Scholar

[13] Gogotsi Y 2018 Nat. Nanotechnol. 13 621

Google Scholar

Google Scholar

[14] Chen B, Jiang H F, Liu X, Hu X J 2017 ACS Appl. Mater. Interfaces 9 22826

Google Scholar

Google Scholar

[15] Yang Y B, Yang X D, Liang L, Gao Y Y, Cheng H Y, Li X M, Zou M C, Cao A Y, Ma R Z, Yuan Q, Duan X F 2019 Science 364 1057

Google Scholar

Google Scholar

[16] McGinnis R L, Reimund K, Ren J, Xia L L, Chowdhury M R, Sun X H, Abril M, Moon J D, Merrick M M, Park J, Stevens K A, McCutcheon J R, Freeman B D 2018 Sci. Adv. 4 e1700938

Google Scholar

Google Scholar

[17] Chen X F, Zhu Y B, Yu H, Liu J Z, Easton C D, Wang Z Y, Hu Y X, Xie Z L, Wu H A, Zhang X W, Li D, Wang H T 2021 J. Membrane Sci. 621 118934

Google Scholar

Google Scholar

[18] Qi H, Zhang Z Y, Li Z W, Nan H Y, Bi K D, Chen Y F 2021 J. Phys. Chem. C 125 507

Google Scholar

Google Scholar

[19] Esfandiar A, Radha B, Wang F C, Yang Q, Hu S, Garaj S, Nair R R, Geim A K, Gopinadhan K 2017 Science 358 511

Google Scholar

Google Scholar

[20] Joshi R K, Carbone P, Wang F C, Kravets V G, Su Y, Grigorieva I V, Wu H A, Geim A K, Nair R R 2014 Science 343 752

Google Scholar

Google Scholar

[21] Wang Y H, He Z J, Gupta K M, Shi Q, Lu R F 2017 Carbon 116 120

Google Scholar

Google Scholar

[22] Morelos-Gomez A, Cruz-Silva R, Muramatsu H, Ortiz-Medina J, Araki T, Fukuyo T, Tejima S, Takeuchi K, Hayashi T, Terrones M, Endo M 2017 Nat. Nanotechnol. 12 1083

Google Scholar

Google Scholar

[23] Mahmoud K A, Mansoor B, Mansour A, Khraisheh M 2015 Desalination 356 208

Google Scholar

Google Scholar

[24] Sun C Z, Zhu S H, Liu M C, Shen S H, Bai B F 2019 J. Phys. Chem. Lett. 10 7188

Google Scholar

Google Scholar

[25] 孙成珍, 周润峰, 白博峰 2020 物理化学学报 36 11911044

Google Scholar

Google Scholar

Sun C Z, Zhou R F, Bai B F 2020 Acta Phys. -Chim. Sin. 36 11911044

Google Scholar

Google Scholar

[26] 张忠强, 于凡顺, 刘珍, 张福建, 程广贵 2020 69 098201

Google Scholar

Google Scholar

Zhang Z Q, Yu F S, Liu Z, Zhang F J, Cheng G G 2020 Acta Phys. Sin. 69 098201

Google Scholar

Google Scholar

[27] Droudian A, Lokesh M, Youn S K, Park H G 2018 J. Membrane Sci. 567 1

Google Scholar

Google Scholar

[28] Tu Q S, Li T G, Deng A, Zhu K, Liu Y F, Li S F 2018 Technology 6 36

Google Scholar

Google Scholar

[29] Li T G, Tu Q S, Li S F 2019 Desalination 451 182

Google Scholar

Google Scholar

[30] Corry B 2008 J. Phys. Chem. B 112 1427

Google Scholar

Google Scholar

[31] Zhang Z Q, Li S F, Mi B X, Wang J B, Ding J N 2020 Sci. Adv. 6 eaba9471

Google Scholar

Google Scholar

[32] Li W, Wang W, Zheng X, Dong Z, Yan Y, Zhang J 2017 Comput. Mater. Sci. 136 60

Google Scholar

Google Scholar

[33] Werber J R, Osuji C O, Elimelech M 2016 Nat. Rev. Mater. 1 1

Google Scholar

Google Scholar

[34] Qin Y Z, Hu Y Y, Koehler S, Cai L H, Wen J J, Tan X J, Xu W L, Sheng Q, Hou X, Xue J M, Yu M, Weitz D 2017 ACS Appl. Mater. Interfaces 9 9239

Google Scholar

Google Scholar

[35] Wang Z Y, Tu Q S, Zheng S X, Urban J J, Li S F, Mi B X 2017 Nano Lett. 17 7289

Google Scholar

Google Scholar

[36] 张泽程, 刘珍, 王孟妮, 张福建, 张忠强 2021 70 098201

Google Scholar

Google Scholar

Zhang Z C, Liu Z, Wang M N, Zhang F J, Zhang Z Q 2021 Acta Phy. Sin. 70 098201

Google Scholar

Google Scholar

-

图 1 多孔GC膜模型, 石墨烯挡板外侧与GC膜内侧红色、蓝色小球分别代表盐水溶液中的钠离子、氯离子; 透明部分表示的是水分子; 灰色圆柱为GC膜, 黑色平板为石墨烯挡板. 左侧图中间红色虚线是GC的直径D; 右侧图中红色线表示的是GC膜上纳米孔的直径d; 模拟系统模型z方向总高度为H, 滤盐设备主体高度为h, 模型呈对称分布. (为便于观察模型结构对视图进行了剖面处理)

Fig. 1. Porous GC membrane model. The red, bule balls on the outside of graphene baffle and inside of GC membrane respectively represent sodium ion and chloride ion in saltwater. The transparent part represents the water molecules, gray cylinder is GC membrane, black plate is graphene baffle. The red dotted line in the middle of the image on the left is the GC with a diameter of D. The red line in the figure on the right represents the nanopore on the GC membrane with a diameter of d. The total height of the simulation system model in the z direction is H, and the main height of the salt filter equipment is h, and the model is symmetrically distributed. (A certain degree of section processing is made to the view to facilitate observation of the model structure.)

图 2 (a)汲取区水分子增长数的变化; (b)汲取区盐离子数的变化; (c) 滑移速度与角速度值对应的关系; (d) 不同角速度下GC内溶液径向速度变化

Fig. 2. (a) The variation of the number of water molecules in the draw region; (b) the variation of the number of salt ions in the draw region; (c) the relation between slip velocity and angular velocity value; (d) the radial velocity gradient of salt solution in GC at different angular velocities.

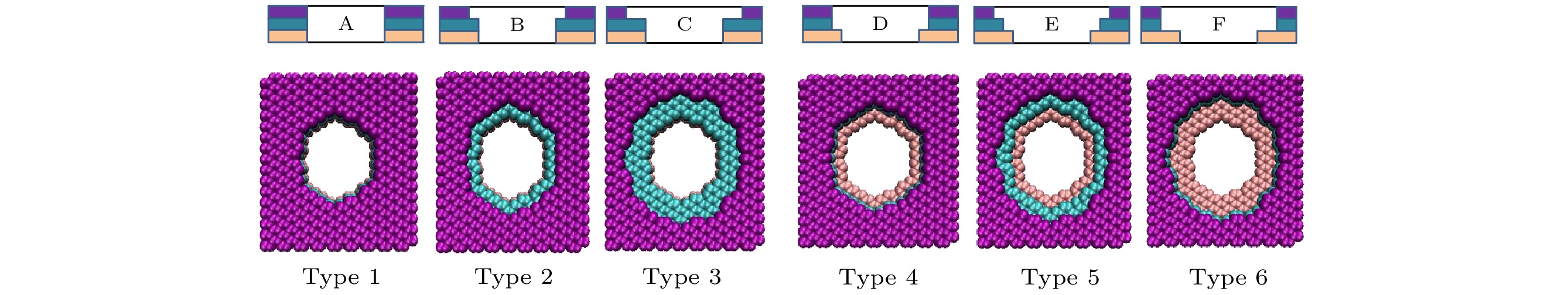

图 6 纳米孔形状和内部结构的示意图(GC膜由内往外观察, 取4 nm×4 nm的方块展示孔的形状, Type1-Type6分别对应A-F: A-类型1柱形纳米孔; B-类型2小蘑菇形纳米孔; C-类型3蘑菇形纳米孔; D-类型4矮小蘑菇纳米孔; E-类型5台阶形纳米孔; F-类型6矮蘑菇纳米孔)

Fig. 6. The schematic diagram of different nanopore shapes and internal structures. (GC membrane is observed from the inside to the outside, and squares of 4×4 nm are taken to show the shape of nanopore. Type1-6 correspond to A-F respectively: A-Type1 is cylindrical nanopore; B-Type2 is small mushroom-shaped nanopore; C-Type3 is mushroom-shaped nanopore; D-Type4 is short mushroom nanopore; E-Type5 is stepped nanopore; F-Type 6 is short mushroom nanopore)

图 9 滤盐效益对比图(Mo. Bi. Mu.分别表示单层、双层和三层GC膜; T.1—T.6分别代表六种不同的纳米孔结构; 黑色、红色、蓝色、紫色、绿色分别对应的角速度是20, 60, 100, 140和180 rad/ns)

Fig. 9. Comparison chart of salt filtration efficiency. (Mo., Bi. and Mu. represent single-layer, double-layer and three-layer GC membrane respectively; T.1—T.6 respectively represent six different nanopore structures; black, red, blue, purple, and green correspond to angular velocities of 20, 60, 100, 140 and 180 rad/ns respectively)

图 10 与其他性能优良的RO膜的渗透性和盐排斥性比较(包括商用薄膜复合(TFC)RO膜、纳米多孔石墨烯膜G2017、石墨烯-CNT(GNM/SWNT)混合膜、MoS2膜、不同尺寸的CNTs、柱状石墨烯(Columnar graphene, CG)、氢化多孔石墨烯膜(Hydrogenated porous graphene, HPG); 标号表中表示的单层、双层、三层GC膜和不同孔结构T1—T6给出的数据)

Fig. 10. Comparison of permeability and selectivity with other excellent RO membranes (including commercial film composite (TFC) RO membrane, nanopore graphene membrane G2017, graphene-CNT (GNM/SWNT) hybrid membrane, MoS2 membrane, CNTs of different sizes, Columnar graphene (CG), Hydrogenated porous graphene (HPG); In this work, single, double, triple GC membranes and different nanopore structures T1–T6 represented in the label table and given the best data).

表 1 LJ相互势能函数参数和原子电荷量

Table 1. LJ potential function parameters and atomic charge quantity.

Elements C O H Na+ Cl– ε/eV 0.00373 0.00706 0.00 0.00564 0.00434 σ/Å 3.40 3.16 0.00 2.35 4.40 q/e 0 –1.0484 0.5242 1 –1 表 2 GC膜纳米孔直径组合

Table 2. Nanopore diameter combination of GC membrane.

类型 Type 1 Type 2 Type 3 Type 4 Type 5 Type 6 内层膜 2.0 nm 2.5 nm 3.0 nm 2.5 nm 3.0 nm 3.0 nm 中层膜 2.0 nm 2.0 nm 2.0 nm 2.5 nm 2.5 nm 3.0 nm 外层膜 2.0 nm 2.0 nm 2.0 nm 2.0 nm 2.0 nm 2.0 nm -

[1] Homaeigohar S, Elbahri M 2017 NPG Asia Mater. 9 e427

Google Scholar

Google Scholar

[2] Boretti A, Al-Zubaidy S, Vaclavikova M, Al-Abri M, Castelletto S, Mikhalovsky S 2018 NPJ Clean Water 5 1

Google Scholar

Google Scholar

[3] Amy G, Ghaffour N, Li Z Y, Francis L, Linares R V, Missimer T, Lattemann S 2017 Desalination 401 16

Google Scholar

Google Scholar

[4] Liu G P, Jin W Q, Xu N P 2015 Chem. Soc. Rev. 44 5016

Google Scholar

Google Scholar

[5] Sun C Z, Liu M, Bai B F 2019 Carbon 153 481

Google Scholar

Google Scholar

[6] Seo D H, Pineda S, Woo Y C, Xie M, Murdock A T, Ang E Y M, Jiao Y L, Park M J, Lim S I, Lawn M, Borghi F F, Han Z J, Gray S, Millar G, Du A J, Shon H K, Ng T Y, Ostrikov K K 2018 Nat. Commun. 9 683

Google Scholar

Google Scholar

[7] Choi K, Droudian A, Wyss R M, Schlichting K P, Park H G 2018 Sci. Adv. 4 eaau0476

Google Scholar

Google Scholar

[8] Hong S, Constans C, Surmani M M V, Seow Y C, Guevara C J A, Garaj S 2017 Nano Lett. 17 728

Google Scholar

Google Scholar

[9] You Y, Sahajwalla V, Yoshimura M, Joshi R K 2016 Nanoscale 8 117

Google Scholar

Google Scholar

[10] Mi B X 2019 Science 364 1033

Google Scholar

Google Scholar

[11] Abraham J, Vasu K S, Williams C D, Gopinadhan K, Su Y, Cherian C T, Dix J, Prestat E, Haigh S J, Grigorieva I V, Carbone P, Geim A K, Nair R R 2017 Nat. Nanotechnol. 12 546

Google Scholar

Google Scholar

[12] Zhang M C, Guan K C, Ji Y F, Liu G P, Jin W Q, Xu N P 2019 Nat. Commun. 10 1253

Google Scholar

Google Scholar

[13] Gogotsi Y 2018 Nat. Nanotechnol. 13 621

Google Scholar

Google Scholar

[14] Chen B, Jiang H F, Liu X, Hu X J 2017 ACS Appl. Mater. Interfaces 9 22826

Google Scholar

Google Scholar

[15] Yang Y B, Yang X D, Liang L, Gao Y Y, Cheng H Y, Li X M, Zou M C, Cao A Y, Ma R Z, Yuan Q, Duan X F 2019 Science 364 1057

Google Scholar

Google Scholar

[16] McGinnis R L, Reimund K, Ren J, Xia L L, Chowdhury M R, Sun X H, Abril M, Moon J D, Merrick M M, Park J, Stevens K A, McCutcheon J R, Freeman B D 2018 Sci. Adv. 4 e1700938

Google Scholar

Google Scholar

[17] Chen X F, Zhu Y B, Yu H, Liu J Z, Easton C D, Wang Z Y, Hu Y X, Xie Z L, Wu H A, Zhang X W, Li D, Wang H T 2021 J. Membrane Sci. 621 118934

Google Scholar

Google Scholar

[18] Qi H, Zhang Z Y, Li Z W, Nan H Y, Bi K D, Chen Y F 2021 J. Phys. Chem. C 125 507

Google Scholar

Google Scholar

[19] Esfandiar A, Radha B, Wang F C, Yang Q, Hu S, Garaj S, Nair R R, Geim A K, Gopinadhan K 2017 Science 358 511

Google Scholar

Google Scholar

[20] Joshi R K, Carbone P, Wang F C, Kravets V G, Su Y, Grigorieva I V, Wu H A, Geim A K, Nair R R 2014 Science 343 752

Google Scholar

Google Scholar

[21] Wang Y H, He Z J, Gupta K M, Shi Q, Lu R F 2017 Carbon 116 120

Google Scholar

Google Scholar

[22] Morelos-Gomez A, Cruz-Silva R, Muramatsu H, Ortiz-Medina J, Araki T, Fukuyo T, Tejima S, Takeuchi K, Hayashi T, Terrones M, Endo M 2017 Nat. Nanotechnol. 12 1083

Google Scholar

Google Scholar

[23] Mahmoud K A, Mansoor B, Mansour A, Khraisheh M 2015 Desalination 356 208

Google Scholar

Google Scholar

[24] Sun C Z, Zhu S H, Liu M C, Shen S H, Bai B F 2019 J. Phys. Chem. Lett. 10 7188

Google Scholar

Google Scholar

[25] 孙成珍, 周润峰, 白博峰 2020 物理化学学报 36 11911044

Google Scholar

Google Scholar

Sun C Z, Zhou R F, Bai B F 2020 Acta Phys. -Chim. Sin. 36 11911044

Google Scholar

Google Scholar

[26] 张忠强, 于凡顺, 刘珍, 张福建, 程广贵 2020 69 098201

Google Scholar

Google Scholar

Zhang Z Q, Yu F S, Liu Z, Zhang F J, Cheng G G 2020 Acta Phys. Sin. 69 098201

Google Scholar

Google Scholar

[27] Droudian A, Lokesh M, Youn S K, Park H G 2018 J. Membrane Sci. 567 1

Google Scholar

Google Scholar

[28] Tu Q S, Li T G, Deng A, Zhu K, Liu Y F, Li S F 2018 Technology 6 36

Google Scholar

Google Scholar

[29] Li T G, Tu Q S, Li S F 2019 Desalination 451 182

Google Scholar

Google Scholar

[30] Corry B 2008 J. Phys. Chem. B 112 1427

Google Scholar

Google Scholar

[31] Zhang Z Q, Li S F, Mi B X, Wang J B, Ding J N 2020 Sci. Adv. 6 eaba9471

Google Scholar

Google Scholar

[32] Li W, Wang W, Zheng X, Dong Z, Yan Y, Zhang J 2017 Comput. Mater. Sci. 136 60

Google Scholar

Google Scholar

[33] Werber J R, Osuji C O, Elimelech M 2016 Nat. Rev. Mater. 1 1

Google Scholar

Google Scholar

[34] Qin Y Z, Hu Y Y, Koehler S, Cai L H, Wen J J, Tan X J, Xu W L, Sheng Q, Hou X, Xue J M, Yu M, Weitz D 2017 ACS Appl. Mater. Interfaces 9 9239

Google Scholar

Google Scholar

[35] Wang Z Y, Tu Q S, Zheng S X, Urban J J, Li S F, Mi B X 2017 Nano Lett. 17 7289

Google Scholar

Google Scholar

[36] 张泽程, 刘珍, 王孟妮, 张福建, 张忠强 2021 70 098201

Google Scholar

Google Scholar

Zhang Z C, Liu Z, Wang M N, Zhang F J, Zhang Z Q 2021 Acta Phy. Sin. 70 098201

Google Scholar

Google Scholar

计量

- 文章访问数: 6914

- PDF下载量: 63

- 被引次数: 0

下载:

下载: