-

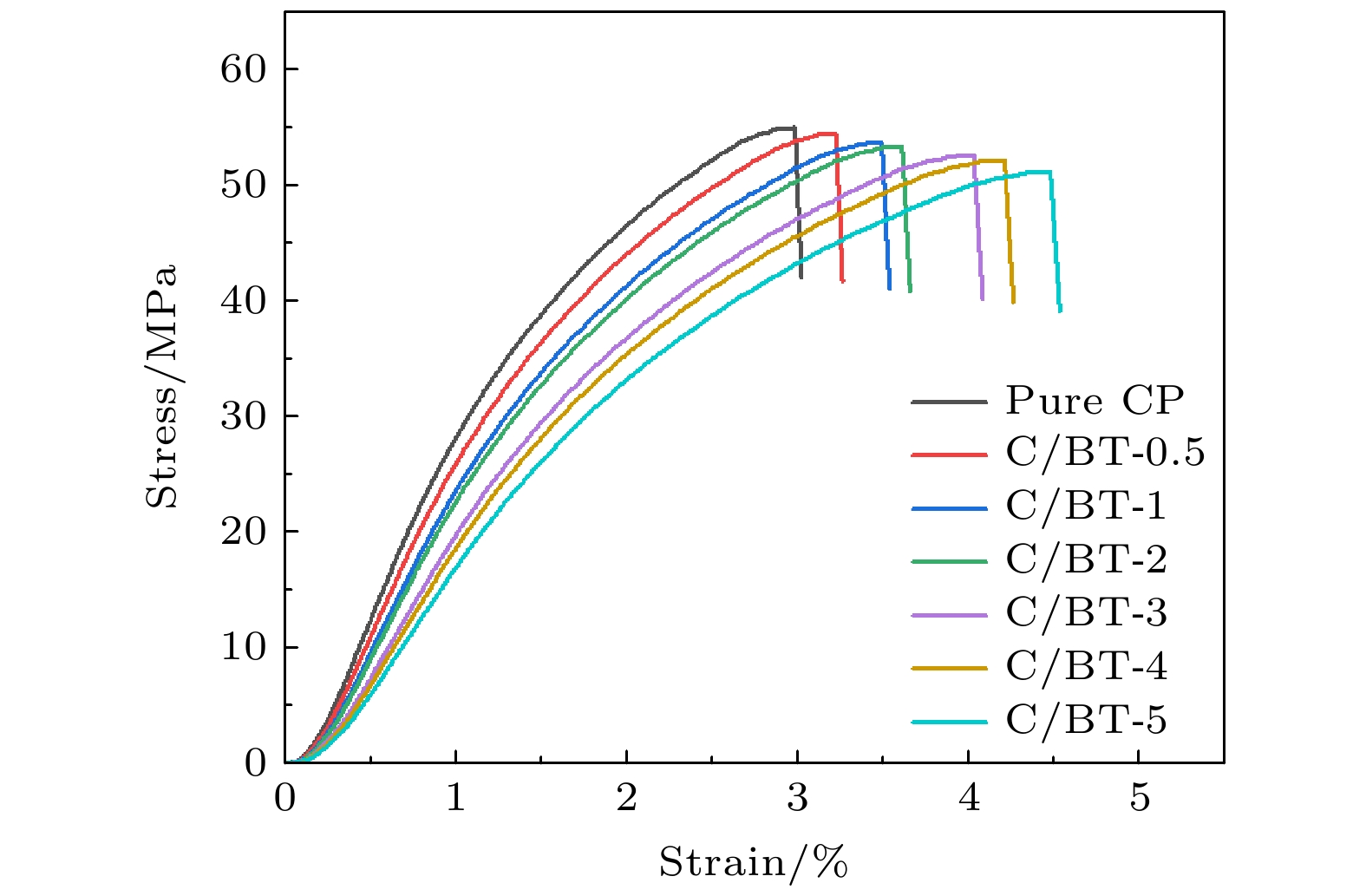

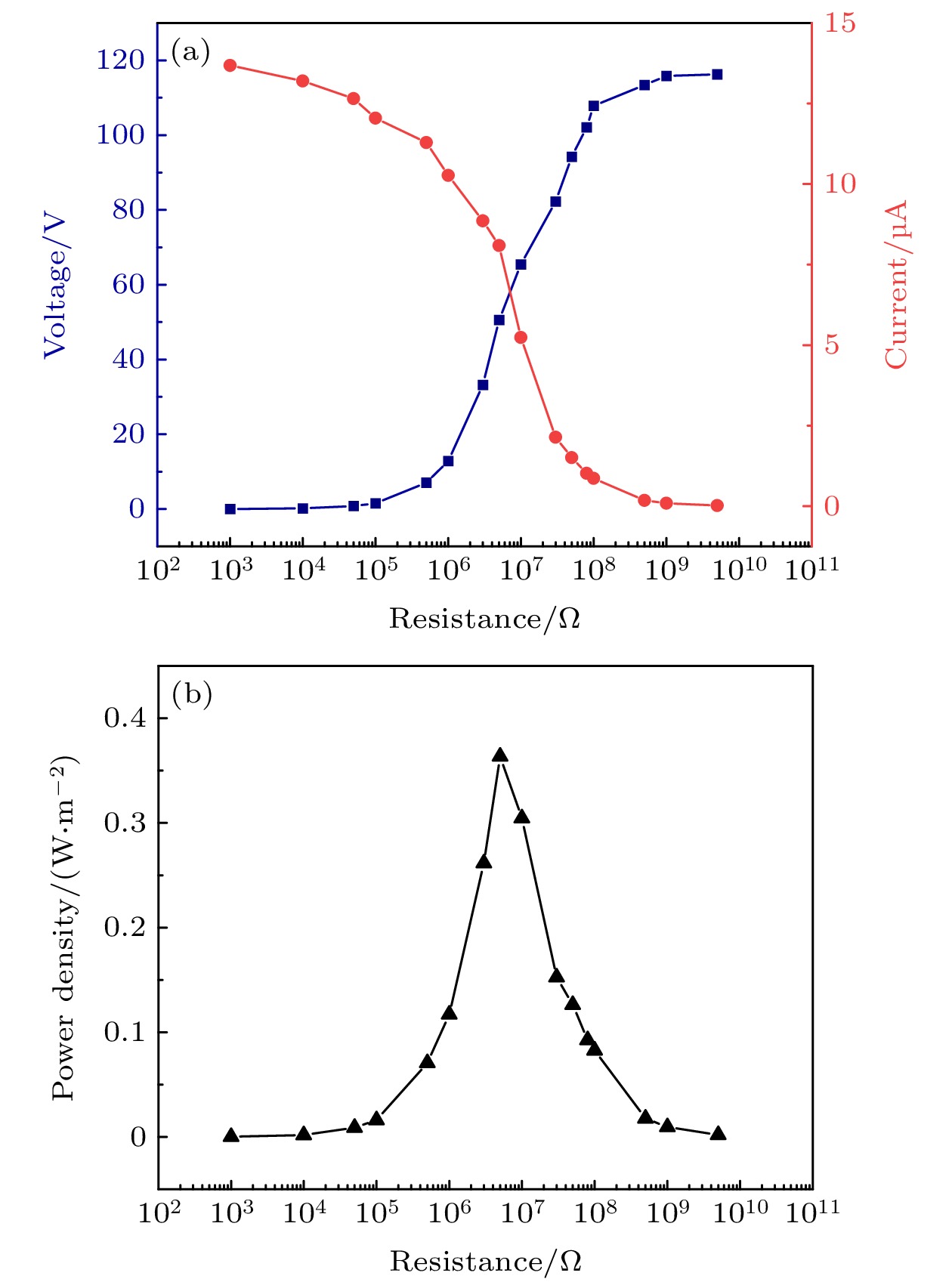

摩擦纳米发电机作为一种能够将机械能转换为电能的新型能源转换装置, 自发明以来便引起了广泛关注, 然而其环保性能由于原料来源多为合成高分子材料而受到制约. 采用绿色环保的纤维素材料制备摩擦纳米发电机是解决上述问题的重要方式之一. 本研究以竹纤维素和钛酸钡(BaTiO3)为原料, 结合湿法造纸和掺杂改性制备了纤维素/钛酸钡复合纸, 并将其作为正极摩擦层构建了纸基摩擦纳米发电机(cellulose/barium titanate-triboelectric nanogenerator, C/BT-TENG). 结果表明, BaTiO3的加入显著提升了复合纸的相对介电常数, C/BT-TENG的输出性能随着BaTiO3掺杂量增加而提升, 在4%掺杂量时, C/BT-TENG的开路电压和短路电流达到最大值118.5 V 和13.51 µA, 相比纯纤维素纸作为正极摩擦层时, 分别提升了51.3% 和41.2%. 通过模型法分析了介电调控提升C/BT-TENG输出性能的机理. 此外, C/BT-TENG具有良好的输出性能和工作稳定性, 在负载电阻为5 MΩ时, 其获得最大输出功率密度0.36 W/m2, 表现出良好的应用前景.As a new energy conversion device that can convert mechanical energy into electrical energy, triboelectric nanogenerator has attracted extensive attention since its invention. However, its environmental performance is limited because the raw materials are mostly synthetic polymer materials. Using green and environmentally friendly cellulose materials to prepare triboelectric nanogenerators is one of the important ways to solve the above problems. In this study, cellulose/barium titanate composite paper is prepared by using bamboo cellulose and barium carbonate (BaTiO3) as raw materials and combining wet papermaking and doping modification. The paper based triboelectric nanogenerator (C/BT-TENG) is constructed by using the cellulose/barium titanate composite paper as a positive friction layer. The results show that the addition of BaTiO3 significantly improves the relative dielectric constant of the composite paper, and the output performance of C/BT-TENG increases with the augment of BaTiO3 doping amount. When the doping amount is 4%, the open-circuit voltage and short-circuit current of C/BT-TENG reach the maximum values of 118.5 V and 13.51 µA, respectively, which are 51.3% and 41.2% higher than when pure cellulose paper is used as the positive friction layer. The mechanism of dielectric regulation to improve the C/BT-TENG output performance is analyzed by the modeling method. In addition, the C/BT-TENG has a good output performance and operation stability. When the load resistance is 5 MΩ, the maximum output power density of C/BT-TENG reaches 0.36 W/m2, simplying a good application prospect.

-

Keywords:

- barium titanate /

- cellulose paper /

- triboelectric nanogenerators /

- energy collection

[1] Meyar-Naimi H, Vaez-Zadeh S 2012 Energ. Policy 43 351

Google Scholar

Google Scholar

[2] Goldemberg J 2006 Energ. Policy 34 2185

Google Scholar

Google Scholar

[3] Bai Y X, Shen B Y, Zhang S L, Zhu Z X, Sun S L, Gao J, Li B H, Wang Y, Zhang R F, Wei F 2019 Adv. Mater. 31 1800680

Google Scholar

Google Scholar

[4] Jie Y, Jia X T, Zou J D, Chen Y D, Wang N, Wang Z L, Cao X 2018 Adv. Energy Mater. 8 1703133

[5] Zi Y L, Wang J, Wang S H, Li S M, Wen Z, Guo H Y, Wang Z L 2016 Nat. Commun. 7 1

Google Scholar

Google Scholar

[6] Wang Z L 2020 Adv. Energy Mater. 10 2000137

Google Scholar

Google Scholar

[7] Shang W Y, Gu G Q, Zhang W H, Luo H C, Wang T Y, Zhang B, Guo J M, Cui P, Yang F, Cheng G, Du Z L 2021 Nano Energy 82 105725

Google Scholar

Google Scholar

[8] Qin H F, Gu G Q, Shang W Y, Luo H C, Zhang W H, Cui P, Zhang B, Guo J M, Cheng G, Du Z L 2020 Nano Energy 68 104372

Google Scholar

Google Scholar

[9] Qin H F, Cheng G, Zi Y L, Gu G Q, Zhang B, Shang W Y, Yang F, Yang J J, Du Z L, Wang Z L 2018 Adv. Funct. Mater. 28 1805216

Google Scholar

Google Scholar

[10] Zhang H, Quan L W, Chen J K, Xu C K, Zhang C H, Dong S R, Lu C F, Luo J K 2019 Nano Energy 56 700

Google Scholar

Google Scholar

[11] Singh M, Sheetal A, Singh H, Sawhney R S, Kaur J 2020 J. Electron. Mater. 49 3409

Google Scholar

Google Scholar

[12] Kwak S S, Kim S M, Ryu H, Kim J, Khan U, Yoon H J, Jeong Y H, Kim S W 2019 Energy Environ. Sci. 12 3156

Google Scholar

Google Scholar

[13] Xu G P, Zheng Y B, Feng Y G, Ma S C, Luo N, Feng M, Chen S G, Wang D 2021 Sci. China Technol. Sc. 64 2003

Google Scholar

Google Scholar

[14] Landauer J, Aigner F, Kuhn M, Foerst P 2019 Adv. Powder Technol. 30 1099

Google Scholar

Google Scholar

[15] Kang H, Kim H T, Woo H J, Kim H, Kim D H, Lee S, Kim S, Song Y J, Kim S W, Cho J H 2019 Nano Energy 58 227

Google Scholar

Google Scholar

[16] Chao S, Ouyang H, Jiang D, Fan Y, Li Z 2021 Eco. Mat. 3 e12072

Google Scholar

Google Scholar

[17] Pang B, Jiang G Y, Zhou J H, Zhu Y, Cheng W K, Zhao D W, Wang K J, Xu G W, Yu H P 2021 Adv. Electron. Mater. 7 2000944

Google Scholar

Google Scholar

[18] Kim I, Jeon H, Kim D, You J, Kim D 2018 Nano Energy 53 975

Google Scholar

Google Scholar

[19] Kafy A, Sadasivuni K K, Akther A, Min S K, Kim J 2015 Mater. Lett. 159 20

Google Scholar

Google Scholar

[20] Darabi S, Hummel M, Rantasalo S, Rissanen M, Mansson I O, Hilke H, Hwang B, Skrifvars M, Hamedi M M, Sixta H, Lund A, Muller C 2020 Acs Appl. Mater. Inter. 12 56403

Google Scholar

Google Scholar

[21] Yao C H, Hernandez A, Yu Y H, Cai Z Y, Wang X D 2016 Nano Energy 30 103

Google Scholar

Google Scholar

[22] Diaz A F, Felix-Navarro R M 2004 J. Electrostat. 62 277

Google Scholar

Google Scholar

[23] Yu A F, Zhu Y X, Wang W, Zhai J Y 2019 Adv. Funct. Mater. 29 1900098

Google Scholar

Google Scholar

[24] Shao J J, Jiang T, Wang Z L 2020 Sci. China Technol. Sc. 63 1087

Google Scholar

Google Scholar

[25] Min G, Manjakkal L, Mulvihill D M, Dahiya R S 2020 IEEE Sens. J. 20 6856

Google Scholar

Google Scholar

[26] Wu C, Kim T W, Choi H Y 2017 Nano Energy 32 542

Google Scholar

Google Scholar

[27] Wang X Z, Yang B, Liu J Q, Zhu Y B, Yang C S, He Q 2016 Sci. Rep. 6 1

Google Scholar

Google Scholar

[28] Ba Y Y, Bao J F, Deng H T, Wang Z Y, Li X W, Gong T X, Huang W, Zhang X S 2020 Acs Appl. Mater. Inter. 12 42859

Google Scholar

Google Scholar

[29] Jia C, Shao Z Q, Fan H Y, Feng R, Wang F J, Wang W J, Wang J Q, Zhang D L, Lü Y Y 2016 Compos. Part A-Appl. S 86 1

Google Scholar

Google Scholar

[30] Ma M Y, Kang Z, Liao Q L, Zhang Q, Gao F F, Zhao X, Zhang Z, Zhang Y 2018 Nano Res. 11 2951

Google Scholar

Google Scholar

[31] Li W B, Zhou D, Pang L X, Xu R, Guo H H 2017 J. Mater. Chem. A 5 19607

Google Scholar

Google Scholar

[32] Zhang X, Lü S S, Lu X C, Yu H, Huang T, Zhang Q H, Zhu M F 2020 Nano Energy 75 104894

Google Scholar

Google Scholar

[33] Sriphan S, Nawanil C, Vittayakorn N 2018 Ceram. Int. 44 S38

Google Scholar

Google Scholar

[34] Dudem B, Kim D H, Bharat L K, Yu J S 2018 Appl. Energ. 230 865

Google Scholar

Google Scholar

[35] Chen J, Guo H Y, He X M, Liu G L, Xi Y, Shi H F, Hu C G 2016 Acs Appl. Mater. Inter. 8 736

Google Scholar

Google Scholar

[36] Zhang W H, Gu G Q, Qin H F, Li S M, Shang W Y, Wang T Y, Zhang B, Cui P, Guo J M, Yang F, Cheng G, Du Z L 2020 Nano Energy 77 105108

Google Scholar

Google Scholar

[37] Zhang W H, Gu G Q, Shang W Y, Luo H C, Wang T Y, Zhang B, Cui P, Guo J M, Yang F, Cheng G, Du Z L 2021 Nano Energy 86 106056

Google Scholar

Google Scholar

[38] Song H M, Yu H W, Zhu L J, Xue L X, Wu D C, Chen H 2017 React. Funct. Polym. 114 110

Google Scholar

Google Scholar

[39] Xiao S H, Jiang W F 2012 Int. J. Min. Met. Mater. 19 762

Google Scholar

Google Scholar

[40] Chen H M, Xu Y, Zhang J S, Wu W T, Song G F 2018 Nanoscale Res. Lett. 13 1

Google Scholar

Google Scholar

[41] Wang Z L 2017 Mater. Today 20 74

Google Scholar

Google Scholar

[42] Wang Z L, Chen J, Lin L 2015 Energy Environ. Sci. 8 2250

Google Scholar

Google Scholar

[43] Shi Y X, Wang F, Tian J W, Li S Y, Fu E G, Nie J H, Lei R, Ding Y F, Chen X Y, Wang Z L 2021 Sci. Adv. 7 eabe2943

Google Scholar

Google Scholar

[44] Nie J H, Ren Z W, Xu L, Lin S Q, Zhan F, Chen X Y, Wang Z L 2020 Adv. Mater. 32 1905696

Google Scholar

Google Scholar

[45] Li S Y, Fan Y, Chen H Q, Nie J H, Liang Y X, Tao X L, Zhang J, Chen X Y, Fu E G, Wang Z L 2020 Energy Environ. Sci. 13 896

Google Scholar

Google Scholar

-

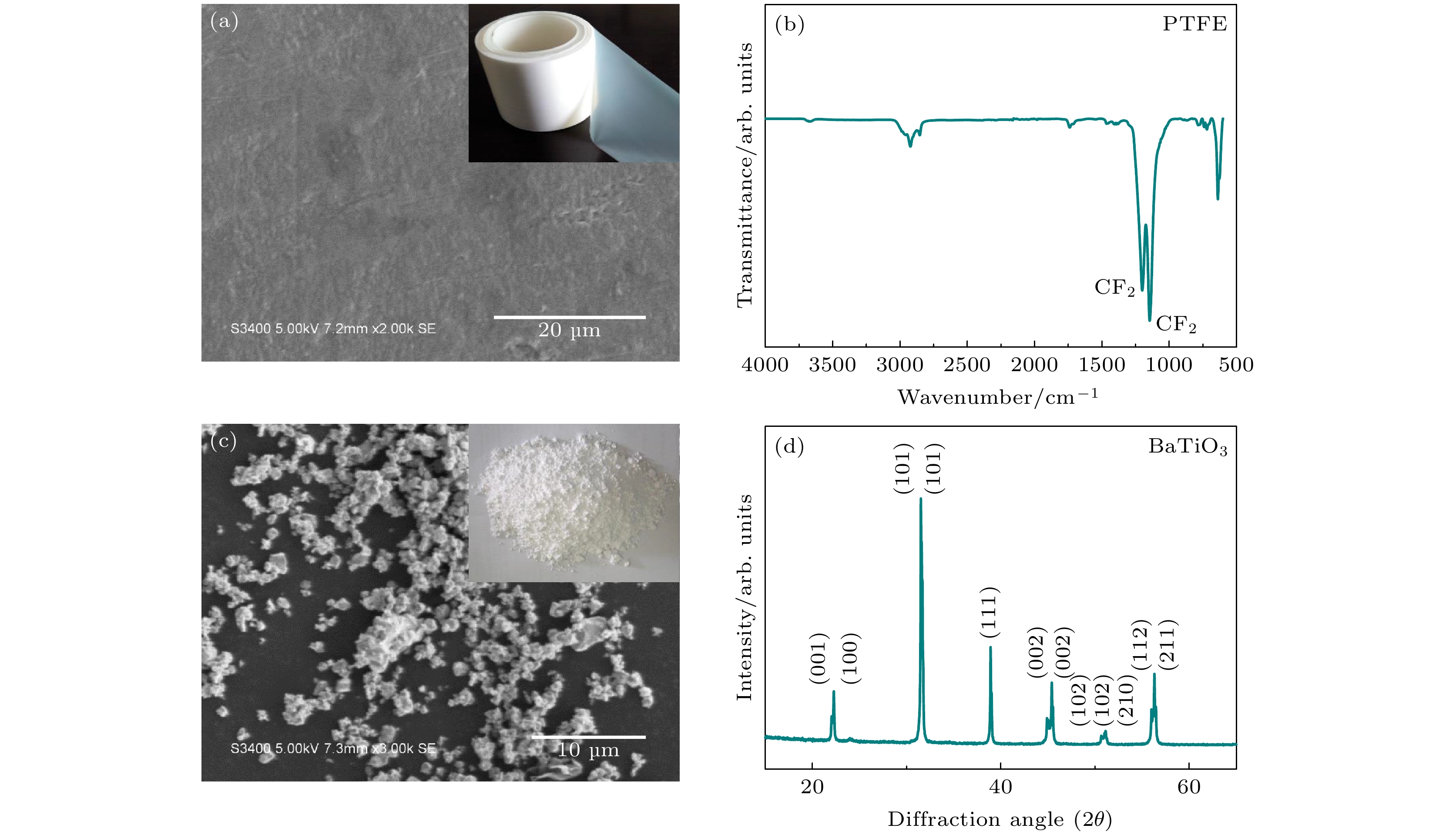

图 3 (a) PTFE表面SEM图(右上角插图为其光学照片); (b) PTFE的红外光谱图; (c) BaTiO3颗粒的SEM图(右上角插图为其光学照片); (d) BaTiO3的X射线衍射图

Fig. 3. (a) The surface SEM image of PTFE (The illustration in the upper right corner is its optical photo); (b) the infrared spectrogram of PTFE; (c) the SEM image of BaTiO3 particles (The illustration in the upper right corner is its optical photo); (d) X-ray diffraction pattern of BaTiO3.

图 5 不同BaTiO3含量C/BT复合纸作为正极摩擦层的C/BT-TENG的(a)开路电压和(b)短路电流; 不同BaTiO3含量C/BT复合纸的(c)相对介电常数和(d)介电损耗角正切随频率的变化情况

Fig. 5. (a) Open circuit voltage and (b) short circuit current of C/BT-TENG with C/BT composite paper with different BaTiO3 content as the positive friction layer; frequency dependence of (c) dielectric constant and (d) dielectric loss tangent of C/BT composite paper with different BaTiO3 content.

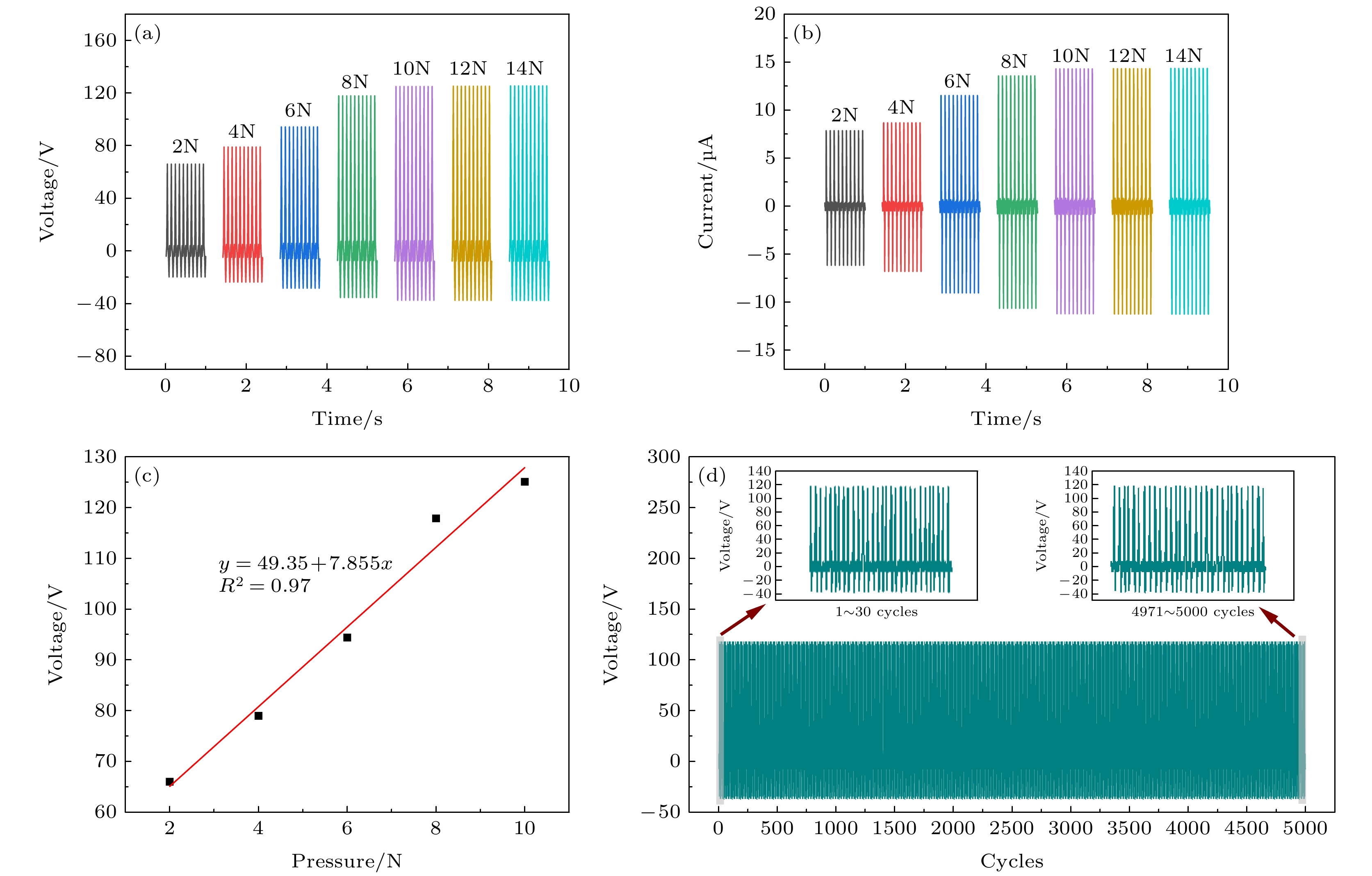

图 8 C/BT-TENG在不同大小外力下的(a)开路电压和(b)短路电流; (c) C/BT-TENG的开路电压与外力大小的线性拟合; (d) C/BT-TENG在5000次连续循环工作过程中的输出电压

Fig. 8. (a) Open circuit voltage and (b) short circuit current of C/BT-TENG under different external forces; (c) linear fit between open circuit voltage of C/BT-TENG and external force; (d) the output voltage of C/BT-TENG during 5000 continuous cycles.

-

[1] Meyar-Naimi H, Vaez-Zadeh S 2012 Energ. Policy 43 351

Google Scholar

Google Scholar

[2] Goldemberg J 2006 Energ. Policy 34 2185

Google Scholar

Google Scholar

[3] Bai Y X, Shen B Y, Zhang S L, Zhu Z X, Sun S L, Gao J, Li B H, Wang Y, Zhang R F, Wei F 2019 Adv. Mater. 31 1800680

Google Scholar

Google Scholar

[4] Jie Y, Jia X T, Zou J D, Chen Y D, Wang N, Wang Z L, Cao X 2018 Adv. Energy Mater. 8 1703133

[5] Zi Y L, Wang J, Wang S H, Li S M, Wen Z, Guo H Y, Wang Z L 2016 Nat. Commun. 7 1

Google Scholar

Google Scholar

[6] Wang Z L 2020 Adv. Energy Mater. 10 2000137

Google Scholar

Google Scholar

[7] Shang W Y, Gu G Q, Zhang W H, Luo H C, Wang T Y, Zhang B, Guo J M, Cui P, Yang F, Cheng G, Du Z L 2021 Nano Energy 82 105725

Google Scholar

Google Scholar

[8] Qin H F, Gu G Q, Shang W Y, Luo H C, Zhang W H, Cui P, Zhang B, Guo J M, Cheng G, Du Z L 2020 Nano Energy 68 104372

Google Scholar

Google Scholar

[9] Qin H F, Cheng G, Zi Y L, Gu G Q, Zhang B, Shang W Y, Yang F, Yang J J, Du Z L, Wang Z L 2018 Adv. Funct. Mater. 28 1805216

Google Scholar

Google Scholar

[10] Zhang H, Quan L W, Chen J K, Xu C K, Zhang C H, Dong S R, Lu C F, Luo J K 2019 Nano Energy 56 700

Google Scholar

Google Scholar

[11] Singh M, Sheetal A, Singh H, Sawhney R S, Kaur J 2020 J. Electron. Mater. 49 3409

Google Scholar

Google Scholar

[12] Kwak S S, Kim S M, Ryu H, Kim J, Khan U, Yoon H J, Jeong Y H, Kim S W 2019 Energy Environ. Sci. 12 3156

Google Scholar

Google Scholar

[13] Xu G P, Zheng Y B, Feng Y G, Ma S C, Luo N, Feng M, Chen S G, Wang D 2021 Sci. China Technol. Sc. 64 2003

Google Scholar

Google Scholar

[14] Landauer J, Aigner F, Kuhn M, Foerst P 2019 Adv. Powder Technol. 30 1099

Google Scholar

Google Scholar

[15] Kang H, Kim H T, Woo H J, Kim H, Kim D H, Lee S, Kim S, Song Y J, Kim S W, Cho J H 2019 Nano Energy 58 227

Google Scholar

Google Scholar

[16] Chao S, Ouyang H, Jiang D, Fan Y, Li Z 2021 Eco. Mat. 3 e12072

Google Scholar

Google Scholar

[17] Pang B, Jiang G Y, Zhou J H, Zhu Y, Cheng W K, Zhao D W, Wang K J, Xu G W, Yu H P 2021 Adv. Electron. Mater. 7 2000944

Google Scholar

Google Scholar

[18] Kim I, Jeon H, Kim D, You J, Kim D 2018 Nano Energy 53 975

Google Scholar

Google Scholar

[19] Kafy A, Sadasivuni K K, Akther A, Min S K, Kim J 2015 Mater. Lett. 159 20

Google Scholar

Google Scholar

[20] Darabi S, Hummel M, Rantasalo S, Rissanen M, Mansson I O, Hilke H, Hwang B, Skrifvars M, Hamedi M M, Sixta H, Lund A, Muller C 2020 Acs Appl. Mater. Inter. 12 56403

Google Scholar

Google Scholar

[21] Yao C H, Hernandez A, Yu Y H, Cai Z Y, Wang X D 2016 Nano Energy 30 103

Google Scholar

Google Scholar

[22] Diaz A F, Felix-Navarro R M 2004 J. Electrostat. 62 277

Google Scholar

Google Scholar

[23] Yu A F, Zhu Y X, Wang W, Zhai J Y 2019 Adv. Funct. Mater. 29 1900098

Google Scholar

Google Scholar

[24] Shao J J, Jiang T, Wang Z L 2020 Sci. China Technol. Sc. 63 1087

Google Scholar

Google Scholar

[25] Min G, Manjakkal L, Mulvihill D M, Dahiya R S 2020 IEEE Sens. J. 20 6856

Google Scholar

Google Scholar

[26] Wu C, Kim T W, Choi H Y 2017 Nano Energy 32 542

Google Scholar

Google Scholar

[27] Wang X Z, Yang B, Liu J Q, Zhu Y B, Yang C S, He Q 2016 Sci. Rep. 6 1

Google Scholar

Google Scholar

[28] Ba Y Y, Bao J F, Deng H T, Wang Z Y, Li X W, Gong T X, Huang W, Zhang X S 2020 Acs Appl. Mater. Inter. 12 42859

Google Scholar

Google Scholar

[29] Jia C, Shao Z Q, Fan H Y, Feng R, Wang F J, Wang W J, Wang J Q, Zhang D L, Lü Y Y 2016 Compos. Part A-Appl. S 86 1

Google Scholar

Google Scholar

[30] Ma M Y, Kang Z, Liao Q L, Zhang Q, Gao F F, Zhao X, Zhang Z, Zhang Y 2018 Nano Res. 11 2951

Google Scholar

Google Scholar

[31] Li W B, Zhou D, Pang L X, Xu R, Guo H H 2017 J. Mater. Chem. A 5 19607

Google Scholar

Google Scholar

[32] Zhang X, Lü S S, Lu X C, Yu H, Huang T, Zhang Q H, Zhu M F 2020 Nano Energy 75 104894

Google Scholar

Google Scholar

[33] Sriphan S, Nawanil C, Vittayakorn N 2018 Ceram. Int. 44 S38

Google Scholar

Google Scholar

[34] Dudem B, Kim D H, Bharat L K, Yu J S 2018 Appl. Energ. 230 865

Google Scholar

Google Scholar

[35] Chen J, Guo H Y, He X M, Liu G L, Xi Y, Shi H F, Hu C G 2016 Acs Appl. Mater. Inter. 8 736

Google Scholar

Google Scholar

[36] Zhang W H, Gu G Q, Qin H F, Li S M, Shang W Y, Wang T Y, Zhang B, Cui P, Guo J M, Yang F, Cheng G, Du Z L 2020 Nano Energy 77 105108

Google Scholar

Google Scholar

[37] Zhang W H, Gu G Q, Shang W Y, Luo H C, Wang T Y, Zhang B, Cui P, Guo J M, Yang F, Cheng G, Du Z L 2021 Nano Energy 86 106056

Google Scholar

Google Scholar

[38] Song H M, Yu H W, Zhu L J, Xue L X, Wu D C, Chen H 2017 React. Funct. Polym. 114 110

Google Scholar

Google Scholar

[39] Xiao S H, Jiang W F 2012 Int. J. Min. Met. Mater. 19 762

Google Scholar

Google Scholar

[40] Chen H M, Xu Y, Zhang J S, Wu W T, Song G F 2018 Nanoscale Res. Lett. 13 1

Google Scholar

Google Scholar

[41] Wang Z L 2017 Mater. Today 20 74

Google Scholar

Google Scholar

[42] Wang Z L, Chen J, Lin L 2015 Energy Environ. Sci. 8 2250

Google Scholar

Google Scholar

[43] Shi Y X, Wang F, Tian J W, Li S Y, Fu E G, Nie J H, Lei R, Ding Y F, Chen X Y, Wang Z L 2021 Sci. Adv. 7 eabe2943

Google Scholar

Google Scholar

[44] Nie J H, Ren Z W, Xu L, Lin S Q, Zhan F, Chen X Y, Wang Z L 2020 Adv. Mater. 32 1905696

Google Scholar

Google Scholar

[45] Li S Y, Fan Y, Chen H Q, Nie J H, Liang Y X, Tao X L, Zhang J, Chen X Y, Fu E G, Wang Z L 2020 Energy Environ. Sci. 13 896

Google Scholar

Google Scholar

计量

- 文章访问数: 8813

- PDF下载量: 187

- 被引次数: 0

下载:

下载: