-

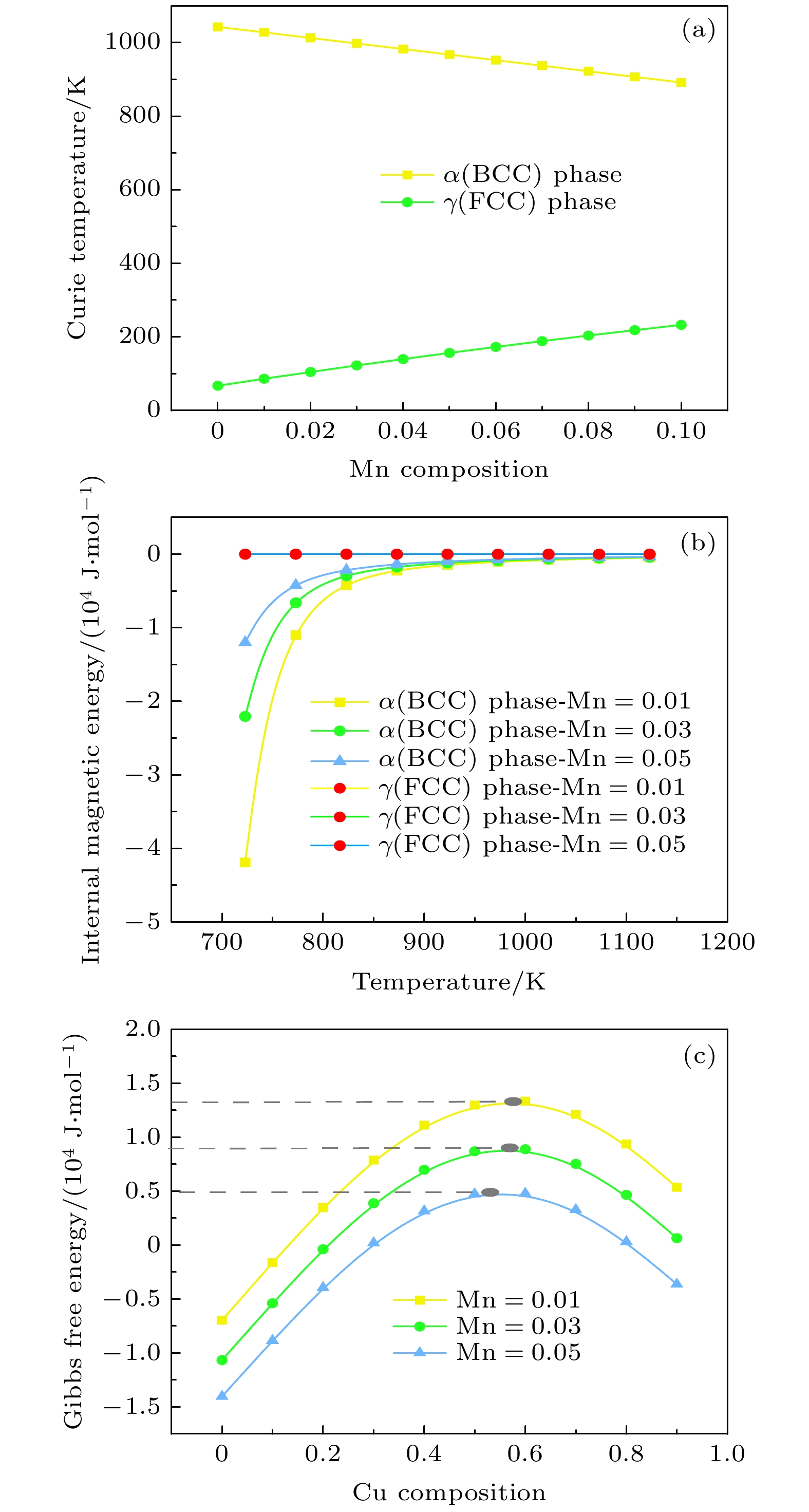

本文基于连续相场模型, 对内磁能作用下Fe-Cu-Mn合金中富Cu相析出行为进行了研究, 得到不同温度、不同Mn, Cu含量条件下的内磁能对富Cu相的平均颗粒半径、体积分数、吉布斯自由能的影响. 模拟结果表明, Mn含量越低, 居里温度越高, 内磁能对自由能的贡献越大, 且内磁能的贡献随温度升高而减小; 内磁能降低了相结构转变势垒, 促进了相结构转变. 沉淀相体积分数随Cu含量增加而增加, 通过对比有无内磁能对沉淀相体积分数的影响, 内磁能作用导致沉淀相拥有更大的体积分数. 因此在内磁能作用下, 富Cu相具有较大的平均粒径、体积分数和较小的矫顽力, 同时预测了合金硬度的变化趋势.

-

关键词:

- Fe-Cu-Mn合金 /

- 相场法 /

- 内磁能 /

- 沉淀析出 /

- 组织性能

Based on the continuous phase field model, the precipitation behavior of Cu rich phase in Fe-Cu-Mn alloy under the action of internal magnetic energy is studied. The effects of internal magnetic energy on the average particle radius, volume fraction and Gibbs free energy of Cu rich phase at different temperatures and different Mn content and Cu content are investigated. The simulation results show that the lower the Mn content and the higher the Curie temperature, the greater the contribution of internal magnetic energy to free energy is, and the contribution of internal magnetic energy decreases with temperature increasing. The internal magnetic energy reduces the phase structure transition barrier and promotes the phase structure transition. The volume fraction of precipitated phase increases with Cu content increasing. Compared with the effect of internal magnetic energy on the volume fraction of precipitated phase, the effect of internal magnetic energy leads to a large volume fraction of precipitated phase. Therefore, under the action of internal magnetic energy, the Cu rich phase has larger average particle size, volume fraction and smaller coercivity. Finally, the change trend of alloy hardness is predicted.-

Keywords:

- Fe-Cu-Mn alloy /

- phase field method /

- internal magnetic energy /

- precipitation /

- microstructure and properties

[1] Que Z, Heczko M, Kuběna I, Seifert H P, Spaetig P 2020 Mater. Charact. 165 110405

Google Scholar

Google Scholar

[2] Deschamps A, Militzer M, Poole W 2001 ISIJ. INT. 41 196

Google Scholar

Google Scholar

[3] Bousquet A, Marie S, Bompard P 2012 Comp. Mater. Sci. 64 17

Google Scholar

Google Scholar

[4] 林民东, 朱娟娟, 王伟, 周邦新, 刘文庆, 徐刚 2010 59 1163

Google Scholar

Google Scholar

Ling M D, Zhu J J, Wang W, Zhou B X, Liu W Q, Xu G, 2010 Acta Phys. Sin. 59 1163

Google Scholar

Google Scholar

[5] Miodownik A 1982 J. Phase. Equil. 2 406

Google Scholar

Google Scholar

[6] Zhao Y, Zhang B, Hou H, Chen W, Wang M 2018 J. Mater. Sci. Technol. 35 1044

Google Scholar

Google Scholar

[7] 祁科武, 赵宇宏, 田晓林, 彭敦维, 孙远洋, 侯华 2020 69 140504

Google Scholar

Google Scholar

Qi K W, ZhaoY H, Tian X L, Peng D W, Sun Y Y, Hou H 2020 Acta Phys. Sin. 69 140504

Google Scholar

Google Scholar

[8] Cui S, Mamivand M, Morgan D 2020 Mater. Des. 191 108574

Google Scholar

Google Scholar

[9] Sun Y Y, Zhao Y H, Zhao B J, Yang W K, Tian X L, H Hua 2019 J. Mater. Sci. 54 11263

Google Scholar

Google Scholar

[10] Gorbatov O, Razumov I, Gornostyrev Y, Razumovskiy V I, Korzhavyi P, Ruban A 2013 Phys. Rev. B 88 174113

Google Scholar

Google Scholar

[11] Korzhavyi P A, Ruban A V, Gorbatov O I, Gornostyrev 2015 Scr. Mater. 102 11

Google Scholar

Google Scholar

[12] Inden G 1981 Physica B+C 103 82

Google Scholar

Google Scholar

[13] Koyama T 2008 Sci. Technol. Adv. Mat. 9 013006

Google Scholar

Google Scholar

[14] Xin T, Zhao Y, Mahjoub R, Jiang J, Yadav A, Nomoto K, Niu R, Tang S, Ji F, Quadir M, Miskovic D, Daniels J, Xu W, Liao X, Chen L Q, Hagihara K, Li X, Ringer S, Ferry M 2021 Sci. Adv. 7 3039

Google Scholar

Google Scholar

[15] Chen L Q, Zhao Y 2022 Prog. Mater. Sci. 124 100868

Google Scholar

Google Scholar

[16] Chen W, Zhao Y, Yang S, Zhang D, Hou H 2021 Adv. Compos. Hybrid Mater. 4 371

Google Scholar

Google Scholar

[17] Zhu N Y, Sun C, Li Y L, Lingyun Q, Hu S, Cai Y, Feng Y H 2021 Comput. Mater. Sci. 200 110858

Google Scholar

Google Scholar

[18] 赵宇宏, 景舰辉, 陈利文, 徐芳泓, 侯华 2021 金属学报 57 19

Google Scholar

Google Scholar

Zhao Y H, Jing J H, Chen L W, Xu F H, Hou H 2021 Acta Metall. Sin. 57 19

Google Scholar

Google Scholar

[19] Zhang J, Wang H, Kuang W, Zhang Y, Li S, Zhao Y, Herlach D M 2018 Acta Mater. 148 86

Google Scholar

Google Scholar

[20] Kuang W, Wang H, Li X, Zhang J, Zhou Q, Zhao Y 2018 Acta Mater. 159 16

Google Scholar

Google Scholar

[21] Wang X, Qiang W 2016 J. Nucl. Mater. 482 135

Google Scholar

Google Scholar

[22] Cahn J, Hilliard J 1958 J. Chem. Phys. 28 258

Google Scholar

Google Scholar

[23] Allen S, Cahn J W 1992 Acta Metall. 20 423

Google Scholar

Google Scholar

[24] Kitashima T, Harada H 2009 Acta Mater. 57 2020

Google Scholar

Google Scholar

[25] Tsukada Y, Koyama T, Murata Y, Miura N, Kondo Y 2014 Comput. Mater. Sci. 83 371

Google Scholar

Google Scholar

[26] Segawa M, Yamanaka A, Nomoto S 2017 Comput. Mater. Sci. 136 67

Google Scholar

Google Scholar

[27] Wrobel J S, Nguyen-Manh D, Lavrentiev M Y, Muzyk M, Dudarev S L 2015 Phys. Rev. B 91 024108

Google Scholar

Google Scholar

[28] Liu D, Zhang L, Du Y, Jin Z 2015 J. Alloys. Compd. 634 148

Google Scholar

Google Scholar

[29] Deng S, Chen W, Zhong J, Zhang L, Du Y, Chen L 2017 Calphad 56 230

Google Scholar

Google Scholar

[30] Biner B, Rao W, Zhang Y 2016 J. Nucl. Mater. 468 9

Google Scholar

Google Scholar

[31] Hu Y, Wang G, Ji Y, Wang L, Rong Y, Chen L Q 2019 Mat. Sci. Eng. A-Struct. 746 105

Google Scholar

Google Scholar

[32] 杨一波, 赵宇宏, 田晓林, 侯华 2020 69 140201

Google Scholar

Google Scholar

Yang Y B, Zhao Y H, Tian X L, Hou H 2020 Acta Phys. Sin. 69 140201

Google Scholar

Google Scholar

[33] Koyama T, Onodera H 2004 Met. Mater. Int. 10 321

Google Scholar

Google Scholar

[34] Koyama T, Onodera H 2005 Mater. Trans. 46 1187

Google Scholar

Google Scholar

[35] Koyama T 2005 Defect. Diffus. Forum. 593 237

Google Scholar

Google Scholar

[36] Saunders N, Miodownik A 1992 Pergamon

[37] Dinsdale A T 1991 Calphad 15 317

Google Scholar

Google Scholar

[38] Liu K, Hu L J, Zhang Q F, Xie Y P, Gao C, Dong H Y, Liang W Y 2017 Chin. Phys. B 26 83601

Google Scholar

Google Scholar

[39] 赵宝军, 赵宇宏, 孙远洋, 杨文奎, 侯华 2019 金属学报 55 8

Google Scholar

Google Scholar

Zhao B J, Zhao Y H, Sun Y Y, Yang W K, Hou H 2019 Acta Metall. Sin. 55 8

Google Scholar

Google Scholar

[40] Tian X L, Zhao Y H, Peng D W, Guo Q W, Guo Z, Hou H 2021 T. Nonferr. Metal. Soc. 31 1175

Google Scholar

Google Scholar

[41] Xiong S, Qi W, Huang B, Yang W, Li Y J 2010 Mater. Chem. Phys. 120 446

Google Scholar

Google Scholar

[42] Zhu J, Tianlong Z, Yang Y, Liu C T 2019 Acta Mater. 166 560

Google Scholar

Google Scholar

[43] Waseda A, Kimura K, Ino H 1994 Mat. Sci. Eng. A-struct. 181 762

Google Scholar

Google Scholar

[44] Wang L, Darvishi Kamachali R 2021 Acta Mater. 207 116668

Google Scholar

Google Scholar

[45] Sun Y, Zhao Y, Zhao B, Guo Z, Tian X, Yang W, Hou H 2020 Calphad 69 101759

Google Scholar

Google Scholar

[46] Gorbatov O, Okatov S, Gornostyrev Y, Korzhavyi P, Ruban A 2013 Phys. Met. Metallogr+. 114 642

Google Scholar

Google Scholar

[47] Deschamps A, Militzer M, Poole W 2003 ISIJ. INT. 43 1826

Google Scholar

Google Scholar

[48] Osamura K, Okuda H, Shojiro O, Takashima M, Asano K, Furusaka M, Kishida K, Kurosawa F 1994 ISIJ. INT. 34 359

Google Scholar

Google Scholar

[49] Guo H, Enomoto M, Shang C J 2018 Comp. Mater. Sci. 141 101

Google Scholar

Google Scholar

[50] Shu S, Wells P B, Almirall N, Odette G R, Morgan D D 2018 Acta Mater. 157 298

Google Scholar

Google Scholar

[51] 田晓林, 赵宇宏, 田晋忠, 侯华 2018 67 230201

Google Scholar

Google Scholar

Tian X L, Zhao Y H, Tian J Z, Hou H 2018 Acta Phys. Sin. 67 230201

Google Scholar

Google Scholar

[52] Shu S, Wirth B, Wells P, Morgan D, Odette G R 2018 Acta Mater. 146 237

Google Scholar

Google Scholar

[53] Isheim D, Gagliano M, Fine M, Seidman D 2006 Acta Mater. 54 841

Google Scholar

Google Scholar

[54] Xie Y P, Zhao S J 2012 Comp. Mater. Sci. 63 329

Google Scholar

Google Scholar

[55] Zheng Z, Lei L, Zhou Q, Wang W H, Zeng D C, Qiu Z, Hong Y 2019 J. Magn. Magn. Mater. 484 105

Google Scholar

Google Scholar

[56] Xie Y P, Zhao S J 2011 Comp. Mater. Sci. 50 2586

Google Scholar

Google Scholar

[57] Ngayam-Happy R, Becquart C S, Domain C, Malerba L 2012 J. Nucl. Mater. 426 198

Google Scholar

Google Scholar

[58] Vincent E, Becquart C S, Domain C 2006 J. Nucl. Mater. 359 227

Google Scholar

Google Scholar

[59] Wang X, Qiang W, Shu G, Qiao J, Wu Y 2021 J. Magn. Magn. Mater. 527 167698

Google Scholar

Google Scholar

[60] Vandenbossche L P, Konstantinović M J, Almazouzi A, Dupré L R 2007 J. Phys. D 40 4114

Google Scholar

Google Scholar

[61] Kamada Y, Park D G, Takahashi S, Kikuchi H, Kobayashi S, Ara K, Hong J H, Park I G 2007 IEEE. T. Magn. 43 2701

Google Scholar

Google Scholar

[62] Lo C 2012 AIP Conf. Proc. 1430 1351

Google Scholar

Google Scholar

[63] Takahashi S, Kubota A, Kobayashi S, Kamada Y, Kikuchi H, Ara K 2007 J. Mater. Process. Technol. 181 199

Google Scholar

Google Scholar

[64] 高阳 2008 先进材料测试仪器基础教程(上册) (北京: 清华大学出版社)

Gao Y 2008 The Fundamental of Advanced Measuring Instruments for Materials (Vol. 1) (Beijing: Tsinghua University Press) (in Chinese)

[65] Cui S, Jung I H 2017 Calphad 56 241

Google Scholar

Google Scholar

[66] Miettinen J 2001 Calphad 25 43

Google Scholar

Google Scholar

-

图 2 (a)—(e) 823 K时无IME作用下的演化过程 (a)

$ {t}^{\mathrm{*}} $ = 7500, (b)$ {t}^{\mathrm{*}} $ = 8500, (c)$ {t}^{\mathrm{*}} $ = 9000, (d)$ {t}^{\mathrm{*}} $ = 9500, (e)$ {t}^{\mathrm{*}} $ = 11000; (f)—(j) 有IME作用下的演化过程 (f)$ {t}^{\mathrm{*}} $ = 7500, (g)$ {t}^{\mathrm{*}} $ = 8500, (h)$ {t}^{\mathrm{*}} $ = 9000, (i)$ {t}^{\mathrm{*}} $ = 9500, (j)$ {t}^{\mathrm{*}} $ = 11000; (k) 有IME与无IME作用下的平均颗粒半径变化Fig. 2. (a)–(e) The evolution process without internal magnetism at 823 K: (a)

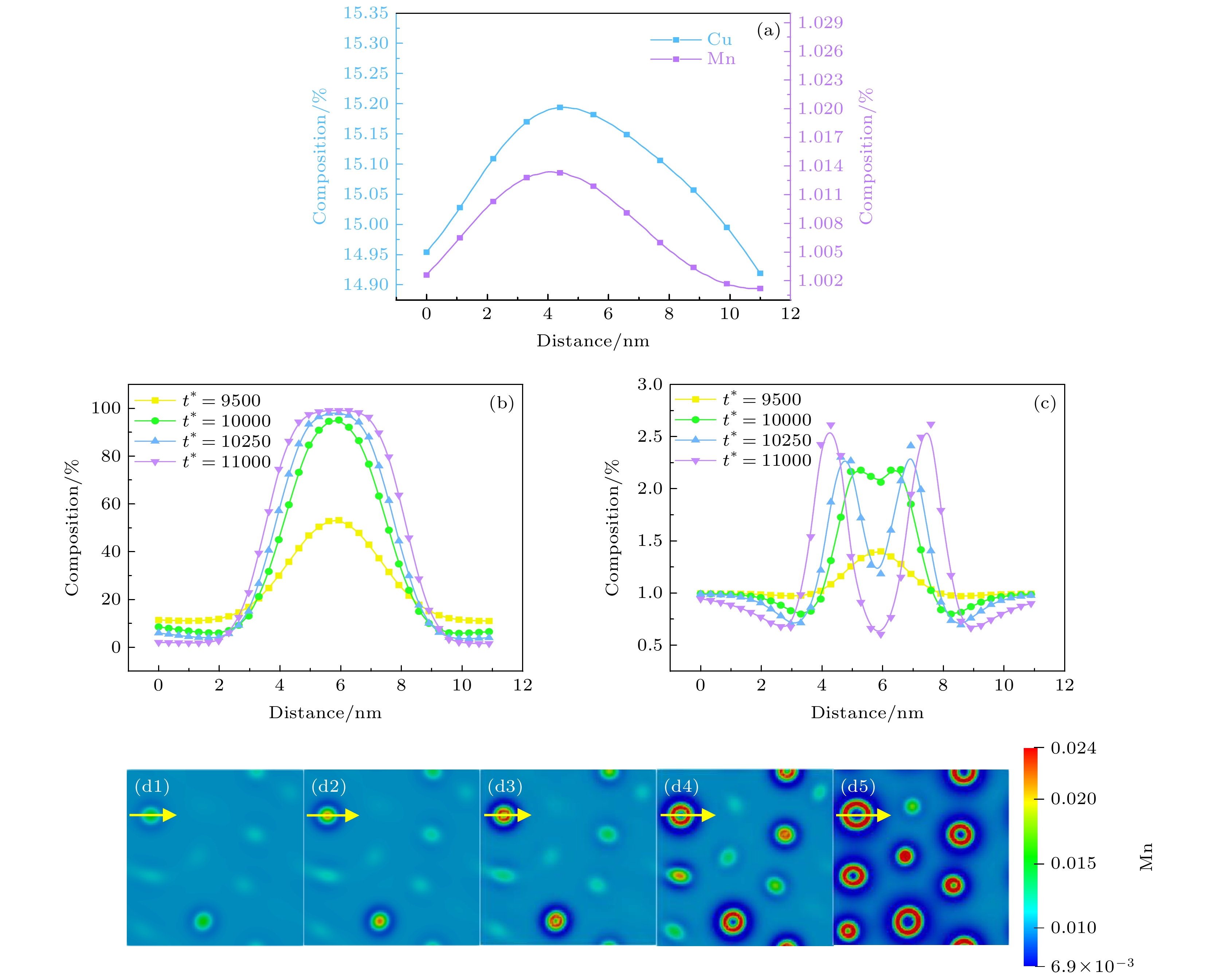

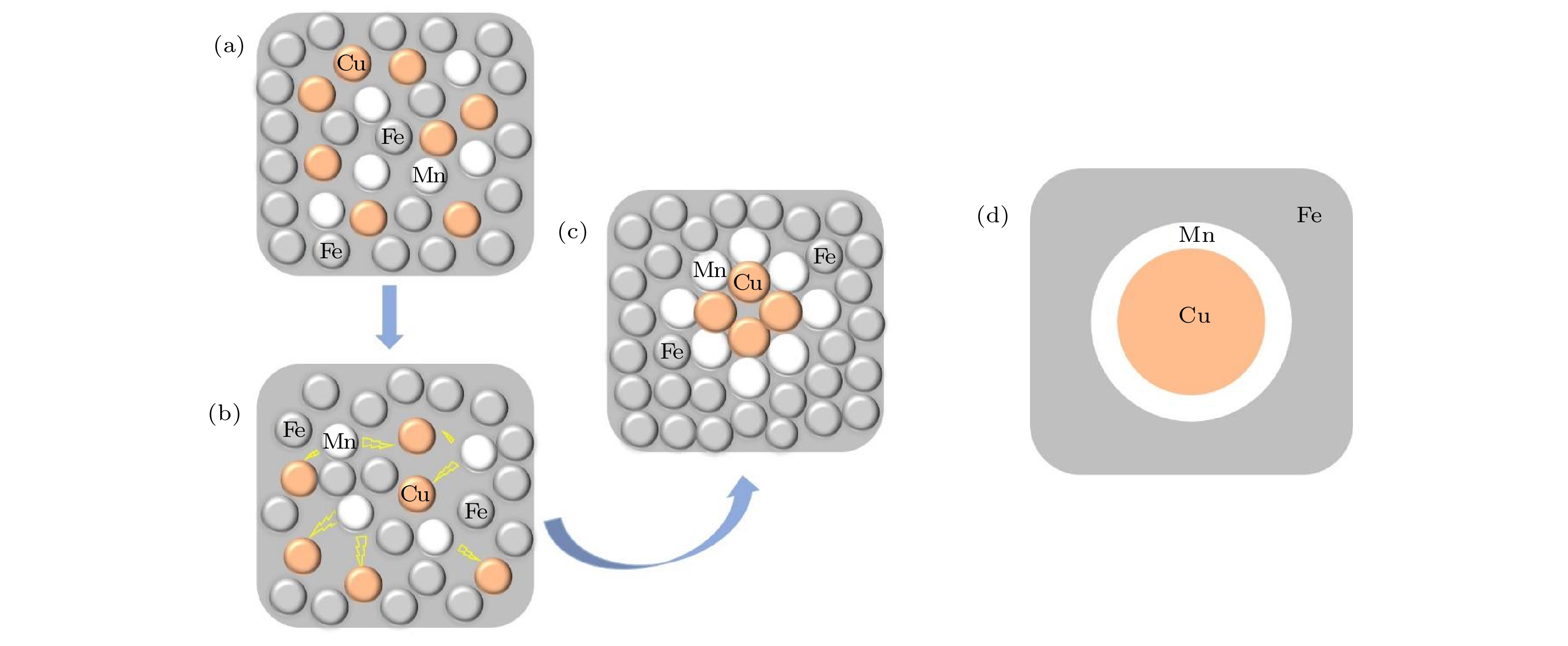

$ {t}^{\mathrm{*}} $ = 7500, (b)$ {t}^{\mathrm{*}} $ = 8500, (c)$ {t}^{\mathrm{*}} $ = 9000, (d)$ {t}^{\mathrm{*}} $ = 9500, (e)$ {t}^{\mathrm{*}} $ = 11000; (f)–(j) the evolution process with internal magnetism: (f)$ {t}^{\mathrm{*}} $ = 7500, (g)$ {t}^{\mathrm{*}} $ = 8500, (h)$ {t}^{\mathrm{*}} $ = 9000, (i)$ {t}^{\mathrm{*}} $ = 9500, (j)$ {t}^{\mathrm{*}} $ = 11000; (k) the change of average particle radius with and without internal magnetism.图 3 温度为823 K时IME作用下Mn与Cu沉淀析出的成分曲线(原子含量) (a) 早期(t * = 2500)时Cu与Mn的成分曲线; (b) 不同时间步数Cu的成分曲线; (c) 不同时间步数Mn的成分曲线; (d) Mn环在不同时间步数的演化过程

Fig. 3. The composition curve of precipitation of Mn and Cu under the action of magnetic energy in 823 K (atomic percent): (a) The composition curve of Cu and Mn in early (t * = 2500); (b) composition curve of Cu with different time steps; (c) composition curve with different time step size of Mn; (d) evolution process of Mn ring with different time steps.

图 7 矫顽力(

$ {H}_{\mathrm{c}} $ )与颗粒半径以及硬度的关系示意图 (a)$ {H}_{\mathrm{c}} $ 与平均颗粒半径的关系示意图; (b)$ {H}_{\mathrm{c}} $ 与硬度关系示意图Fig. 7. The relationship between coercivity (

$ {H}_{\mathrm{c}} $ ) and particle radius and hardness: (a) Schematic diagram of relationship between$ {H}_{\mathrm{c}} $ and average particle radius; (b) schematic diagram of relationship between$ {H}_{\mathrm{c}} $ and hardness. -

[1] Que Z, Heczko M, Kuběna I, Seifert H P, Spaetig P 2020 Mater. Charact. 165 110405

Google Scholar

Google Scholar

[2] Deschamps A, Militzer M, Poole W 2001 ISIJ. INT. 41 196

Google Scholar

Google Scholar

[3] Bousquet A, Marie S, Bompard P 2012 Comp. Mater. Sci. 64 17

Google Scholar

Google Scholar

[4] 林民东, 朱娟娟, 王伟, 周邦新, 刘文庆, 徐刚 2010 59 1163

Google Scholar

Google Scholar

Ling M D, Zhu J J, Wang W, Zhou B X, Liu W Q, Xu G, 2010 Acta Phys. Sin. 59 1163

Google Scholar

Google Scholar

[5] Miodownik A 1982 J. Phase. Equil. 2 406

Google Scholar

Google Scholar

[6] Zhao Y, Zhang B, Hou H, Chen W, Wang M 2018 J. Mater. Sci. Technol. 35 1044

Google Scholar

Google Scholar

[7] 祁科武, 赵宇宏, 田晓林, 彭敦维, 孙远洋, 侯华 2020 69 140504

Google Scholar

Google Scholar

Qi K W, ZhaoY H, Tian X L, Peng D W, Sun Y Y, Hou H 2020 Acta Phys. Sin. 69 140504

Google Scholar

Google Scholar

[8] Cui S, Mamivand M, Morgan D 2020 Mater. Des. 191 108574

Google Scholar

Google Scholar

[9] Sun Y Y, Zhao Y H, Zhao B J, Yang W K, Tian X L, H Hua 2019 J. Mater. Sci. 54 11263

Google Scholar

Google Scholar

[10] Gorbatov O, Razumov I, Gornostyrev Y, Razumovskiy V I, Korzhavyi P, Ruban A 2013 Phys. Rev. B 88 174113

Google Scholar

Google Scholar

[11] Korzhavyi P A, Ruban A V, Gorbatov O I, Gornostyrev 2015 Scr. Mater. 102 11

Google Scholar

Google Scholar

[12] Inden G 1981 Physica B+C 103 82

Google Scholar

Google Scholar

[13] Koyama T 2008 Sci. Technol. Adv. Mat. 9 013006

Google Scholar

Google Scholar

[14] Xin T, Zhao Y, Mahjoub R, Jiang J, Yadav A, Nomoto K, Niu R, Tang S, Ji F, Quadir M, Miskovic D, Daniels J, Xu W, Liao X, Chen L Q, Hagihara K, Li X, Ringer S, Ferry M 2021 Sci. Adv. 7 3039

Google Scholar

Google Scholar

[15] Chen L Q, Zhao Y 2022 Prog. Mater. Sci. 124 100868

Google Scholar

Google Scholar

[16] Chen W, Zhao Y, Yang S, Zhang D, Hou H 2021 Adv. Compos. Hybrid Mater. 4 371

Google Scholar

Google Scholar

[17] Zhu N Y, Sun C, Li Y L, Lingyun Q, Hu S, Cai Y, Feng Y H 2021 Comput. Mater. Sci. 200 110858

Google Scholar

Google Scholar

[18] 赵宇宏, 景舰辉, 陈利文, 徐芳泓, 侯华 2021 金属学报 57 19

Google Scholar

Google Scholar

Zhao Y H, Jing J H, Chen L W, Xu F H, Hou H 2021 Acta Metall. Sin. 57 19

Google Scholar

Google Scholar

[19] Zhang J, Wang H, Kuang W, Zhang Y, Li S, Zhao Y, Herlach D M 2018 Acta Mater. 148 86

Google Scholar

Google Scholar

[20] Kuang W, Wang H, Li X, Zhang J, Zhou Q, Zhao Y 2018 Acta Mater. 159 16

Google Scholar

Google Scholar

[21] Wang X, Qiang W 2016 J. Nucl. Mater. 482 135

Google Scholar

Google Scholar

[22] Cahn J, Hilliard J 1958 J. Chem. Phys. 28 258

Google Scholar

Google Scholar

[23] Allen S, Cahn J W 1992 Acta Metall. 20 423

Google Scholar

Google Scholar

[24] Kitashima T, Harada H 2009 Acta Mater. 57 2020

Google Scholar

Google Scholar

[25] Tsukada Y, Koyama T, Murata Y, Miura N, Kondo Y 2014 Comput. Mater. Sci. 83 371

Google Scholar

Google Scholar

[26] Segawa M, Yamanaka A, Nomoto S 2017 Comput. Mater. Sci. 136 67

Google Scholar

Google Scholar

[27] Wrobel J S, Nguyen-Manh D, Lavrentiev M Y, Muzyk M, Dudarev S L 2015 Phys. Rev. B 91 024108

Google Scholar

Google Scholar

[28] Liu D, Zhang L, Du Y, Jin Z 2015 J. Alloys. Compd. 634 148

Google Scholar

Google Scholar

[29] Deng S, Chen W, Zhong J, Zhang L, Du Y, Chen L 2017 Calphad 56 230

Google Scholar

Google Scholar

[30] Biner B, Rao W, Zhang Y 2016 J. Nucl. Mater. 468 9

Google Scholar

Google Scholar

[31] Hu Y, Wang G, Ji Y, Wang L, Rong Y, Chen L Q 2019 Mat. Sci. Eng. A-Struct. 746 105

Google Scholar

Google Scholar

[32] 杨一波, 赵宇宏, 田晓林, 侯华 2020 69 140201

Google Scholar

Google Scholar

Yang Y B, Zhao Y H, Tian X L, Hou H 2020 Acta Phys. Sin. 69 140201

Google Scholar

Google Scholar

[33] Koyama T, Onodera H 2004 Met. Mater. Int. 10 321

Google Scholar

Google Scholar

[34] Koyama T, Onodera H 2005 Mater. Trans. 46 1187

Google Scholar

Google Scholar

[35] Koyama T 2005 Defect. Diffus. Forum. 593 237

Google Scholar

Google Scholar

[36] Saunders N, Miodownik A 1992 Pergamon

[37] Dinsdale A T 1991 Calphad 15 317

Google Scholar

Google Scholar

[38] Liu K, Hu L J, Zhang Q F, Xie Y P, Gao C, Dong H Y, Liang W Y 2017 Chin. Phys. B 26 83601

Google Scholar

Google Scholar

[39] 赵宝军, 赵宇宏, 孙远洋, 杨文奎, 侯华 2019 金属学报 55 8

Google Scholar

Google Scholar

Zhao B J, Zhao Y H, Sun Y Y, Yang W K, Hou H 2019 Acta Metall. Sin. 55 8

Google Scholar

Google Scholar

[40] Tian X L, Zhao Y H, Peng D W, Guo Q W, Guo Z, Hou H 2021 T. Nonferr. Metal. Soc. 31 1175

Google Scholar

Google Scholar

[41] Xiong S, Qi W, Huang B, Yang W, Li Y J 2010 Mater. Chem. Phys. 120 446

Google Scholar

Google Scholar

[42] Zhu J, Tianlong Z, Yang Y, Liu C T 2019 Acta Mater. 166 560

Google Scholar

Google Scholar

[43] Waseda A, Kimura K, Ino H 1994 Mat. Sci. Eng. A-struct. 181 762

Google Scholar

Google Scholar

[44] Wang L, Darvishi Kamachali R 2021 Acta Mater. 207 116668

Google Scholar

Google Scholar

[45] Sun Y, Zhao Y, Zhao B, Guo Z, Tian X, Yang W, Hou H 2020 Calphad 69 101759

Google Scholar

Google Scholar

[46] Gorbatov O, Okatov S, Gornostyrev Y, Korzhavyi P, Ruban A 2013 Phys. Met. Metallogr+. 114 642

Google Scholar

Google Scholar

[47] Deschamps A, Militzer M, Poole W 2003 ISIJ. INT. 43 1826

Google Scholar

Google Scholar

[48] Osamura K, Okuda H, Shojiro O, Takashima M, Asano K, Furusaka M, Kishida K, Kurosawa F 1994 ISIJ. INT. 34 359

Google Scholar

Google Scholar

[49] Guo H, Enomoto M, Shang C J 2018 Comp. Mater. Sci. 141 101

Google Scholar

Google Scholar

[50] Shu S, Wells P B, Almirall N, Odette G R, Morgan D D 2018 Acta Mater. 157 298

Google Scholar

Google Scholar

[51] 田晓林, 赵宇宏, 田晋忠, 侯华 2018 67 230201

Google Scholar

Google Scholar

Tian X L, Zhao Y H, Tian J Z, Hou H 2018 Acta Phys. Sin. 67 230201

Google Scholar

Google Scholar

[52] Shu S, Wirth B, Wells P, Morgan D, Odette G R 2018 Acta Mater. 146 237

Google Scholar

Google Scholar

[53] Isheim D, Gagliano M, Fine M, Seidman D 2006 Acta Mater. 54 841

Google Scholar

Google Scholar

[54] Xie Y P, Zhao S J 2012 Comp. Mater. Sci. 63 329

Google Scholar

Google Scholar

[55] Zheng Z, Lei L, Zhou Q, Wang W H, Zeng D C, Qiu Z, Hong Y 2019 J. Magn. Magn. Mater. 484 105

Google Scholar

Google Scholar

[56] Xie Y P, Zhao S J 2011 Comp. Mater. Sci. 50 2586

Google Scholar

Google Scholar

[57] Ngayam-Happy R, Becquart C S, Domain C, Malerba L 2012 J. Nucl. Mater. 426 198

Google Scholar

Google Scholar

[58] Vincent E, Becquart C S, Domain C 2006 J. Nucl. Mater. 359 227

Google Scholar

Google Scholar

[59] Wang X, Qiang W, Shu G, Qiao J, Wu Y 2021 J. Magn. Magn. Mater. 527 167698

Google Scholar

Google Scholar

[60] Vandenbossche L P, Konstantinović M J, Almazouzi A, Dupré L R 2007 J. Phys. D 40 4114

Google Scholar

Google Scholar

[61] Kamada Y, Park D G, Takahashi S, Kikuchi H, Kobayashi S, Ara K, Hong J H, Park I G 2007 IEEE. T. Magn. 43 2701

Google Scholar

Google Scholar

[62] Lo C 2012 AIP Conf. Proc. 1430 1351

Google Scholar

Google Scholar

[63] Takahashi S, Kubota A, Kobayashi S, Kamada Y, Kikuchi H, Ara K 2007 J. Mater. Process. Technol. 181 199

Google Scholar

Google Scholar

[64] 高阳 2008 先进材料测试仪器基础教程(上册) (北京: 清华大学出版社)

Gao Y 2008 The Fundamental of Advanced Measuring Instruments for Materials (Vol. 1) (Beijing: Tsinghua University Press) (in Chinese)

[65] Cui S, Jung I H 2017 Calphad 56 241

Google Scholar

Google Scholar

[66] Miettinen J 2001 Calphad 25 43

Google Scholar

Google Scholar

计量

- 文章访问数: 7225

- PDF下载量: 96

- 被引次数: 0

下载:

下载: